Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Reduce system pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

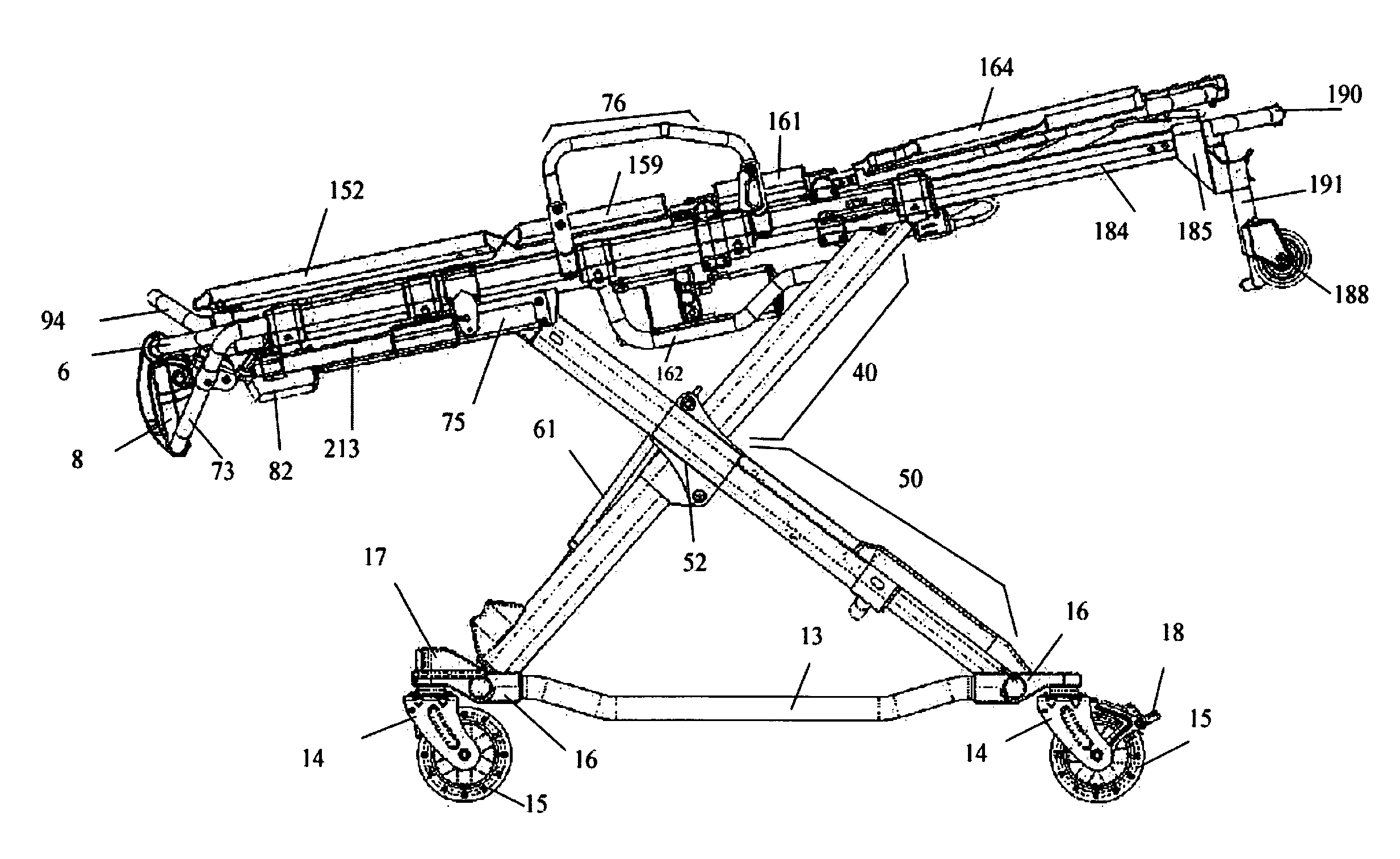

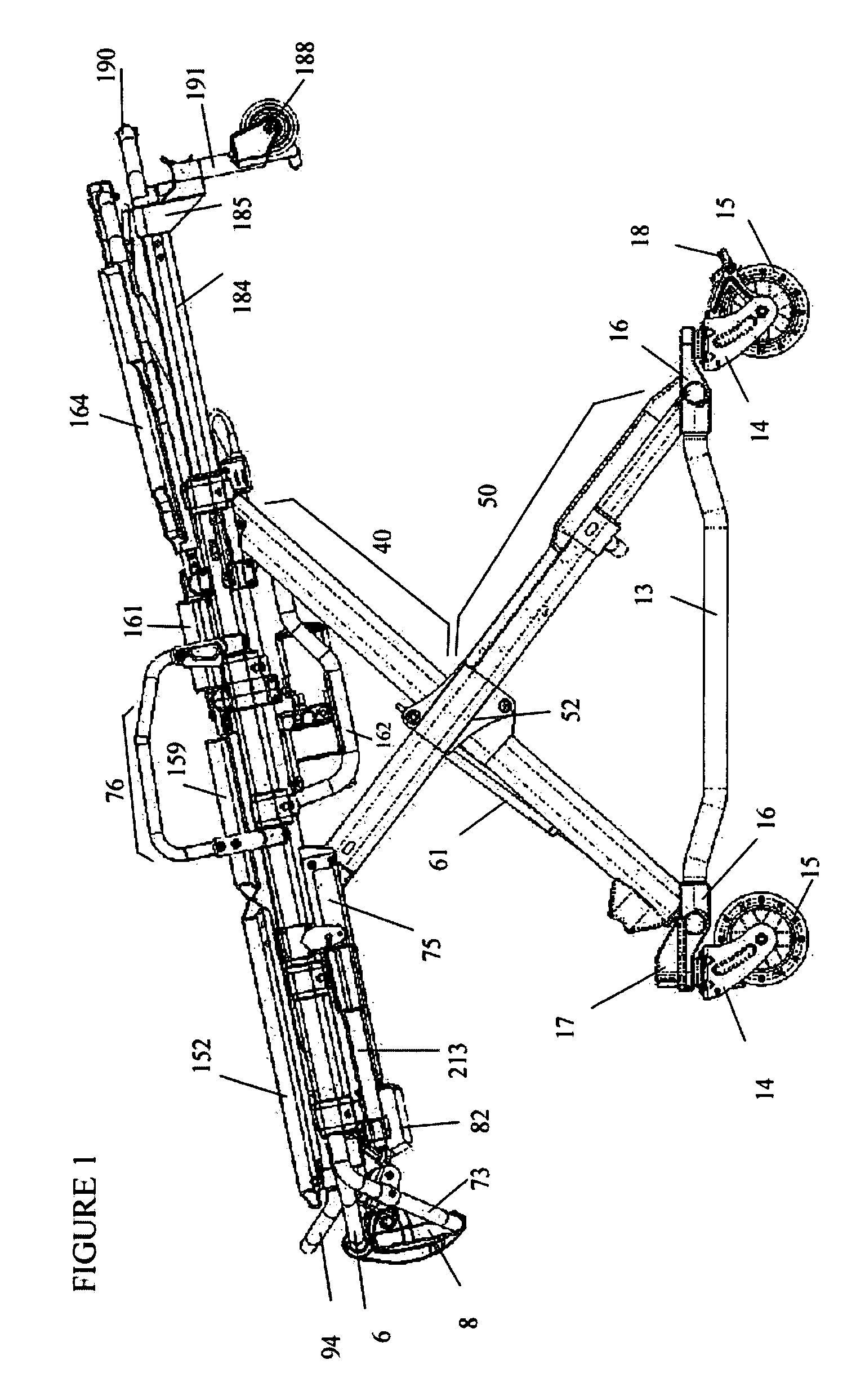

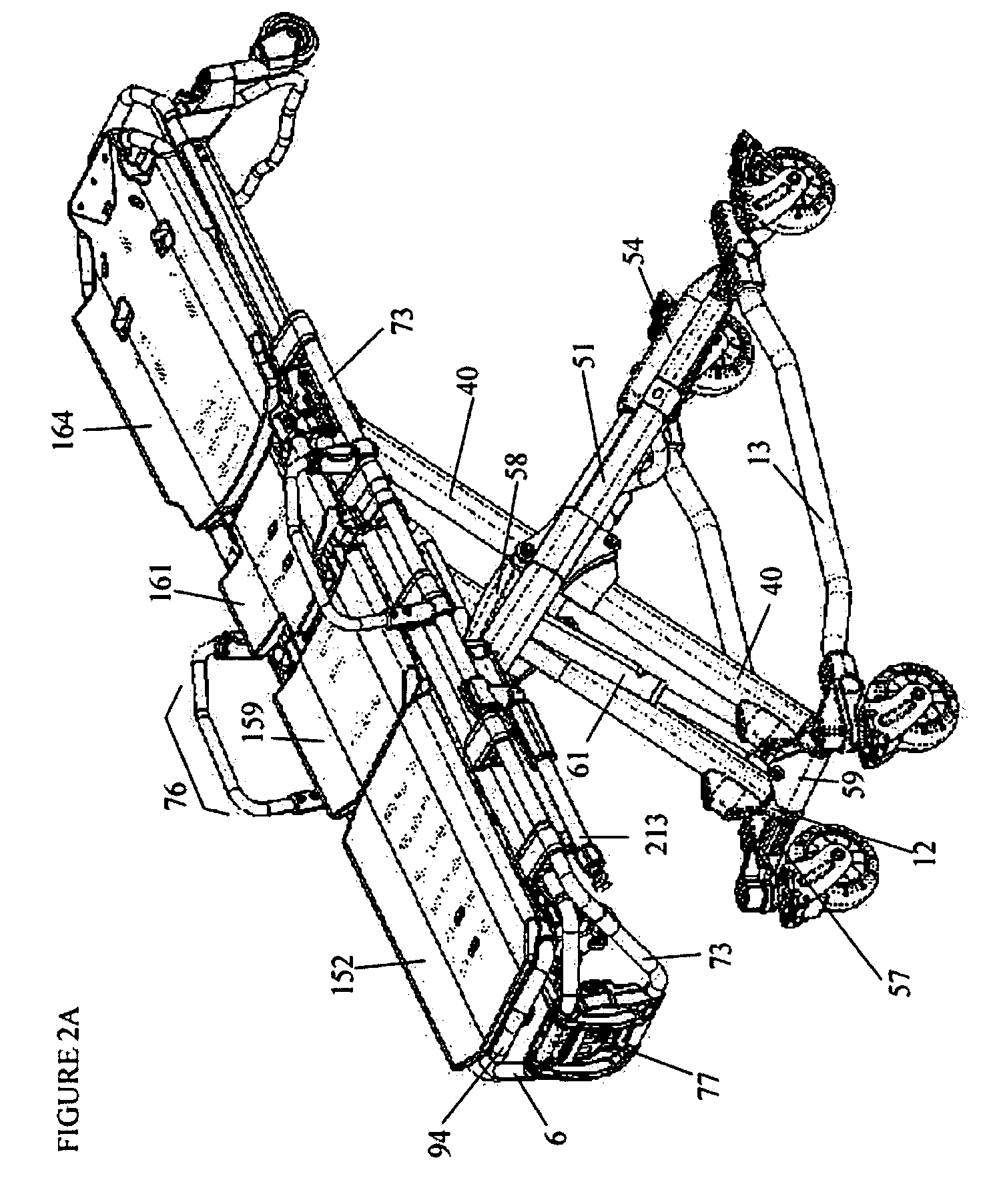

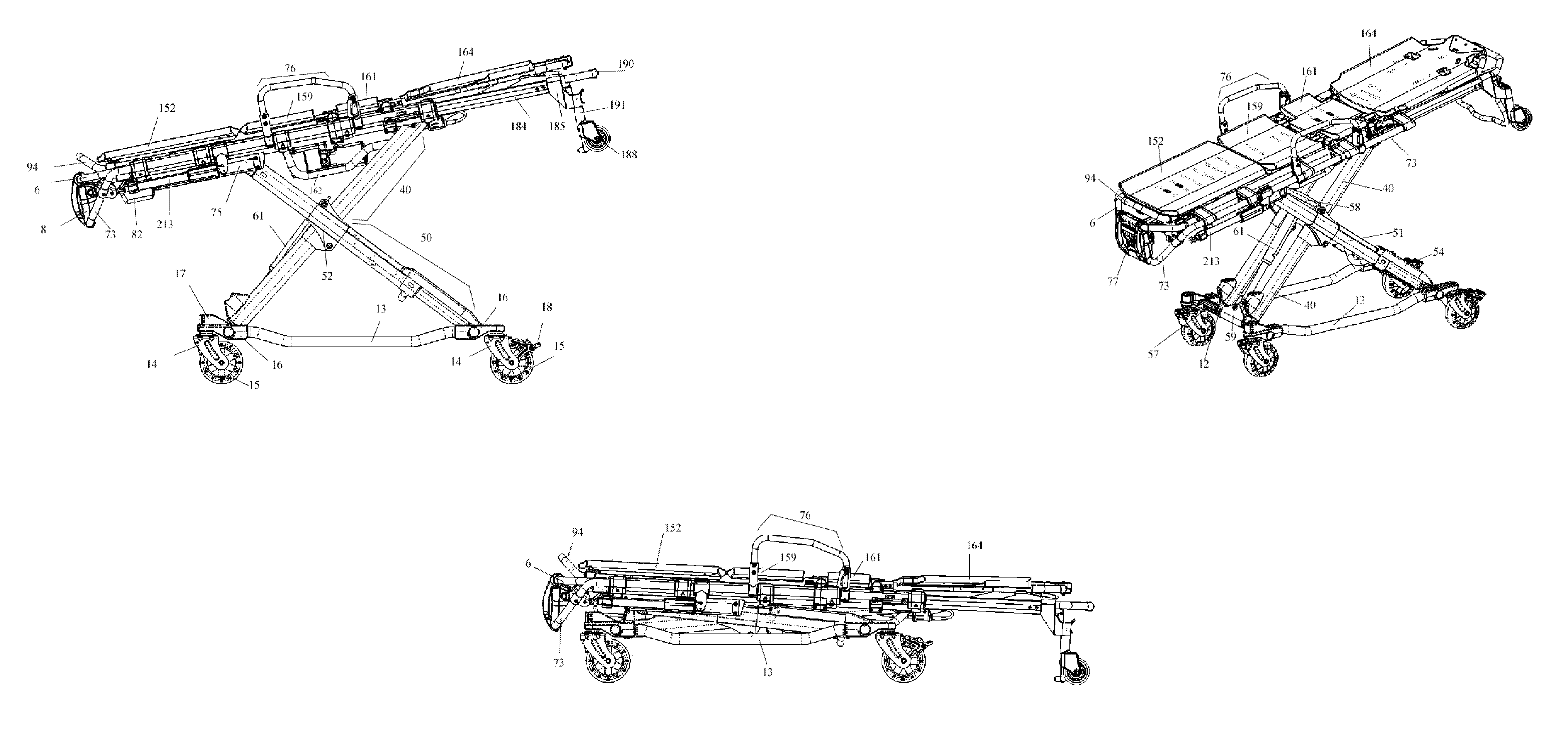

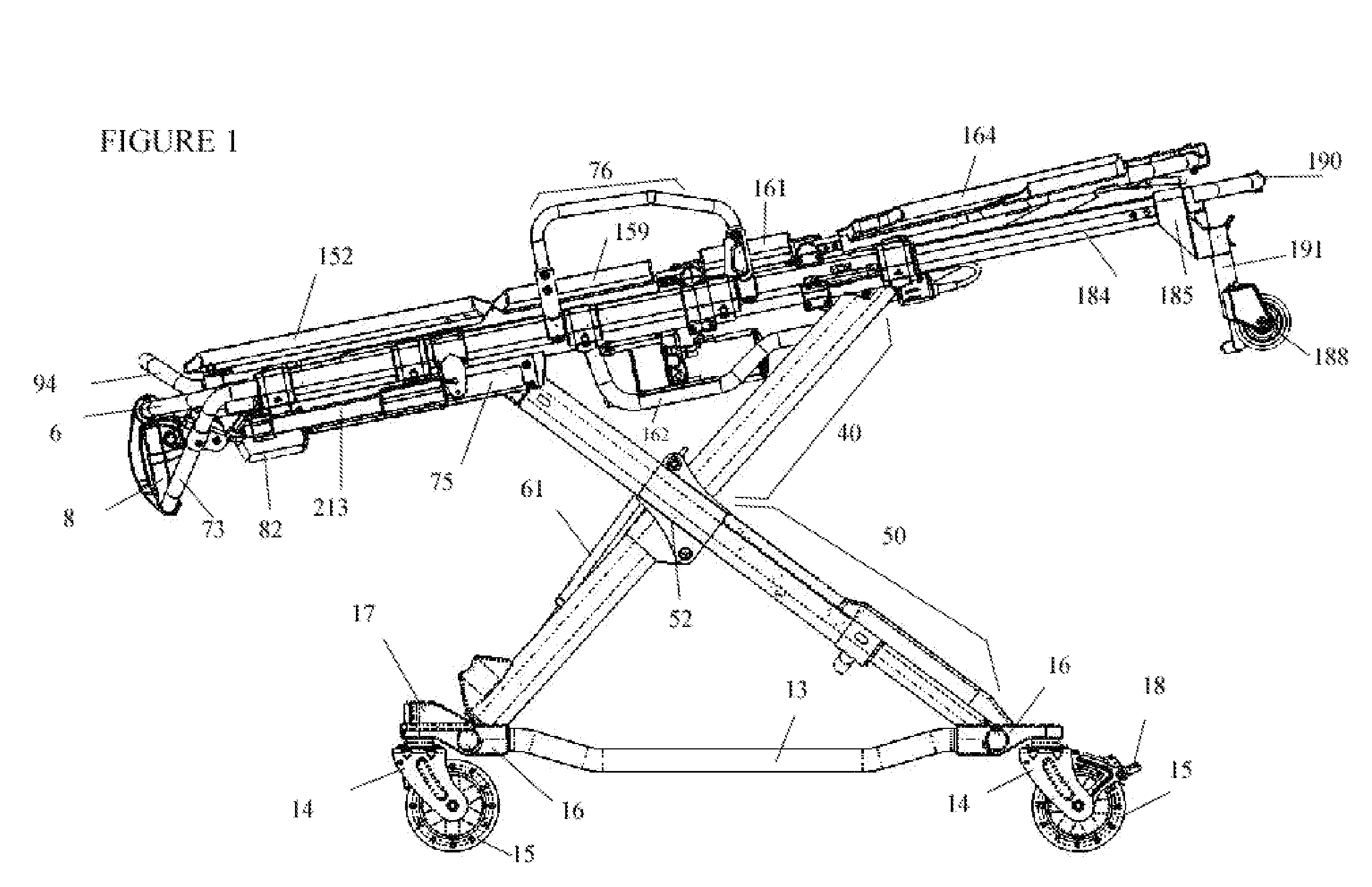

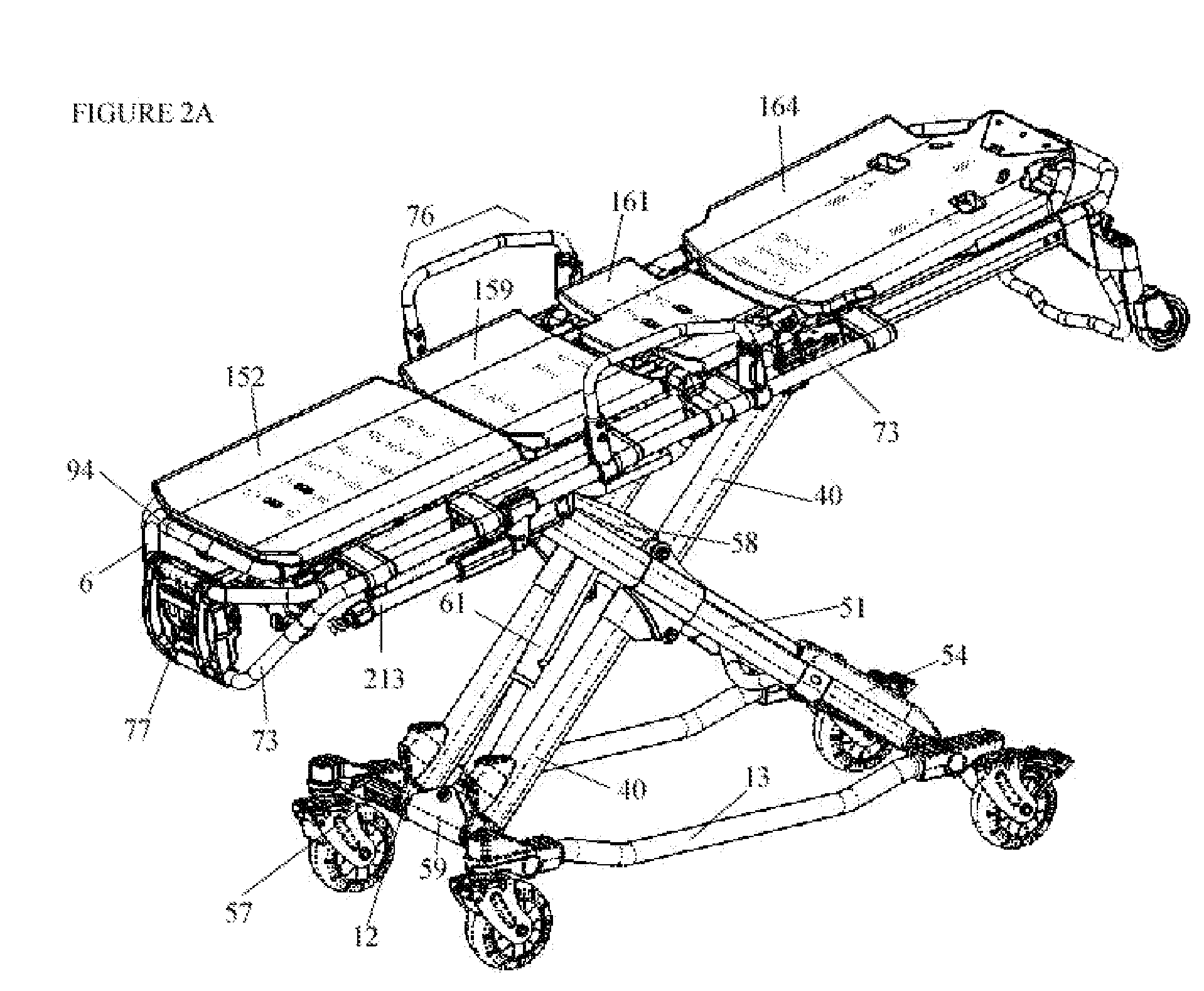

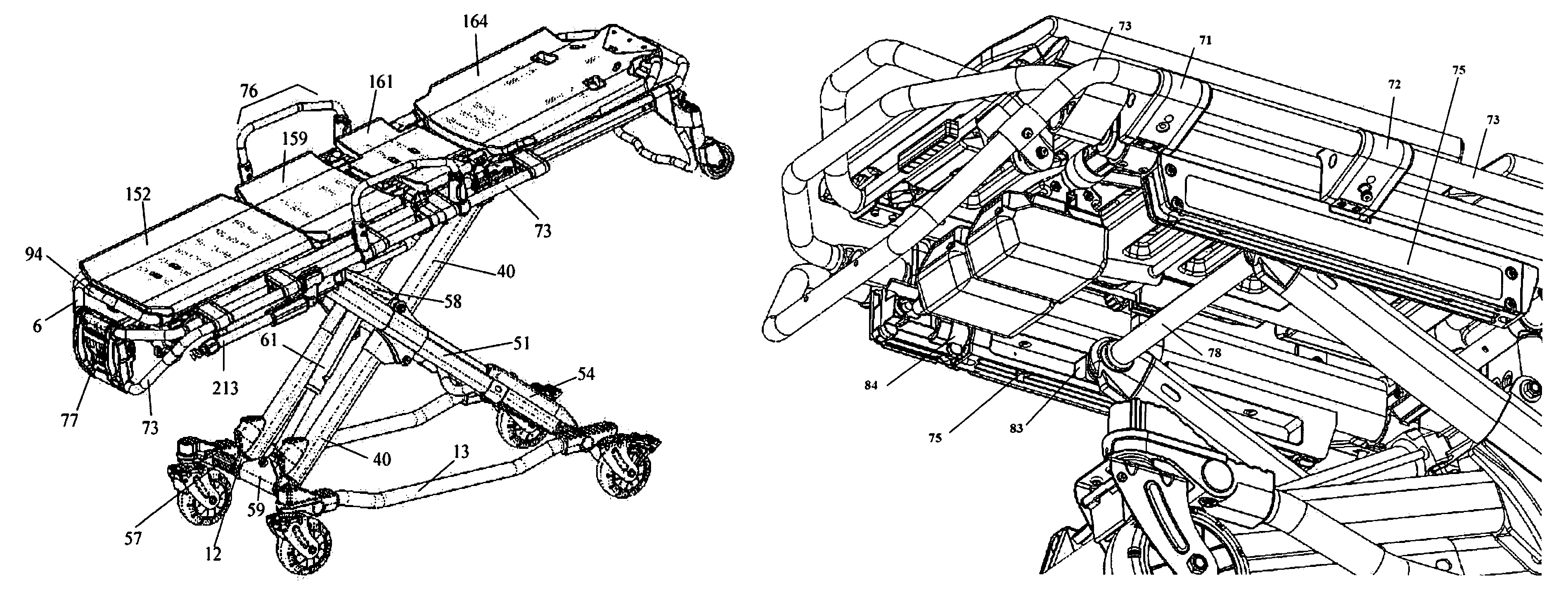

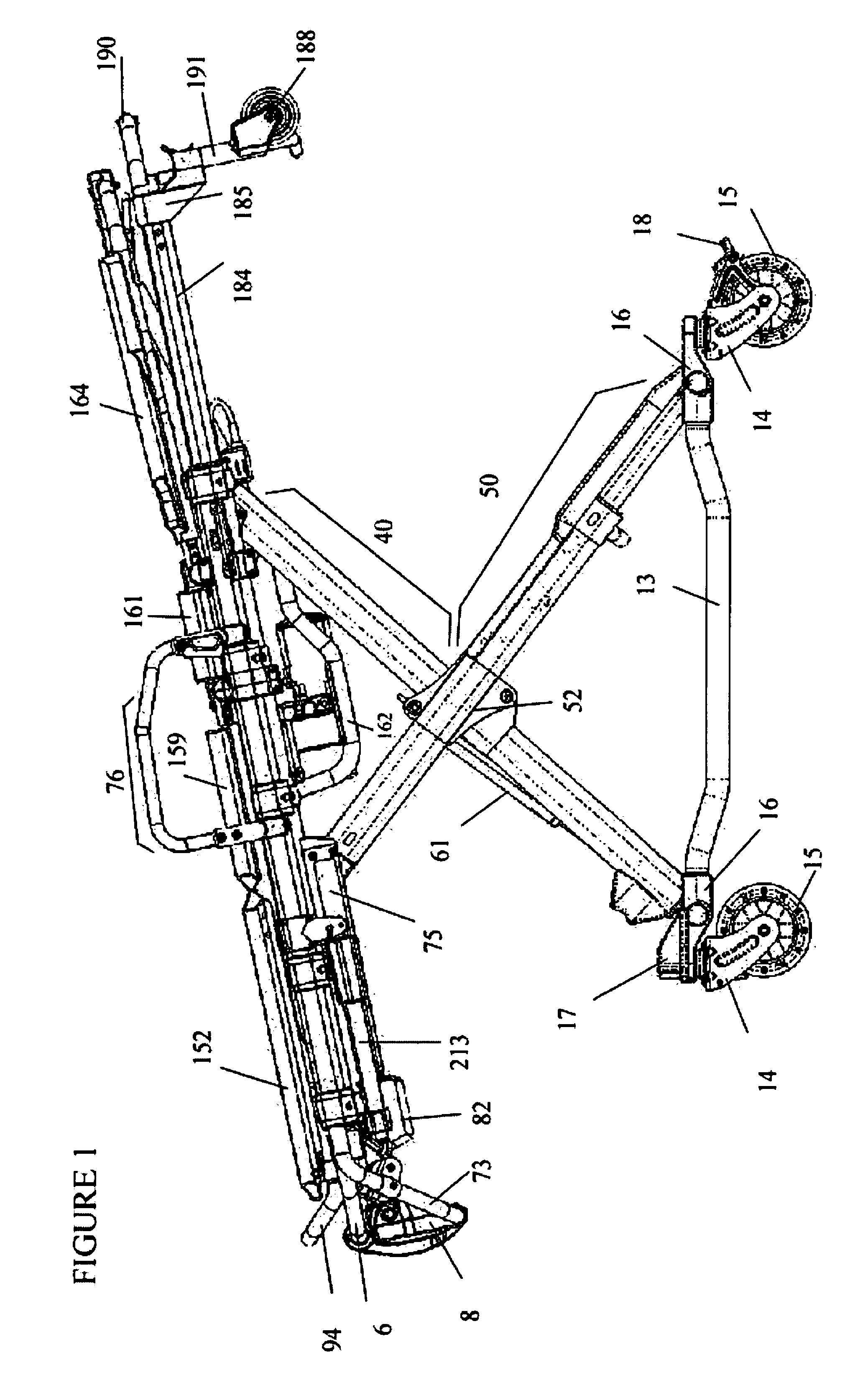

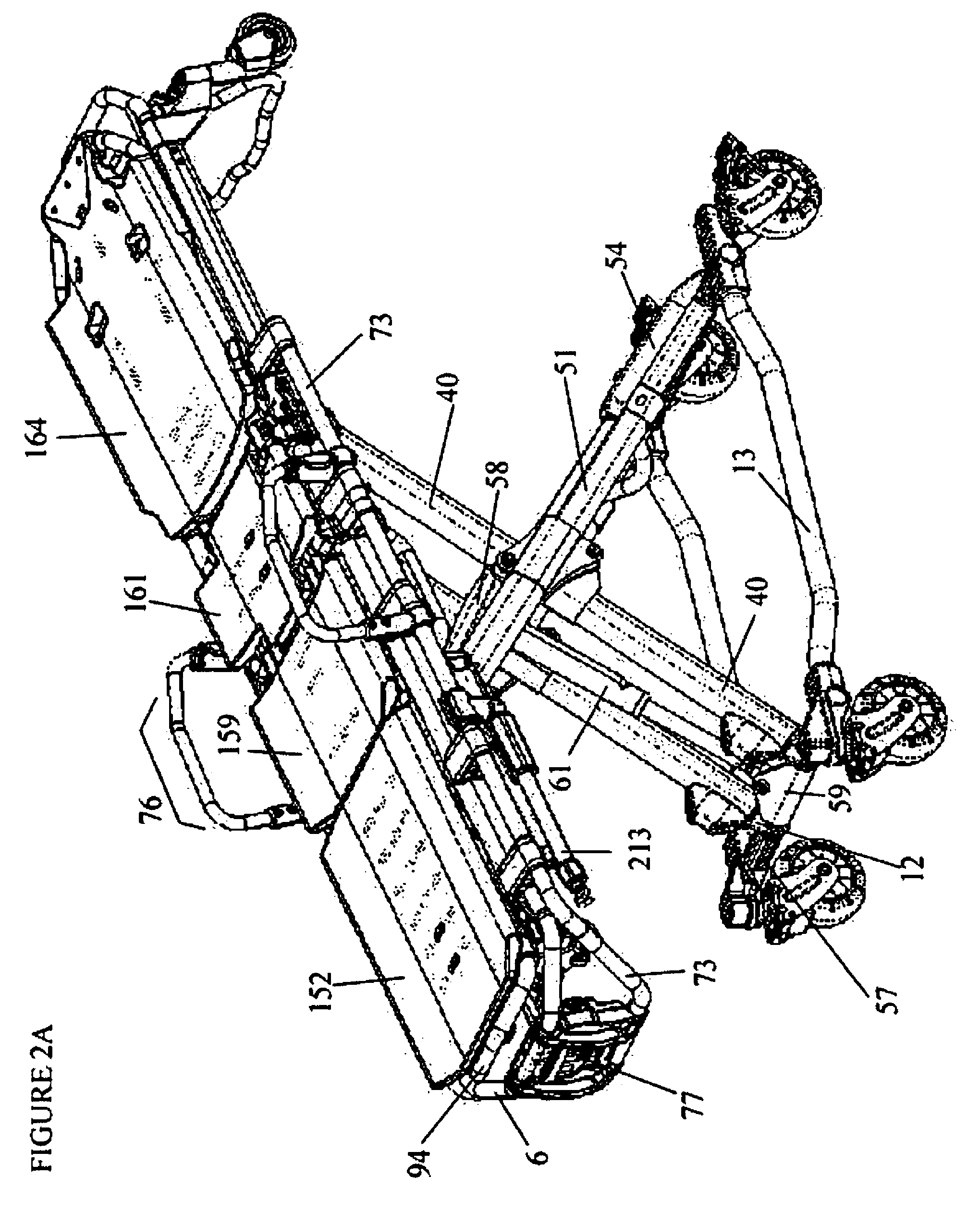

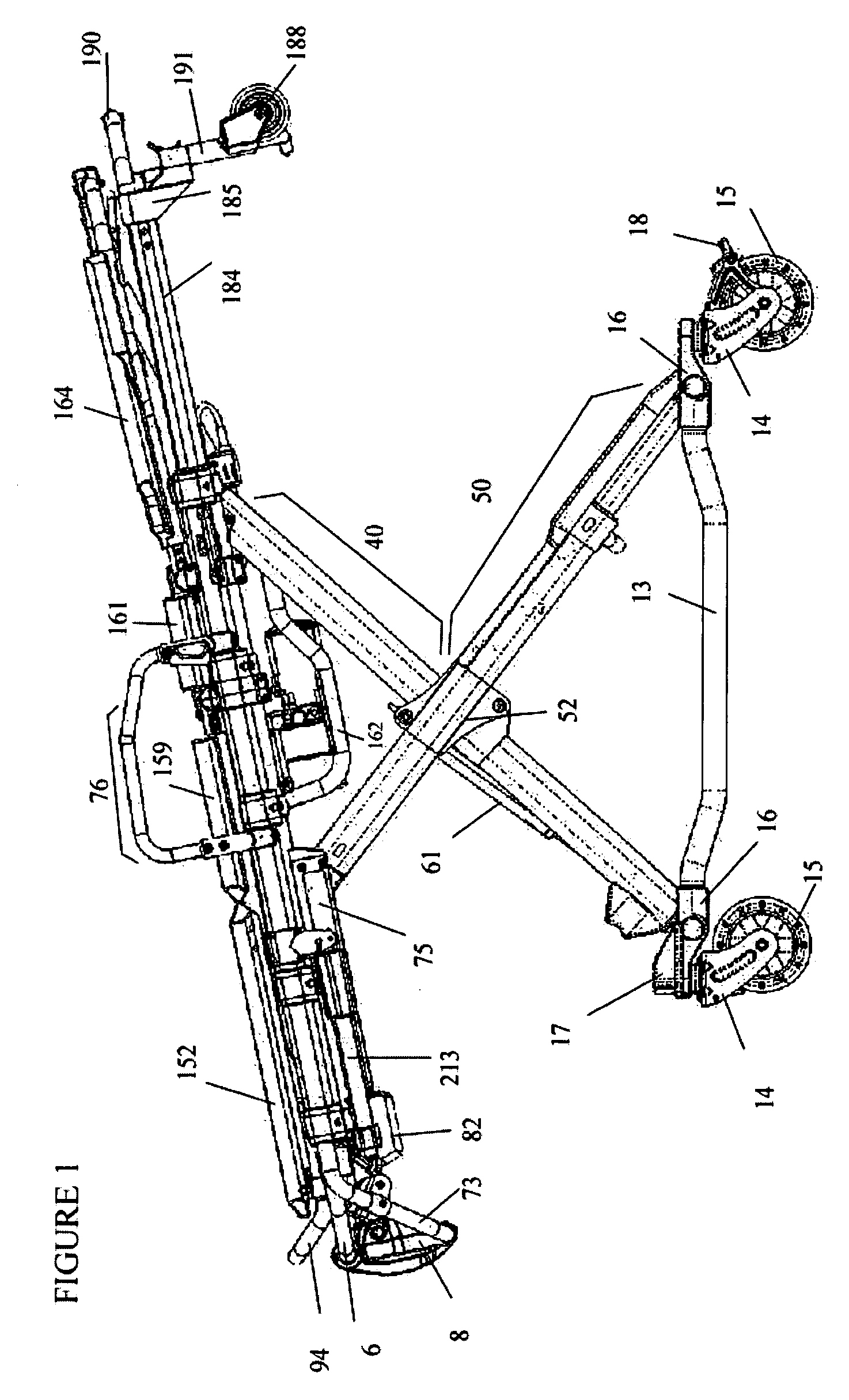

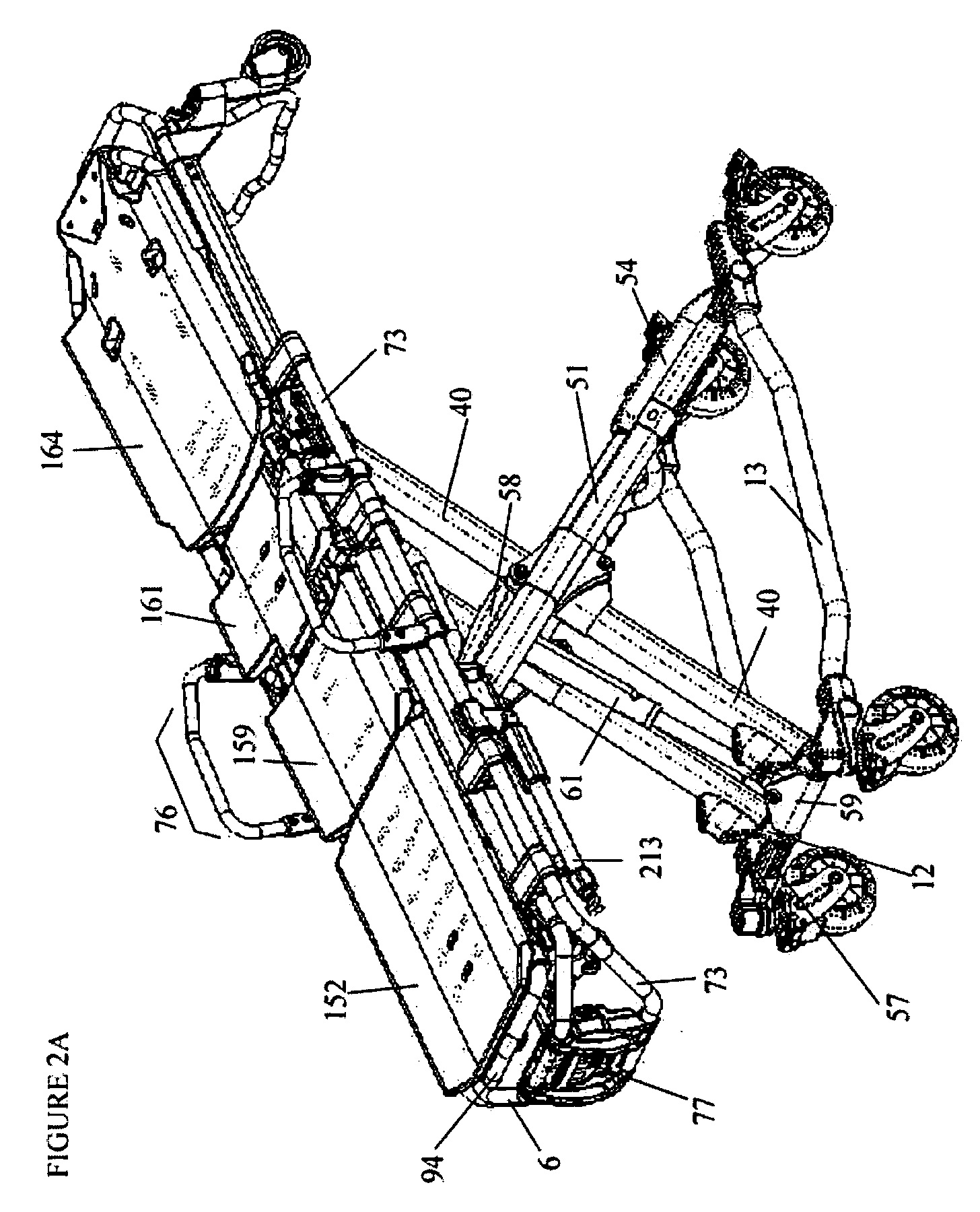

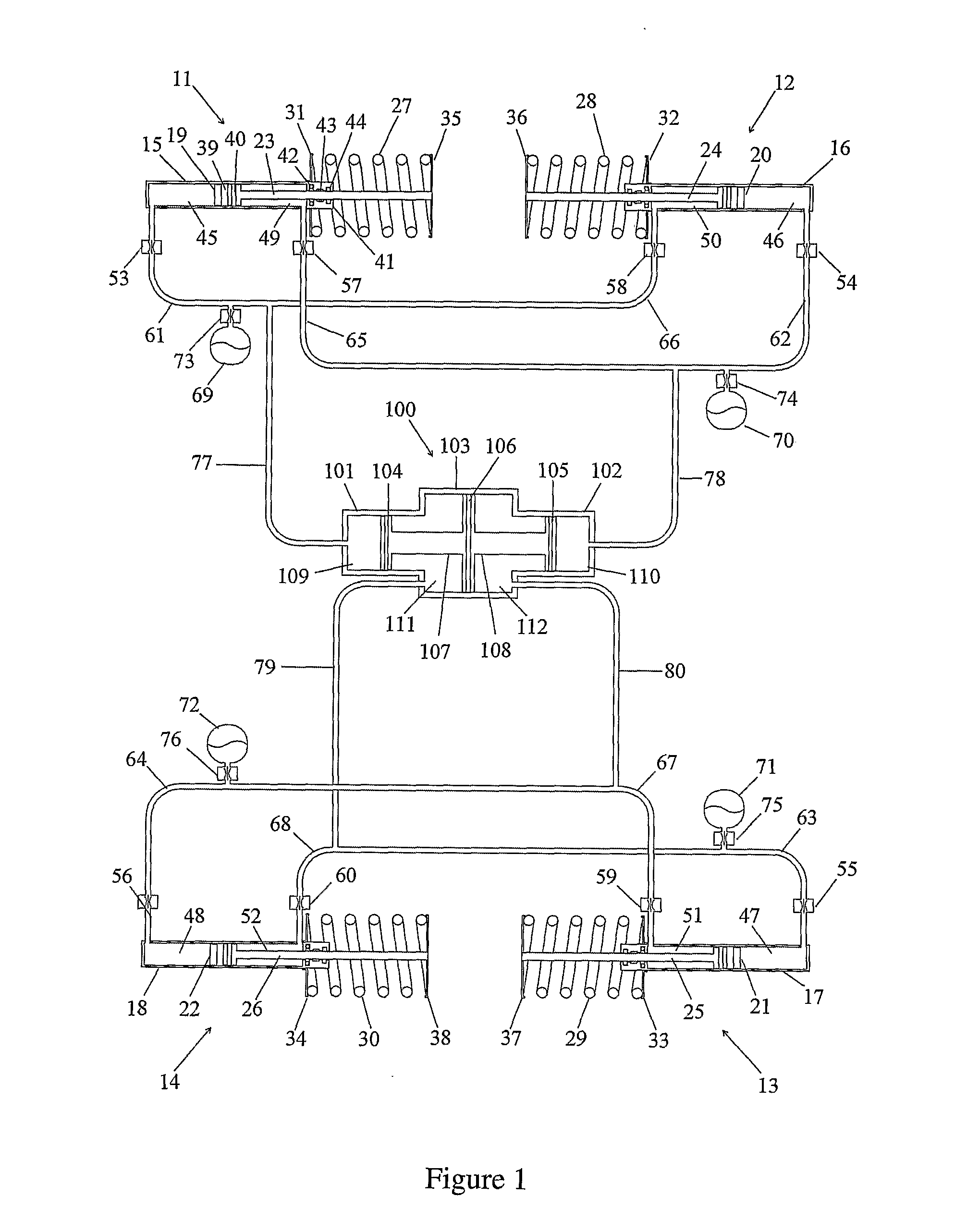

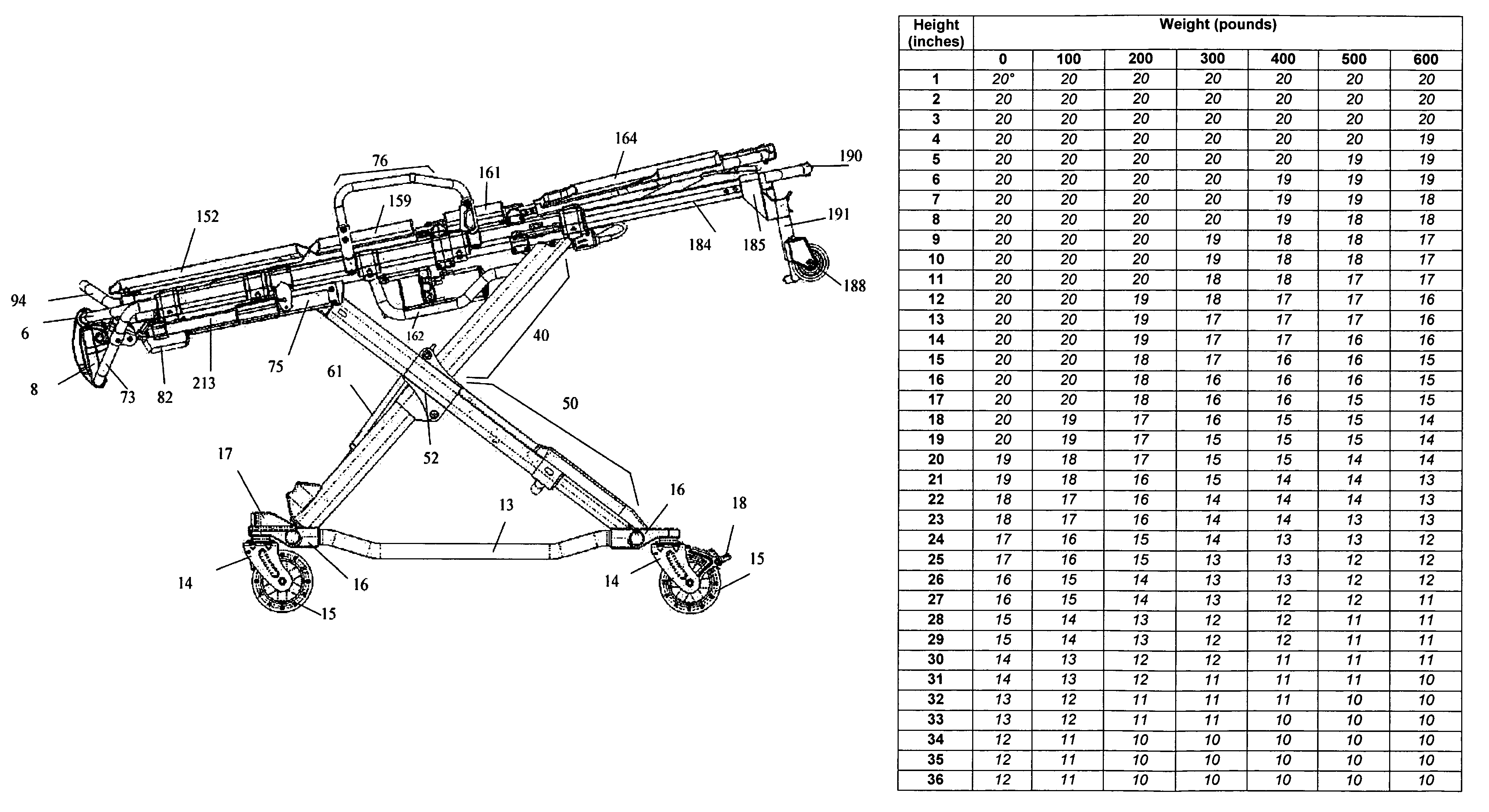

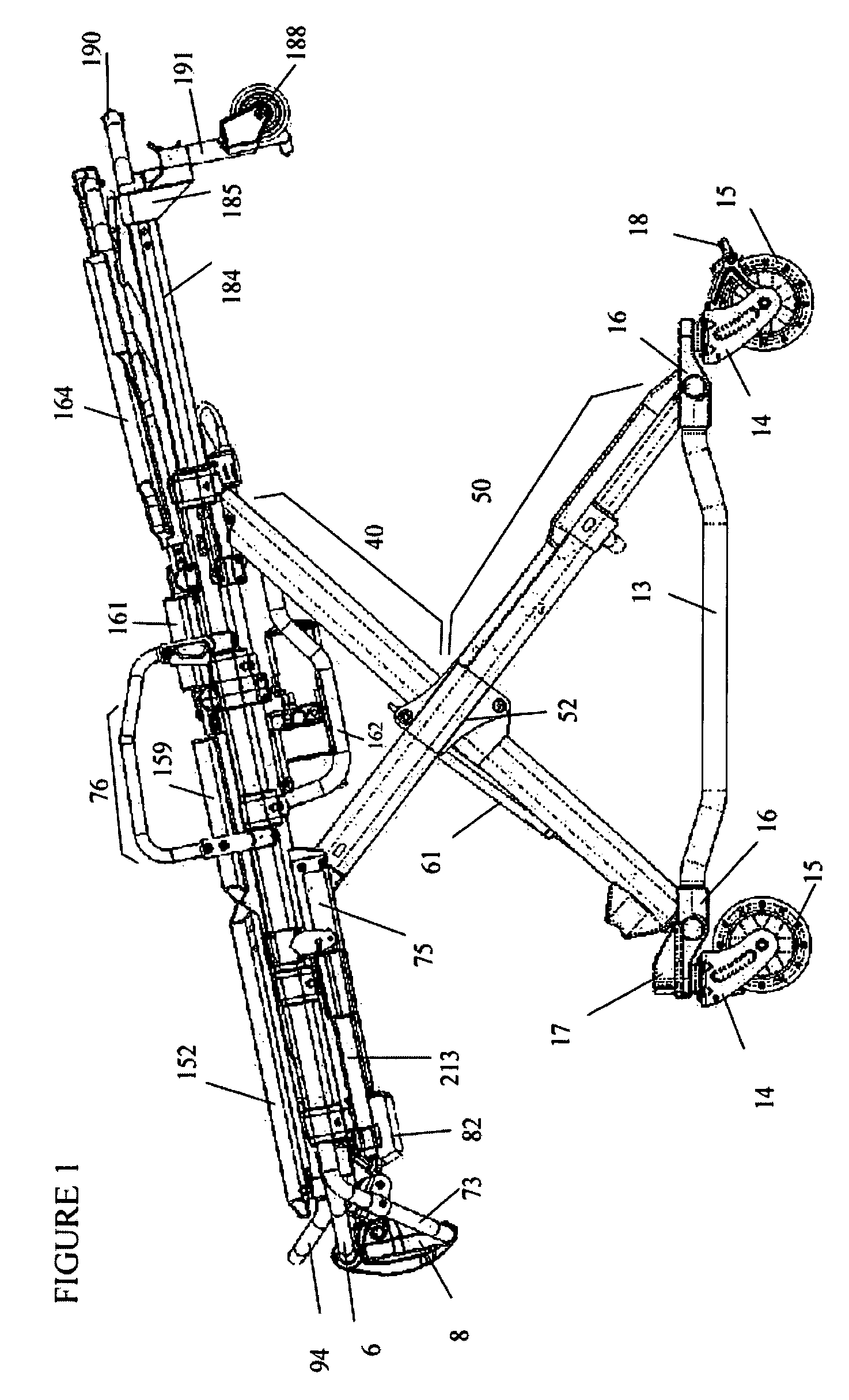

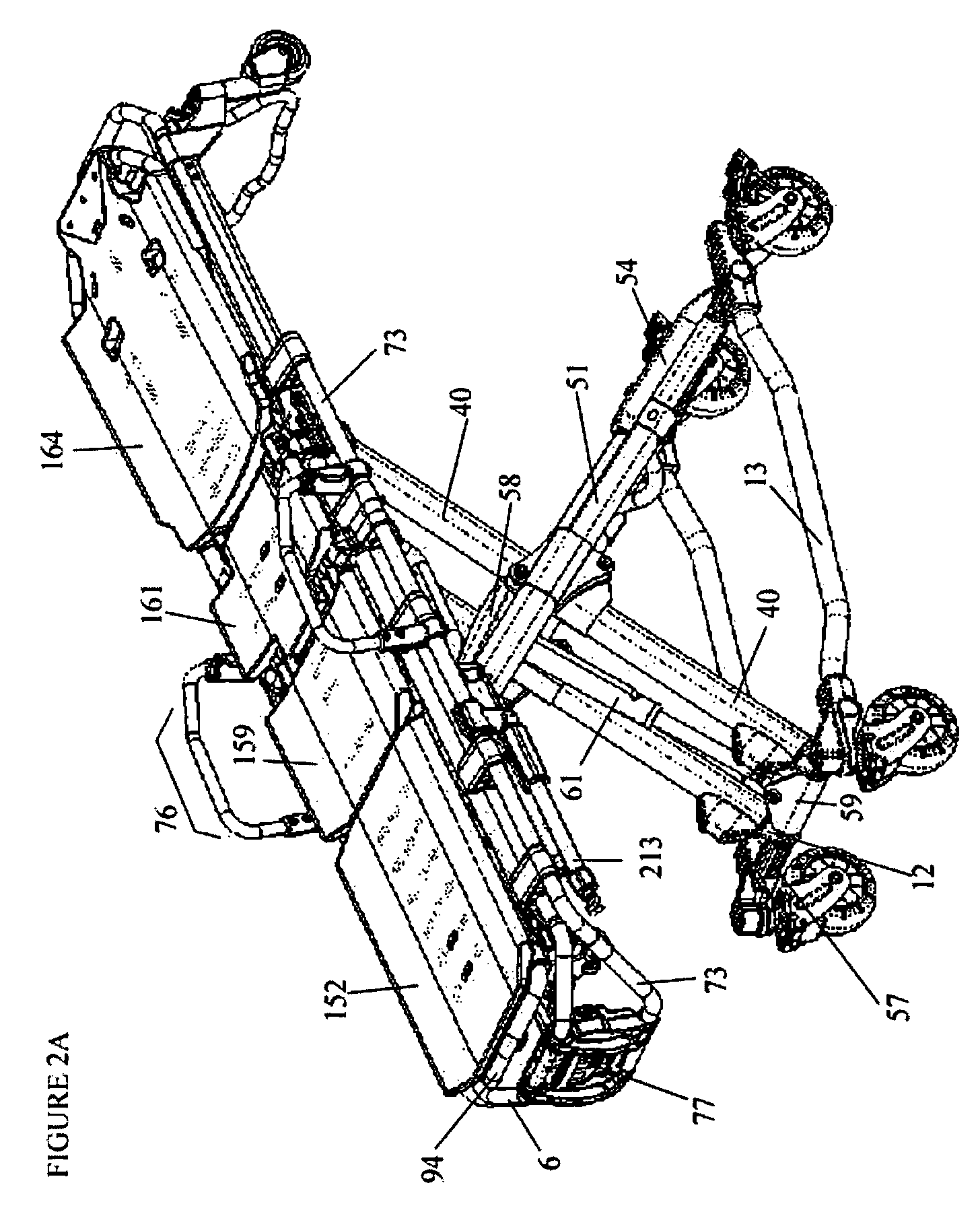

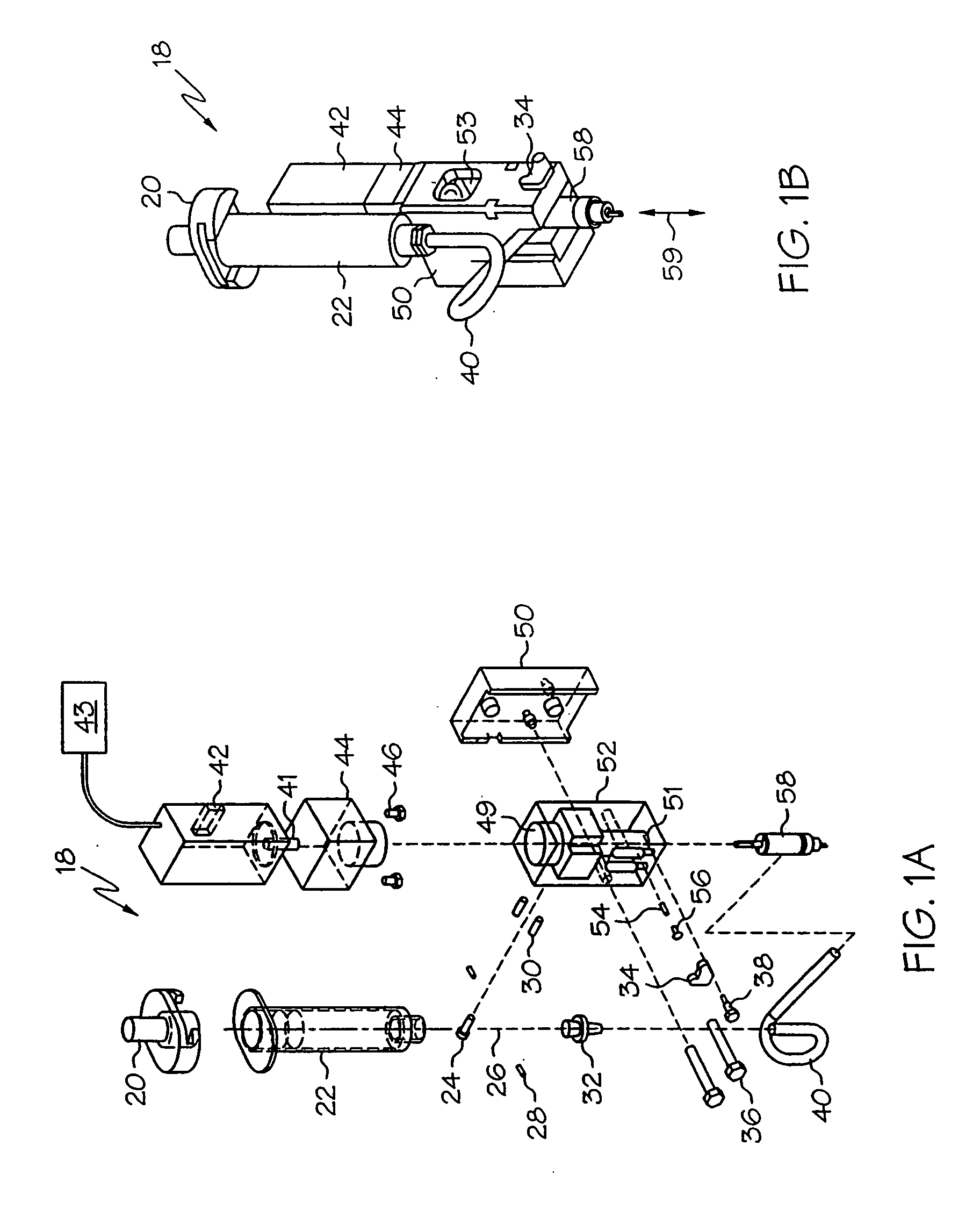

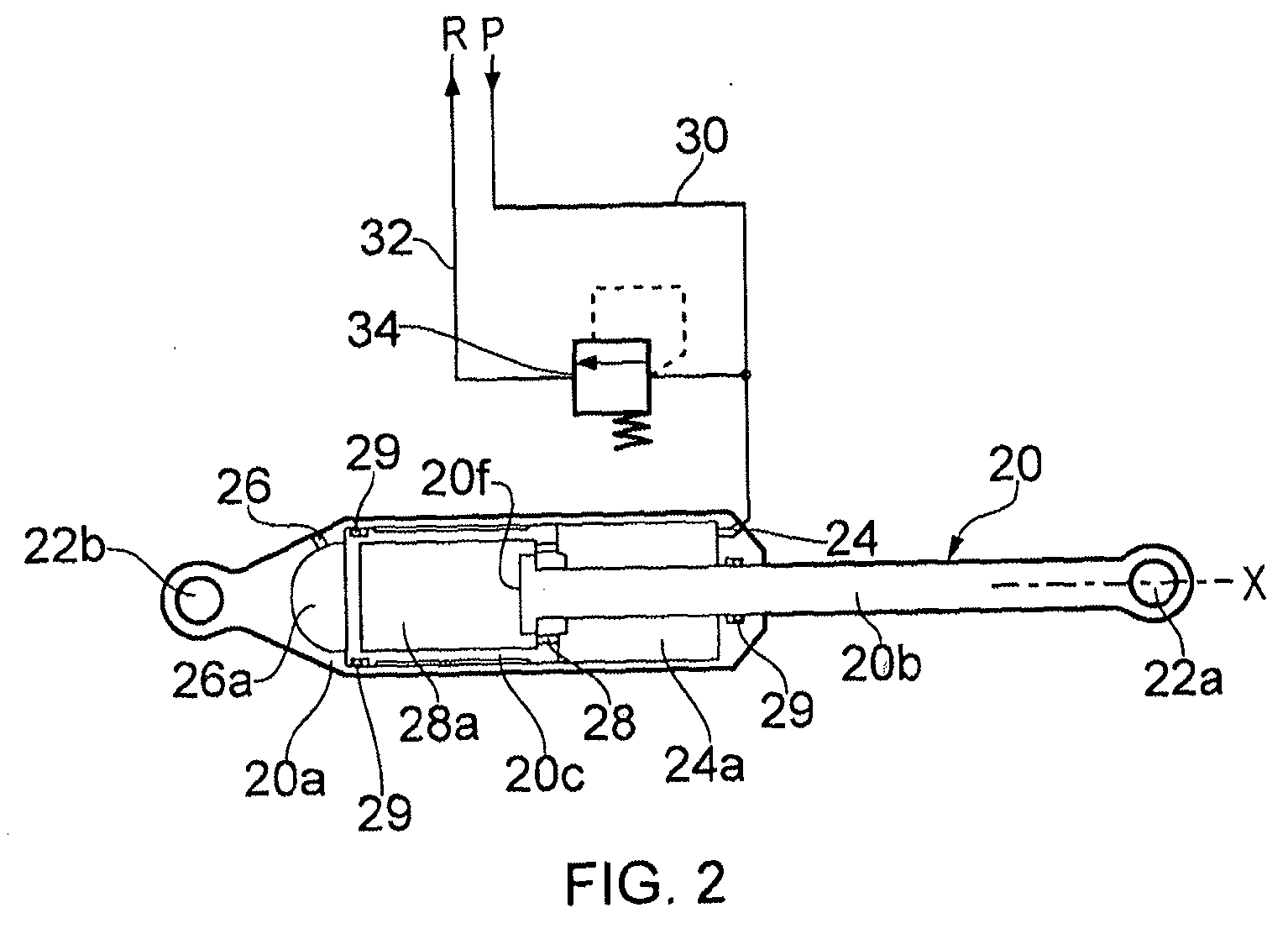

Ambulance cot system

ActiveUS20090165208A1Reduce frictionTotal current dropStretcherDigital computer detailsEngineeringFull Term Infant

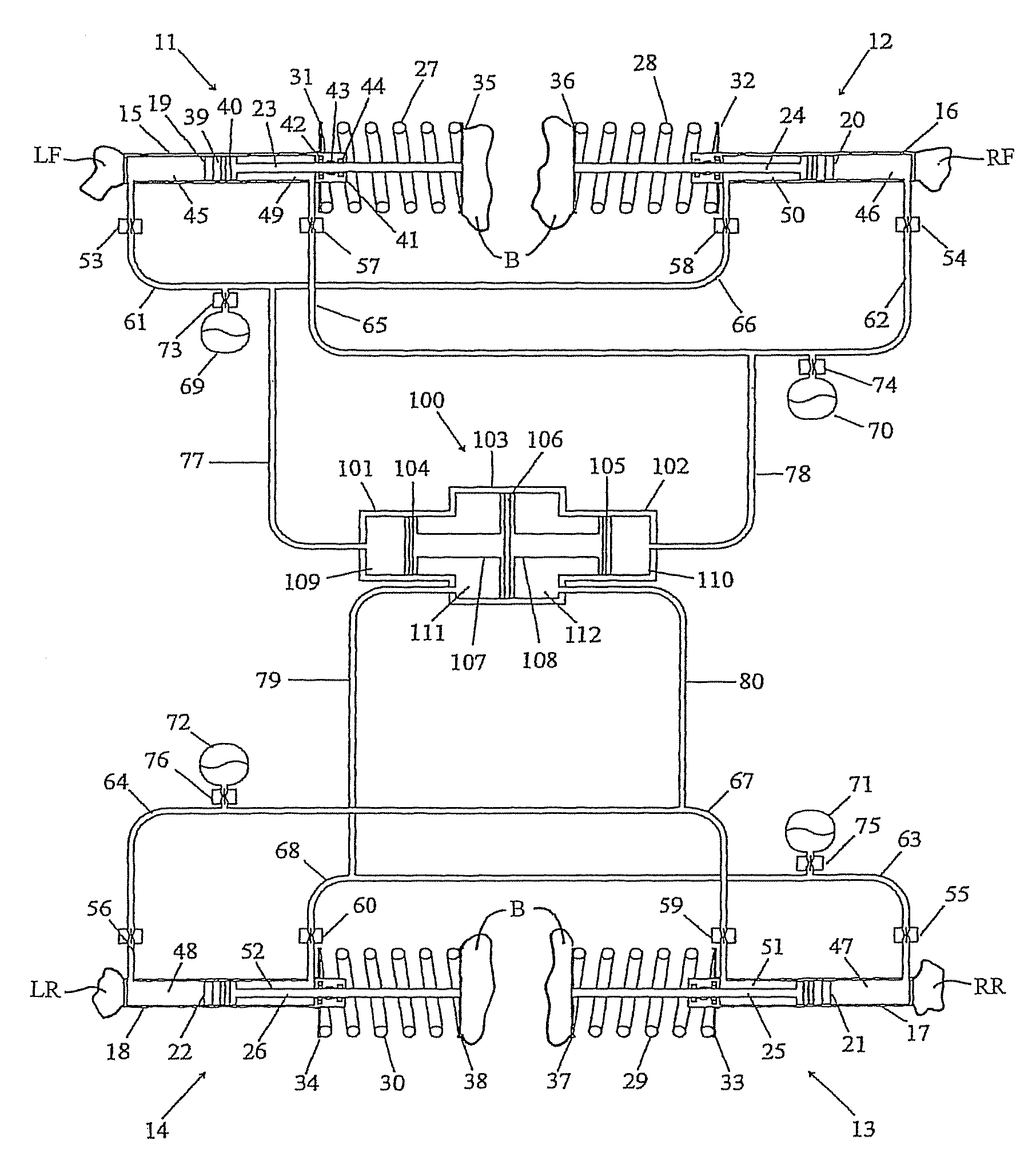

The present invention relates to ambulance cots, cot systems and methods of using the same. In particular, the present invention provides an ambulance cot comprising a hydraulic system and a tip angle monitoring, recording and alert system, and methods of using the same (e.g., to transport subjects and / or to detect and / or record operational data related to cot usage).

Owner:FERNO WASHINGTON

Ambulance cot system

ActiveUS7389552B1Reduce frictionTotal current dropStretcherAcceleration measurementEngineeringAlert system

The present invention relates to ambulance cots, cot systems and methods of using the same. In particular, the present invention provides an ambulance cot comprising a hydraulic system and a tip angle monitoring, recording and alert system, and methods of using the same (e.g., to transport subjects and / or to detect and / or record operational data related to cot usage).

Owner:FERNO WASHINGTON

Ambulance cot system

ActiveUS8051513B2Reduce frictionTotal current dropStretcherDigital computer detailsEngineeringAlert system

Owner:FERNO WASHINGTON

Ambulance Cot System

ActiveUS20090165207A1Reduce frictionTotal current dropBraking element arrangementsDiagnosticsEngineeringAlert system

The present invention relates to ambulance cots, cot systems and methods of using the same. In particular, the present invention provides an ambulance cot comprising a hydraulic system and a tip angle monitoring, recording and alert system, and methods of using the same (e.g., to transport subjects and / or to detect and / or record operational data related to cot usage).

Owner:FERNO WASHINGTON

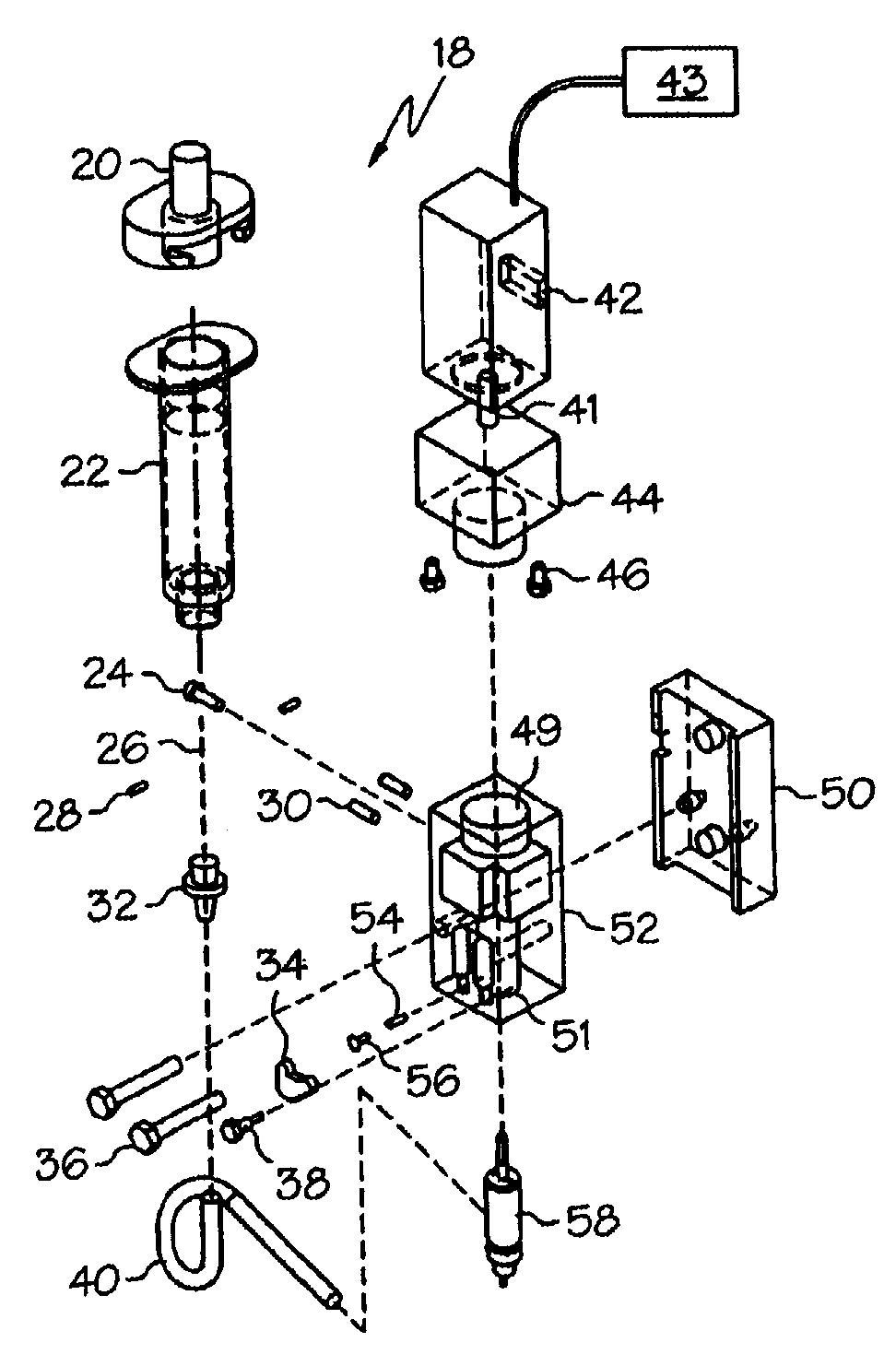

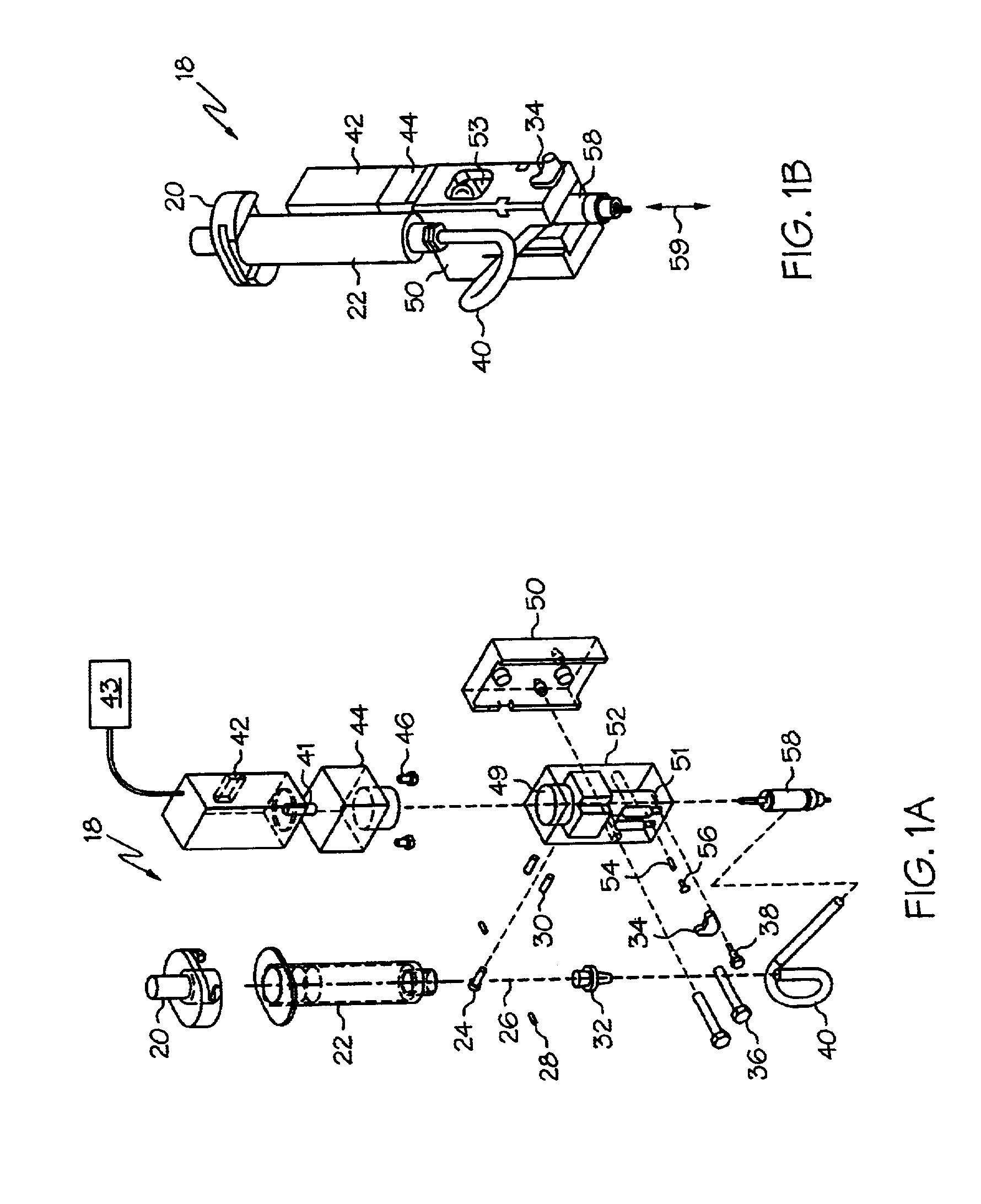

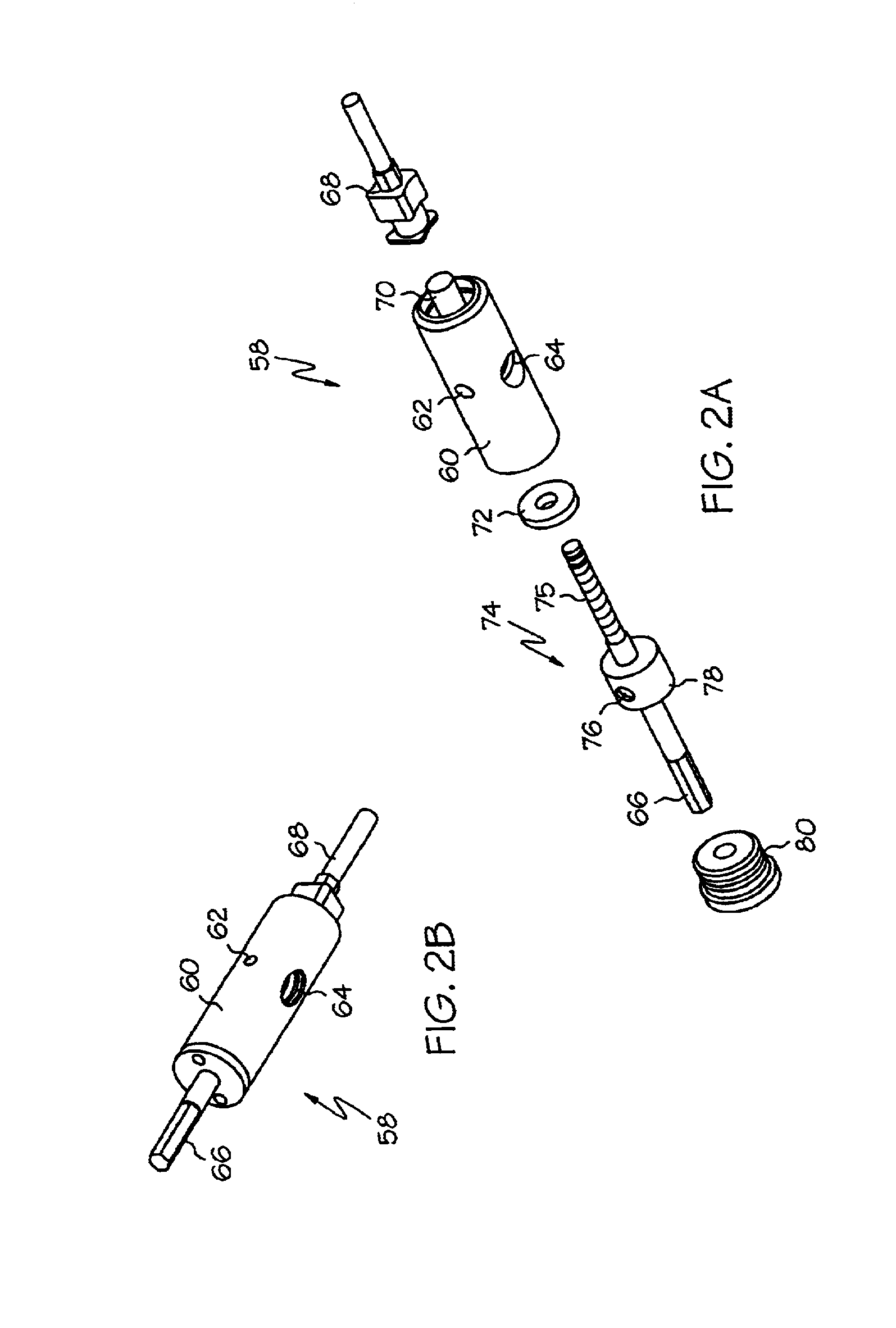

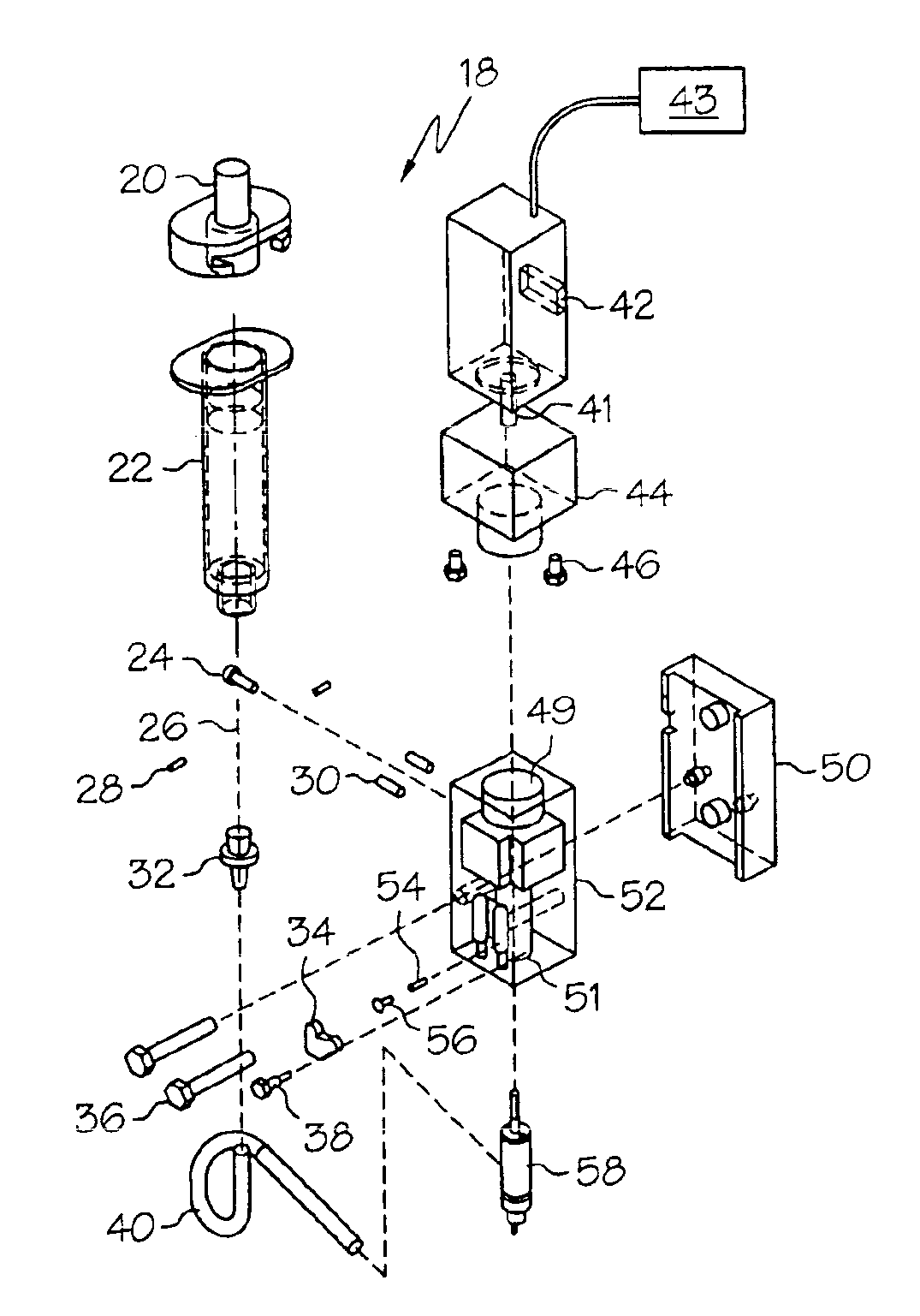

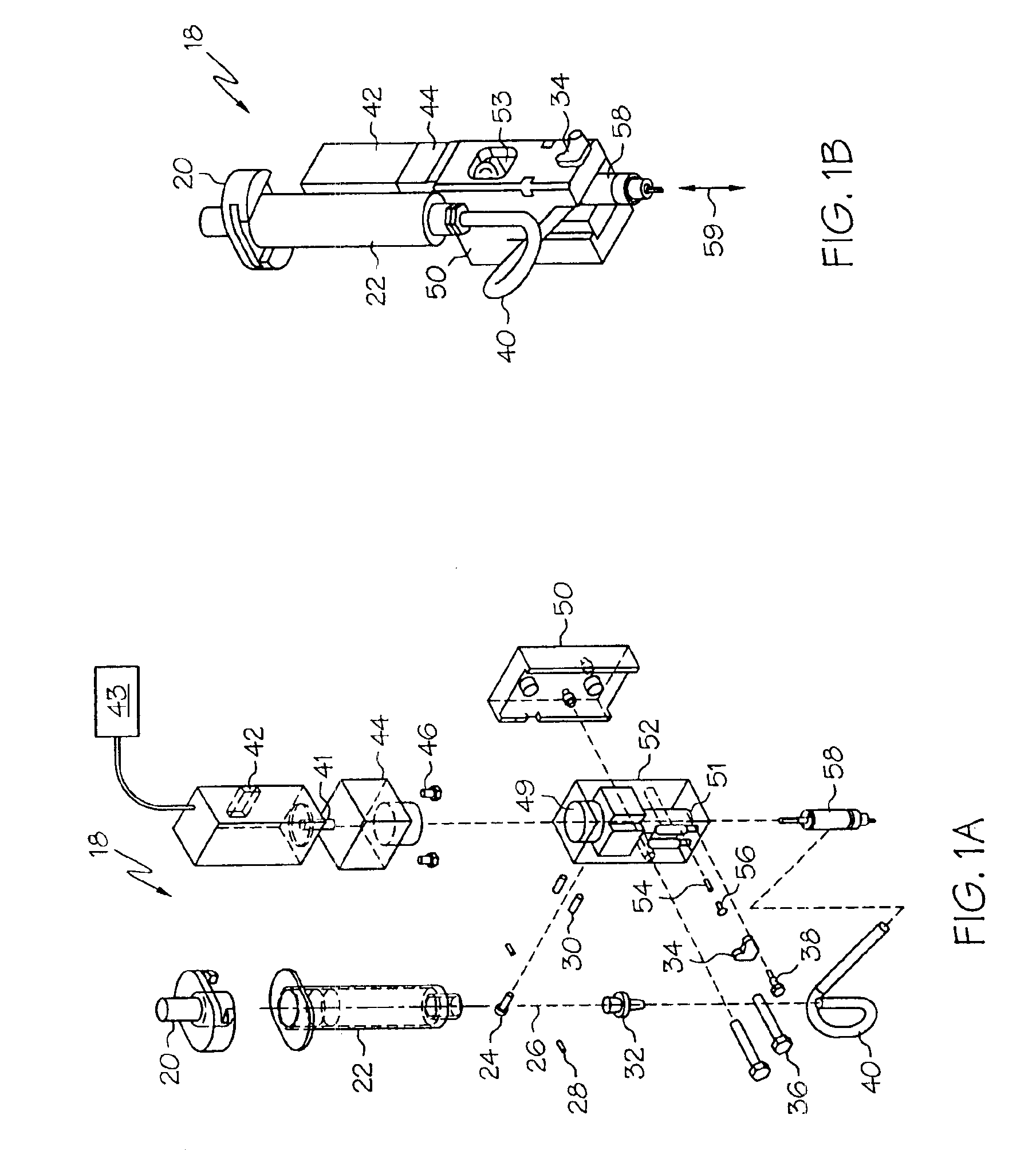

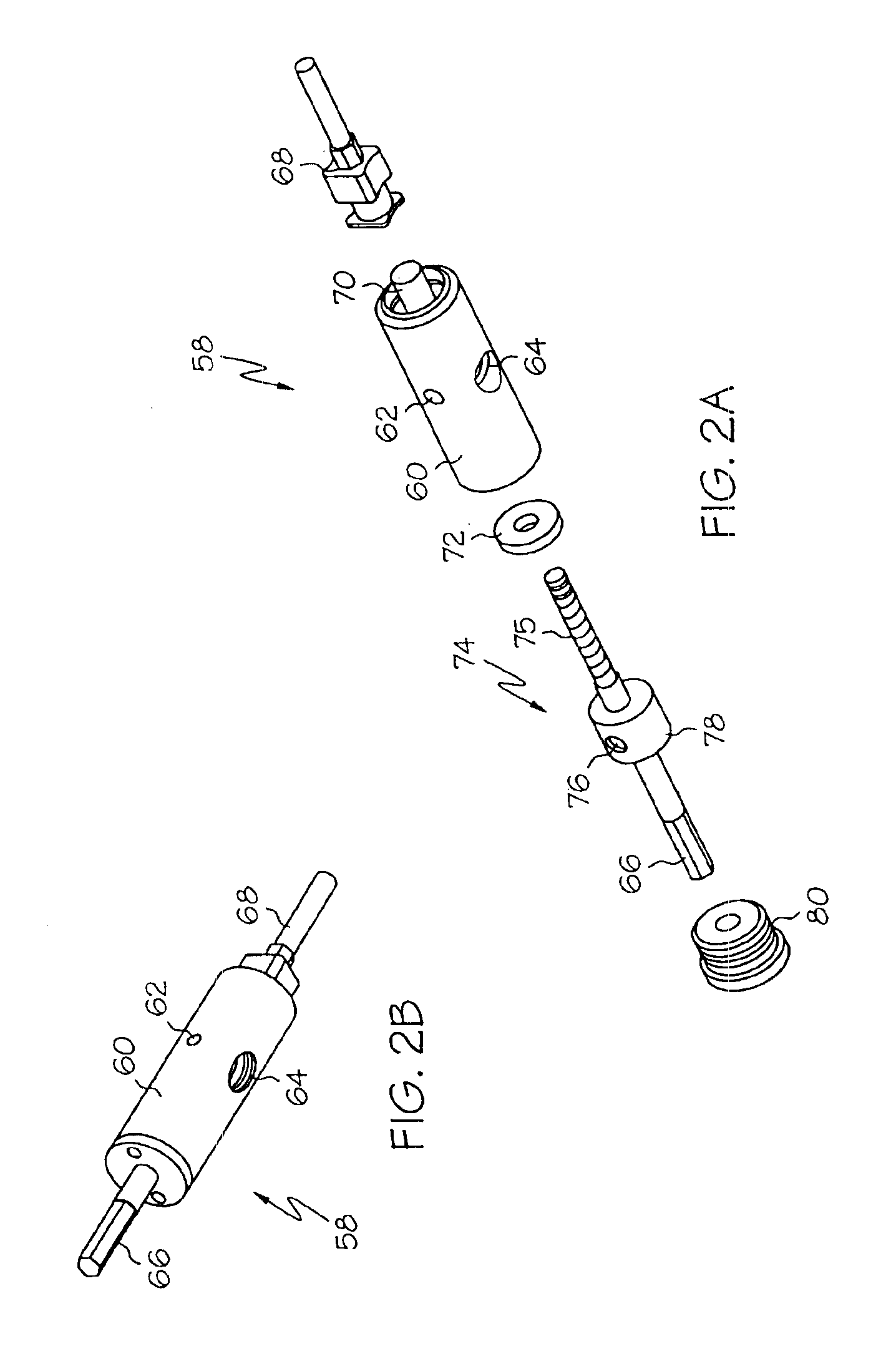

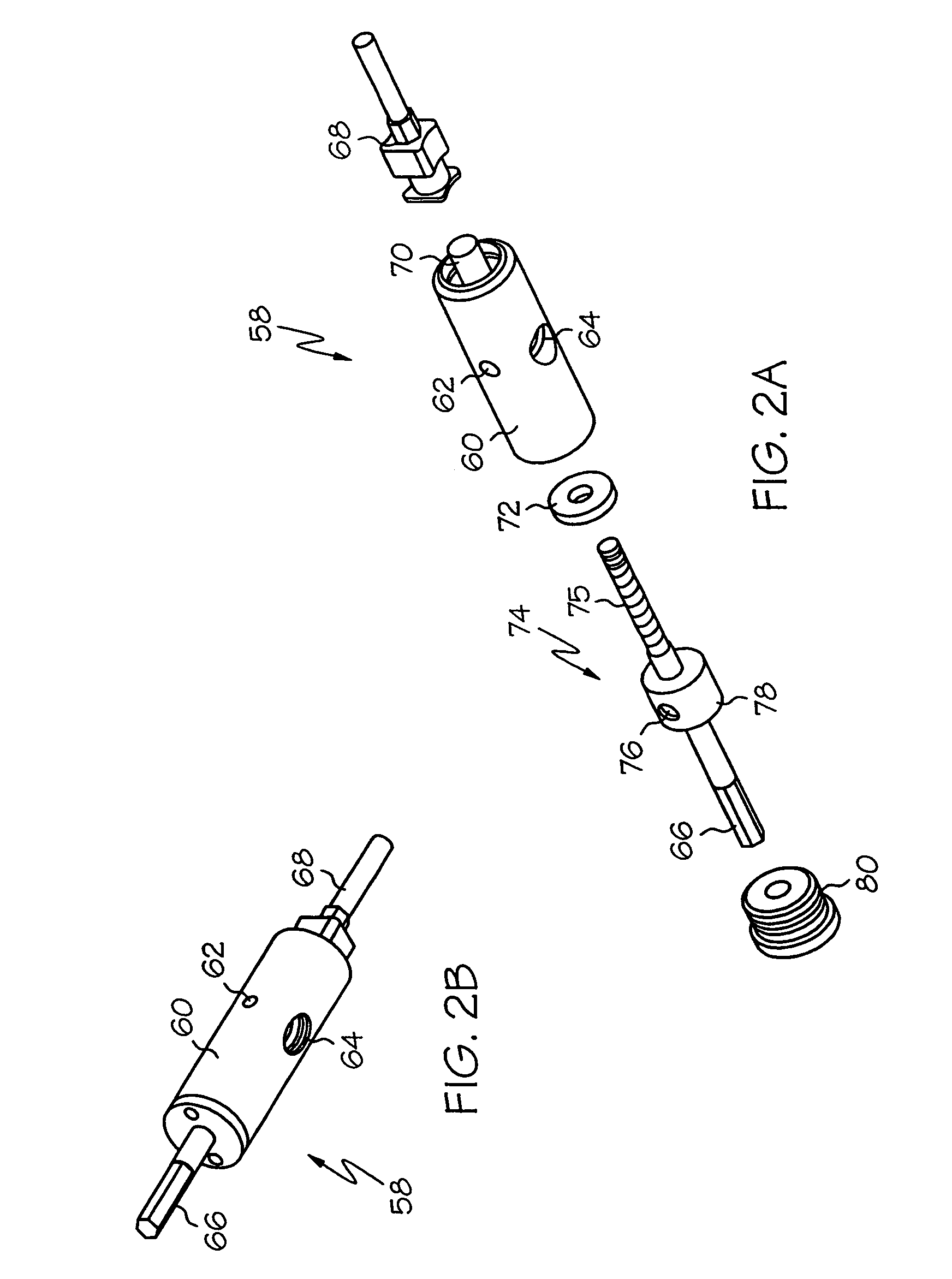

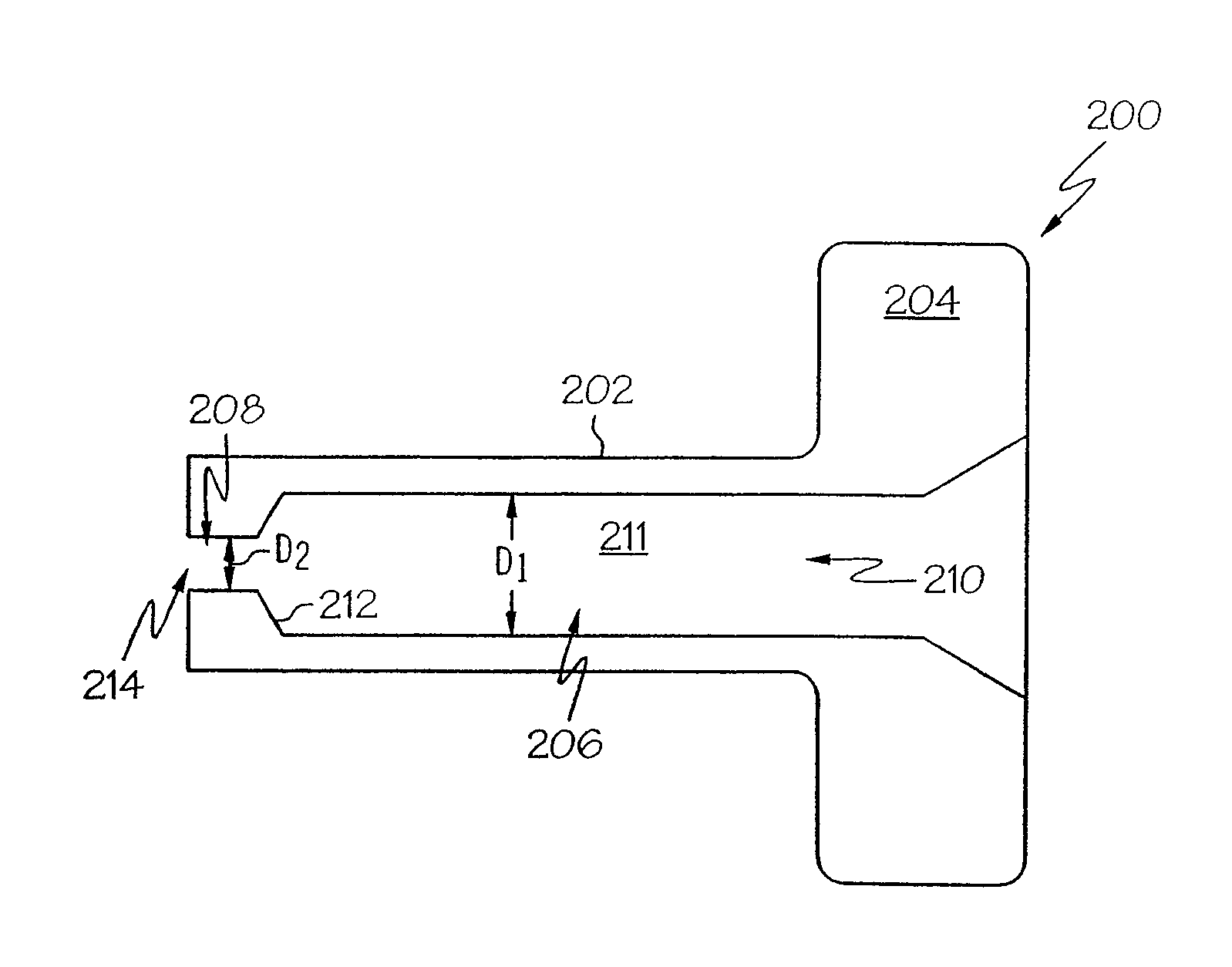

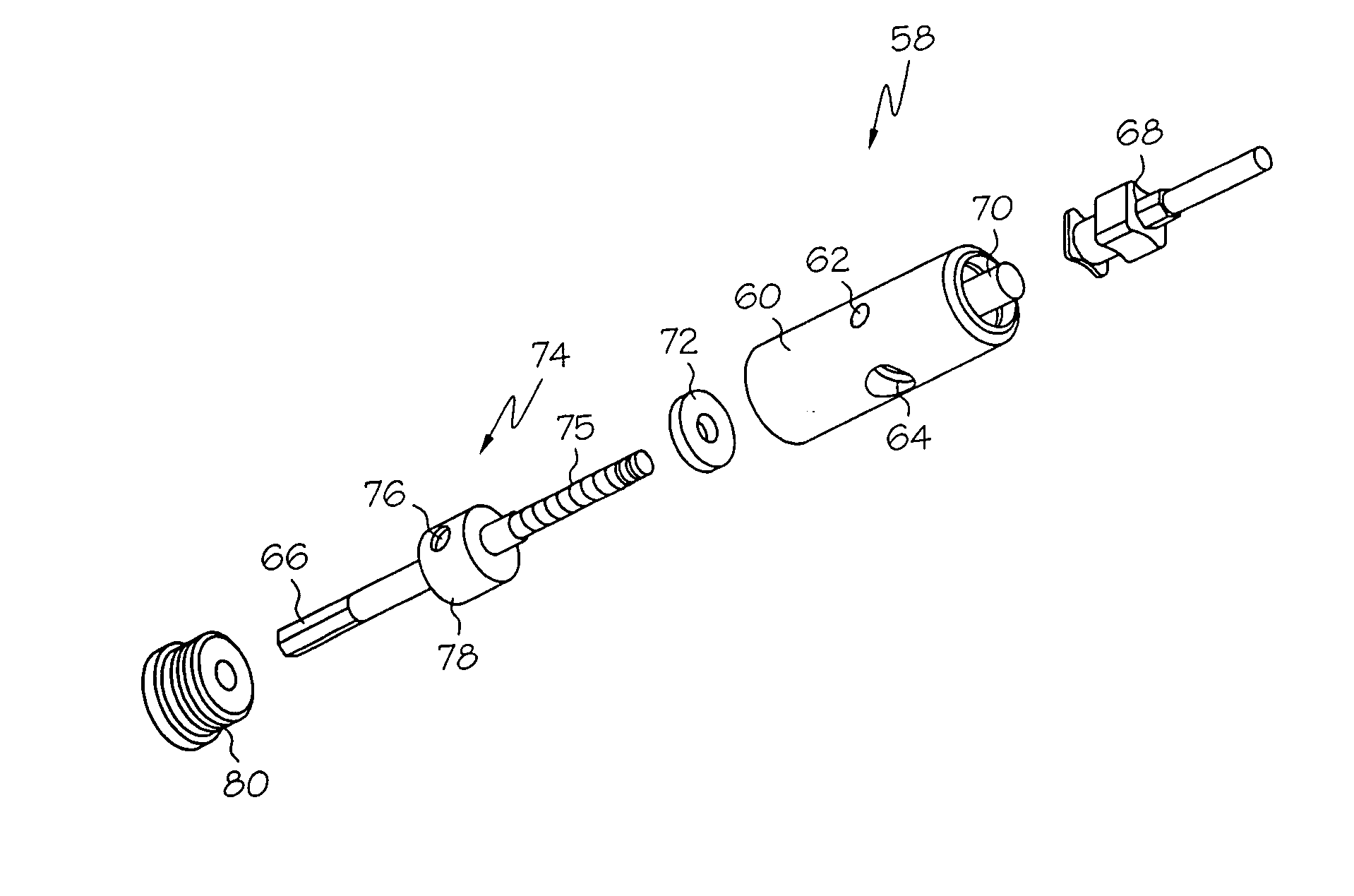

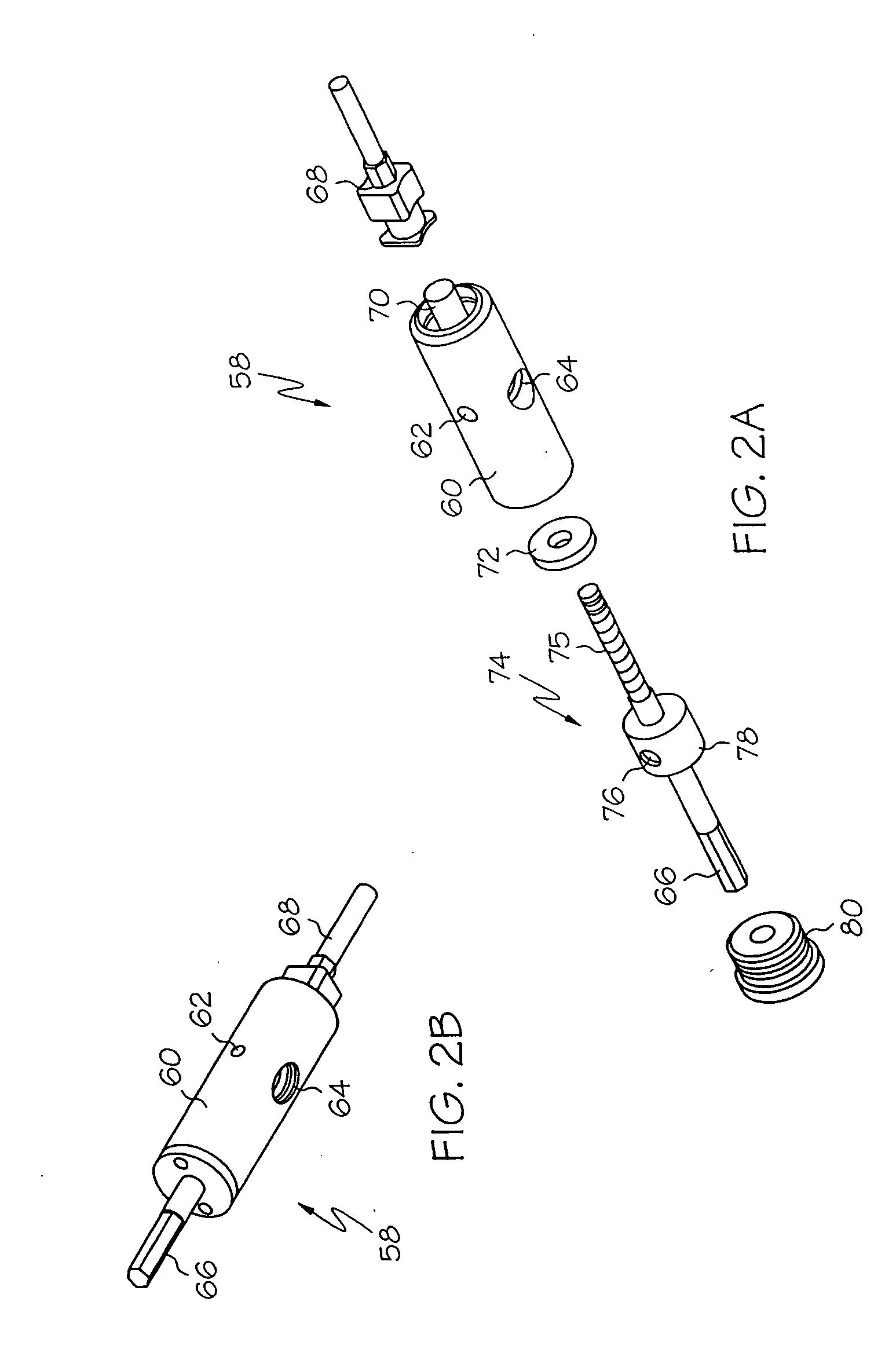

Dispense tip with vented outlets

InactiveUS6957783B1Lower system pressureReduce likelihoodLiquid surface applicatorsSpray nozzlesImage resolutionEngineering

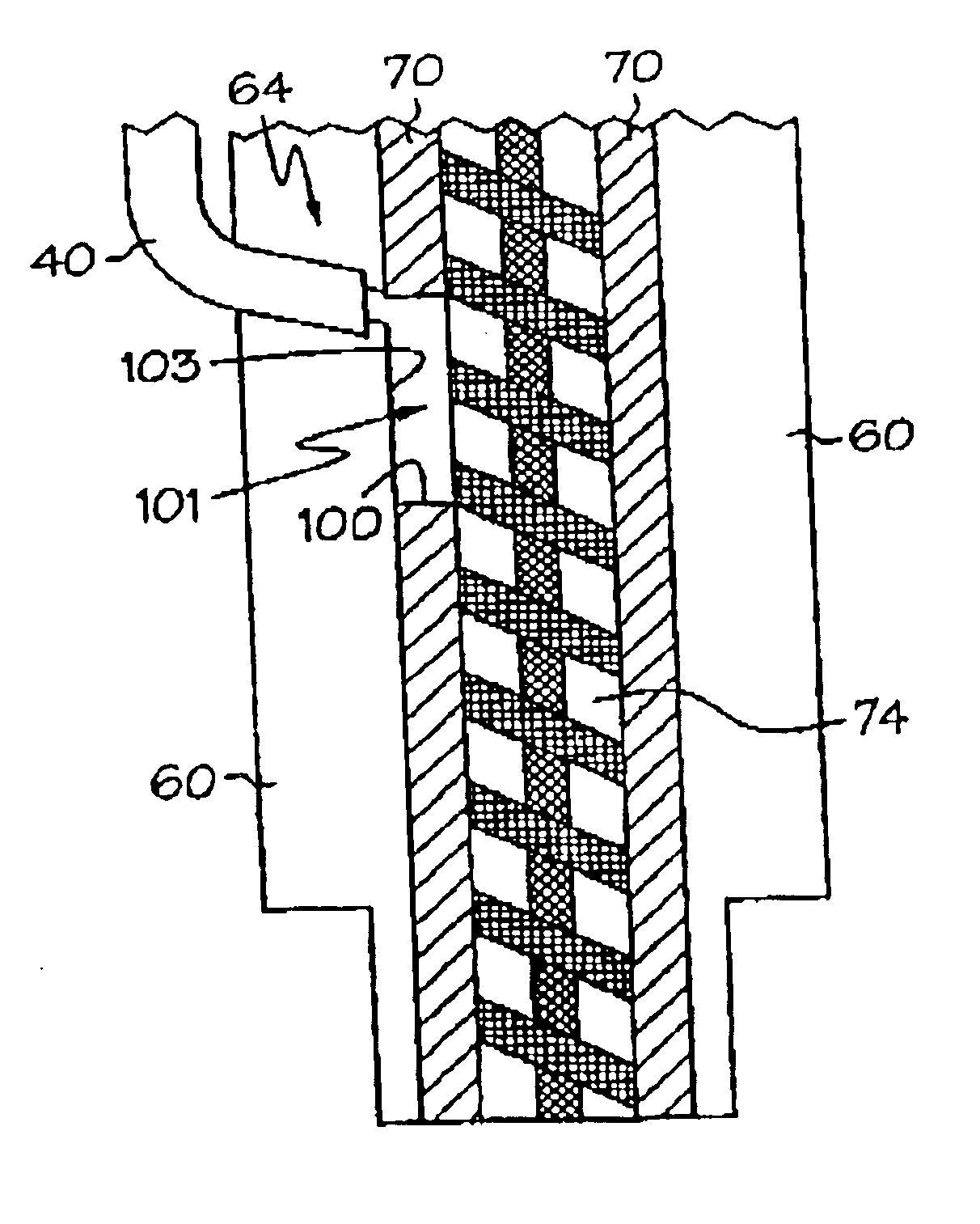

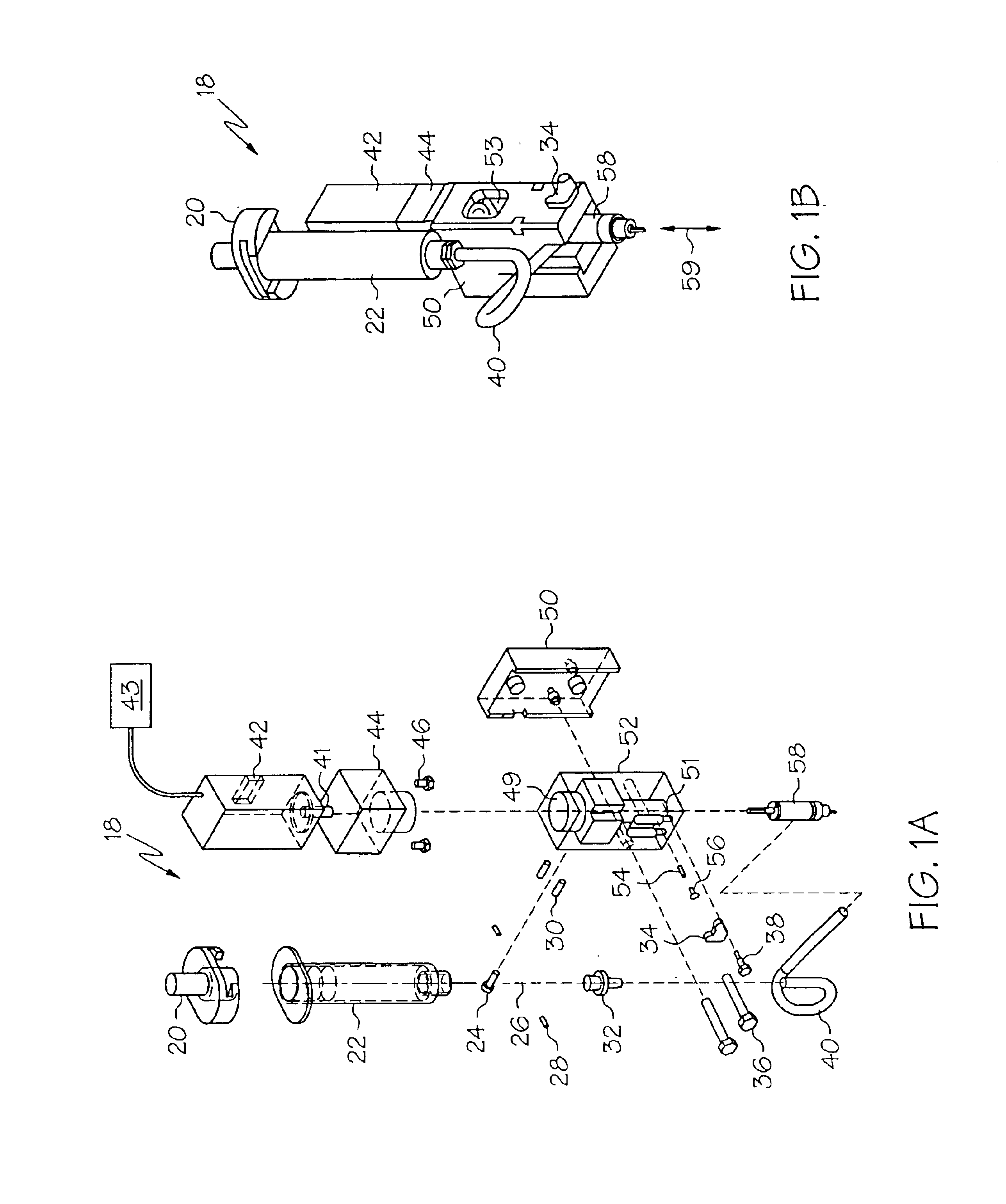

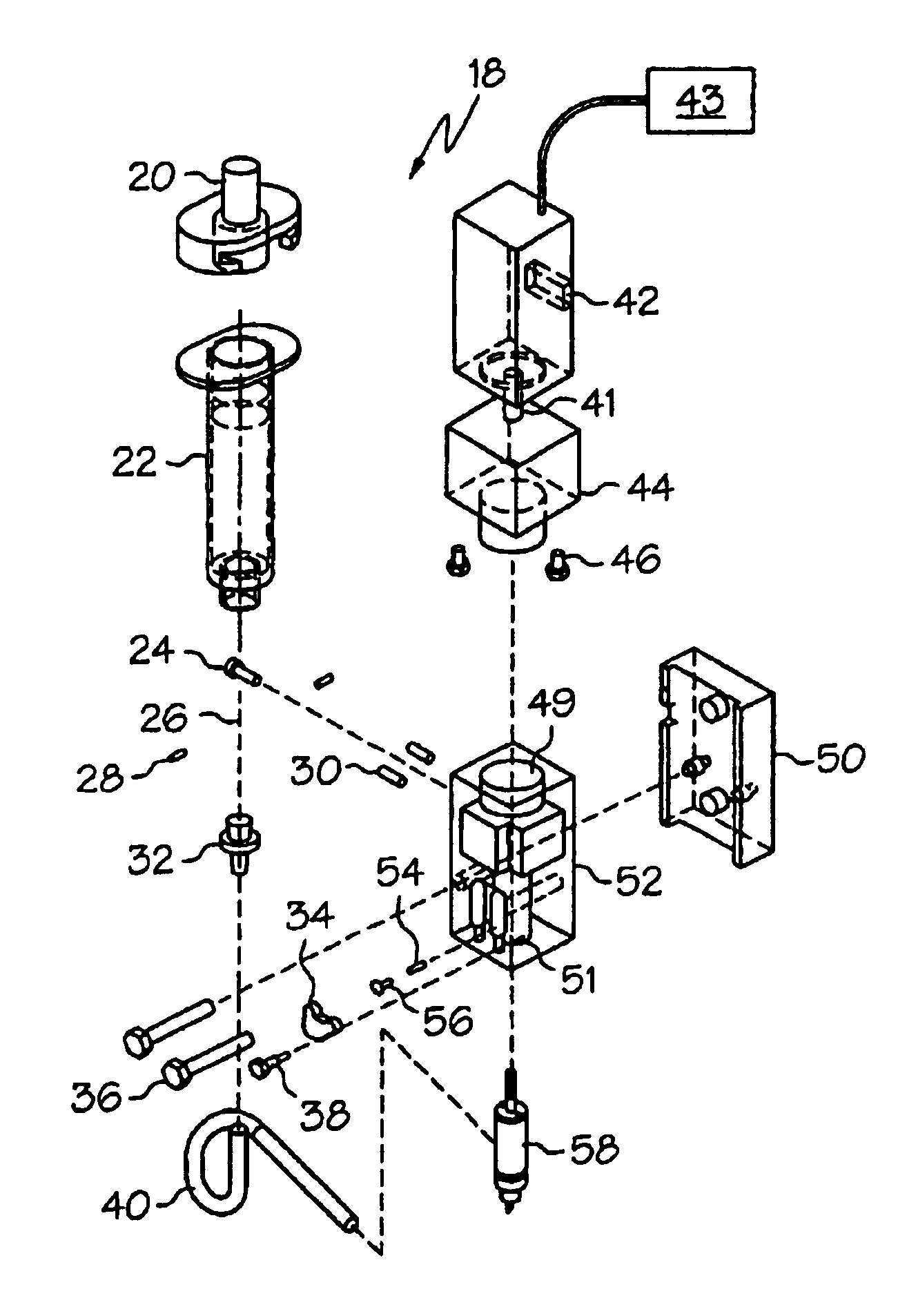

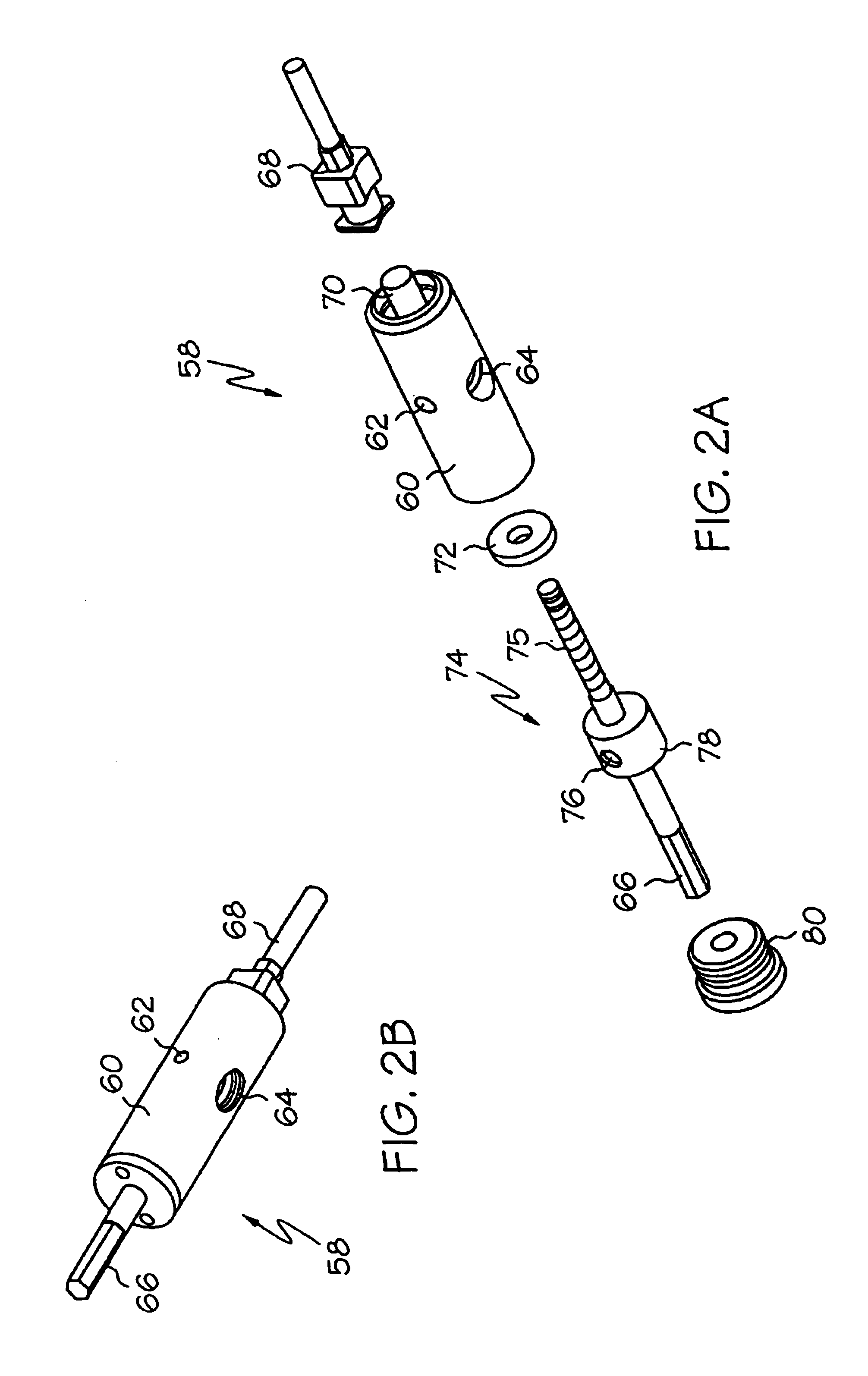

In a fluid pump and cartridge assembly, a cartridge includes a material inlet port, a material outlet port, and a feed screw. The feed screw delivers fluid to be dispensed from the fluid inlet to the outlet port. The fluid inlet is preferably elongated in a direction along a longitudinal axis of the feed screw to enhance consistency in material flow through the cartridge. The feed screw is preferably driven by a closed-loop servo motor to achieve high-performance dispensing resolution. The assembly is preferably compatible with fixed-z and floating-z cartridges. A optional vented dispense tip, in combination with the fluid pump, allows for repeatable deposit of fillet patterns while maintaining optimal consistency.

Owner:DL TECH

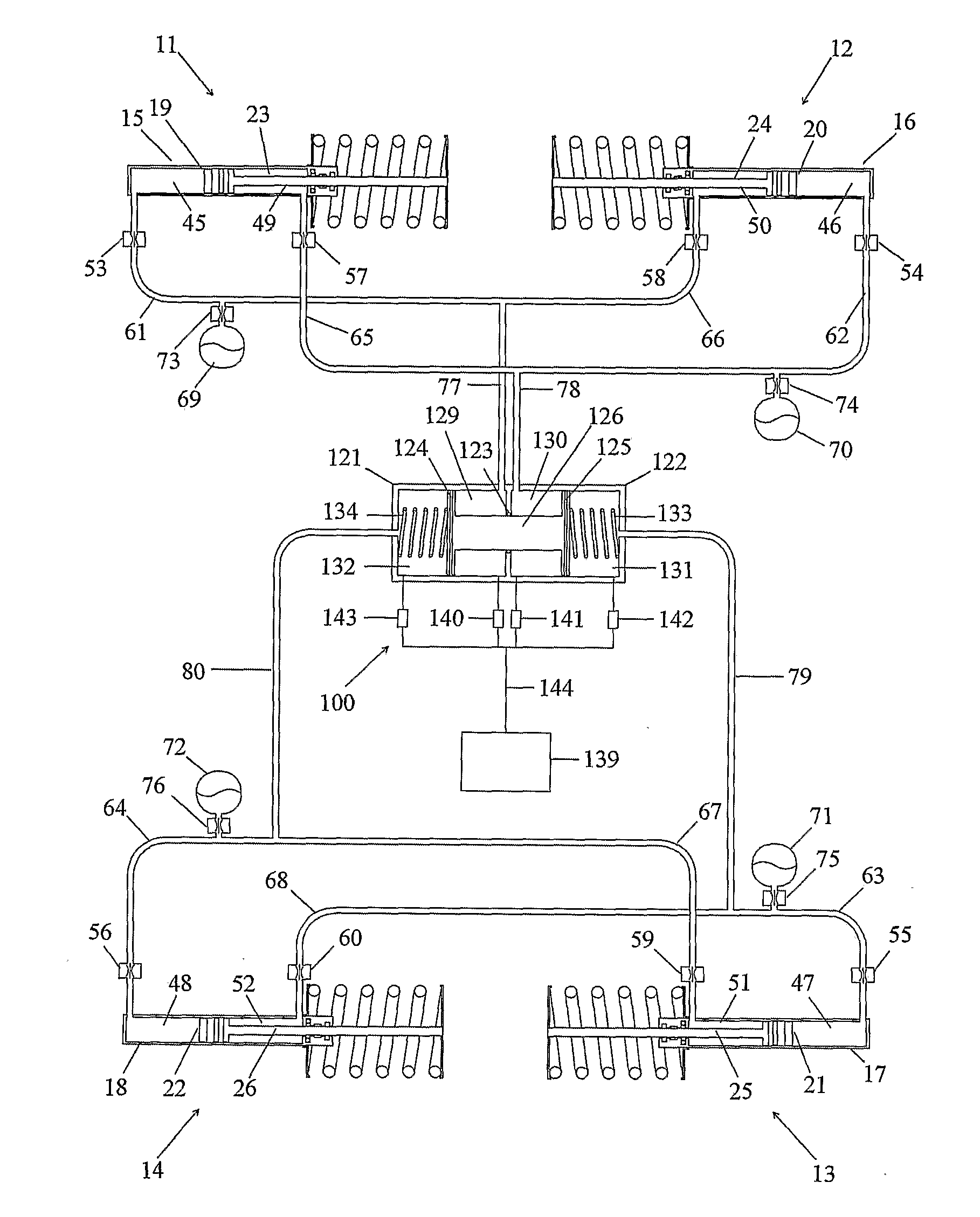

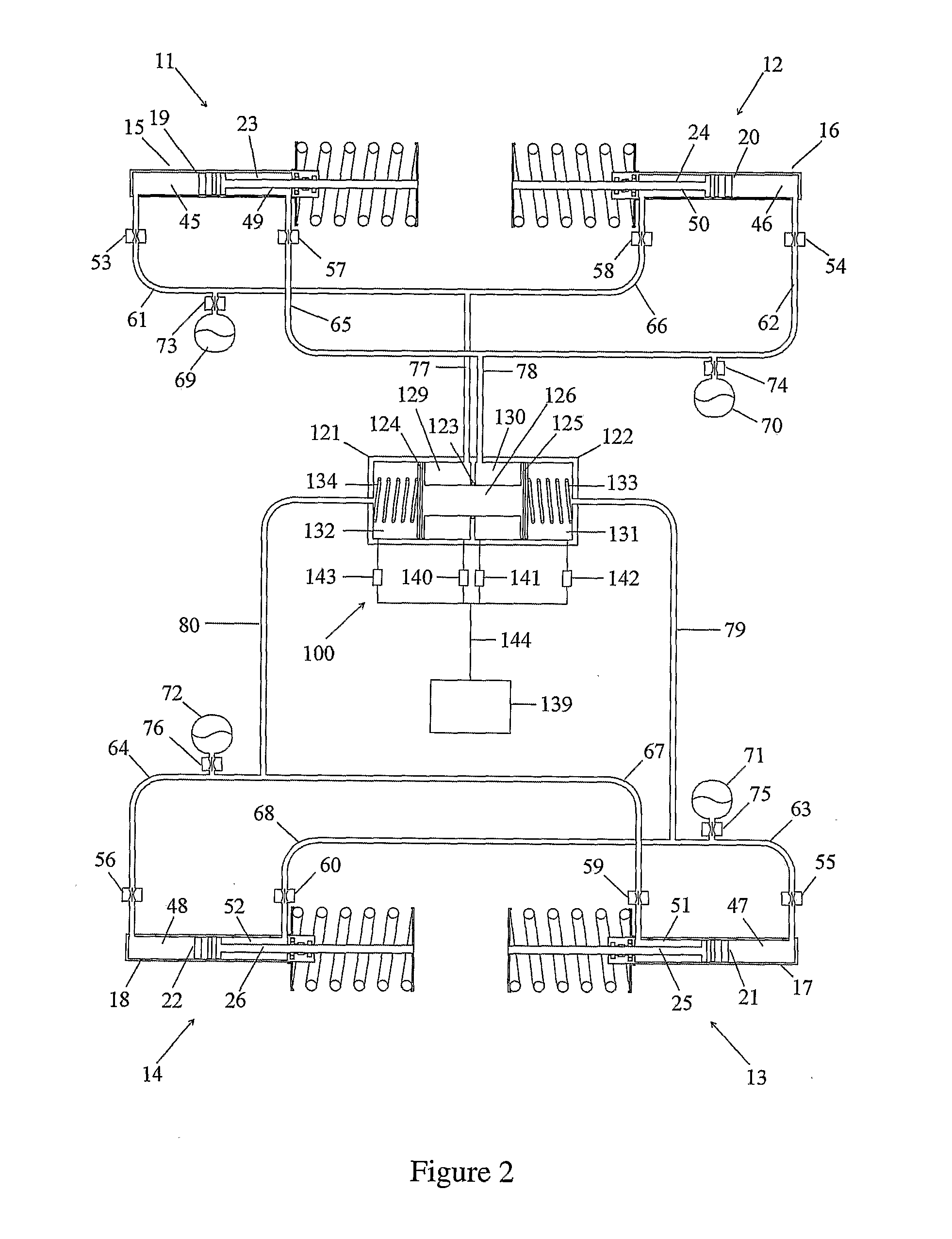

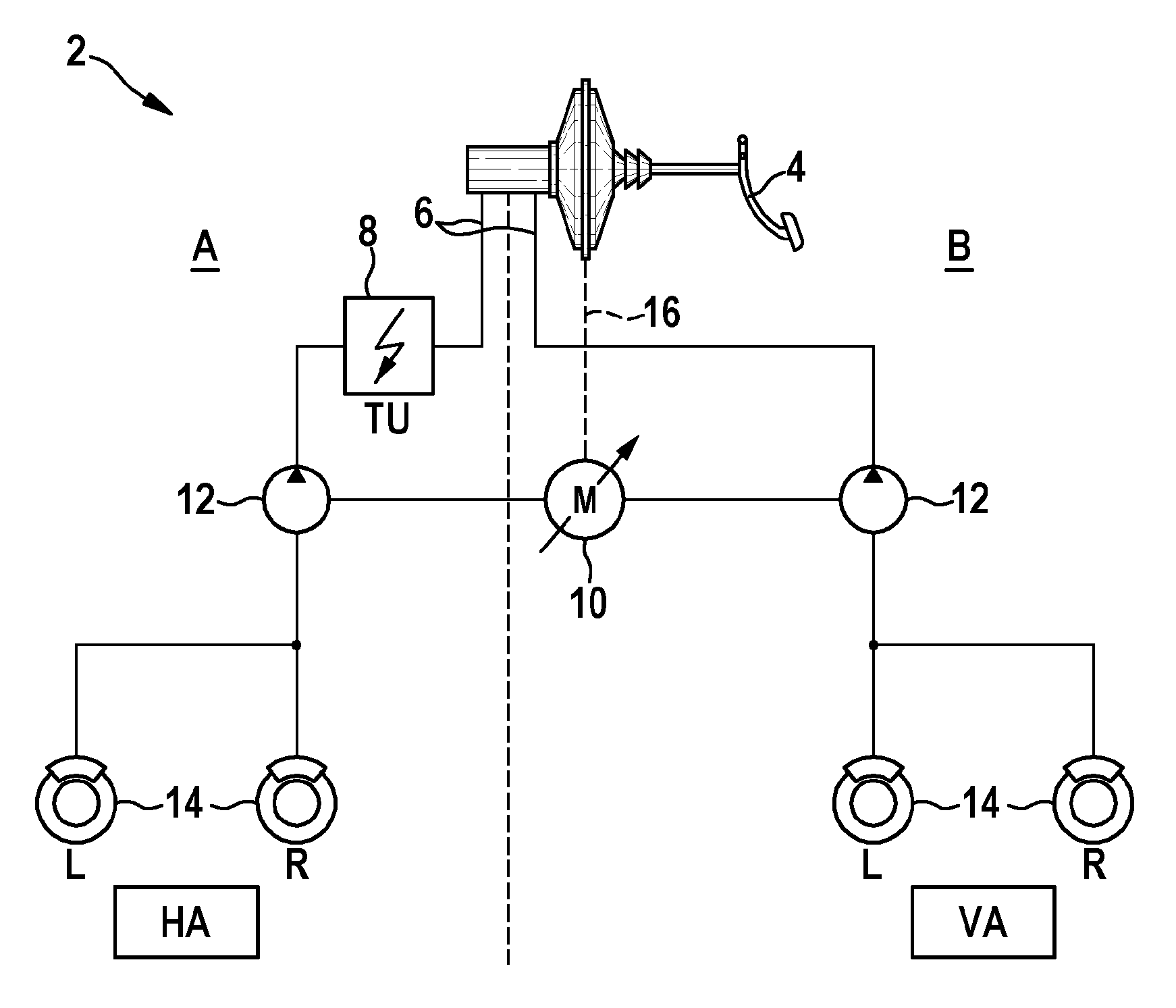

Hydraulic System for a Vehicle Suspension

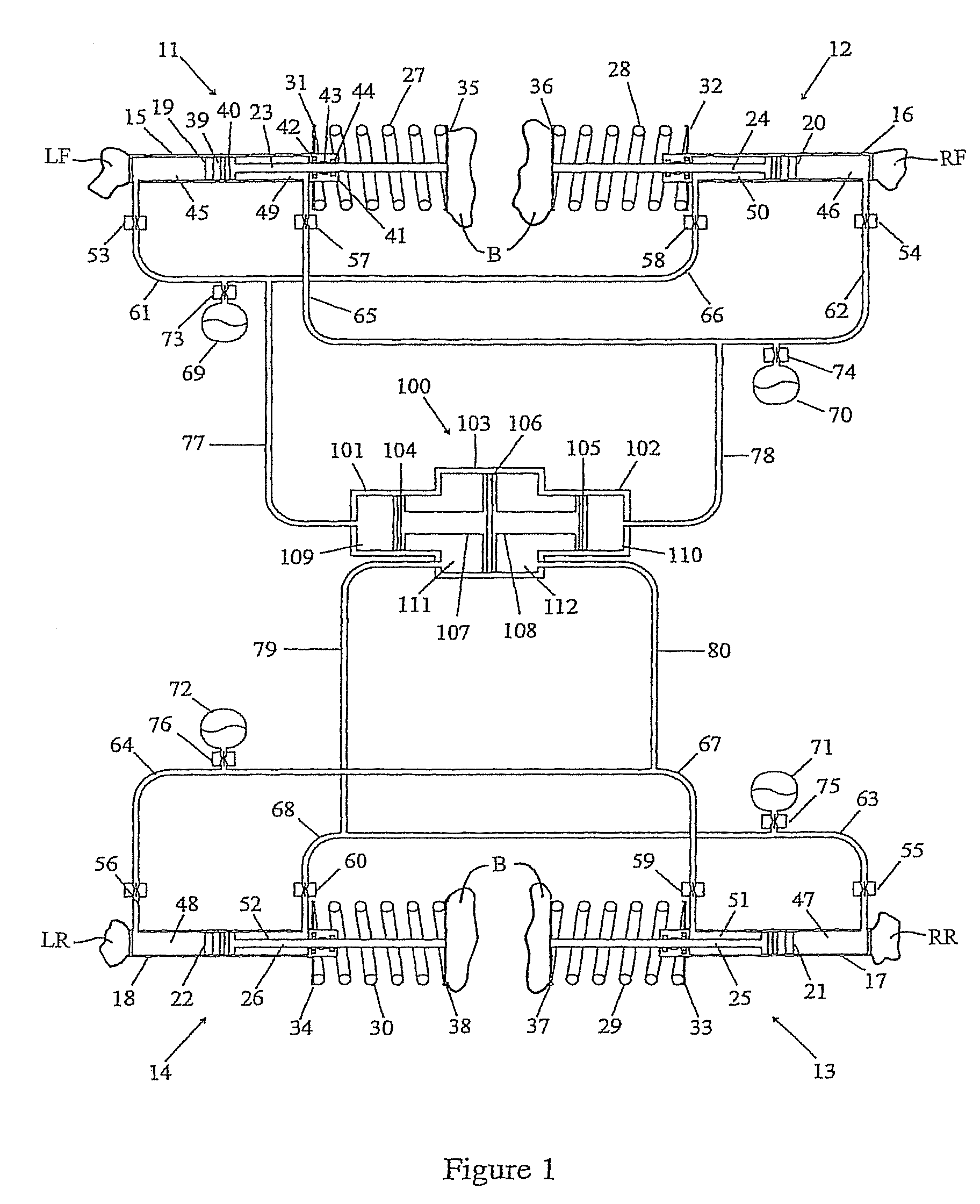

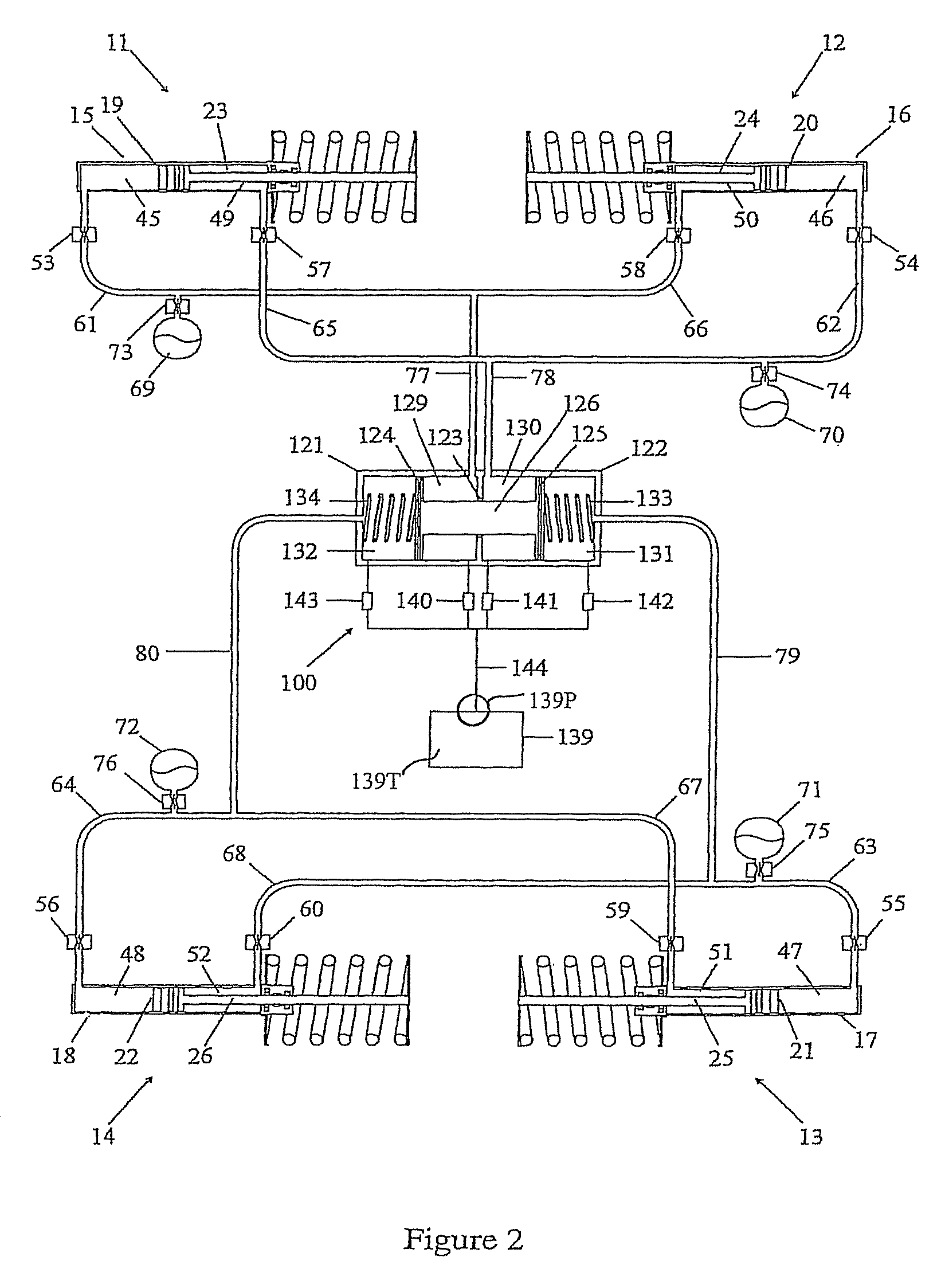

ActiveUS20080272561A1Reduce system pressureReduce frictionInterconnection systemsResilient suspensionsPiston rodHydraulic pressure

A vehicle hydraulic suspension system has front left (15), front right (16), rear left (18) and rear right (17) wheel ram. There is a mode decoupling device (100) with first (129), second (130), third (132) and fourth (131) balance chambers formed by a cylinder / piston rod assembly (124,125,126). The compression chamber (45) of the front left wheel ram (15) is in fluid communication with the first balance chamber (129), the compression chamber (46) of the front right wheel ram (16) is in fluid communication with the second balance chamber (130), the compression chamber (48) of the rear left wheel ram (18) is in fluid communication with the third balance chamber (132), and the compression chamber (47) of the rear right wheel ram (17) is in fluid communication with the fourth balance chamber (131). There are also front and rear resilient vehicle support means between vehicle body and the wheel assemblies.

Owner:KINEHTIK PTI LTD

Ambulance cot system

ActiveUS8155918B2Reduce frictionTotal current dropBraking element arrangementsDiagnosticsEngineeringAlert system

The present invention relates to ambulance cots, cot systems and methods of using the same. In particular, the present invention provides an ambulance cot comprising a hydraulic system and a tip angle monitoring, recording and alert system, and methods of using the same (e.g., to transport subjects and / or to detect and / or record operational data related to cot usage).

Owner:FERNO WASHINGTON

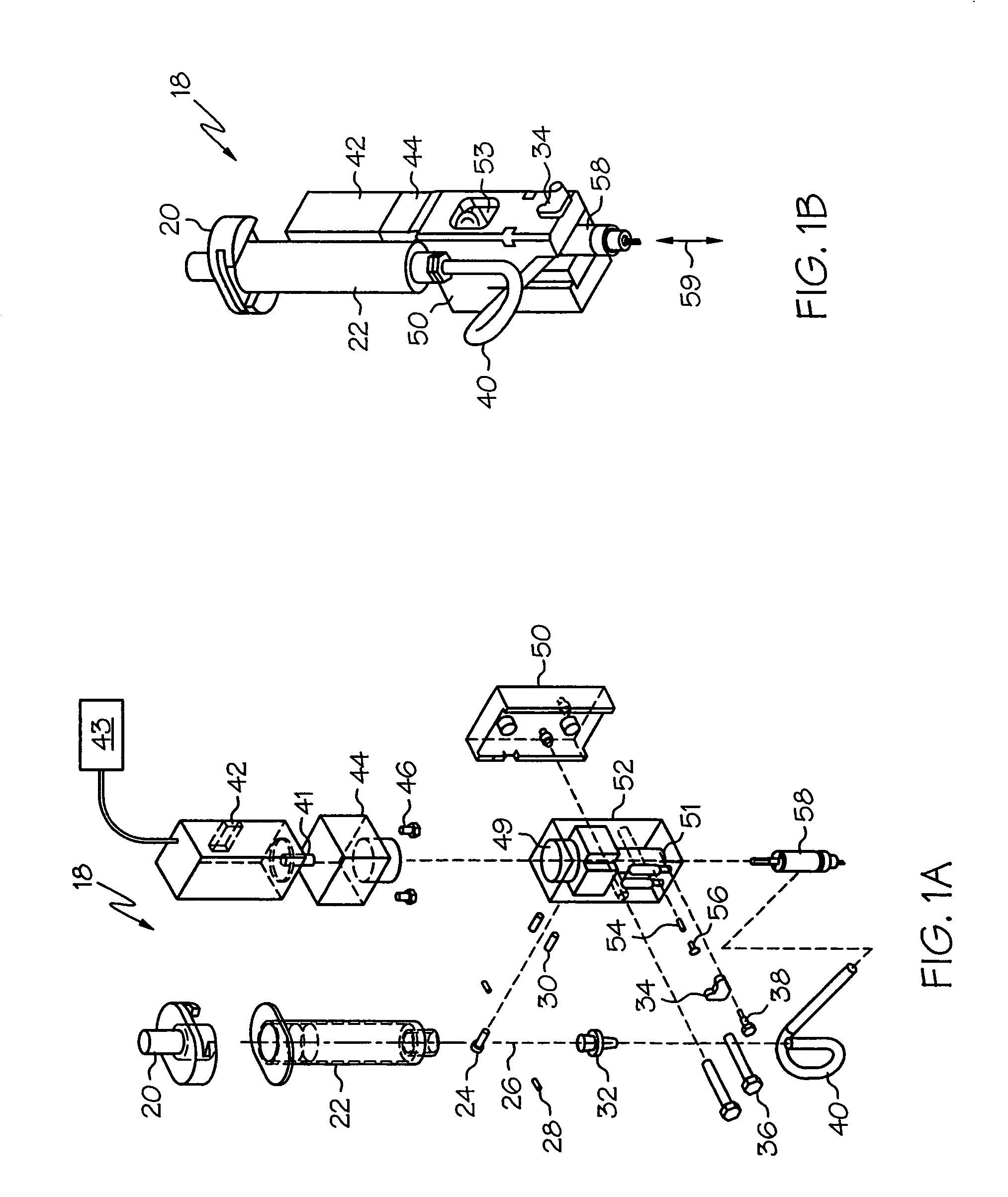

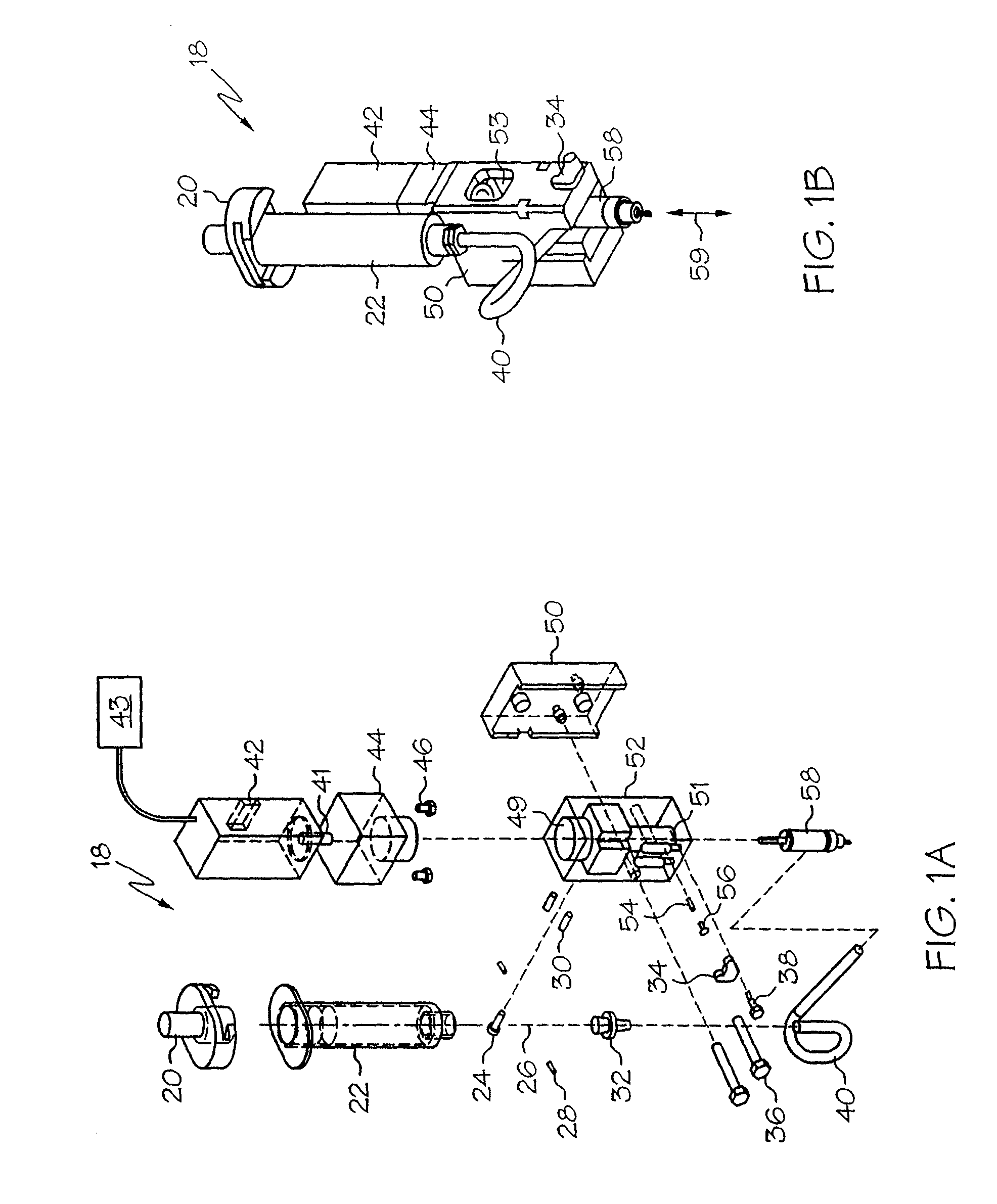

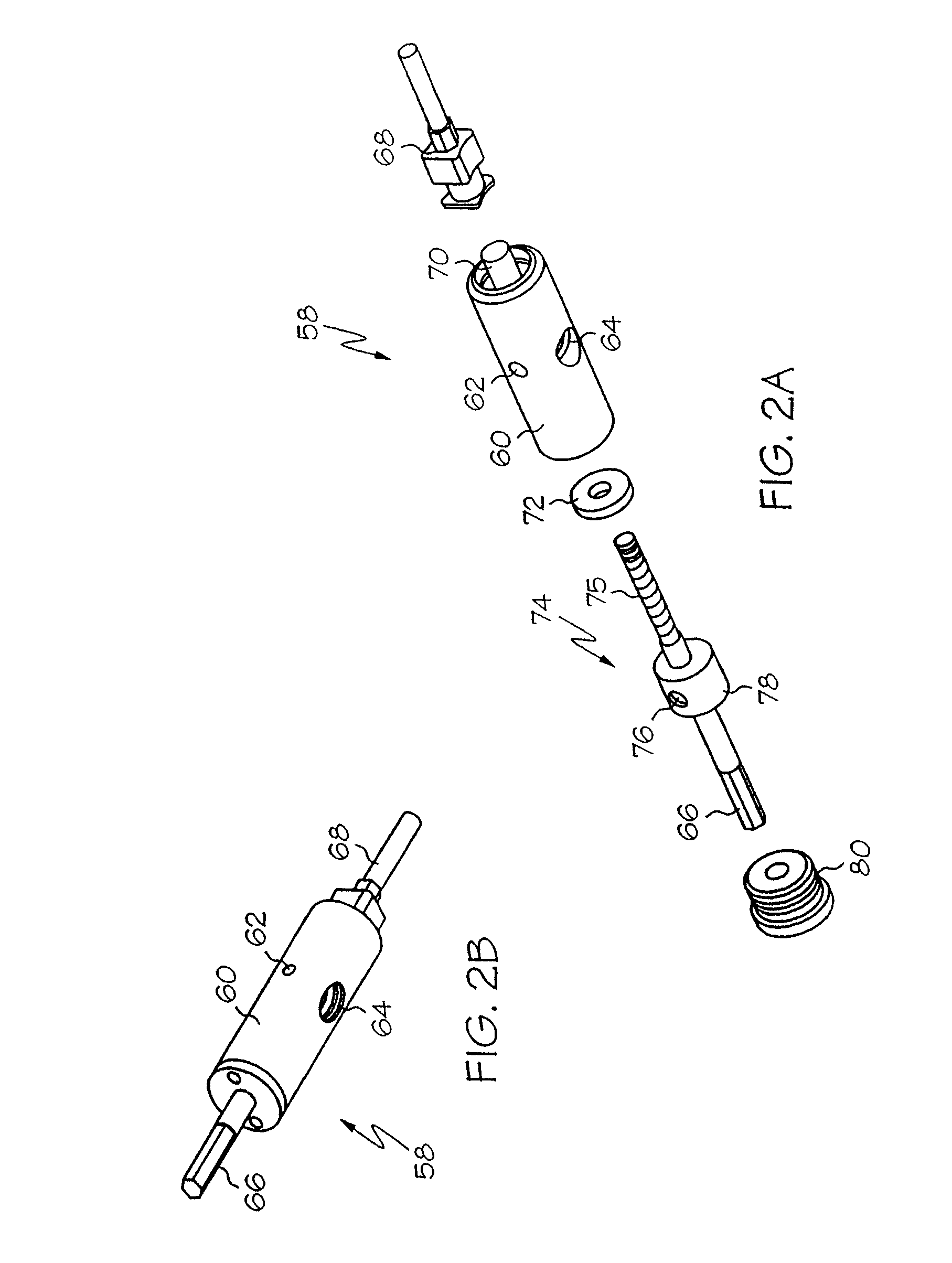

System and method for control of fluid dispense pump

InactiveUS6892959B1Promotes even distributionReduce the possibilityLiquid surface applicatorsPower plant exhaust arrangementsDistribution controlClosed loop

In a fluid pump and cartridge assembly, a cartridge includes a material inlet port, a material outlet port, and a feed screw. The feed screw delivers fluid to be dispensed from the fluid inlet to the outlet port. The fluid inlet is preferably elongated in a direction along a longitudinal axis of the feed screw to enhance consistency in material flow through the cartridge. The feed screw is preferably driven by a closed-loop servo motor to achieve high-performance dispensing resolution. The assembly is preferably compatible with fixed-z and floating-z cartridges. A optional vented dispense tip, in combination with the fluid pump, allows for repeatable deposit of fillet patterns while maintaining optimal consistency. A dispense controller allows for reverse-compatibility such that the fluid pump of the present invention can be mounted to, and controlled by, conventional pump position controllers.

Owner:DL TECH

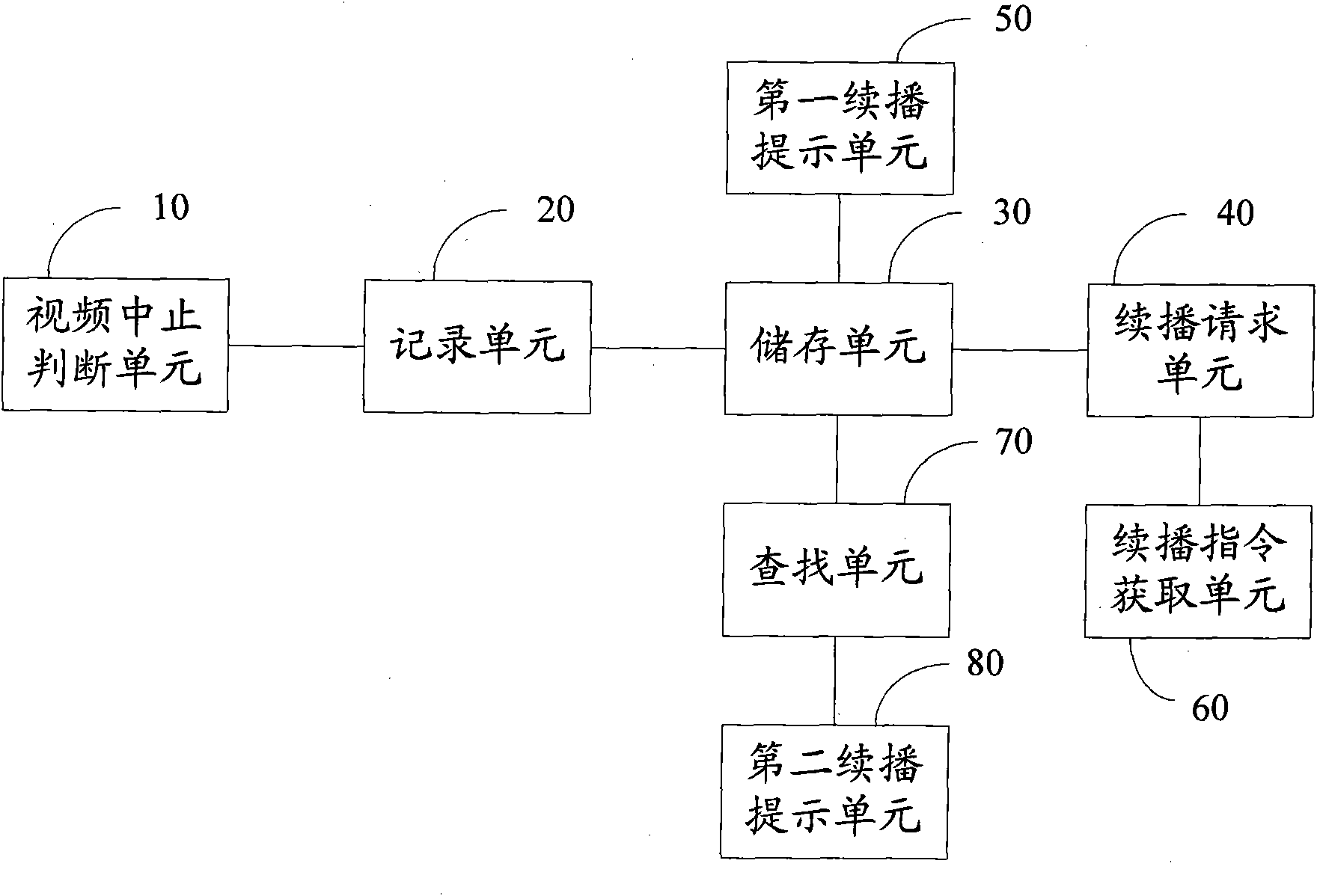

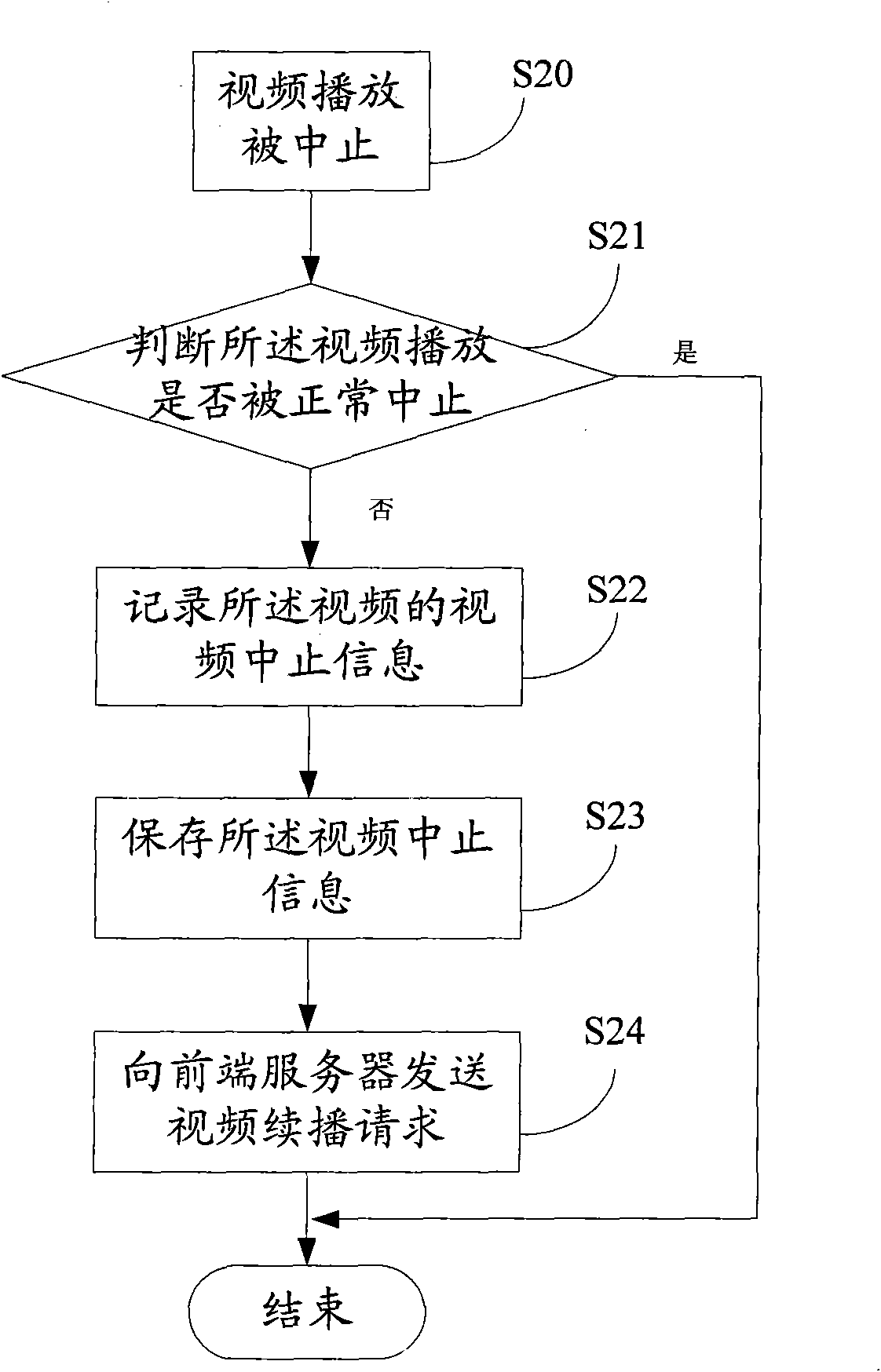

Break-point continuous playing method for digital television and digital television

InactiveCN101867780ARealize breakpoint resumeReduce system pressureTwo-way working systemsTransmissionBreaking pointSystem pressure

The embodiment of the invention provides a break-point continuous playing method for a digital television, which comprises the following steps of: when the video play is suspended, judging whether the video play is suspended normally; if the video play is not suspended normally, recording video suspension information of the video, wherein the video suspension information comprises video source information and suspension time information; storing the video suspension information; and sending a video continuous playing request to a front-end server according to the video suspension information. The embodiment of the invention also provides the digital television. The method can realize break-point continuous play of the video play, realizes record of the suspension information at one end of the digital television, and relieves the system pressure for the front-end server.

Owner:SUN YAT SEN UNIV

Dispense tip with vented outlets

InactiveUS7178745B1Promotes even distributionReduce the possibilityLiquid surface applicatorsSpray nozzlesClosed loopEngineering

In a fluid pump and cartridge assembly, a cartridge includes a material inlet port, a material outlet port, and a feed screw. The feed screw delivers fluid to be dispensed from the fluid inlet to the outlet port. The fluid inlet is preferably elongated in a direction along a longitudinal axis of the feed screw to enhance consistency in material flow through the cartridge. The feed screw is preferably driven by a closed-loop servo motor to achieve high-performance dispensing resolution. The assembly is preferably compatible with fixed-z and floating-z cartridges. A optional vented dispense tip, in combination with the fluid pump, allows for repeatable deposit of fillet patterns while maintaining optimal consistency.

Owner:DL TECH

Fluid pump and cartridge

InactiveUS6851923B1Promotes even distributionReduce the possibilityLiquid surface applicatorsPositive displacement pump componentsClosed loopEngineering

In a fluid pump and cartridge assembly, a cartridge includes a material inlet port, a material outlet port, and a feed screw. The feed screw delivers fluid to be dispensed from the fluid inlet to the outlet port. The fluid inlet is preferably elongated in a direction along a longitudinal axis of the feed screw to enhance consistency in material flow through the cartridge. The feed screw is preferably driven by a closed-loop servo motor to achieve high-performance dispensing resolution. The assembly is preferably compatible with fixed-z and floating-z cartridges.

Owner:DL TECH

Fluid pump and cartridge

InactiveUSRE40539E1Promotes even distributionReduce the possibilityLiquid surface applicatorsPositive displacement pump componentsClosed loopMechanical engineering

In a fluid pump and cartridge assembly, a cartridge includes a material inlet port, a material outlet port, and a feed screw. The feed screw delivers fluid to be dispensed from the fluid inlet to the outlet port. The fluid inlet is preferably elongated in a direction along a longitudinal axis of the feed screw to enhance consistency in material flow through the cartridge. The feed screw is preferably driven by a closed-loop servo motor to achieve high-performance dispensing resolution. The assembly is preferably compatible with fixed-z and floating-z cartridges.

Owner:DL TECH

Dispense tip with vented outlets

InactiveUS7762480B1Promotes even distributionReduce the possibilityLiquid surface applicatorsWatering devicesImage resolutionClosed loop

In a fluid pump and cartridge assembly, a cartridge includes a material inlet port, a material outlet port, and a feed screw. The feed screw delivers fluid to be dispensed from the fluid inlet to the outlet port. The fluid inlet is preferably elongated in a direction along a longitudinal axis of the feed screw to enhance consistency in material flow through the cartridge. The feed screw is preferably driven by a closed-loop servo motor to achieve high-performance dispensing resolution. The assembly is preferably compatible with fixed-z and floating-z cartridges. A optional vented dispense tip, in combination with the fluid pump, allows for repeatable deposit of fillet patterns while maintaining optimal consistency.

Owner:DL TECH

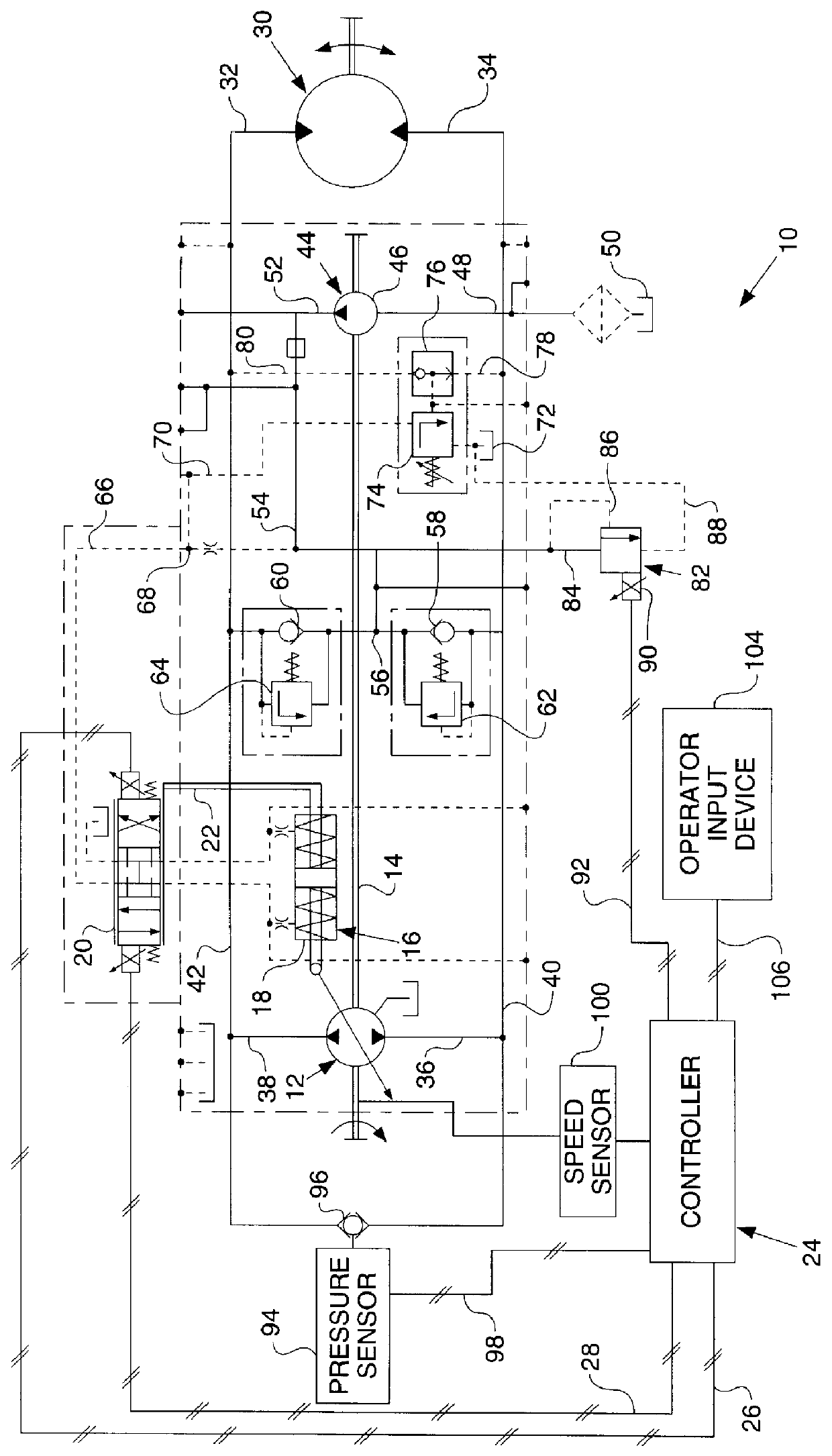

Closed loop hydraulic system with variable charge pressure

A closed loop hydraulic system having a variable charge pressure capability without parasitic power losses is disclosed. The present system includes a variable displacement hydraulic pump driven by a power source, a tilt control means for controlling a tilt angle of the variable displacement hydraulic pump, and a hydraulic motor having a pair of inlet / outlet ports connected in a closed circuit to a pair of inlet / outlet ports of the variable displacement hydraulic pump by way of a pair of main conduits. The system has a charging system including a charge pump driven by a power source, the charge pump including an inlet connected to a supply of oil, and an outlet port connected to the closed circuit for supplying pressurized oil to the variable displacement hydraulic pump. The charge system further includes an electrohydraulic proportional relief valve including means for varying an operating pressure setting thereof, which electrohydraulic proportional relief valve is connected to the charging system for controlling the pressure level of the pressurized oil supplied to the variable displacement hydraulic pump. The means for varying the operating pressure setting of the proportional relief valve are controlled by control means responsive to at least a pressure condition in the closed circuit. According to another aspect of the invention, the charging system is also connected to a hydraulic circuit of the tilt control means for supplying pressurized oil thereto.

Owner:CATERPILLAR INC

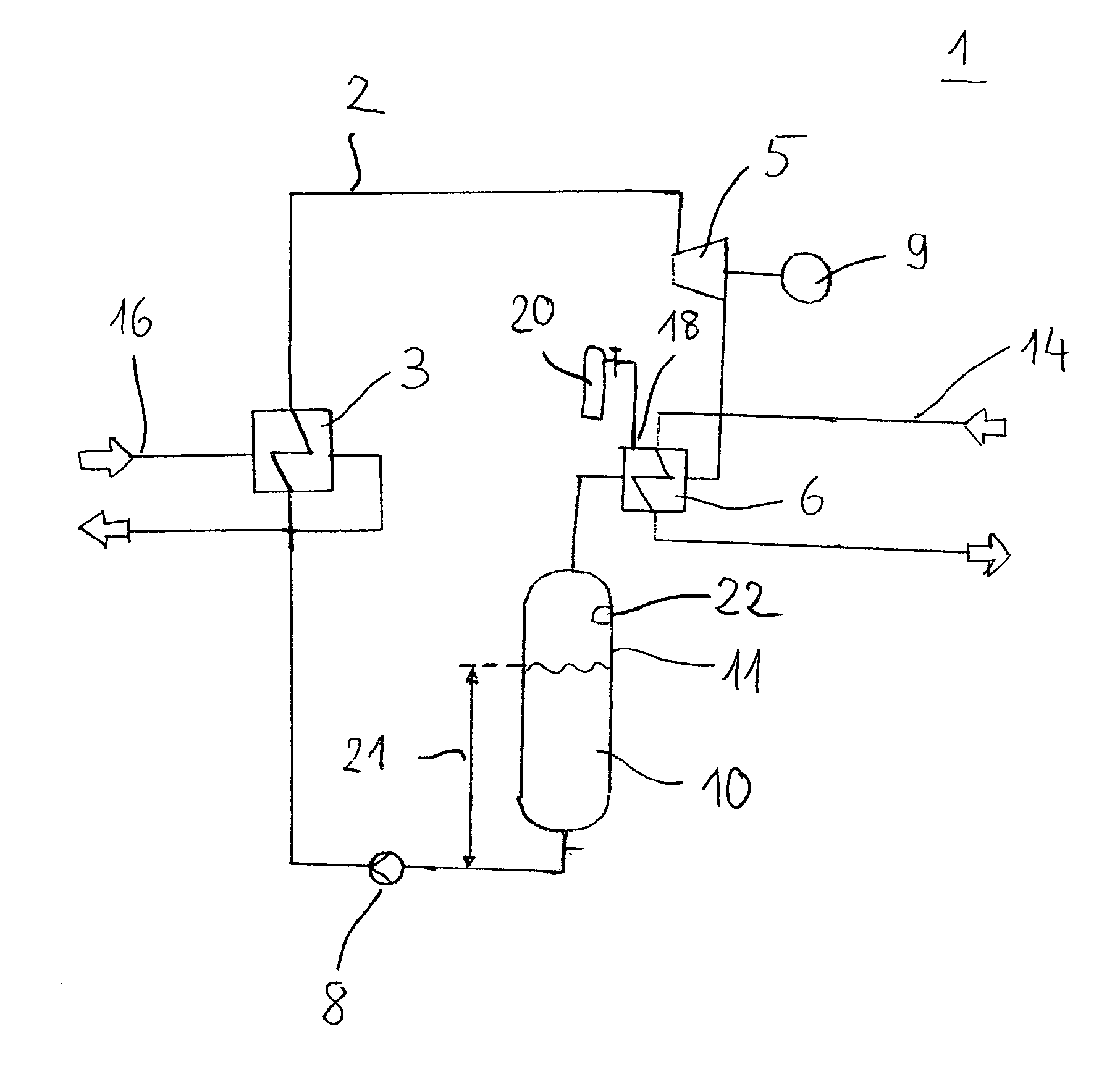

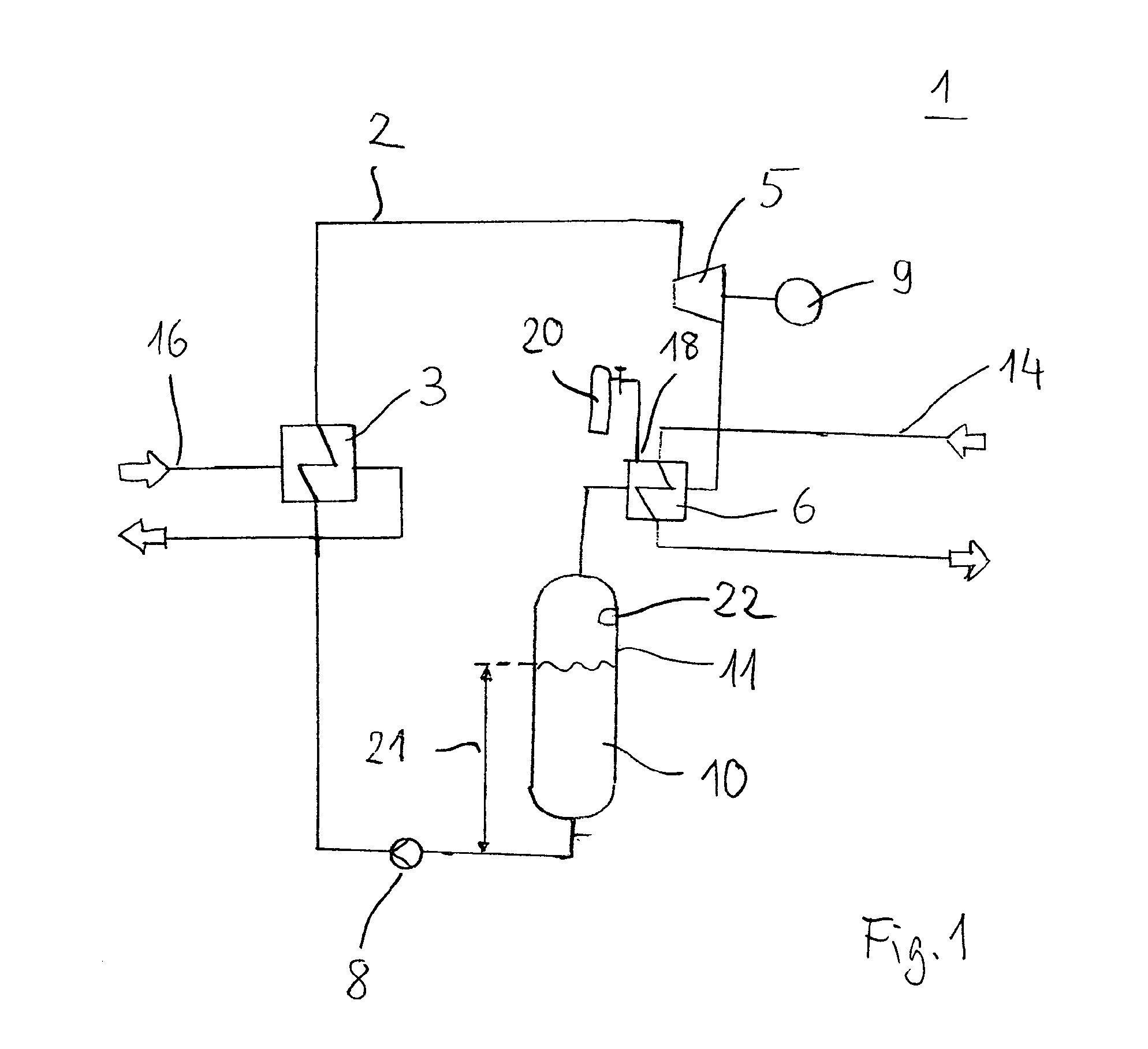

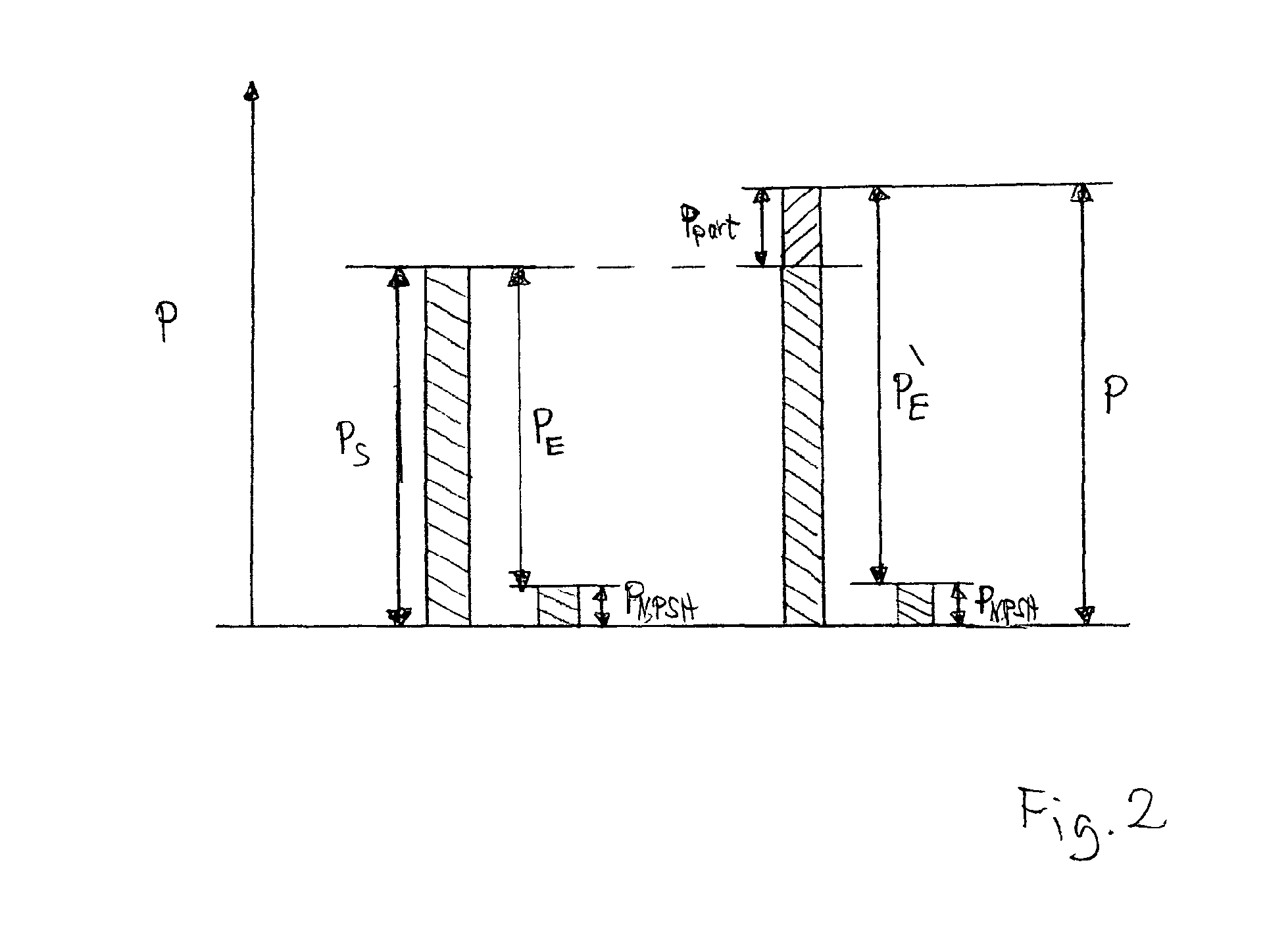

Thermodynamic Machine and Method for the Operation Thereof

ActiveUS20120227404A1Avoid it happening againAvoid cavitationExhaust apparatusSilencing apparatusWorking fluidCavitation

The invention relates to a thermodynamic machine having a circulation system in which a working fluid, in particular a low-boiling working fluid, circulates alternately in a gaseous and a liquid phase, a heat exchanger, an expansion machine, a condenser, and a fluid pump. The invention also relates to a method for operating the thermodynamic machine. According to certain embodiments of the invention, in the flow line of the fluid pump, a partial pressure increasing the system pressure is applied to the liquid working fluid by adding a non-condensing auxiliary gas. Compact ORC machines can be implemented, preventing cavitation in the liquid working fluid.

Owner:ORCAN ENERGY AG

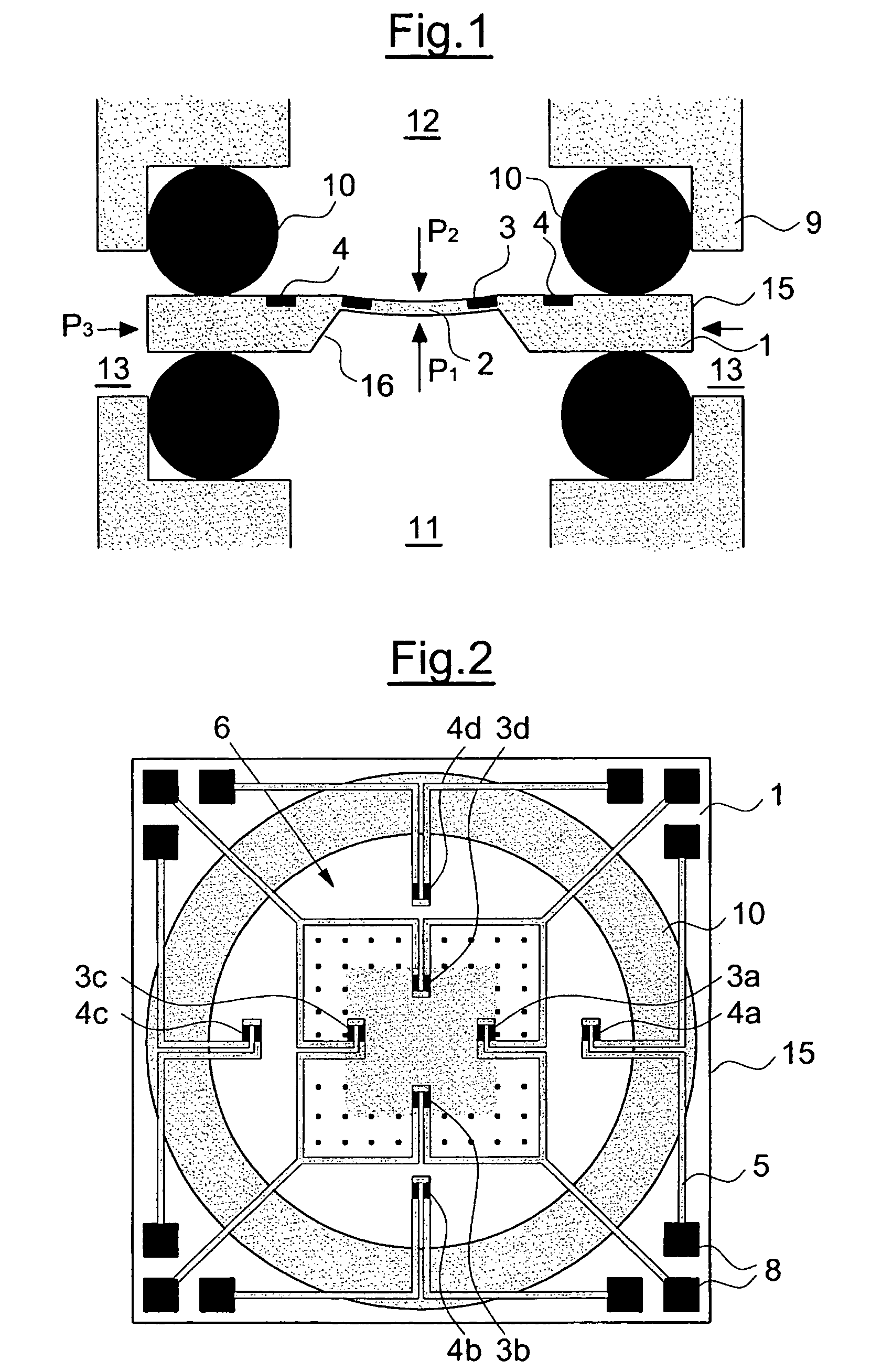

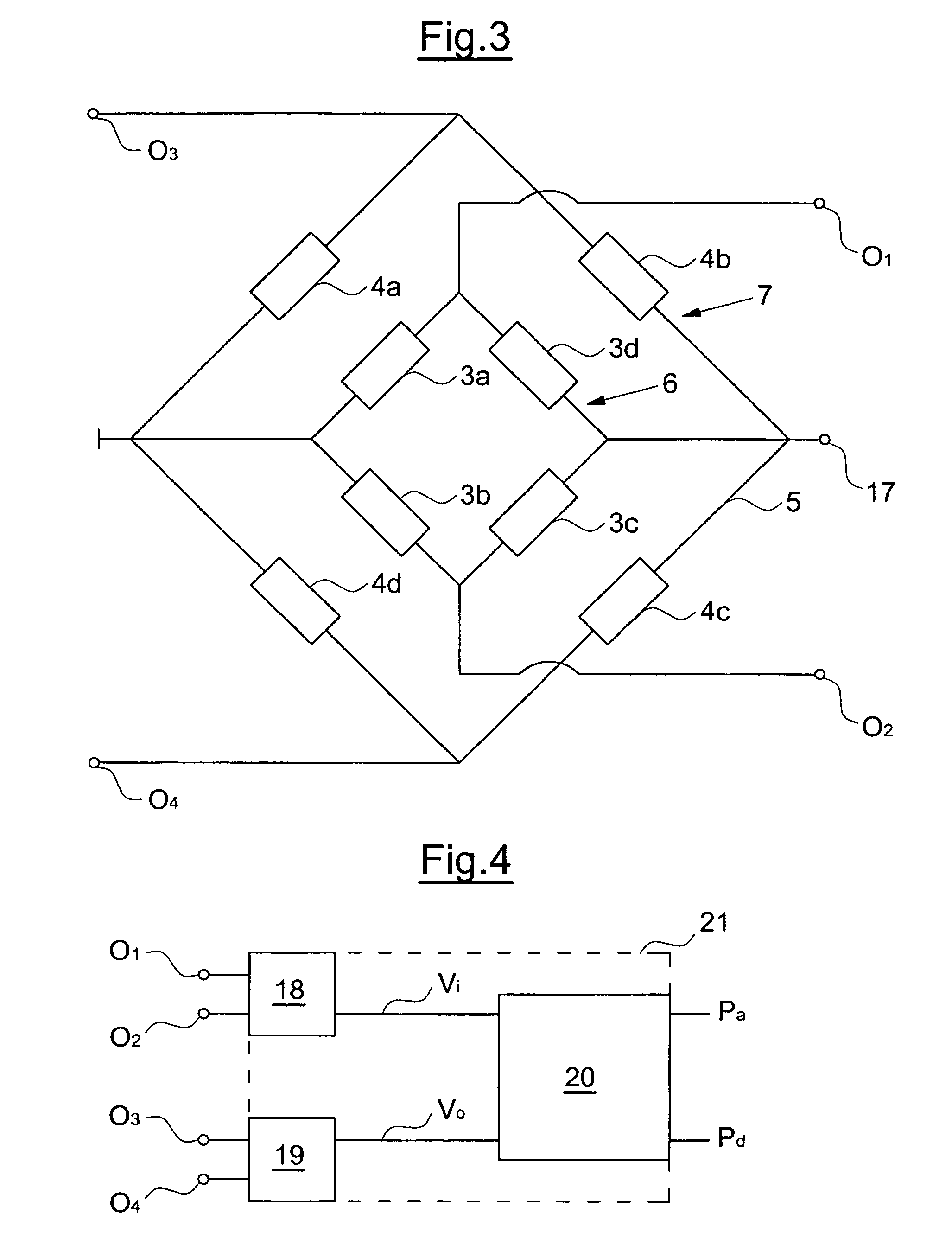

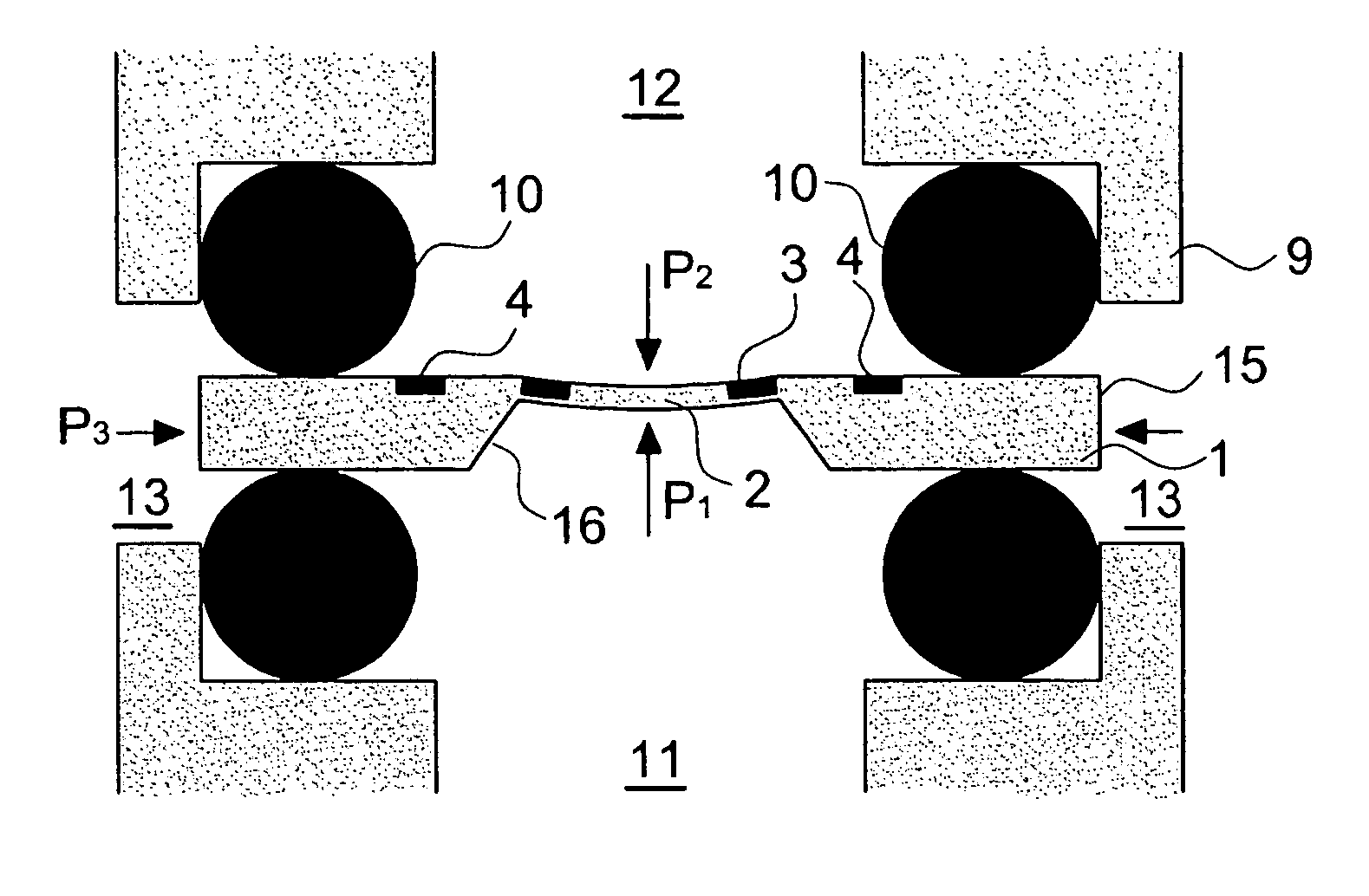

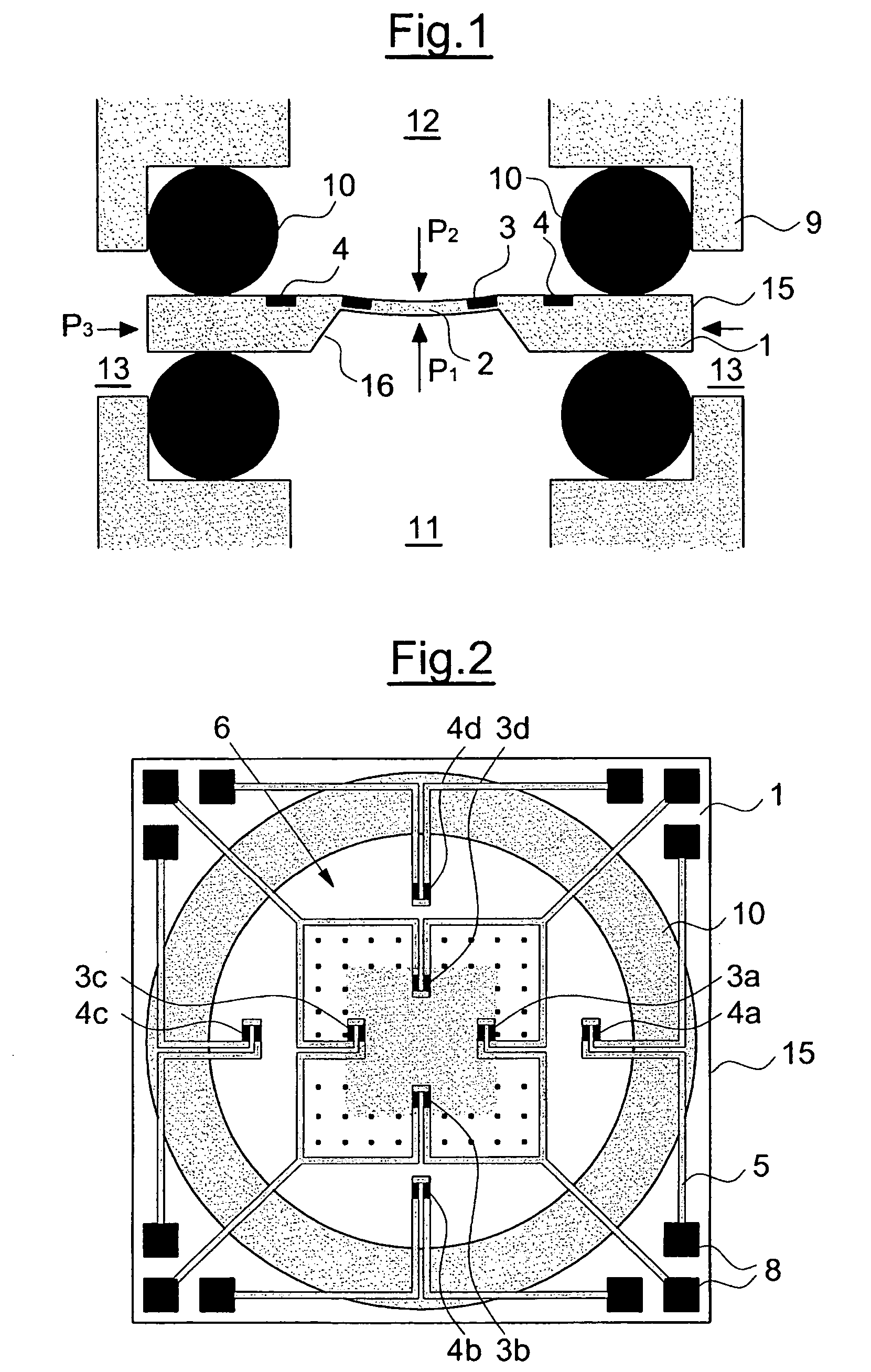

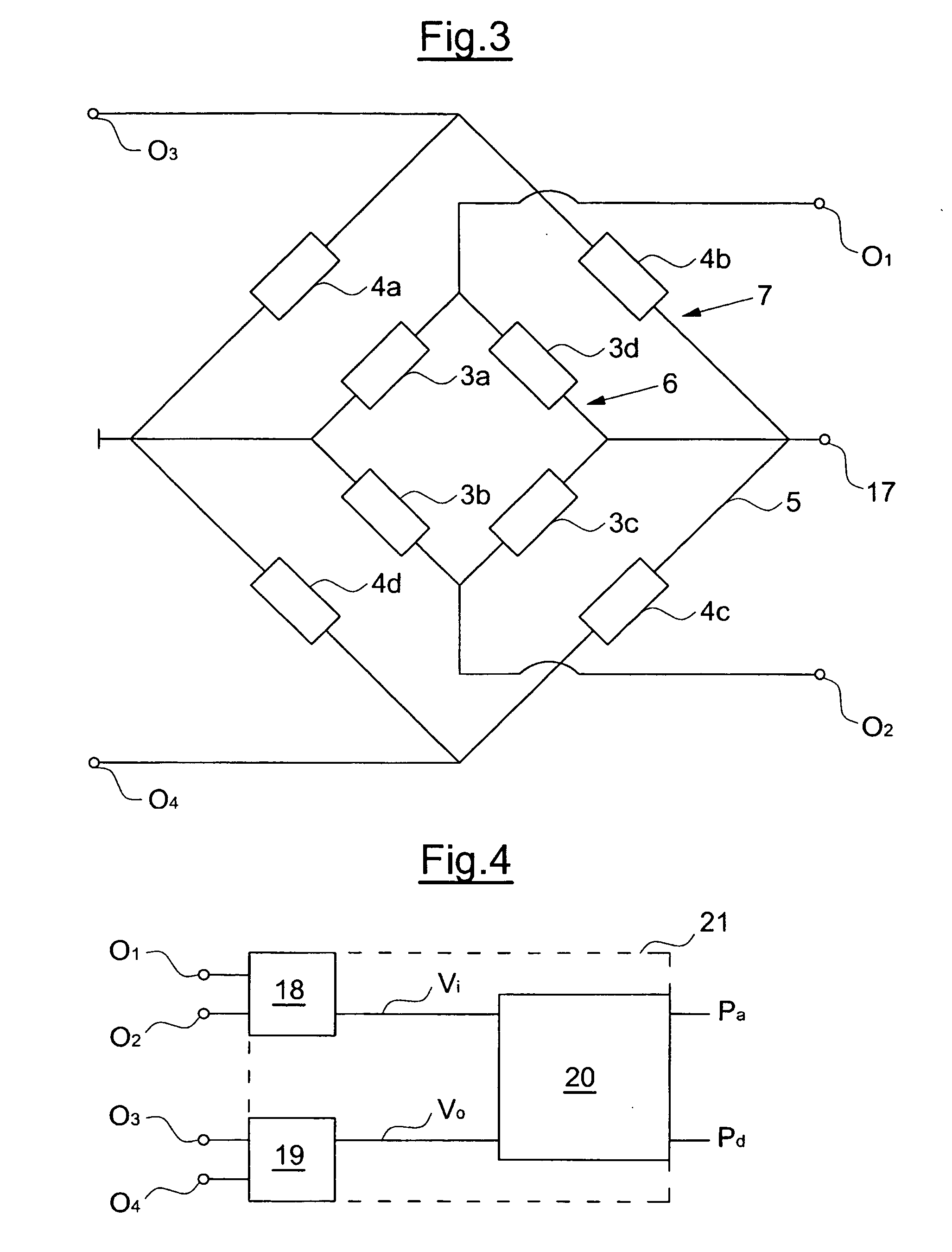

Differential pressure sensor

ActiveUS7010984B2High measurement accuracyReduce system pressureFluid pressure measurement using ohmic-resistance variationPressure difference measurement between multiple valvesDifferential pressureSemiconductor

The differential pressure sensor is formed of a semiconductor substrate (1) which is thinned out in an inner region into a membrane (2) which may be impinged by pressure on both sides. Measurement resistances (3a to 3d) for detecting the differential pressure (P1 minus P2) are formed within the membrane (2), and compensation resistances (4) are formed on the carrier, which are connected to measurement resistances (3). The measurement resistances (3) are connected into a first measurement bridge (6) and the compensation resistances (4a to 4d) into a second measurement bridge (7).

Owner:GRUNDFOS

Hydraulic system for a vehicle suspension

ActiveUS8123235B2Reduce system pressureReduce frictionInterconnection systemsResilient suspensionsPiston rodAutomotive engineering

Owner:KINEHTIK PTI LTD

System and method for control of fluid dispense pump

InactiveUS20050100457A1Promotes even distributionReduce system pressureLiquid surface applicatorsSelf-acting watering devicesClosed loopEngineering

In a fluid pump and cartridge assembly, a cartridge includes a material inlet port, a material outlet port, and a feed screw. The feed screw delivers fluid to be dispensed from the fluid inlet to the outlet port. The fluid inlet is preferably elongated in a direction along a longitudinal axis of the feed screw to enhance consistency in material flow through the cartridge. The feed screw is preferably driven by a closed-loop servo motor to achieve high-performance dispensing resolution. The assembly is preferably compatible with fixed-z and floating-z cartridges. A optional vented dispense tip, in combination with the fluid pump, allows for repeatable deposit of fillet patterns while maintaining optimal consistency. A dispense controller allows for reverse-compatibility such that the fluid pump of the present invention can be mounted to, and controlled by, conventional pump position controllers.

Owner:DL TECH

Alkyl ester method glyphosate solvent recovery system and process

PendingCN108380029AImprove intrinsic safetyReduce system pressureGas treatmentOrganic compound preparationSolventChemistry

The invention provides an alkyl ester method produced glyphosate solvent recovery method. A diluted methanol solution collection tank is connected with the upper part of a primary rectifying tower through a pipeline, and the primary rectifying tower is connected with a return tank I through a condenser I; the return tank I is connected with a methyl alcohol methylal solution intermediate tank; themethyl alcohol methylal solution intermediate tank is connected with a secondary rectifying tank, a return tank II is connected to a methyl alcohol methylal finished product tank, and the secondary rectifying tank is connected to a methyl alcohol finished product tank. The recovery process comprises the following steps: enabling diluted methanol inside the diluted methanol solution collection tank to enter into the primary rectifying tower, enabling gas inside the primary rectifying tower to condense through the condenser to return back to the return tank, and feeding to the methyl alcohol methylal solution intermediate tank; feeding to the methyl alcohol finished product tank from a secondary rectifying tower extraction pump, condensing liquid at the bottom of the tower through the condenser and then feeding to the methyl alcohol finished product tank. According to the equipment and process provided by the invention, the defect that a traditional liquid-phase recovery process highlydepends on a graphite condenser and the problem that a traditional gas-phase recovery process is unstable in operation are solved, the process has the characteristics of energy saving and economical efficiency, and the steam consumption of glyphosate is 1.2t.

Owner:HUBEI TAISHENG CHEM

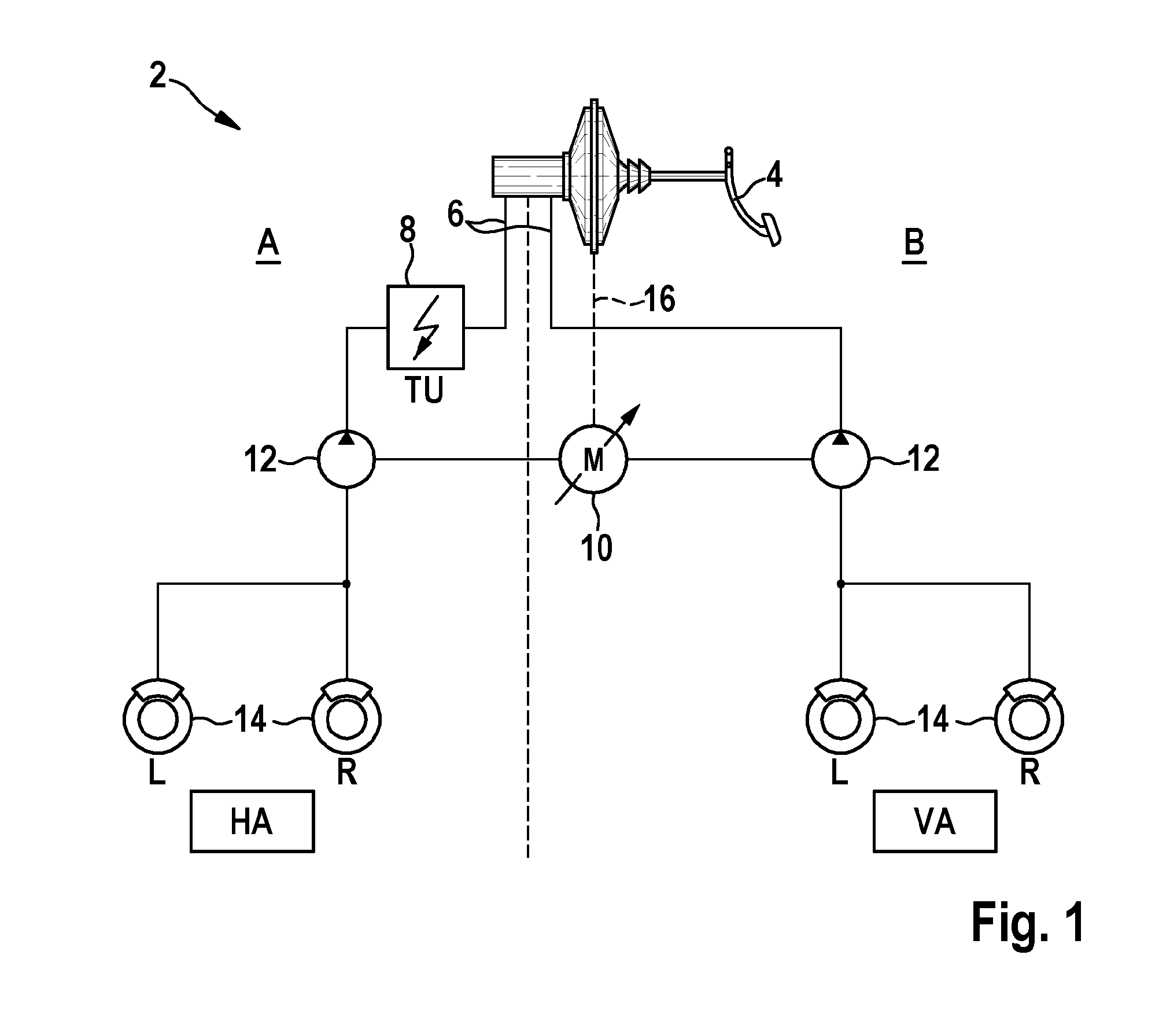

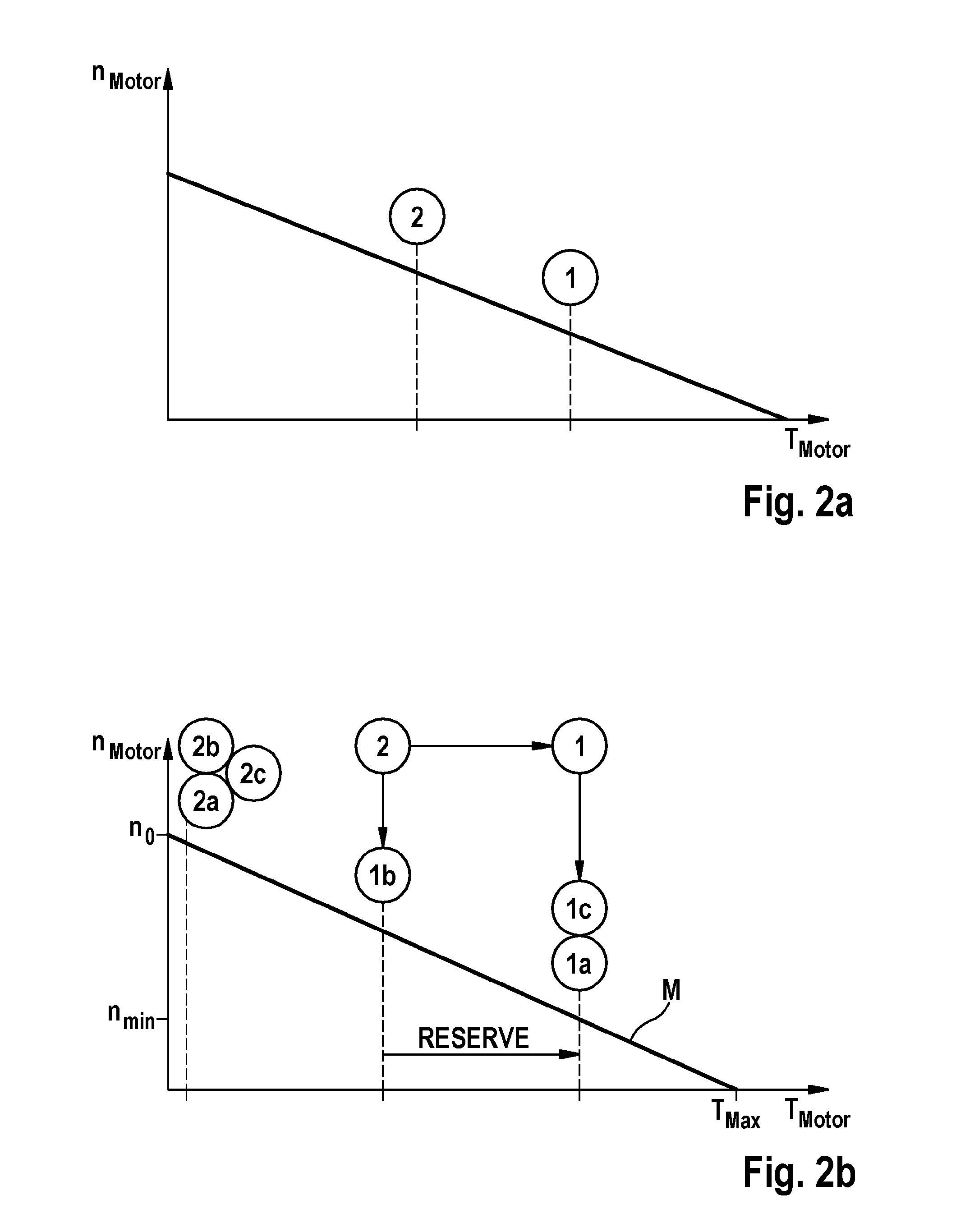

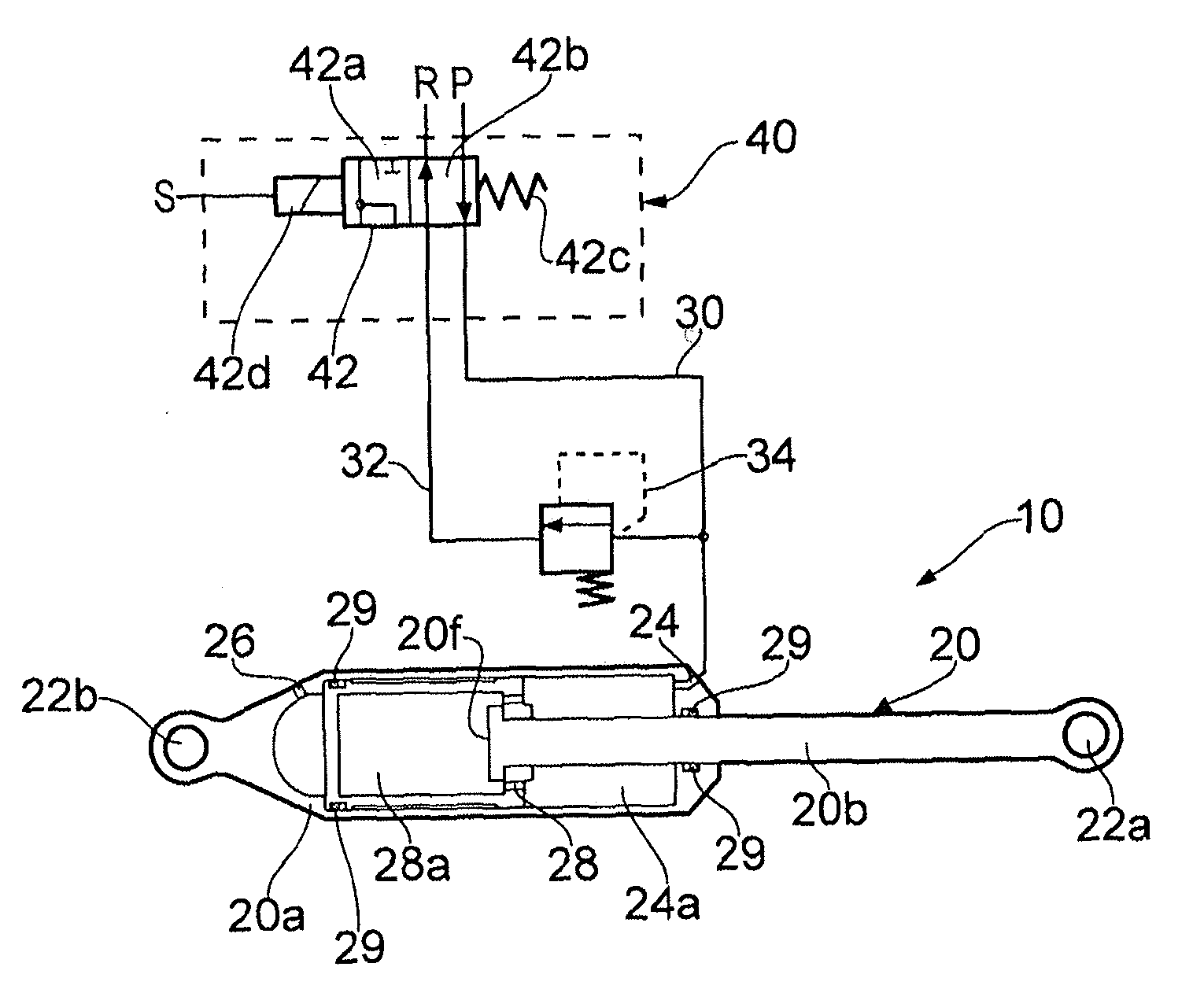

Braking system and method for dimensioning a braking system

ActiveUS20150367823A1Reduce pressureIncrease speedBraking action transmissionApplication and release valvesEngineeringBraking system

A method for dimensioning a component of a braking system; the braking system having at least two brake-circuit partial circuits; each brake-circuit partial circuit having at least one pump element for building up a brake-circuit pressure and / or for returning brake-circuit fluid in an ABS case, the pump elements of the at least two brake-circuit partial circuits being operable using a motor element; and the at least two brake-circuit partial circuits being separable using a separating element, so that different brake-circuit pressures may be created in the at least two brake-circuit partial circuits.

Owner:ROBERT BOSCH GMBH

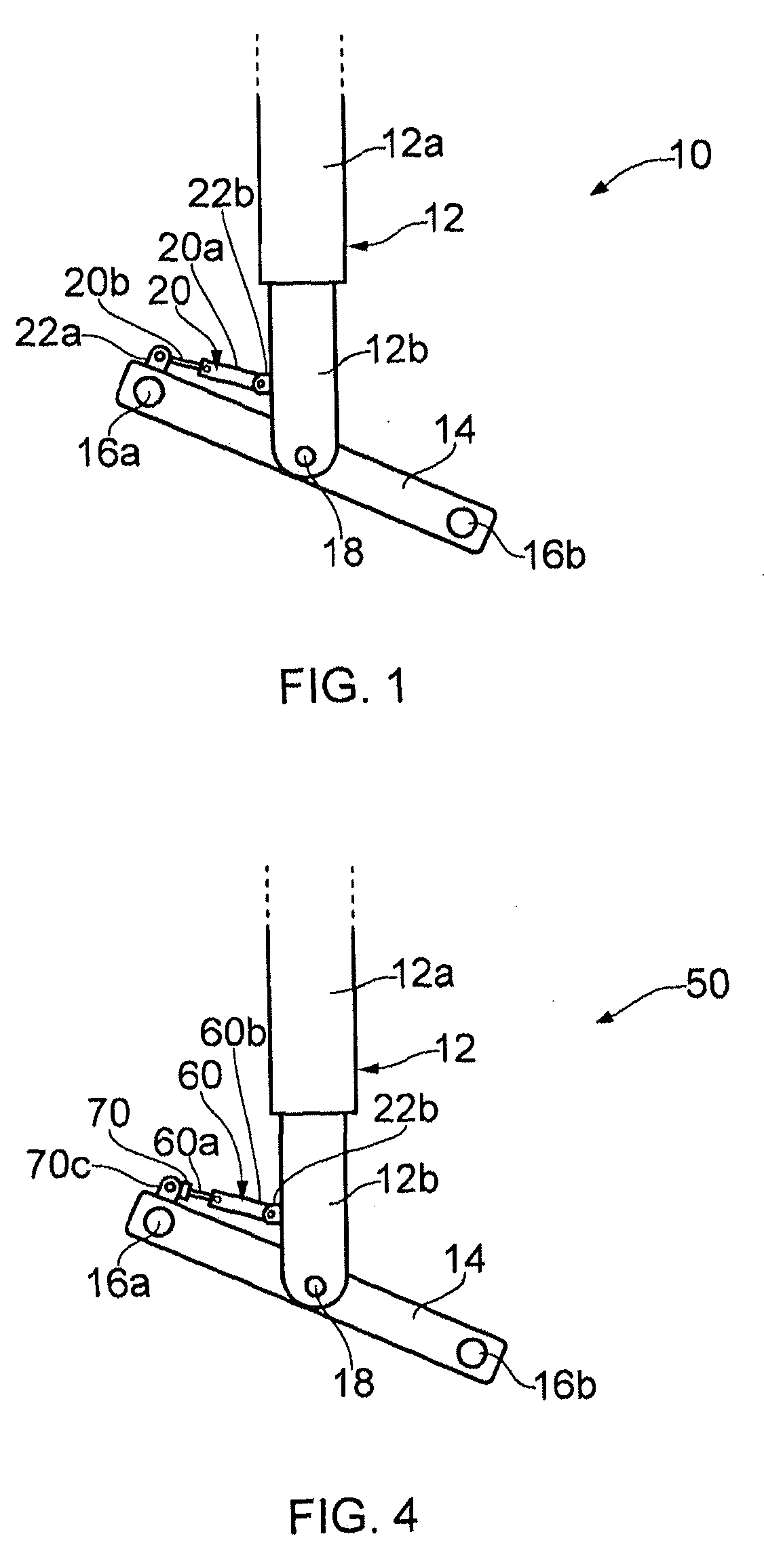

Aircraft landing gear

ActiveUS20130233968A1Reduce loadReduce roughnessWheel arrangementsUndercarriagesBogieEffective length

An aircraft landing gear including: a main strut having an upper portion arranged to be coupled to the underside of an aircraft and a lower portion telescopically mounted with respect to the upper portion; a bogie including a bogie beam pivotally coupled to the lower portion of the main strut, the bogie beam having a plurality of axles mounted on it, each axle carrying one or more wheel assemblies; an actuator arranged such that a change in its effective length causes a change in the angular position of the bogie relative to the main strut, and a control port arranged to be coupled to a control fluid supply system, wherein the aircraft landing gear includes or is in combination with a control valve having a first configuration in which it permits control fluid to be supplied to the control port of the actuator at a first pressure and a second configuration in which the control valve permits the supply of control fluid to the control port at a second pressure less than the first pressure so as to reduce loads experienced by components of the actuator during taxiing.

Owner:MESSIER DOWTY

Differential pressure sensor

ActiveUS20050011270A1High measurement accuracyImprove ranging accuracyFluid pressure measurement using ohmic-resistance variationPressure difference measurement between multiple valvesDifferential pressureSemiconductor

The differential pressure sensor is formed of a semiconductor substrate (1) which is thinned out in an inner region into a membrane (2) which may be impinged by pressure on both sides. Measurement resistances (3a to 3d) for detecting the differential pressure (P1 minus P2) are formed within the membrane (2), and compensation resistances (4) are formed on the carrier, which are connected to measurement resistances (3). The measurement resistances (3) are connected into a first measurement bridge (6) and the compensation resistances (4a to 4d) into a second measurement bridge (7).

Owner:GRUNDFOS

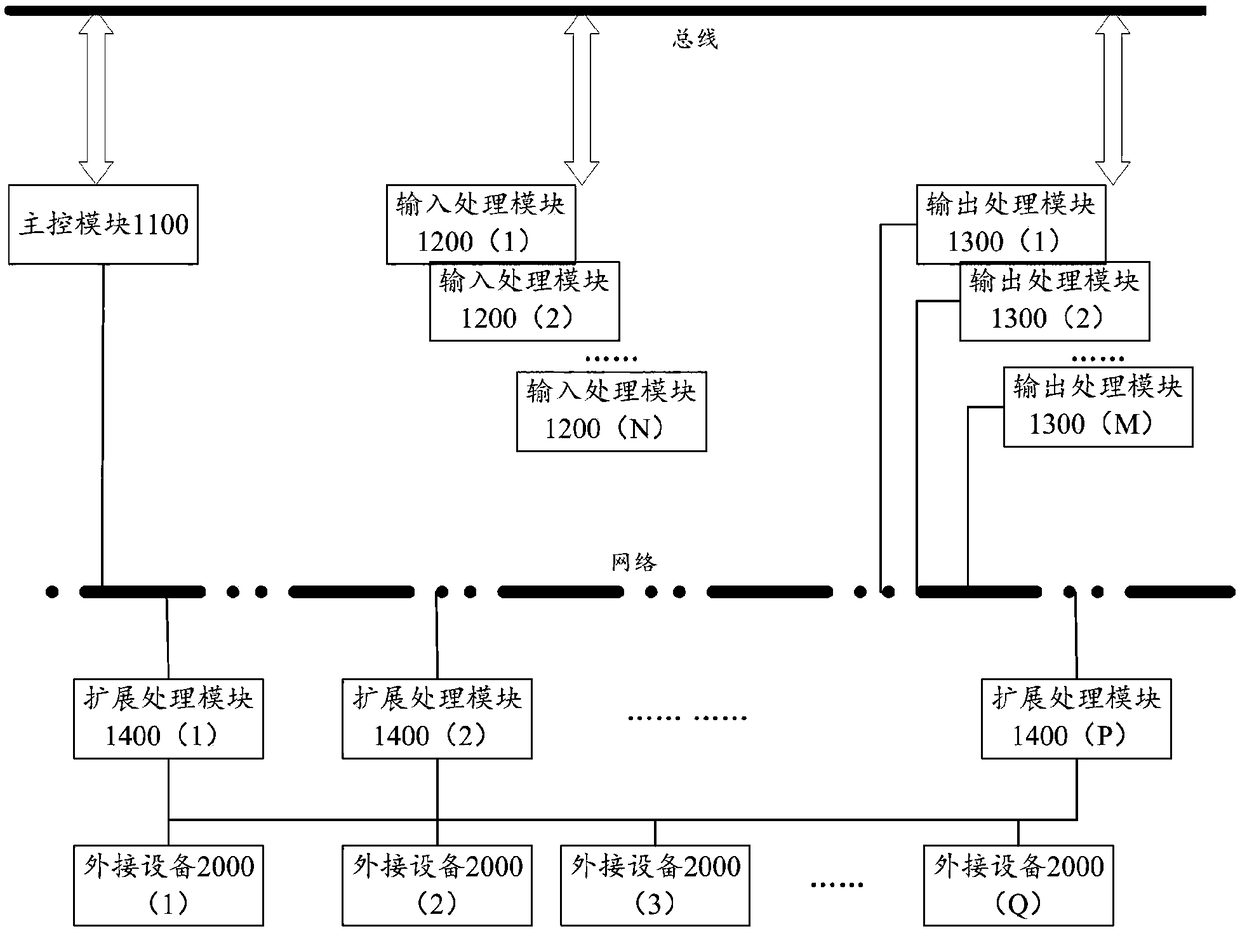

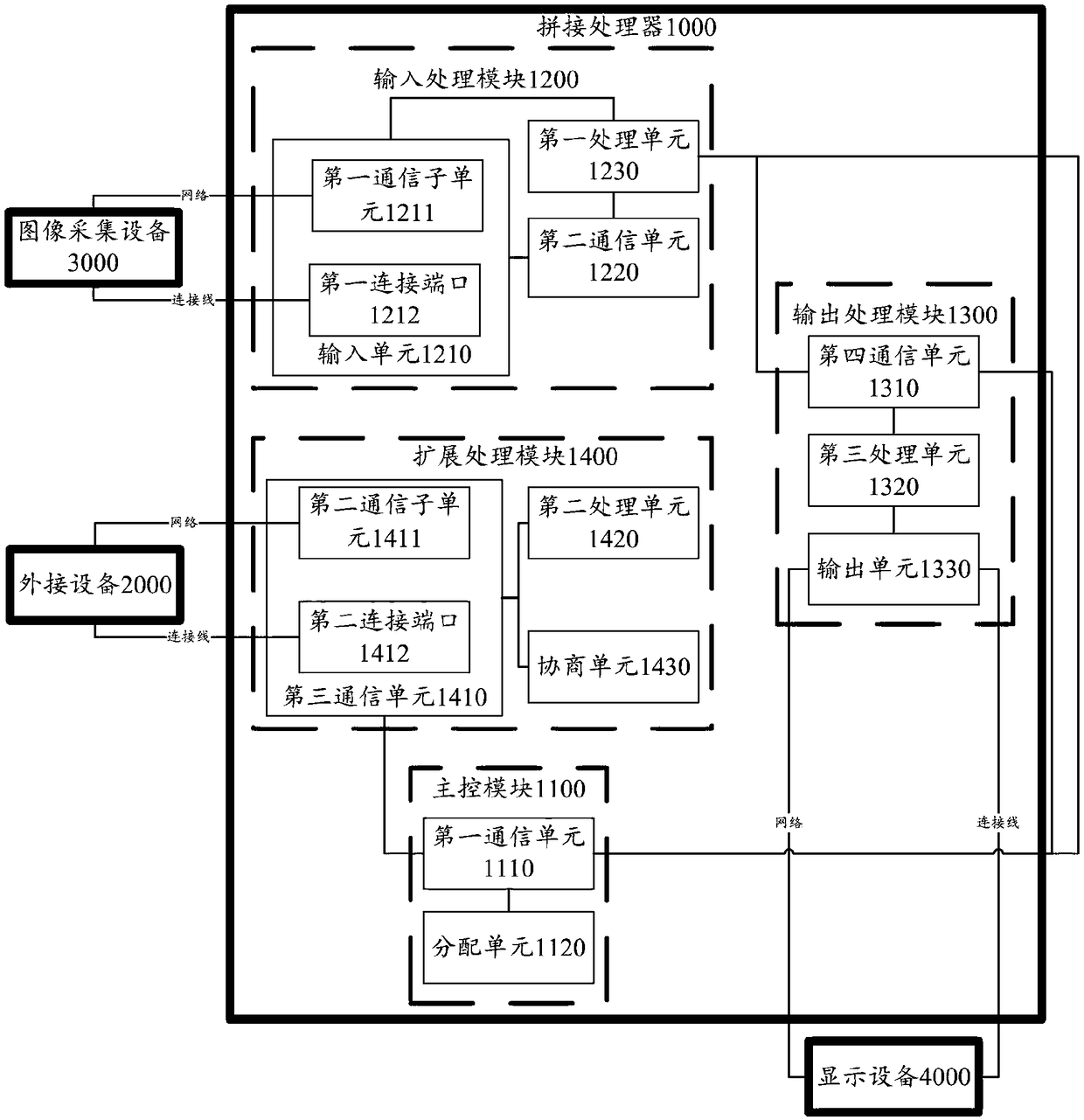

Splicing processor and visual interaction method thereof

ActiveCN108255454AImprove processing efficiencyReduce the burden onDigital output to display deviceTarget controlComputer module

The invention relates to a splicing processor and a visual interaction method thereof; the splicing processor includes: a master control module, an extension processing module, an input processing module and an output processing module. The extension processing module acquires control operation data and converts the same to obtain corresponding target control commands which include control information and spatial information corresponding to the same; the input processing module acquires first image information; the output processing module processes the first image information according to the target control commands to obtain corresponding second image information; the master control module is connected with the extension processing module, the input processing module and the output processing module, controls the extension processing module to acquire the target control command, controls the input processing module to acquire the first image information, and controls the output processing module to perform processing to obtain the second image information. The splicing processor and the visual interaction method thereof have the advantages that convenience and interaction for auser to operate a large screen are improved and interactive control responding efficiency is improved.

Owner:SHANGHAI ZHUOXIANG INFORMATION SCI & TECH

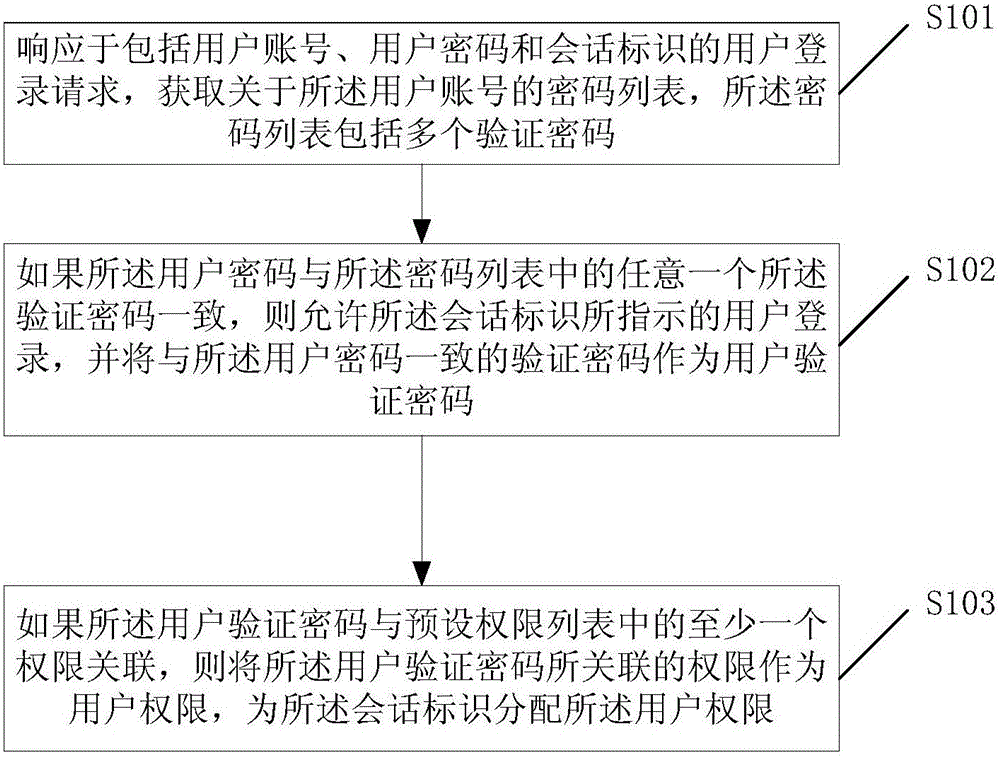

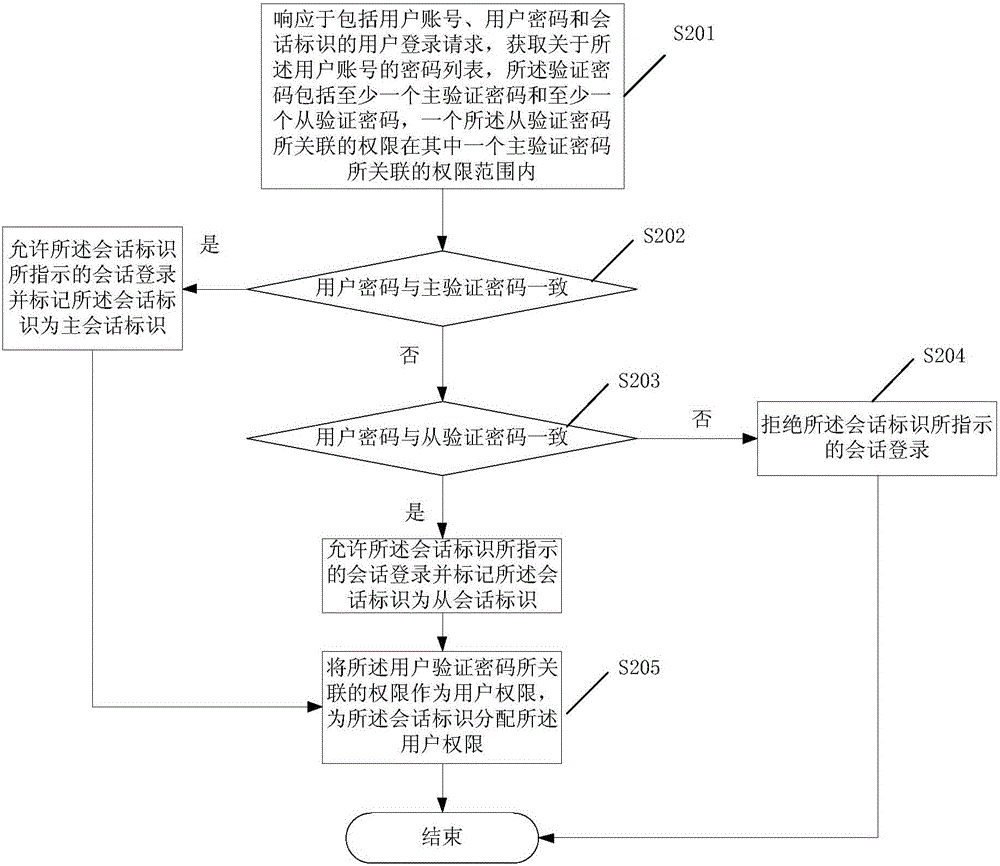

User permission management method and system

InactiveCN105959309AReduce system pressureRelieve pressureDigital data protectionDigital data authenticationFull PermissionSystem pressure

The embodiment of the present invention discloses a user rights management method and system, including: in response to a user login request including a user account, a user password, and a session ID, acquiring a password list related to the user account, the password list including a plurality of verification Password; if the user password is consistent with any one of the verification passwords in the password list, the user indicated by the session identifier is allowed to log in, and the verification password consistent with the user password is used as the user verification password; If the user authentication password is associated with at least one authority in the preset authority list, the authority associated with the user authentication password is used as a user authority, and the user authority is assigned to the session identifier. In the embodiment of the present invention, multiple passwords are maintained for the same user account. Since the same user account is used to log in, the system does not need to maintain a large number of user accounts, reducing system pressure.

Owner:LETV HLDG BEIJING CO LTD +1

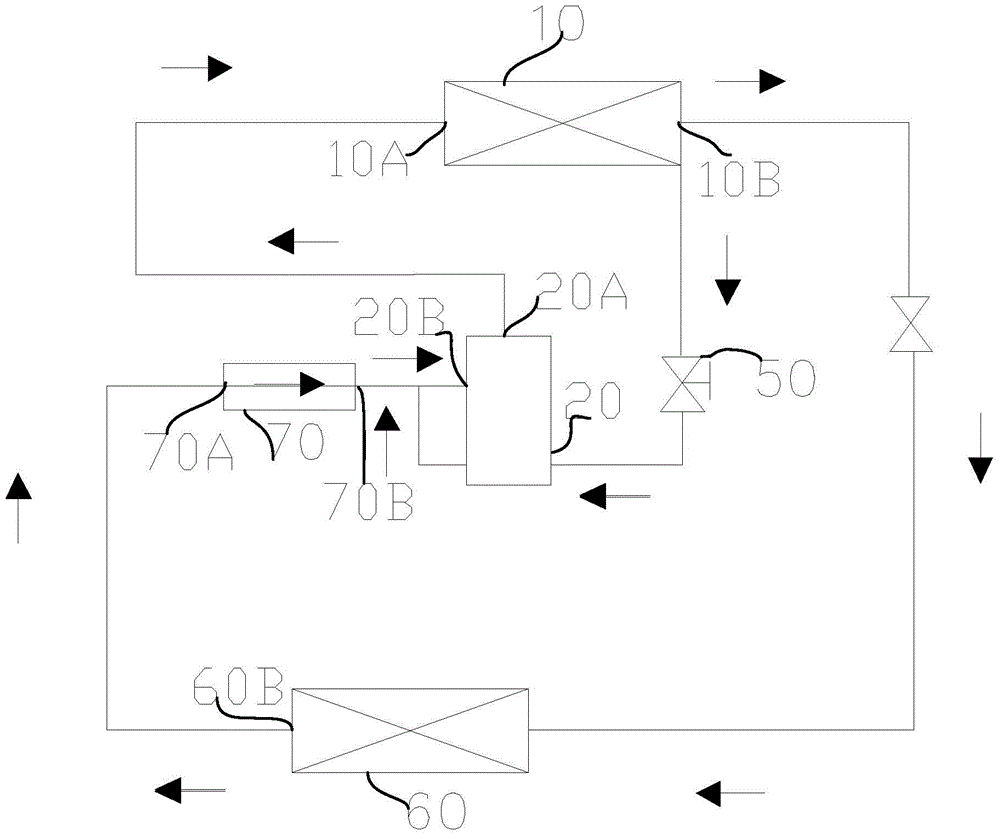

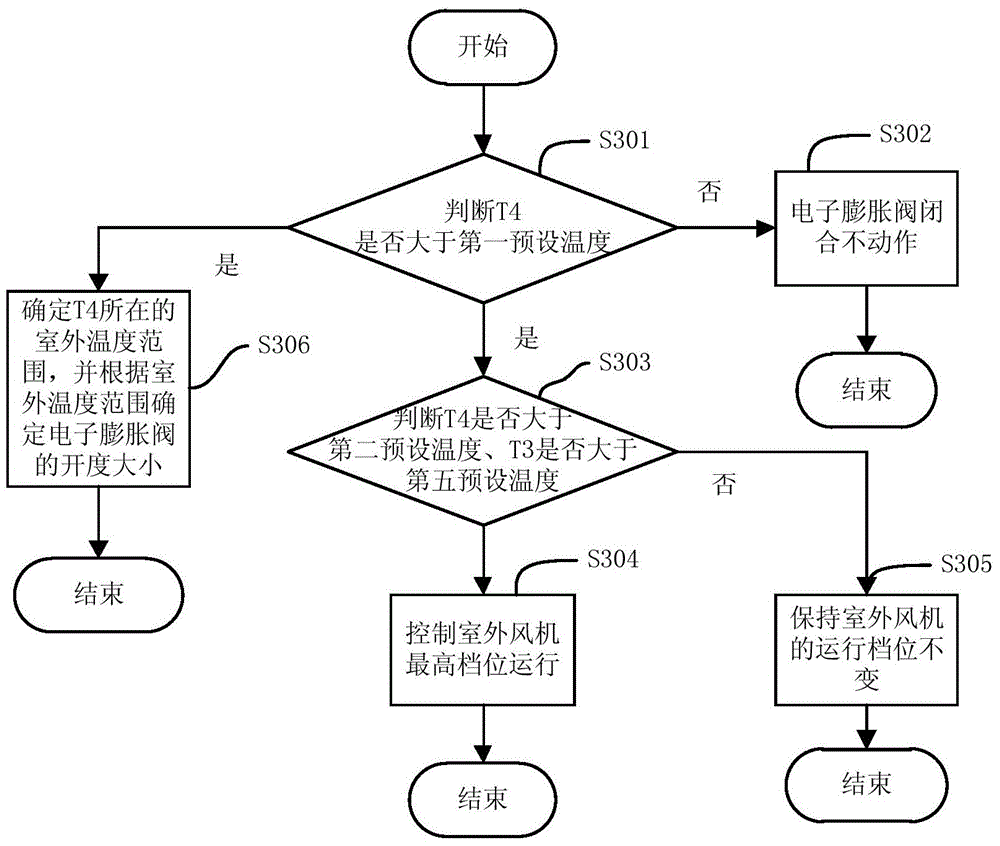

Air conditioner and refrigeration control method thereof

ActiveCN104676856AReduce system operating pressureImprove system reliabilityMechanical apparatusSpace heating and ventilation safety systemsSystem pressureEngineering

The invention discloses an air conditioner and a refrigeration control method thereof. The air conditioner comprises an outdoor heat exchanger, a compressor, a first temperature sensor and a control module, wherein an exhaust port of the compressor is connected to the inlet end of the outdoor heat exchanger, the compressor is provided with a cooling device, one end of the cooling device is connected with the outdoor heat exchanger through an electronic expansion valve, and the other end of the cooling device is connected with a suction port of the compressor; the first temperature sensor is used for detecting outdoor environment temperature; the control module is used for controlling the electronic expansion valve to open when the outdoor environment temperature is greater than first preset temperature, so that the compressor can be cooled by the cooling device, and the system pressure of the air conditioner is reduced during operation. The air conditioner can be used for operating and refrigerating at high temperature, and the system operation pressure can be effectively reduced during system overload, so that the air conditioning system can continuously operate, the system reliability is increased, and the user experience is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

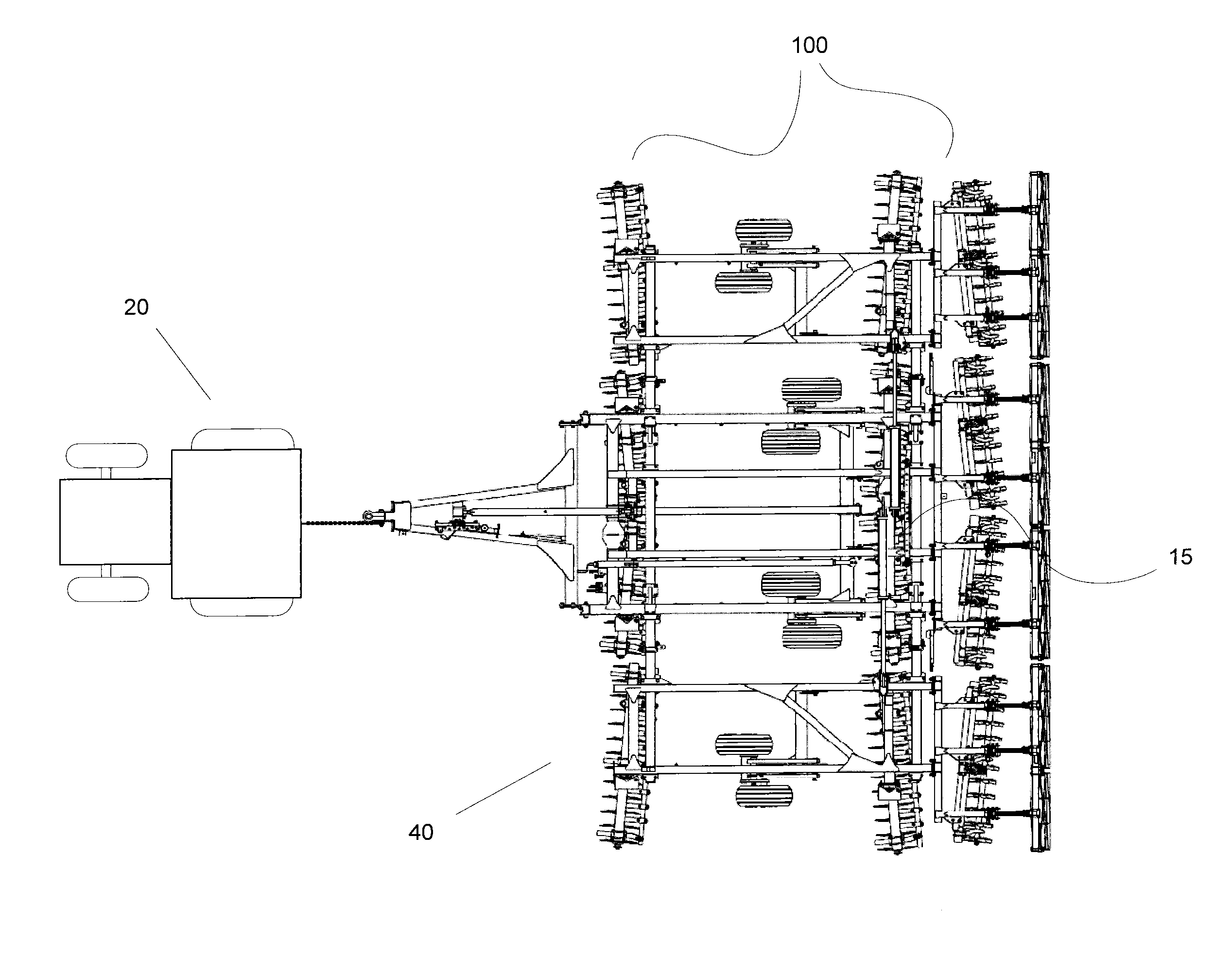

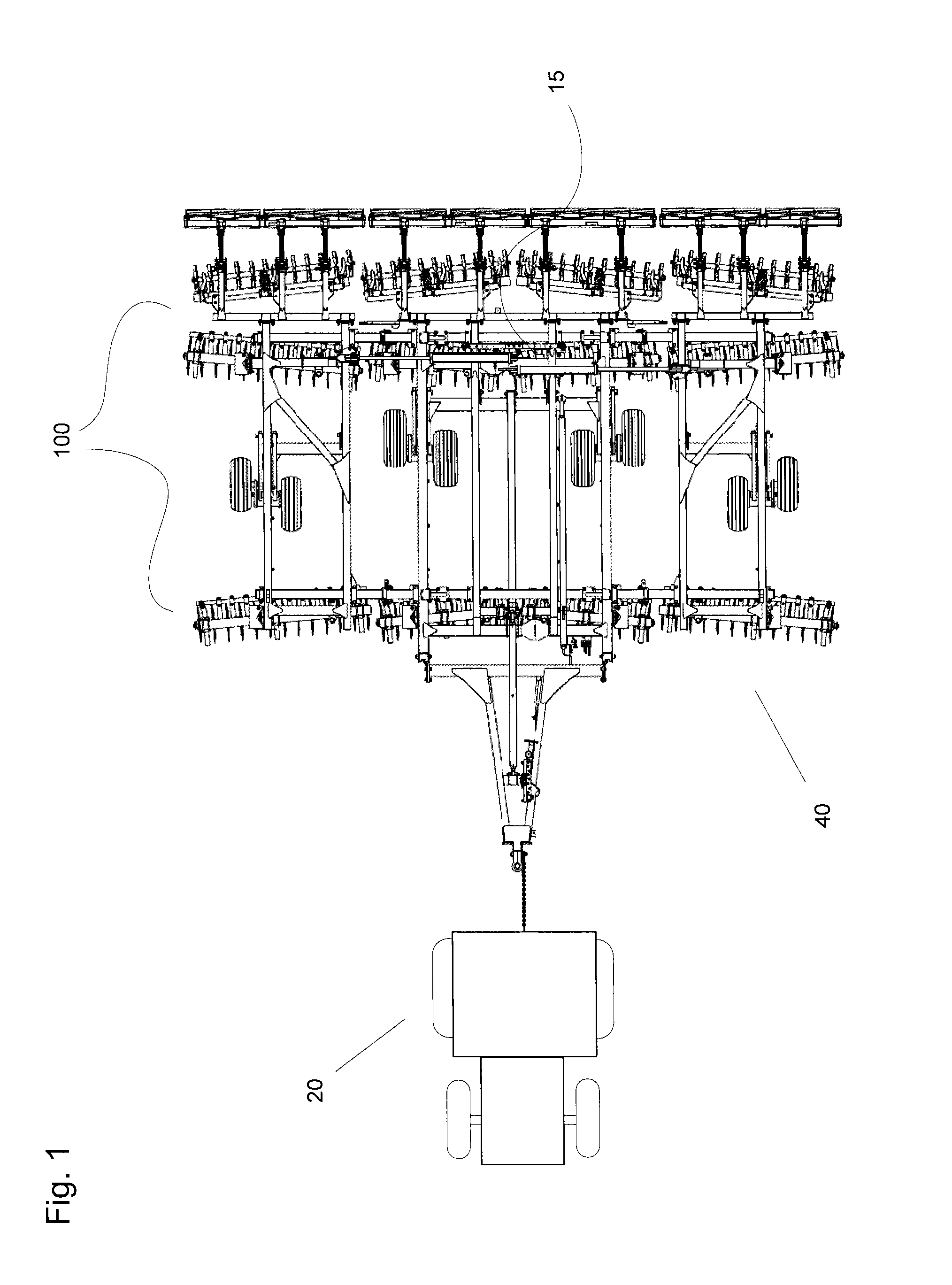

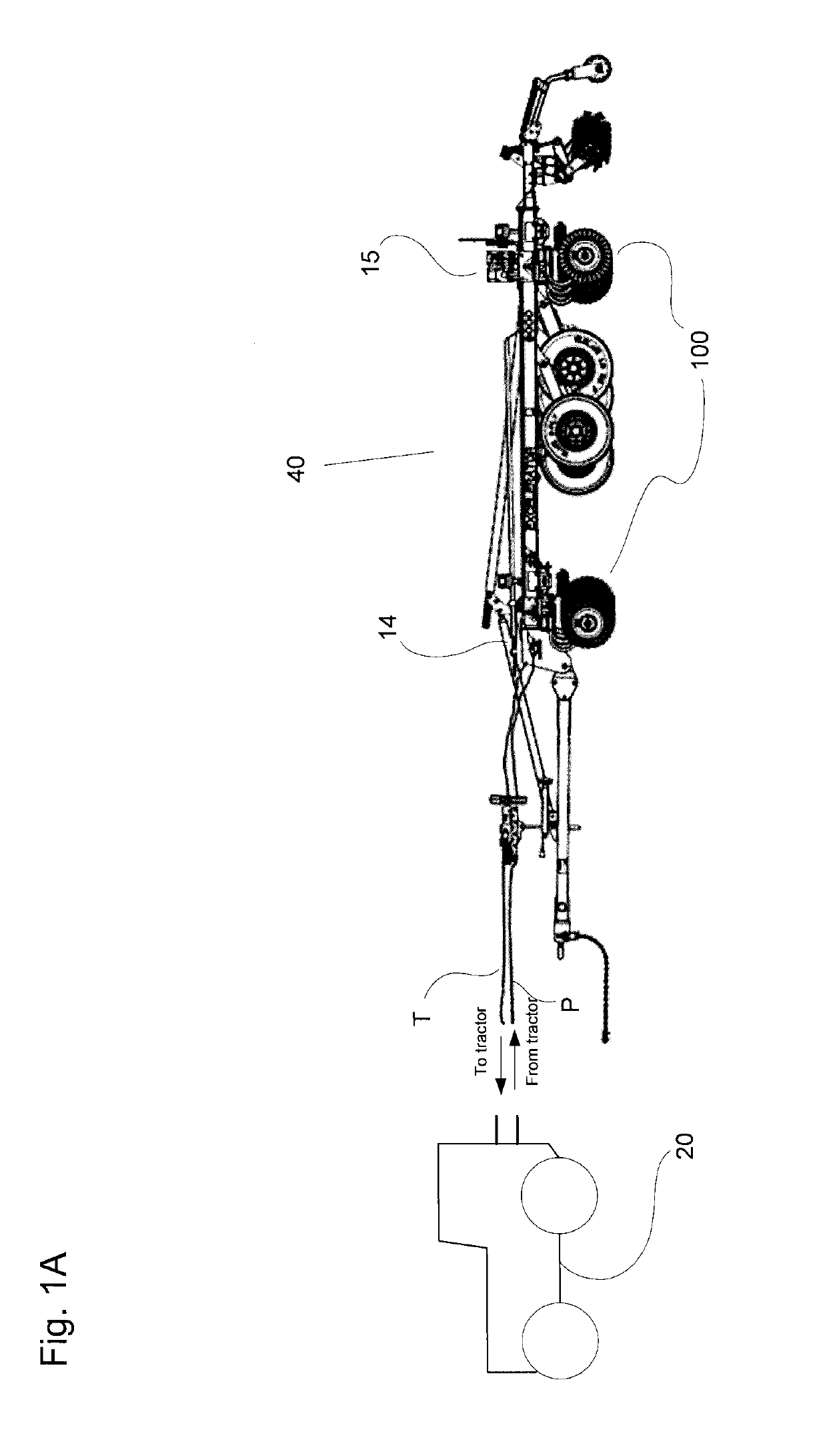

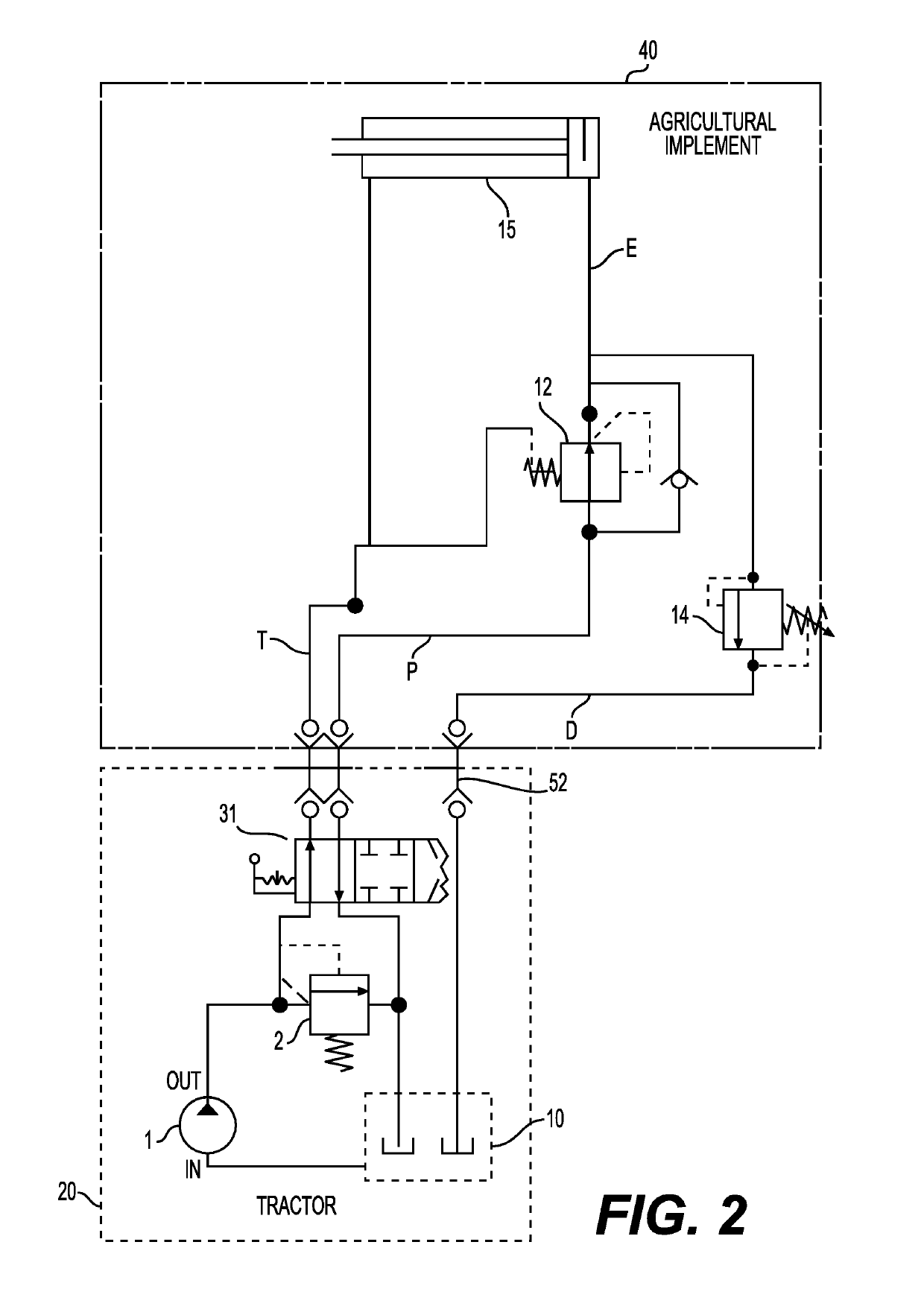

Constant pressure hydraulic circuit with relief protection independent of pressure circuit

ActiveUS20160316611A1Avoid damageFaster rateAgricultural machinesServomotor componentsHydraulic cylinderHydraulic circuit

A hydraulic circuit for an agricultural implement consisting of a hydraulic cylinder that exerts a force on a component of the implement. A pressure reduction valve located between a hydraulic power source and the hydraulic cylinder maintains pressure to no more than a preset maximum to protect the hydraulic cylinder by routing excess hydraulic fluid back through a hydraulic line into a reservoir. A pressure relief valve with a preset maximum pressure greater than that of the pressure reduction valve is located between the pressure reduction valve and the hydraulic cylinder, and is connected to the reservoir through a dedicated return line. If hydraulic fluid pressure in the circuit increases to greater than the maximum of the pressure reduction valve, hydraulic fluid is diverted back to the reservoir through the pressure relief valve and a dedicated return line.

Owner:KUHN KRAUSE

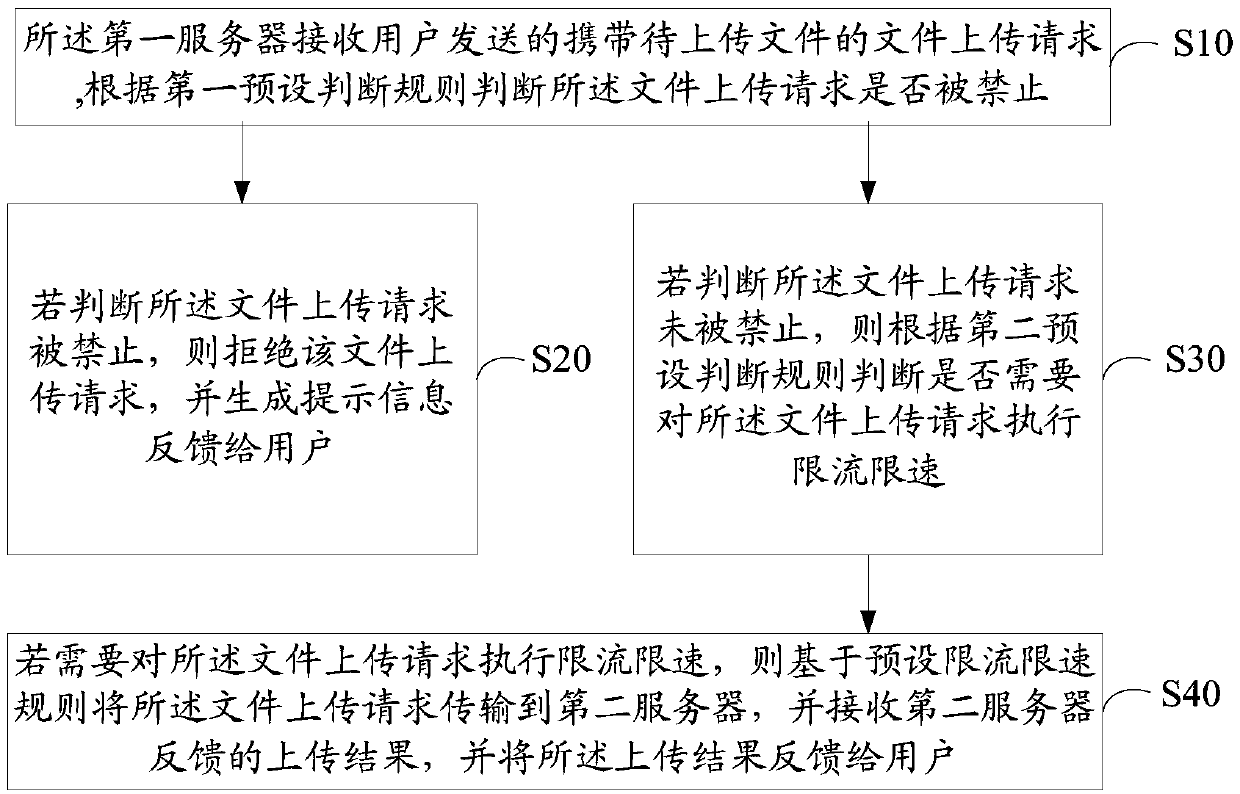

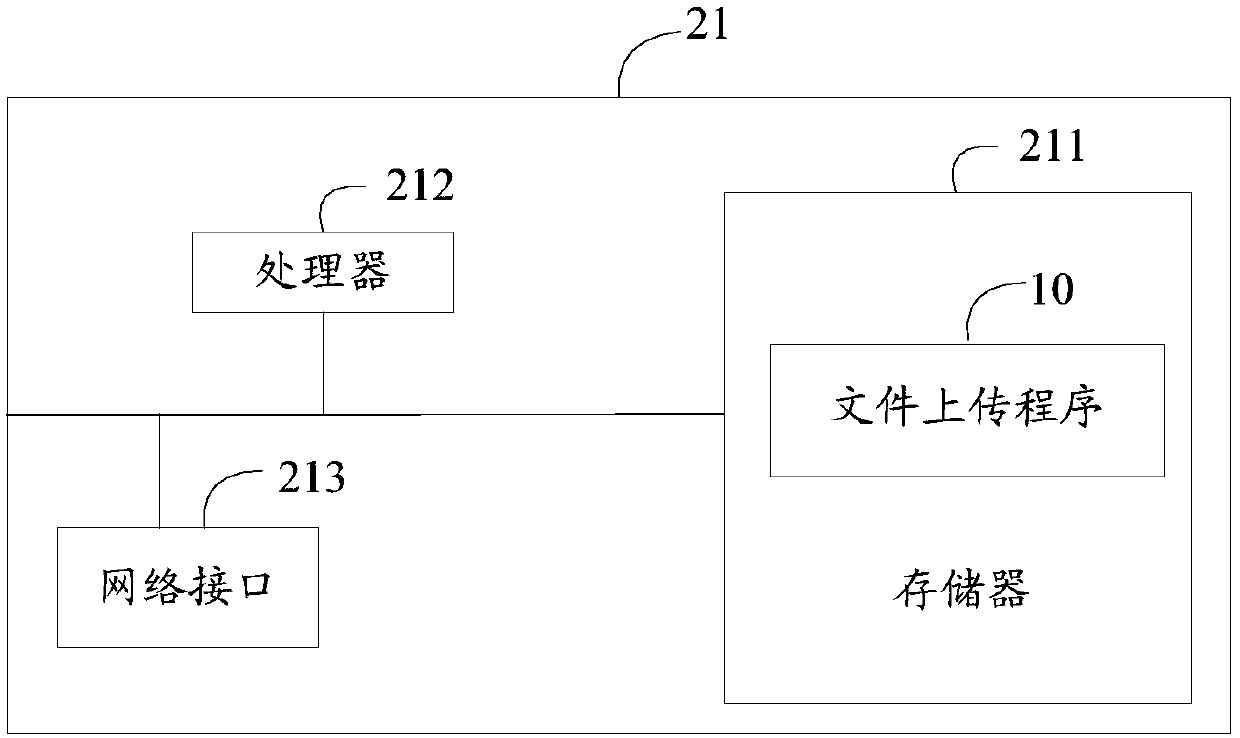

File uploading and downloading methods, server and computer readable storage medium

ActiveCN109617996AReduce system pressureImprove processing efficiencyData switching networksData processingSpeed limit

The invention relates to data processing, and provides a file uploading method. The method comprises the steps of: after first servers receive file uploading requests sent by users, carrying out judgment on compliance of the file uploading requests, if the file uploading requests are not compliant, directly refusing the file uploading requests; and for the file uploading requests which pass compliance judgment, judging whether a load of a second server cluster is relatively high, and if yes, transmitting the file uploading requests to second servers on the basis of a preset flow-limiting speed-limiting rule for the second servers to carry out file uploading processing. The invention further provides a file downloading method, a server and a computer storage medium. By utilizing the file uploading method, the file downloading method, the server and the computer readable storage medium which are provided by the invention, file uploading and downloading efficiency can be improved, stability of a system is improved, and use experience of the users is promoted.

Owner:PING AN TECH (SHENZHEN) CO LTD

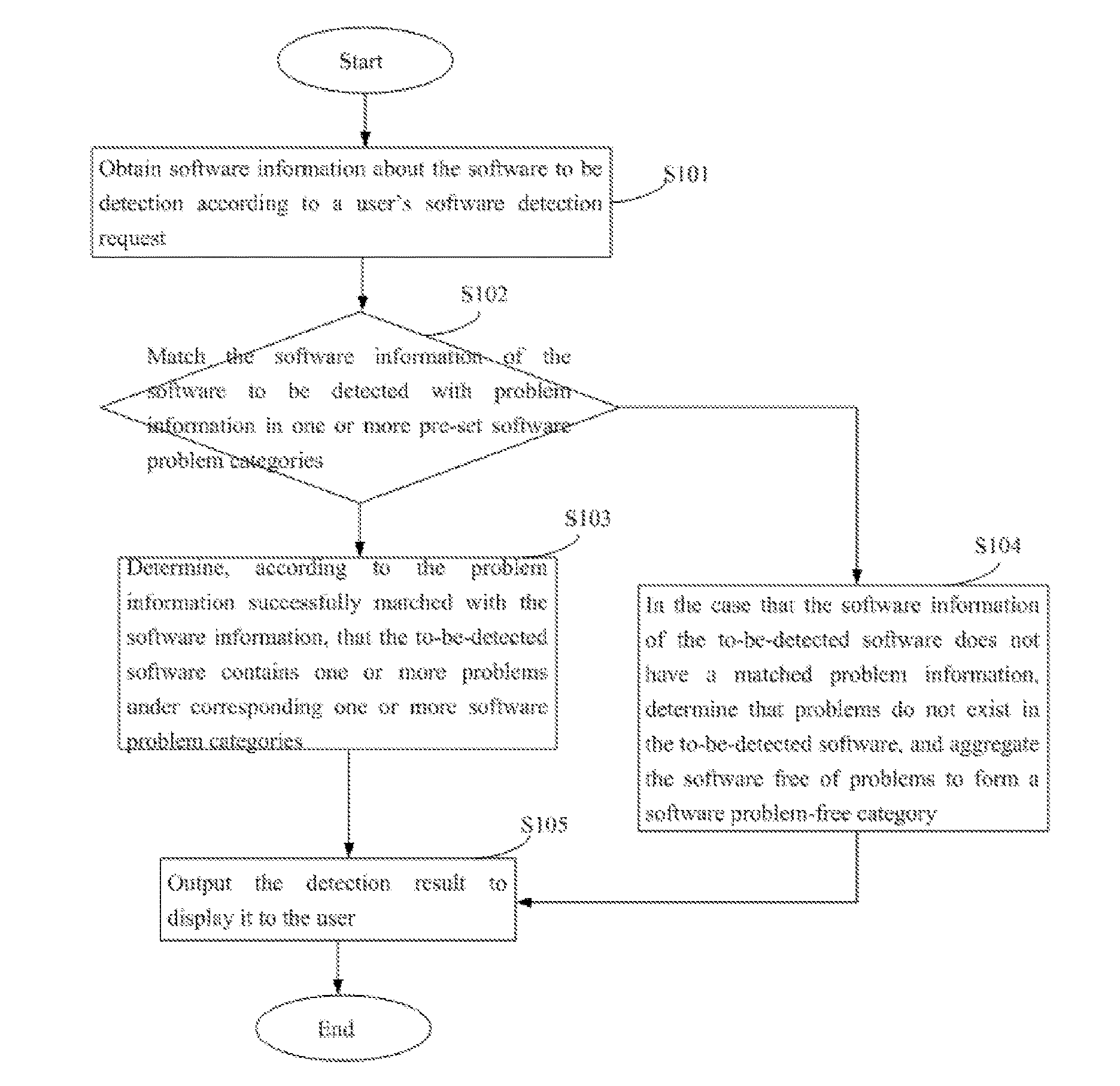

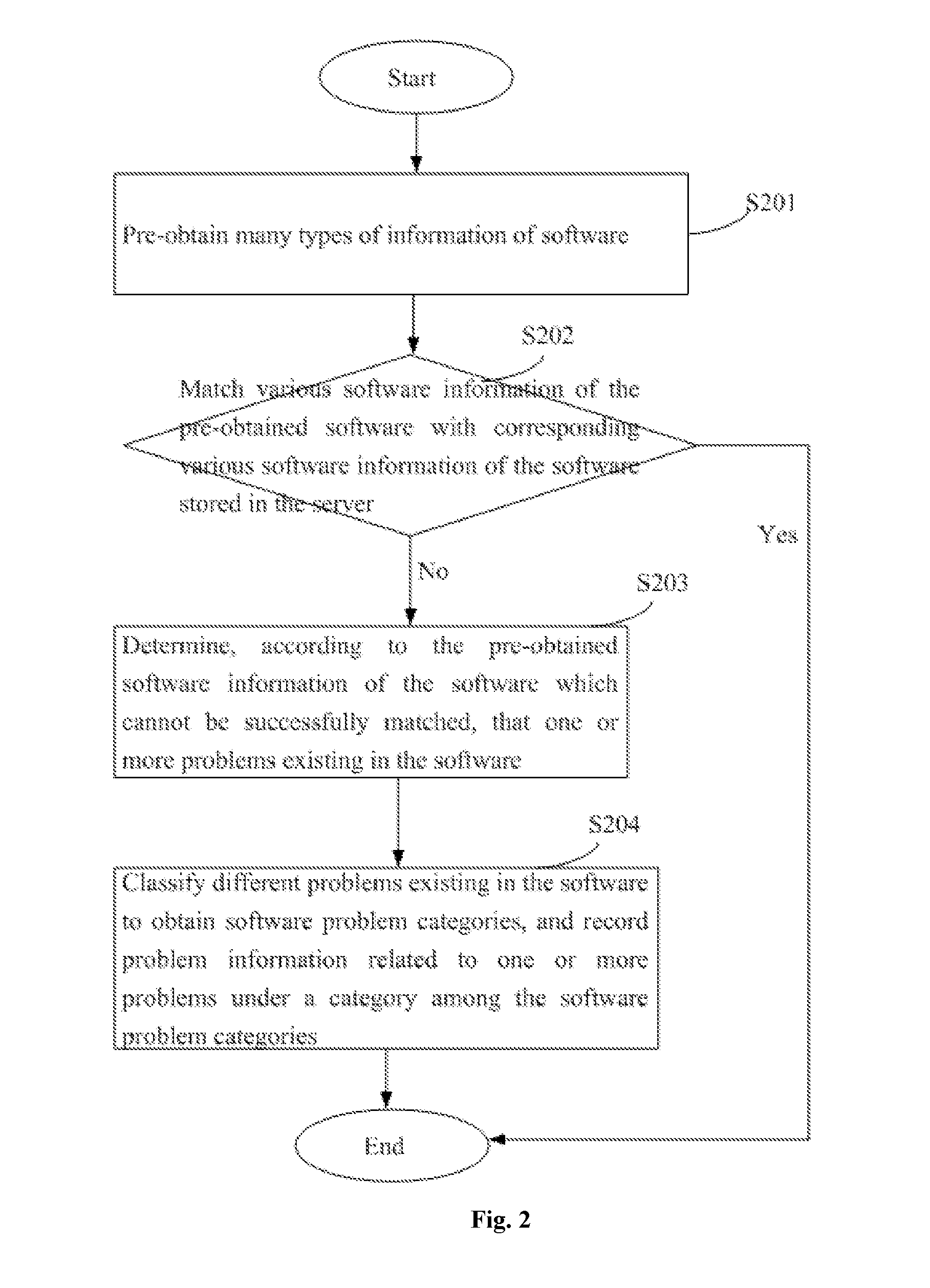

Software detection method and device

InactiveUS20170017561A1Improve software safetyEfficient executionRelational databasesComputer security arrangementsSoftware engineeringSystem pressure

Provided are a software detection method and device. The method comprises: matching software information about software to be detected with information in one or more pre-set software problem categories to perform detection (S501), wherein the software problem categories are obtained by classifying one or more problems existing in the software, and each software problem category contains problem information related to one or more problems under the category; and if the software information about the software to be detected is successfully matched with the problem information in the one or more software problem categories, determining that the software to be detected has one or more problems under the corresponding one or more software problem categories (S502), so that a conclusion that the software has a problem can be quickly and accurately made without specifically scanning all support files or corresponding assemblies of each piece of software one by one, thereby being able to quickly find a problem before the operation of the software, guaranteeing the security of user software, reducing the system pressure of a user terminal, and improving the user experience.

Owner:BEIJING QIHOO TECH CO LTD

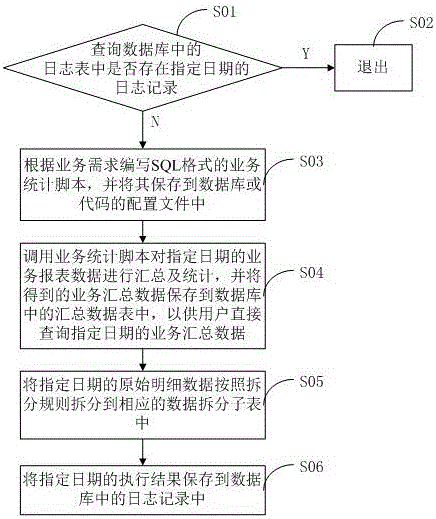

Statistical method and statistical device for big data in database

ActiveCN106649869AShorten the timeReduce wasteSpecial data processing applicationsComputer scienceBusiness requirements

The invention discloses a statistical method and a statistical device for big data in a database. The method comprises the following steps: inquiring whether a log list in the database has a log record of an appointed data or not, if so, exiting; otherwise, compiling a service statistical script in an SQL format according to a service demand and storing the script in the database or a configuration file of a code to execute the next step; calling the service statistical script to summarize and perform statistics on the service report table data of the appointed data and storing the obtained service report table data to a summarized data table in the database for a user to directly inquire the service summarized data of the appointed data; splitting original detailed data of the appointed data into corresponding data split sub-tables according to a splitting rule; and storing the executing result of the appointed data to the log record in the database. According to the method and the device disclosed by the invention, the time of the user for inquiry can be greatly shortened, the efficiency of statistical query can be greatly improved, and wastes of the hardware resources and costs can be greatly reduced.

Owner:深圳博十强志科技有限公司

Constant pressure hydraulic circuit with relief protection independent of pressure circuit

ActiveUS10349571B2Reduce system pressureFaster rateAgricultural machinesServomotor componentsHydraulic cylinderHydraulic circuit

A hydraulic circuit for an agricultural implement consisting of a hydraulic cylinder that exerts a force on a component of the implement. A pressure reduction valve located between a hydraulic power source and the hydraulic cylinder maintains pressure to no more than a preset maximum to protect the hydraulic cylinder by routing excess hydraulic fluid back through a hydraulic line into a reservoir. A pressure relief valve with a preset maximum pressure greater than that of the pressure reduction valve is located between the pressure reduction valve and the hydraulic cylinder, and is connected to the reservoir through a dedicated return line. If hydraulic fluid pressure in the circuit increases to greater than the maximum of the pressure reduction valve, hydraulic fluid is diverted back to the reservoir through the pressure relief valve and a dedicated return line.

Owner:KUHN KRAUSE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com