Anti-fouling and water-resistant silicone-acrylate emulsion and preparation method thereof

A silicone-acrylic emulsion and aqueous solution technology, applied in antifouling/underwater coatings, applications, coatings, etc., can solve the problems of difficulty in the selection of copolymerized silicone monomers, affecting the stability of the emulsion polymerization reaction, and achieve a stable polymerization process. Control, good storage stability, small particle size of emulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

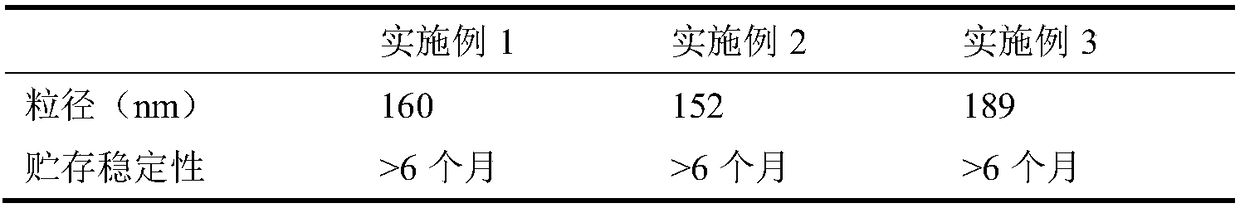

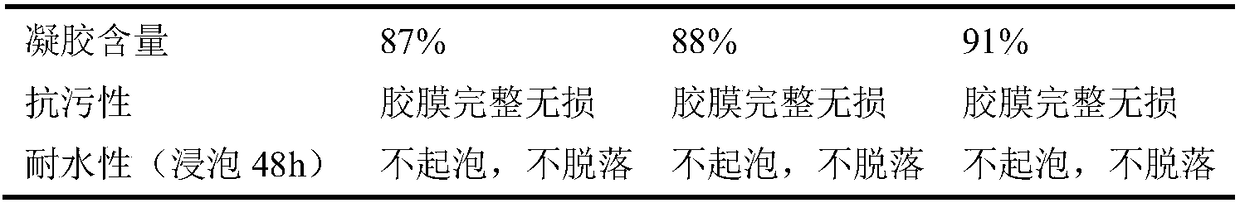

Embodiment 1

[0038] Raw material manufacturers used in the following:

[0039] n-butyl acrylate monomer (Guangzhou Zhongye Chemical Co., Ltd.), AC-76 (Ark (Fogang) Chemical Material Co., Ltd.), methyl methacrylate monomer (Guangzhou Zhongye Chemical Co., Ltd.), isopropyl Benzene hydroperoxide (SIGMA-ALDRICH company), N,N-dimethyltoluidine (Tianjin CITIC Kaitai Chemical Co., Ltd.), NE-10 (ADEKA company), SE-1025A (ADEKA company), sodium persulfate ( Suzhou Huahang Chemical Technology Co., Ltd.), isopropanol (Yonghua Chemical Technology (Jiangsu) Co., Ltd.), sodium bicarbonate (Shanghai Abby Chemical Reagent Co., Ltd.), tert-butyl hydroperoxide (Shanghai Baiyi Chemical Co., Ltd.) , Diaobaifen (Shanghai Fengrui Chemical Co., Ltd.).

[0040] Preparation of silicone acrylic emulsion:

[0041] (1) Preparation of shell monomer dropwise addition phase:

[0042] Mix 5g n-butyl acrylate monomer, 20g AC-76, 7g methyl methacrylate monomer, 0.7g cumene hydroperoxide, 0.6g N,N-dimethyltoluidine, 1g N...

Embodiment 2

[0045] Raw material manufacturers used in the following:

[0046] n-butyl acrylate monomer (Guangzhou Zhongye Chemical Co., Ltd.), AC-76 (Ark (Fogang) Chemical Material Co., Ltd.), methyl methacrylate monomer (Guangzhou Zhongye Chemical Co., Ltd.), isopropyl Benzene hydroperoxide (SIGMA-ALDRICH company), N,N-dimethyltoluidine (Tianjin CITIC Kaitai Chemical Co., Ltd.), NE-10 (ADEKA company), SE-1025A (ADEKA company), sodium persulfate ( Suzhou Huahang Chemical Technology Co., Ltd.), isopropanol (Yonghua Chemical Technology (Jiangsu) Co., Ltd.), sodium bicarbonate (Shanghai Abby Chemical Reagent Co., Ltd.), tert-butyl hydroperoxide (Shanghai Baiyi Chemical Co., Ltd.) , Diaobaifen (Shanghai Fengrui Chemical Co., Ltd.).

[0047] Preparation of silicone acrylic emulsion:

[0048] (1) Preparation of shell monomer dropwise addition phase:

[0049] Mix 5g n-butyl acrylate monomer, 21g AC-76, 7g methyl methacrylate monomer, 0.6g cumene hydroperoxide, 0.55g N,N-dimethyltoluidine, 1.1...

Embodiment 3

[0052] Raw material manufacturers used in the following:

[0053] n-butyl acrylate monomer (Guangzhou Zhongye Chemical Co., Ltd.), AC-76 (Ark (Fogang) Chemical Material Co., Ltd.), methyl methacrylate monomer (Guangzhou Zhongye Chemical Co., Ltd.), isopropyl Benzene hydroperoxide (SIGMA-ALDRICH company), N,N-dimethyltoluidine (Tianjin CITIC Kaitai Chemical Co., Ltd.), NE-10 (ADEKA company), SE-1025A (ADEKA company), sodium persulfate ( Suzhou Huahang Chemical Technology Co., Ltd.), isopropanol (Yonghua Chemical Technology (Jiangsu) Co., Ltd.), sodium bicarbonate (Shanghai Abby Chemical Reagent Co., Ltd.), tert-butyl hydroperoxide (Shanghai Baiyi Chemical Co., Ltd.) , Diaobaifen (Shanghai Fengrui Chemical Co., Ltd.).

[0054] Preparation of silicone acrylic emulsion:

[0055] (1) Preparation of shell monomer dropwise addition phase:

[0056] Mix 5g n-butyl acrylate monomer, 25g AC-76, 10g methyl methacrylate monomer, 0.8g cumene hydroperoxide, 0.6g N,N-dimethyltoluidine, 2g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com