Disperse dye composition and applications thereof

A disperse dye and composition technology, applied in the field of dye composition, to achieve the effect of exempting the reduction cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

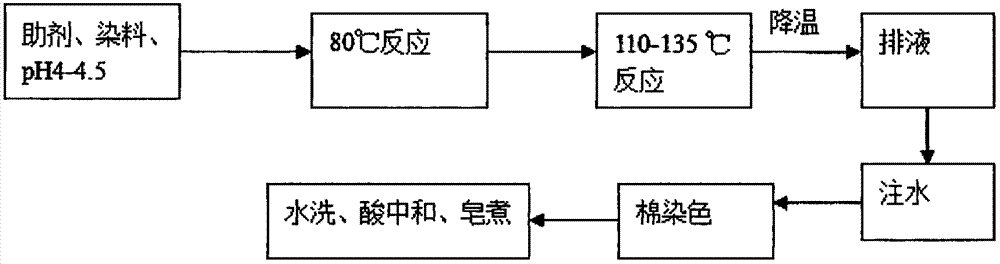

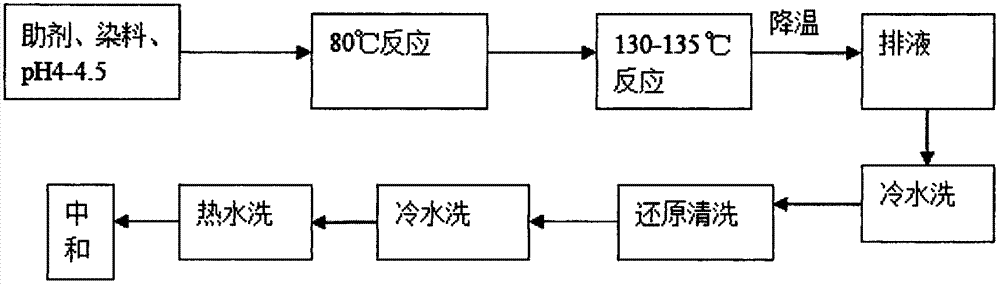

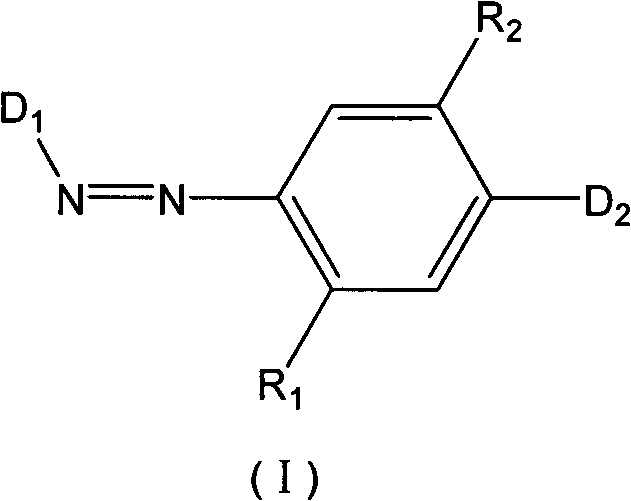

Method used

Image

Examples

Embodiment 4

[0105] The energy consumption contrast of embodiment 4 and comparative example 1 :

[0106]The chromatic monomers contained in the disperse dye composition in Example 4 are: Disperse Orange 30#, Disperse Red 60# and Disperse Blue 56#; the contained auxiliary agents are sodium lignosulfonate and leveling agent; traditional dyeing methods are used , using water-based dispersion at 130-135°C, in a high-temperature and high-pressure dyeing machine, use 6X105Pa high-temperature steam to heat the dyeing process, that is, use 160°C high-temperature steam to heat the liquid with dye, and directly pass the high-temperature steam into the dye liquid.

[0107] The energy consumption in Example 4 is: the difference in heating value per unit volume of water heated from 30°C to 130°C: 503.67-125.69=377.98J / kg, the heating value released by cooling the unit volume of water from 160°C to 120°C: 675.33-503.67= 171.66J / kg, 120°C dyeing steam consumption per unit volume of water (theoretical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com