Distillation dehydration device and process for co-producing ethanol fuels and custom grade edible alcohols

A technology for edible alcohol and fuel ethanol, which is used in chemical instruments and methods, preparation of organic compounds, separation/purification of hydroxyl compounds, etc. , the reduction of power generation of thermal power plants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

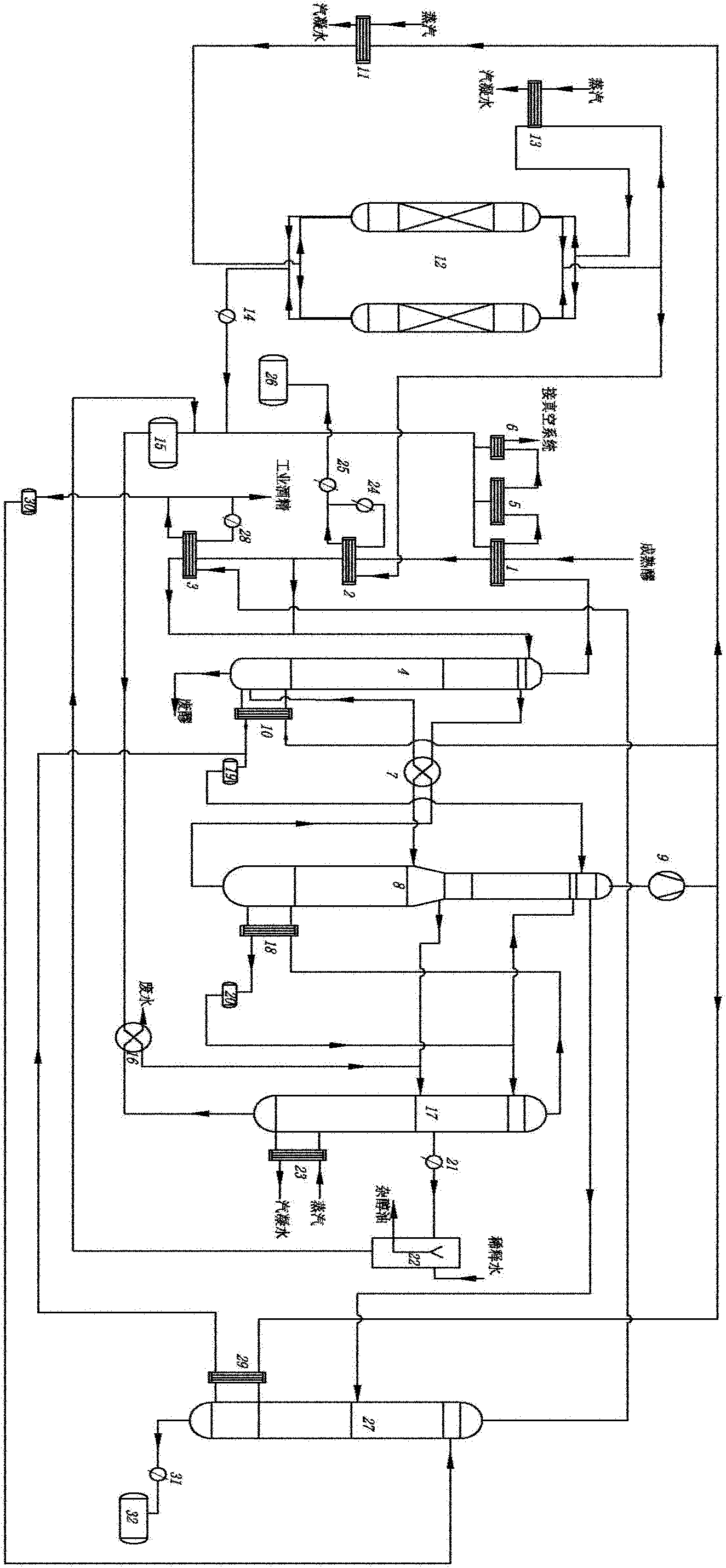

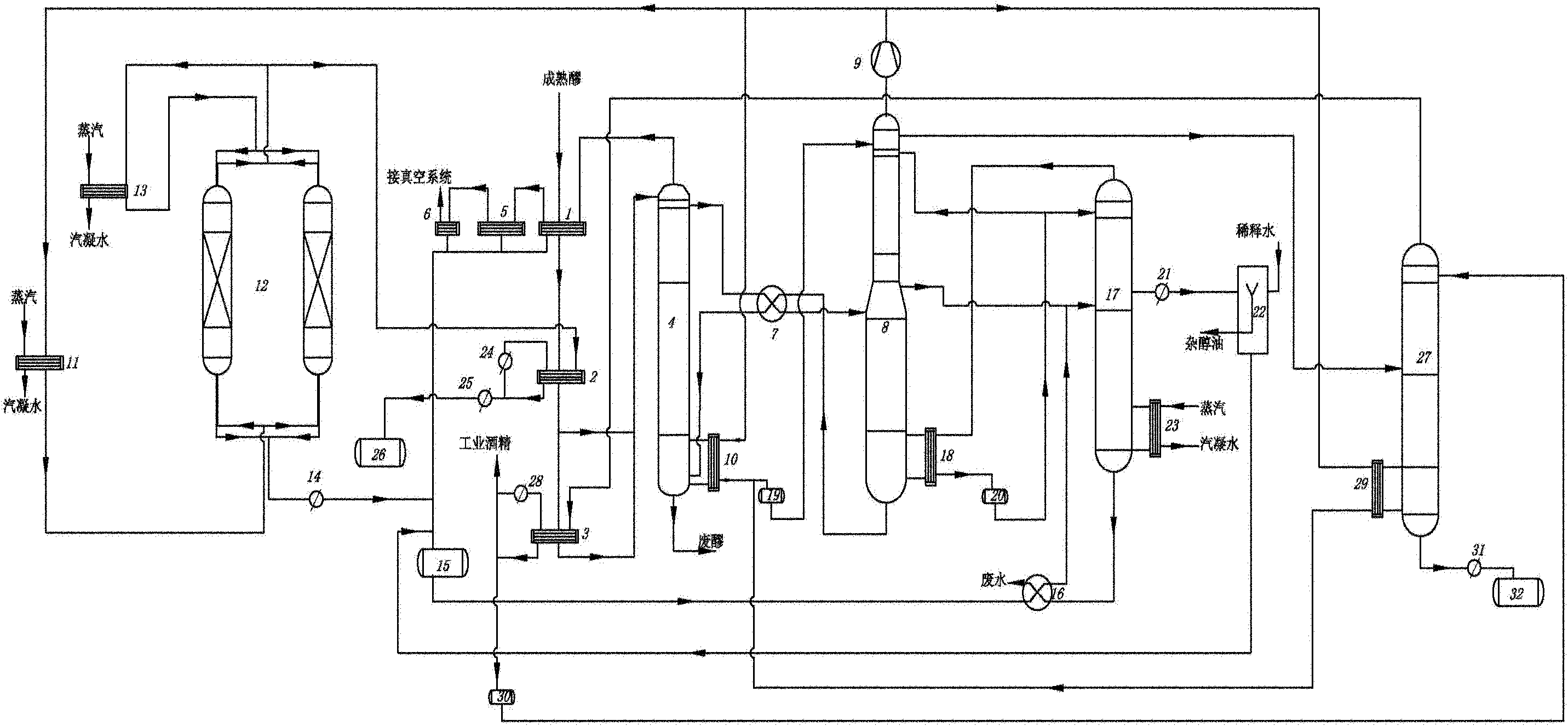

[0077] A kind of distilling and dehydrating device (such as figure 1 shown), comprising molecular sieve adsorption / desorption tower 12, crude distillation tower 4, combined tower 8, rectification tower 17, methanol tower 27, the first mash preheater 1 and the second mash preheater connected in series in the tube pass successively device 2 and the third mash preheater 3;

[0078] Wherein, the mash inlet of the first mash preheater 1 is connected with the fermented mature mash inlet, and the mash outlet is connected with the mash inlet of the second mash preheater 2; The end inlet is connected with the wine vapor outlet of the crude distillation tower 4; the hot end outlet includes a gas phase outlet and a liquid phase outlet, and the gas phase outlet is connected with the crude distillation tower condenser 5 and the crude distillation tower final stage condenser 6 successively, and the liquid phase outlet, the crude distillation tower The liquid phase outlet of the distillatio...

Embodiment 2

[0087] Utilize the device described in embodiment 1 to produce fuel ethanol, sweet potato fermented mature mash is raw material:

[0088] The 13% V / V fermented mature mash from the fermentation section has a temperature of 30°C and a flow rate of 144t / h. It is preheated to 45°C through the first mash preheater 1 and second mash preheater 2. After being preheated to 70°C, it enters the crude distillation tower 4, and the alcohol vapor (temperature 55°C, pressure -70kPa) at the top of the crude distillation tower 4 passes through the first preheater 1 of the mash, the crude distillation tower condenser 5 and the end of the crude distillation tower Enter the crude wine tank 15 after the stage condenser 6 condenses. Simultaneously, the light wine from the light wine vapor condenser 14 of the molecular sieve dehydration device and the light wine from the fusel oil separator 22 also enter the crude wine tank 15 . The crude wine is preheated to 90° C. by the crude wine preheater 16 ...

Embodiment 3

[0097] Utilize the device described in embodiment 1 to produce general-grade edible alcohol, cassava fermented mature mash is raw material:

[0098] The 13.5% V / V fermented mature mash from the fermentation section has a temperature of 30°C and a flow rate of 135t / h. It is preheated to 54°C by the first mash preheater 1 and the third mash preheater 3 After preheating to 75°C, it enters the crude distillation tower, and the alcohol vapor at the top of the crude distillation tower (temperature 75°C, pressure -30kPa) passes through the first preheater 1 of the mash, the condenser 5 of the crude distillation tower and the final stage of the crude distillation tower. Enter crude wine tank 15 after device 6 condenses. The light wine from fusel oil separator 22 also enters crude wine tank 15 simultaneously. The crude wine is preheated to 88° C. by the crude wine preheater 16 and then enters the rectification tower 17 for concentration treatment. The heat source is the waste water di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com