Closed loop hydraulic system with variable charge pressure

a closed loop, hydraulic technology, applied in the direction of fluid couplings, servomotors, couplings, etc., can solve the problems of wasting hydraulic power, parasitic losses, and difficulty in reducing the charge flow in a closed loop system without incurring corresponding parasitic power losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

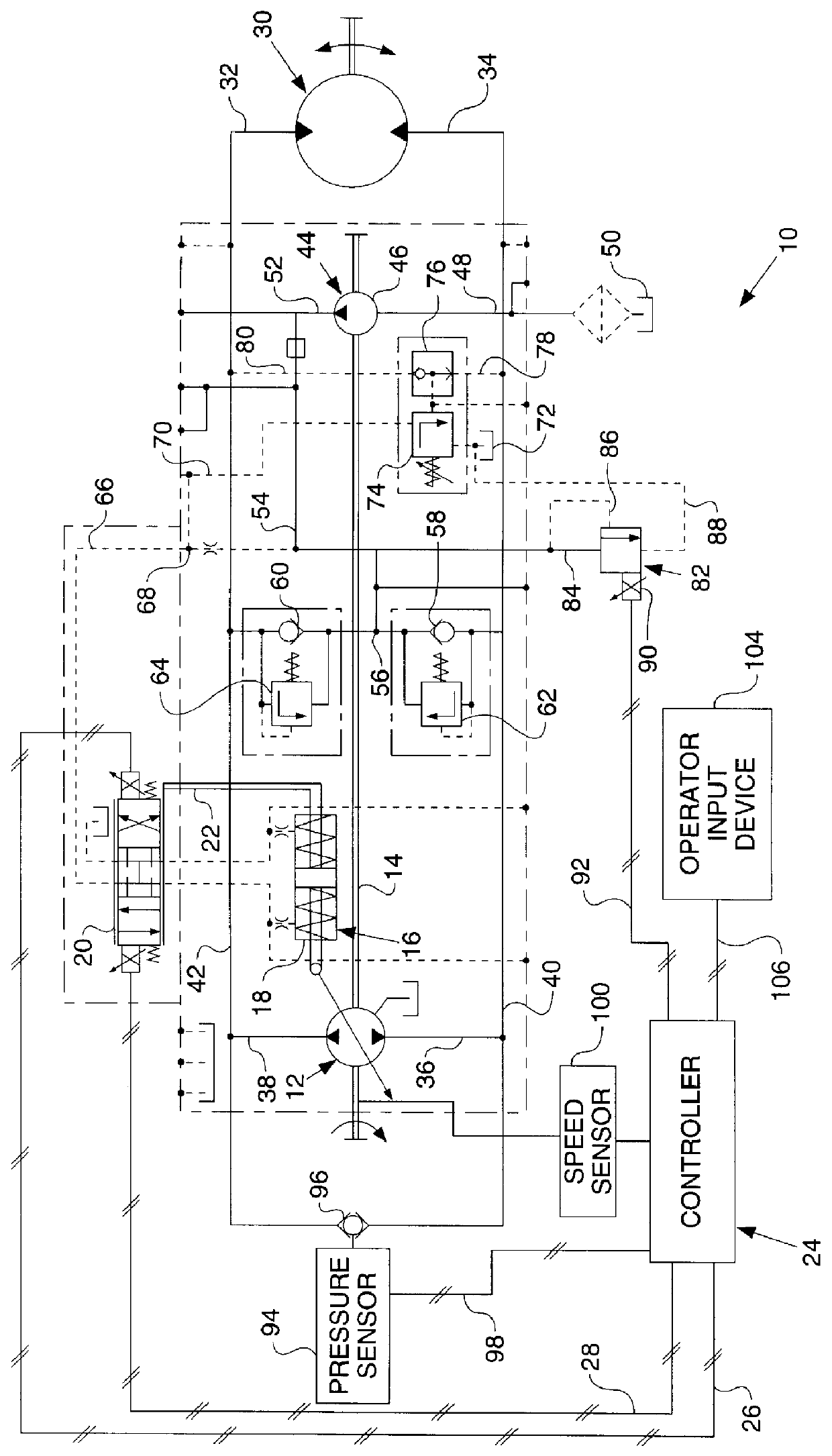

Referring now to the drawing, a hydraulic system 10 is illustrated. Hydraulic system 10 is a closed loop system including a variable displacement hydraulic pump 12 conventionally connected in driven communication with a power source (not shown) by a drive shaft 14. Pump 12 is of conventional construction and operation and includes an internal tilt plate (not shown) operable for varying the displacement thereof, connected to tilt control means 16 including an actuator 18 operatively connected to a variably operable pump control valve 20 via lines 22. Pump control valve 20 is operator or system controllable using a controller 24 connected to valve 20 via wires 26 and 28. Controller 24 is preferably a computerized device including a microprocessor or similar processor conventionally operable for controlling a tilt angle of the tilt plate of variable displacement hydraulic pump 12, and also a charging system, as will be explained.

Hydraulic system 10 includes a hydraulic motor 30 having ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com