Hydrogenation method for producing clean diesel oil

A diesel and clean technology, applied in the direction of refining to remove heteroatoms, etc., can solve the problems of high cost, low operating flexibility, and inability to greatly increase the cetane number, and achieve simple process, low operating pressure, equipment investment and operation The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

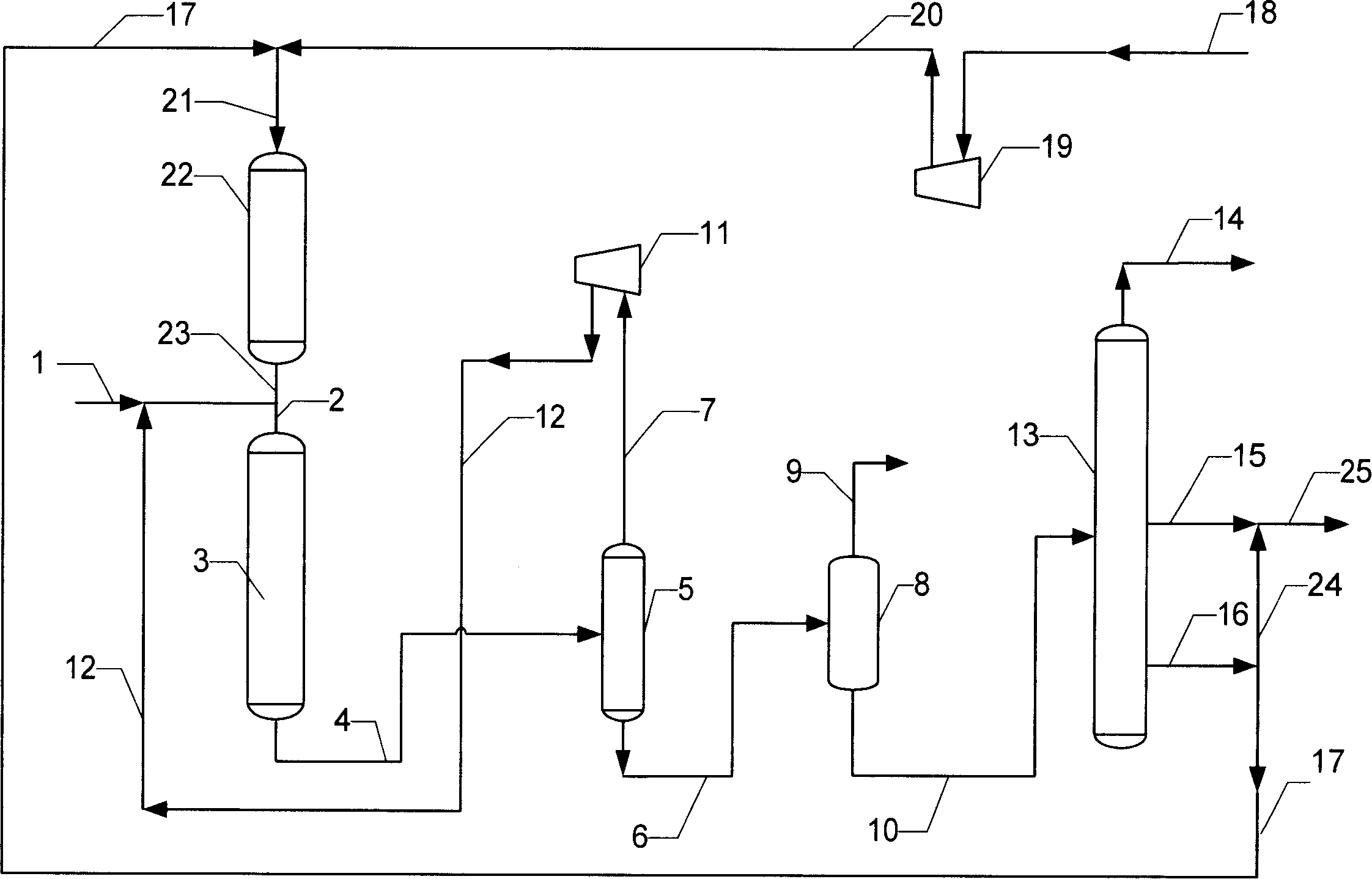

[0021] Through the above in-depth analysis and understanding of the composition and distribution of sulfides, aromatics, hydrodesulfurization and hydrodearomatization reactions, the specific embodiments of the present invention are:

[0022](1) After the raw material oil is mixed with circulating hydrogen, it enters the second hydrogenation reaction zone of the hydrogenation reactor, together with the product from the first hydrogenation reaction zone, under the action of the hydrofining catalyst, hydrodesulfurization, hydrogenation Hydrogen denitrogenation, olefin saturation and partial aromatic saturation reaction, the reaction conditions are: reaction temperature 250-450°C, preferably 260-420°C, hydrogen partial pressure 1.0-12.0MPa, preferably 2.0-10.0MPa, liquid hourly volume space velocity 0.3- 10.0h -1 , preferably 0.5~8.0h -1 , Hydrogen oil volume ratio 100~1500Nm 3 / m 3 , preferably 150-1000Nm 3 / m 3 .

[0023] (2) After the reaction effluent in the second hydro...

Embodiment 1

[0041]After the raw material oil A is mixed with the circulating hydrogen, it enters the second hydrogenation reaction zone together with the reaction product in the first reaction zone, and reacts under the action of the hydrofinishing catalyst. After the reaction product is cooled and separated, the obtained hydrogen-rich The gas is circulating hydrogen, and the obtained liquid phase fraction enters the fractionation system and is cut into naphtha fraction, light diesel fraction and heavy diesel fraction, among which the cut point of light diesel fraction and heavy diesel fraction is 320°C. 70% by weight of the heavy diesel oil fraction is mixed with new hydrogen and reacts with the hydrogenation upgrading catalyst in the first hydrogenation reaction zone, and the remaining heavy diesel oil fraction is mixed with the light diesel oil fraction to obtain a clean diesel product, wherein the hydrogenation upgrading The packing volume ratio of the mass and the hydrotreating cataly...

Embodiment 2

[0043] The raw material oil B is mixed with the circulating hydrogen and enters the second hydrogenation reaction zone together with the reaction product in the first reaction zone, and reacts under the action of the hydrofinishing catalyst, and the reaction product is cooled and separated, and the obtained hydrogen-rich The gas is circulating hydrogen, and the obtained liquid phase fraction enters the fractionation system and is cut into naphtha fraction, light diesel fraction and heavy diesel fraction, among which the cut point of light diesel fraction and heavy diesel fraction is 320°C. 80% by weight of the heavy diesel oil fraction is mixed with new hydrogen and reacts with the hydrogenation upgrading catalyst in the first hydrogenation reaction zone, and the remaining heavy diesel oil fraction is mixed with the light diesel oil fraction to obtain a clean diesel product. The packing volume ratio of the mass and the hydrotreating catalyst is 4:6. The reaction conditions of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com