Drying and dry distillation combined quality improving process and system for low rank coal

A low-rank coal and dry distillation technology, which is applied to the discharge device of dry distillation gas, special forms of dry distillation, indirect heating dry distillation, etc., can solve the problems of large coking wastewater treatment capacity and large gas treatment capacity, and reduce investment and operating costs. , The effect of increasing the heat exchange area and strengthening the dry distillation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

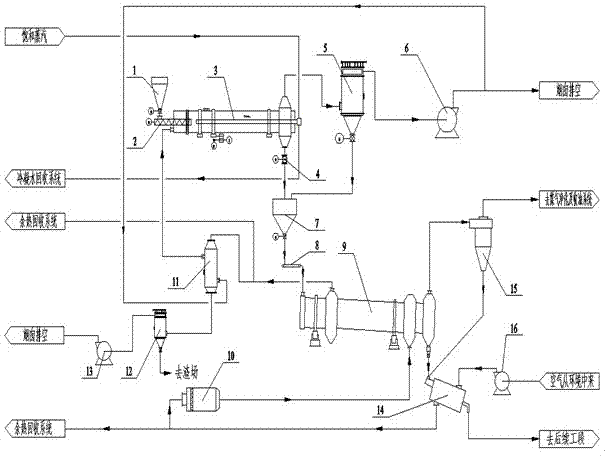

[0033] Such as figure 1 As shown, the 0-10mm raw coal from the raw coal bunker 1 enters the steam rotary dryer 3 through the double-screw conveyor 2. With the rotation of the steam rotary dryer 3 cylinder, it is lifted and sprinkled by the heat exchange tube, and is connected with the built-in heat exchange dryer. The tube and the superheated steam are in full contact with heat exchange, and the slope of the steam rotary dryer 3 is moved from the higher end to the lower end. By controlling the residence time of the coal in the cylinder, it is dried to a moisture content of less than 8%, preferably 5%. Next, it is discharged into the blending silo 7 by the discharge valve 4 at the tail of the steam rotary dryer 3 .

[0034]The pulverized coal from the blending silo 7 is fed into the multi-tube pulverized coal feeder in the multi-tube rotary carbonizer 9 through the belt 8, and then evenly distributed into the multiple dry distillation tubes through the feeder. On the one hand,...

Embodiment 2

[0039] Such as figure 2 As shown, the 0-10mm raw coal from the raw coal bunker 1 enters the inner heating fluidized bed dryer 19 through the double screw conveyor 2, and under the action of the blower I17, the superheated steam enters the bed after being uniformly distributed by the air distribution device to drive the coal to start flowing. The coal particles suspended in the gas flow exchange heat with the superheated steam for the first time. At the same time, during the fluidization process, the coal particles fully contact with the steam coil built in the internal heating fluidized bed dryer 19, so that the coal particles and the steam coil conduct a second heat exchange, and the internal heating of the fluidized bed by controlling the pulverized coal The residence time in the drier 19 is dried until the water content is below 8%, preferably below 5%, and the dry coal powder is sent into the blending bin 7 through the discharge valve 4.

[0040] The pulverized coal / gran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com