Method for cyclic dyeing by using wastewater after dyeing in yarn-dyeing field

A technology of wastewater recycling and dyeing wastewater, applied in the fields of textile dyeing, dyeing and weaving, can solve the problem of not being suitable for the reuse and dyeing of reactive dyes, and achieve the effect of reducing comprehensive production and processing costs, reducing production, and achieving obvious benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

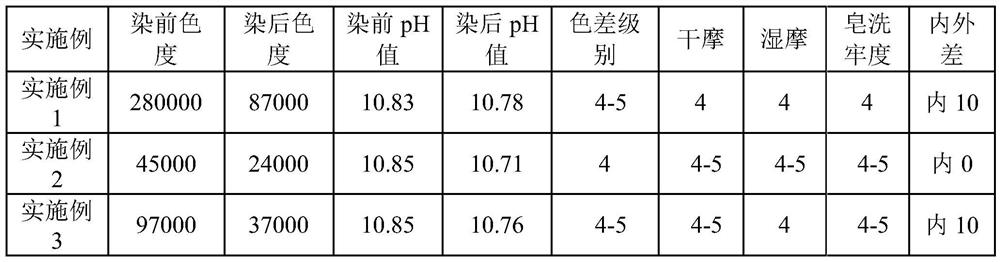

Embodiment 1

[0040] (1) Circular dyeing of dyeing wastewater:

[0041] Using 10.0% (o.w.f) reactive dyes, commercial reactive dyes are NAVYGN (6.3% o.w.f), RED6 (1.9% o.w.f), Y4RN01 (1.8% o.w.f);

[0042] The yarn is made of pure cotton bobbin;

[0043] Dyeing process data: the amount of reactive dyes is 10% o.w.f, the dyeing bath ratio is 1:4, the dyeing temperature is 90°C, the amount of sodium sulfate is 50g / L, and the amount of soda ash is 25g / L;

[0044] Dyeing process: Put the pure cotton bobbin into the high-temperature and high-pressure yarn dyeing machine, collect the reactive dye dyeing wastewater after the previous dyeing and add it to the high-temperature and high-pressure yarn dyeing machine, raise the temperature to 35°C, adjust the pump speed to 80%, and the flow rate to 7500L / MIN / KG, pressure difference 1.2, add 50g / L Yuanming powder and keep it for 10min, then add 10.0% o.w.f reactive dye, then control the heating rate to 2.0℃ / min, raise the temperature to 90℃, keep it f...

Embodiment 2

[0050] (1) Circular dyeing of dyeing wastewater:

[0051] Using 2.0% (o.w.f) reactive dyes, the commercial reactive dyes are BLUEHL (1.1% o.w.f), RK3BS (0.4% o.w.f), YK3RS (0.5% o.w.f);

[0052] The yarn is made of pure cotton bobbin;

[0053] Dyeing process data: the amount of reactive dyes is 2% o.w.f, the dyeing bath ratio is 1:20, the dyeing temperature is 60°C, the amount of sodium sulfate is 0.1g / L, and the amount of soda ash is 10g / L;

[0054] Dyeing process: Put the pure cotton bobbin into the high-temperature and high-pressure yarn dyeing machine, collect the reactive dye dyeing wastewater after the previous dyeing and add it to the high-temperature and high-pressure yarn dyeing machine, raise the temperature to 40°C, adjust the pump speed to 90%, and the flow rate to 9000L / MIN / KG, pressure difference 1.4, add 0.1g / L Yuanming powder and keep it for 10min, then add 2.0% o.w.f reactive dye, then control the heating rate to 1.0℃ / min, raise the temperature to 60℃, keep ...

Embodiment 3

[0060] (1) Circular dyeing of dyeing wastewater:

[0061] Using 5.0% (o.w.f) reactive dyes, commercial reactive dyes are selected from BXBLN (2.8% o.w.f), NXGN (1.3% o.w.f), RX6BN (0.9% o.w.f);

[0062] The yarn is made of pure cotton bobbin;

[0063] Dyeing process data: the dosage of reactive dyes is 5% o.w.f, the dyeing bath ratio is 1:10, the dyeing temperature is 95°C, the dosage of sodium sulfate is 30g / L, and the dosage of soda ash is 15g / L;

[0064] Dyeing process: Put the pure cotton bobbin into the high-temperature and high-pressure yarn dyeing machine, collect the reactive dye dyeing wastewater after the previous dyeing and add it to the high-temperature and high-pressure yarn dyeing machine, raise the temperature to 45°C, adjust the pump speed to 95%, and the flow rate to 10500L / MIN / KG, pressure difference 1.5, add 30g / L Yuanming powder and keep it for 10min, then add 5.0% o.w.f reactive dye, then control the heating rate to 0.5℃ / min, raise the temperature to 95℃...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com