Gradually expanding type screw-feed thermal decomposition furnace integrated in vertical shaft flue behind pulverized coal boiler

A pulverized coal boiler and screw feeding technology, which is applied in coke ovens, special dry distillation, energy input, etc., can solve the problems of material crushing, grinding, inability to prevent the entry of outside air, and uneconomical problems, so as to achieve easy grinding Broken, high usable value, high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention will be described below in conjunction with the accompanying drawings and specific embodiments. The examples given are only used to explain the present invention and are not intended to limit the scope of the present invention.

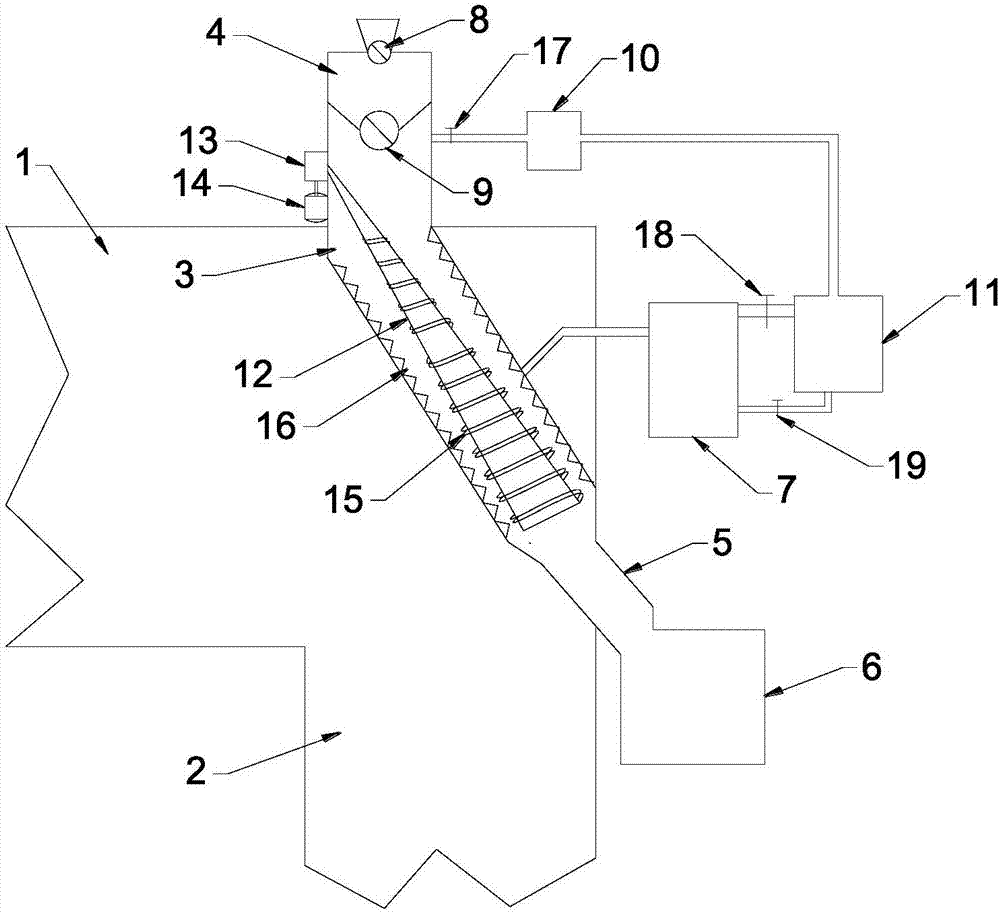

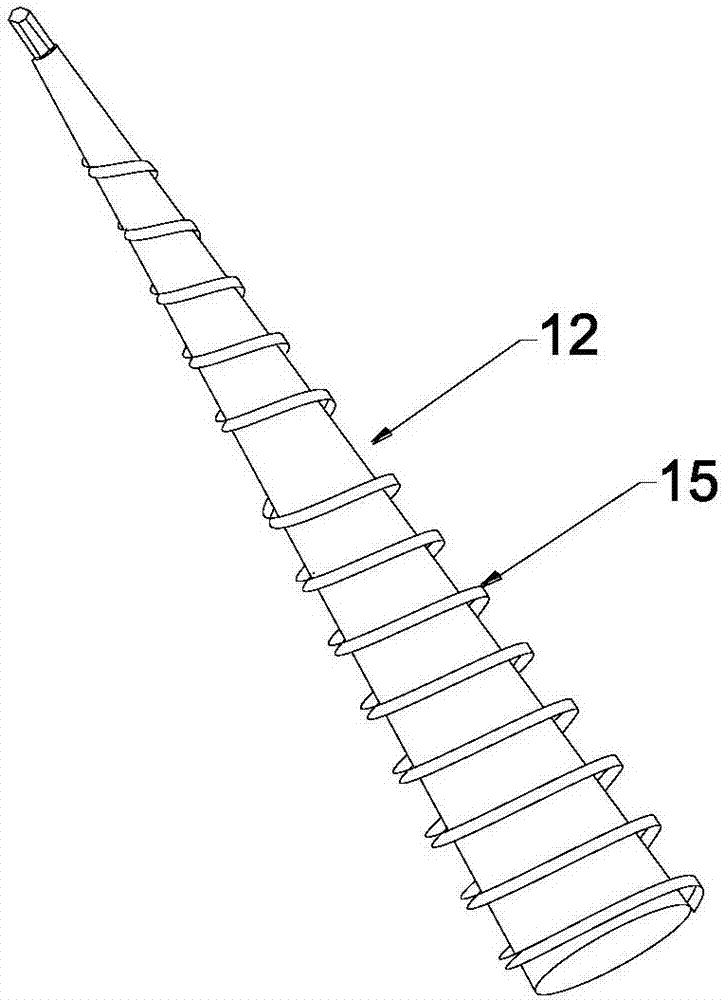

[0037] Such as Figures 1 to 2 As shown, the present invention provides a gradually expanding spiral feed pyrolysis furnace integrated in the rear shaft flue of a pulverized coal boiler, which includes a circular furnace heated at the junction of the horizontal flue 1 and the vertical shaft flue 2 to be heated by the flue gas. A cylindrical furnace body 3, the upper end of the cylindrical furnace body 3 protrudes from the top wall or side wall of the horizontal flue 1 and communicates with the feed chamber 4, and the lower end of the cylindrical furnace body 3 passes through biological The charcoal outlet slideway 5 communicates with the biochar collection bin 6 arranged outside the shaft flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com