Low-pressure ethanol recovery device and method with triple effect rectification

An ethanol and low-pressure technology, which is applied in the field of ethanol recovery devices and methods, can solve the problems of large investment in heat exchange equipment, higher requirements for high-temperature resistance of gaskets, and easy occurrence of liquid leakage, etc., and achieves energy consumption reduction, high temperature resistance Reduced corrosion performance requirements and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

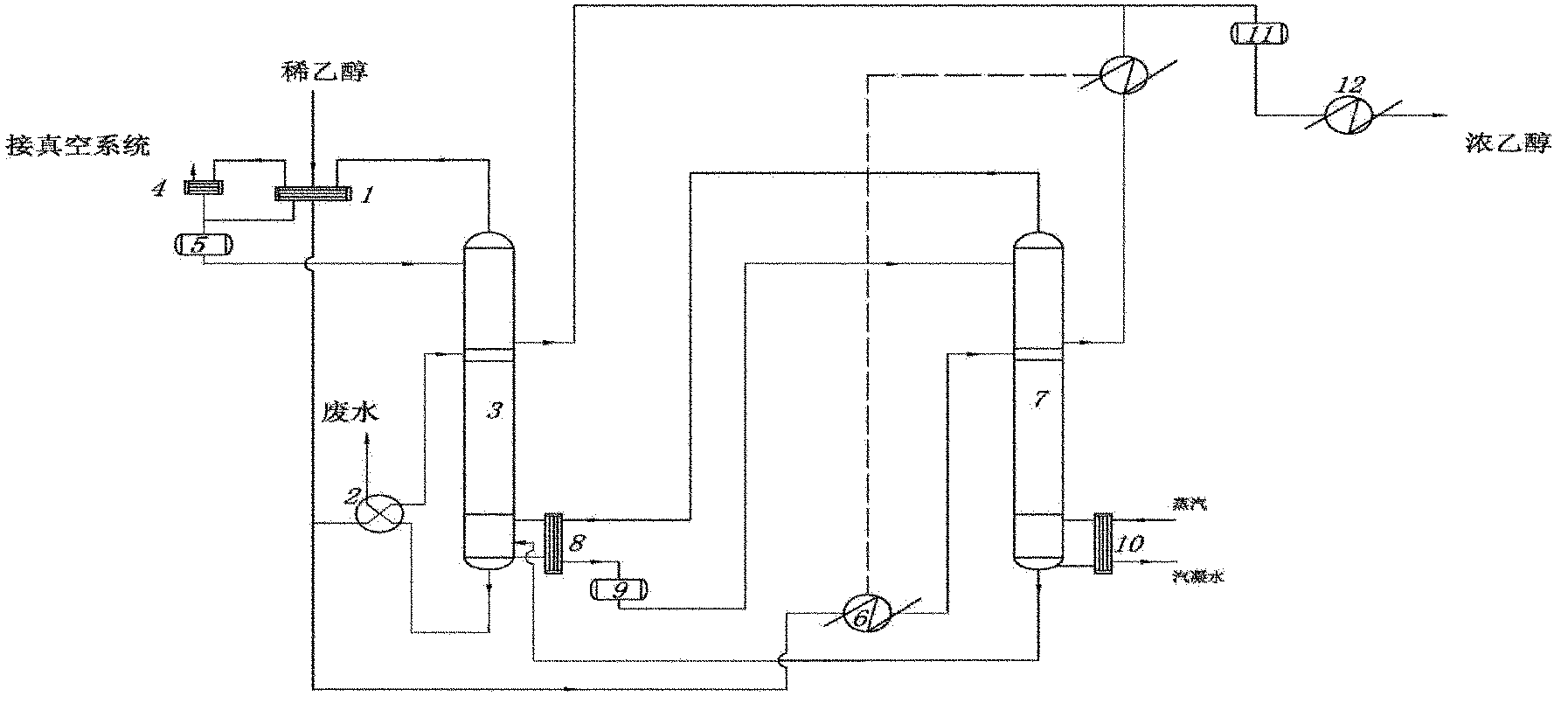

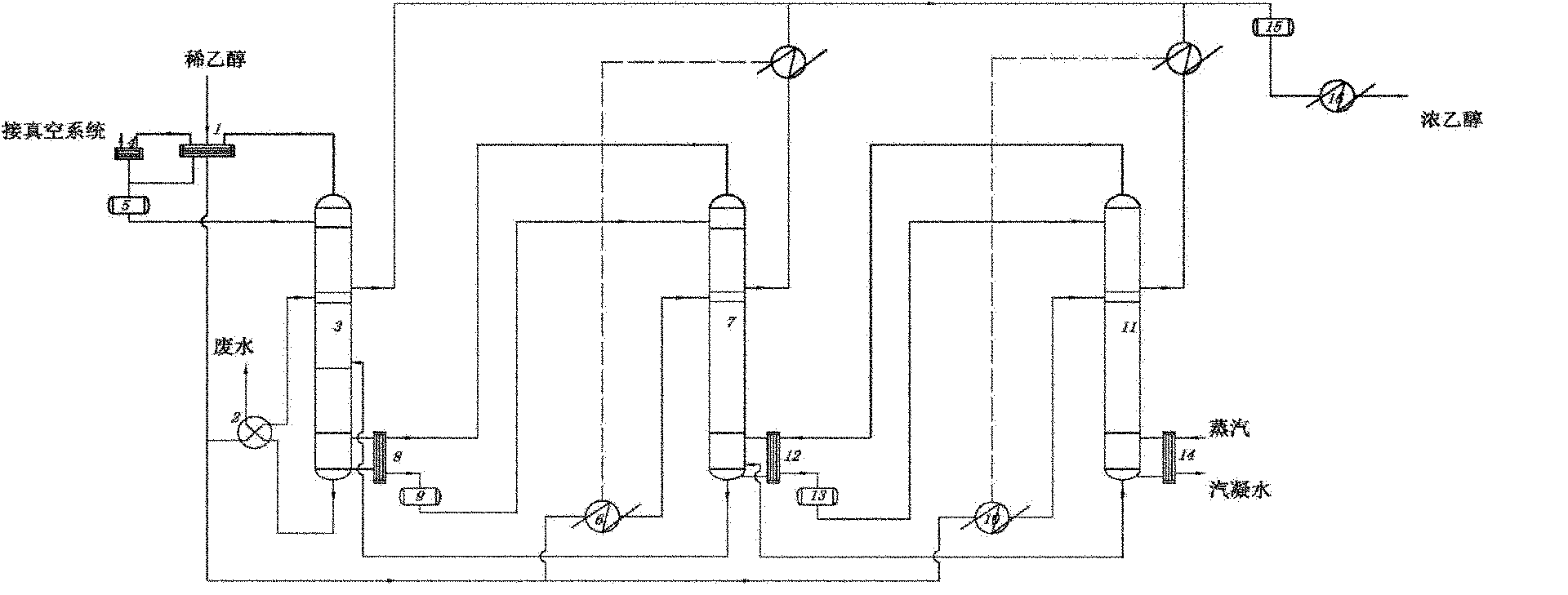

[0042] A kind of low-pressure three-effect rectification ethanol recovery device (such as figure 2 shown), including 1# rectification tower 3, 2# rectification tower 7, 3# rectification tower 11, rectification tower reboiler, vacuum system, dilute ethanol feed preheater 1, finished product cooler 16, etc. .

[0043] Ethanol content is the dilute ethanol (flow rate 200t / h of 50%V / V, 35 ℃ of temperature, sodium chloride content 4wt%) in the dilute ethanol feed preheater 1 through 1# rectifying tower top alcohol vapor preheating to After 50℃, divide into three strands:

[0044] The first dilute ethanol (accounting for 30% of the total feed mass flow rate) enters the 1# rectification tower after being preheated by 1# tower kettle waste water (88 ℃ of temperature) in the feed preheater 2 of 1# rectification tower Feed port, 1# rectification tower 3 is operated by vacuum system negative pressure, operating pressure -75kPa, after the wine vapor at the top is condensed by dilute et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com