Three-dimensional elliptical vibration cutting device

A technology of elliptical vibration and cutting devices, which is applied in the direction of driving devices, turning equipment, manufacturing tools, etc., can solve the problems of difficult tool holder design, difficult to obtain high-order modes, difficult system modeling and control, etc., and achieve simple and reliable preloading methods , achieve precise tracking control, simplify modeling and control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

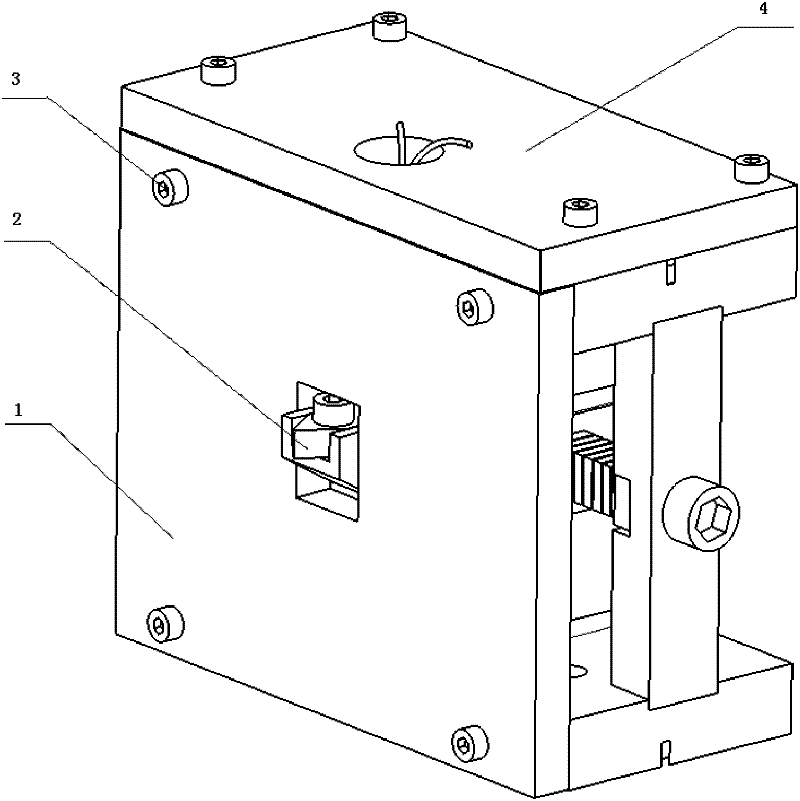

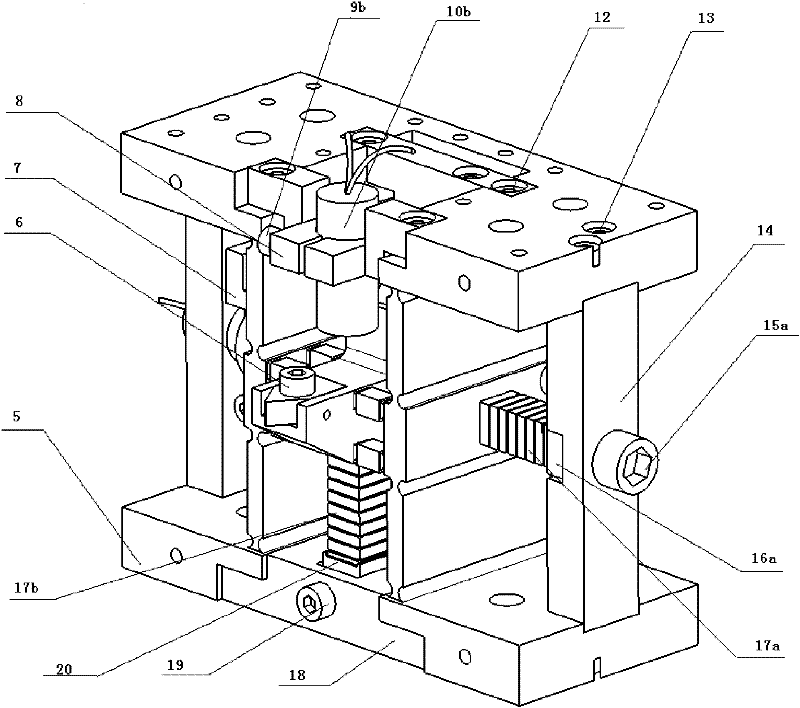

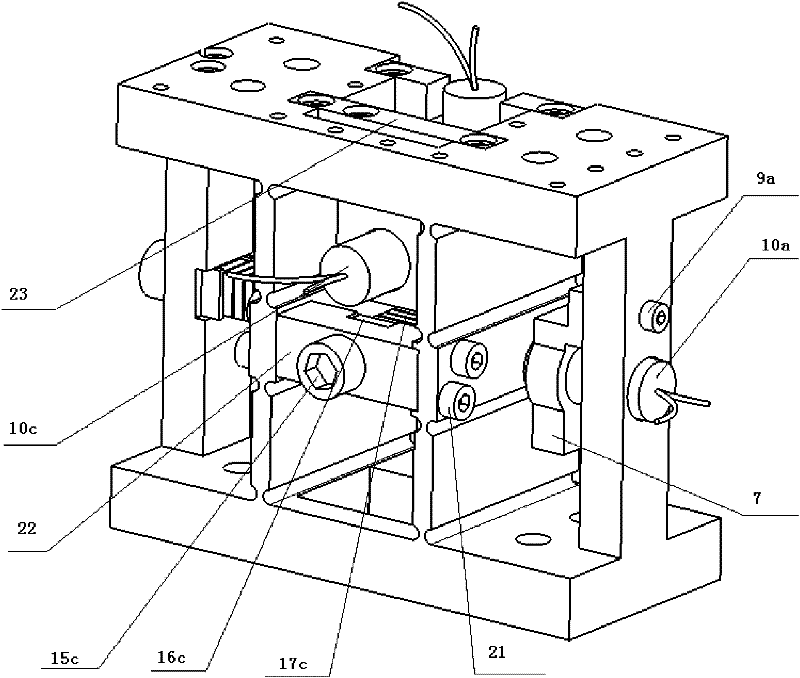

[0039] The front baffle 1 is fixedly connected with the base 5 through screws 3, the upper baffle 4 is fixedly connected with the base, the diamond tool 2 is fixedly connected with the tool holder on the base through set screws 16, and the X-direction support beam 14 is fixedly connected with set screws 2 13 is fixedly connected to the right side of the substrate, the fixed end of the X-direction piezoelectric stack 17a is fixedly connected to the X-direction piezoelectric stack seat 16a, and the X-direction piezoelectric stack seat 16a is connected to the X-direction support beam 14 through the X-direction pre-tightening bolt 15a Fixed connection, the X-direction stainless steel spherical body 11a is fixedly connected to the free end of the X-direction piezoelectric stack 17a, and the front end of the X-direction stainless steel spherical body 12a is connected to the X-direction right guide arm 511;

[0040] The fixed end of the Y-direction piezoelectric stack 17b is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com