Production process of rope ring-dyeing dark-blue yarn dyed fabric

A production process, dark blue technology, applied in the processing of textile materials, continuous processing of textile materials, dyeing methods, etc., can solve the problem that can not fully meet the problems of ultra-dark blue denim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

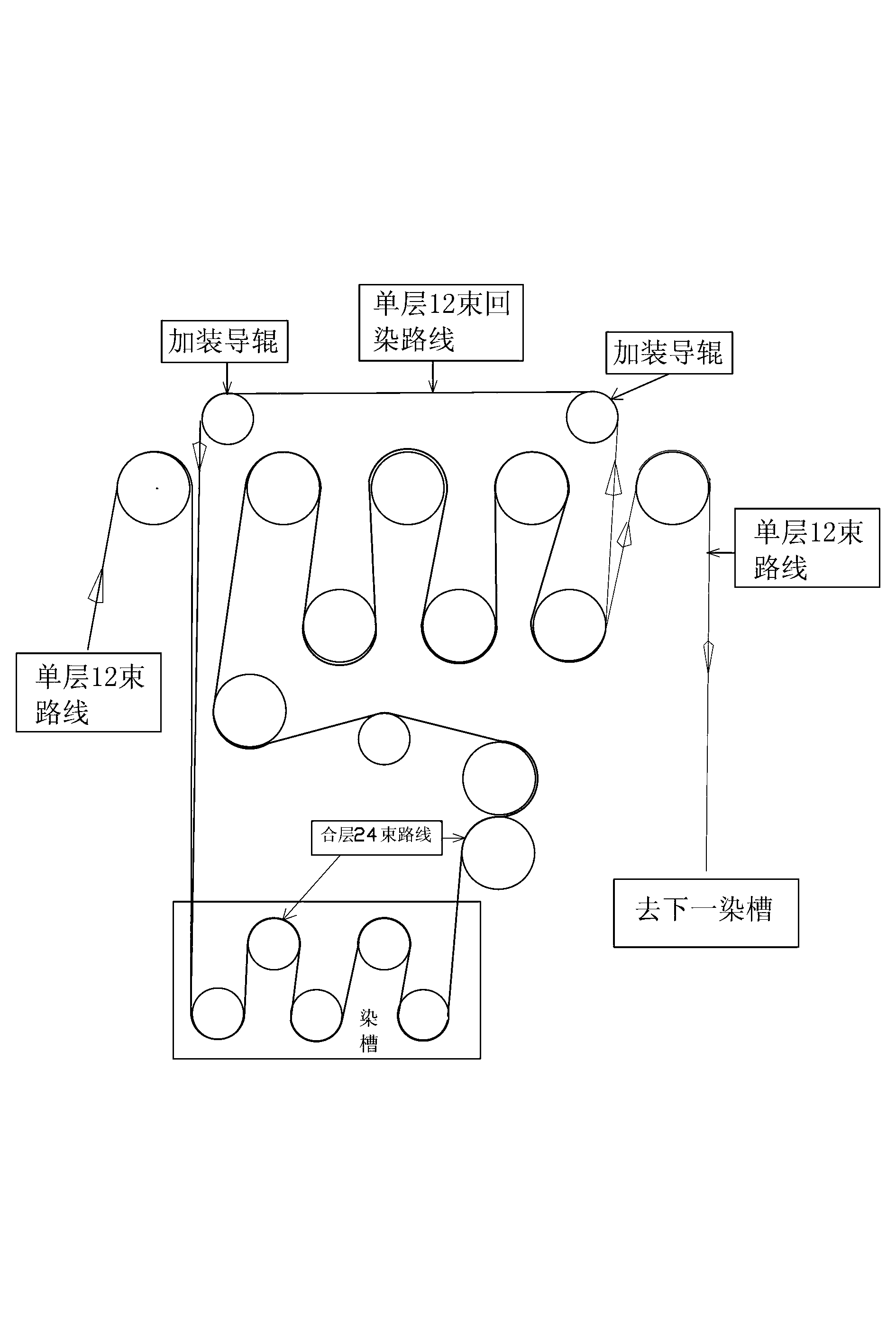

Image

Examples

Embodiment 1

[0041] 1. Speed: 20m / min, pure cotton R20 (ring spinning);

[0042] 2. Technological process: Ball warp shaft—soda boiling (60-90°C rolling pressure 0.4 Mpa)—hot water washing (60-80°C rolling pressure 0.5 Mpa)—cold water washing (1 rolling pressure 0.5 Mpa)- -dye tank (1 paddle pressure 0.5 Mpa)--oxidation stand--dye tank (2, paddle pressure 0.5 Mpa)-oxidation stand-dye tank (2 paddle pressure 0.5 Mpa)-oxidation stand-dye tank (3 rolling car pressure 0.5 Mpa)—oxidation frame-dye tank (4 rolling car pressure 0.5 Mpa)—oxidation frame—dye tank (5 rolling car pressure 0.5 Mpa) oxidation frame—dye tank (6 padding car pressure 0.5 Mpa) --Oxidation frame-dye tank (7 paddles, pressure 0.5 Mpa)--oxidation frame-dyeing tank (8 paddles, pressure 0.5 Mpa)--oxidation frame-dye tank (8 paddles, pressure 0.5 Mpa)--oxidation frame --dye tank (9 paddle pressure 0.5 Mpa)--oxidation frame-dye tank (10 paddle pressure 0.5 Mpa)-oxidation frame-dye tank (11 pad pressure 0.6 Mpa)-oxidation frame-c...

Embodiment 2

[0050] 1. Speed: 24M / min; OE10 (air spinning)

[0051] 2. Technological process: Ball warp shaft—soda boiling (60-90°C rolling pressure 0.4 Mpa)—hot water washing (60-80°C rolling pressure 0.5 Mpa)—cold water washing (1 rolling pressure 0.5 Mpa)- -dye tank (1 paddle pressure 0.5 Mpa)--oxidation stand--dye tank (2, paddle pressure 0.5 Mpa)-oxidation stand-dye tank (2 paddle pressure 0.5 Mpa)-oxidation stand-dye tank (3 rolling car pressure 0.5 Mpa)—oxidation stand-dye tank (4 rolling car pressure 0.5 Mpa)—oxidation stand—dye tank (5 rolling car pressure 0.5 Mpa)oxidation stand—dye tank (5 rolling car pressure 0.5 Mpa) --Oxidation rack—dye tank (6 paddles, pressure 0.5 Mpa)--oxidation rack—dye tank (7 paddles, pressure 0.5 Mpa)--oxidation rack-dye tank (8 paddles, pressure 0.5 Mpa)--oxidation rack -dye tank (8 paddle pressure 0.5 Mpa)--oxidation frame-dye tank (9 paddle pressure 0.5 Mpa)-oxidation frame-dye tank (10 paddle pressure 0.5 Mpa)-oxidation frame-dye tank (11 Pad car...

Embodiment 3

[0059] 1. Speed: 24m / min; RSB12 (ring spinning slub)

[0060] 2. Technological process: Ball warp shaft—soda boiling (60-90°C rolling pressure 0.4 Mpa)—hot water washing (60-80°C rolling pressure 0.5 Mpa)—cold water washing (1 rolling pressure 0.5 Mpa)- -dye tank (1 paddle pressure 0.5 Mpa)--oxidation stand--dye tank (2, paddle pressure 0.5 Mpa)-oxidation stand-dye tank (2 paddle pressure 0.5 Mpa)-oxidation stand-dye tank (3 rolling car pressure 0.5 Mpa)—oxidation stand-dye tank (4 rolling car pressure 0.5 Mpa)—oxidation stand—dye tank (5 rolling car pressure 0.5 Mpa)oxidation stand—dye tank (5 rolling car pressure 0.5 Mpa) --Oxidation rack—dye tank (6 paddles, pressure 0.5 Mpa)--oxidation rack—dye tank (7 paddles, pressure 0.5 Mpa)--oxidation rack-dye tank (8 paddles, pressure 0.5 Mpa)--oxidation rack -dye tank (8 paddle pressure 0.5 Mpa)--oxidation frame-dye tank (9 paddle pressure 0.5 Mpa)-oxidation frame-dye tank (10 paddle pressure 0.5 Mpa)-oxidation frame-dye tank (11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com