Method for manufacturing pole coil

A technology of a magnetic pole coil and a manufacturing method, which is applied in the directions of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of increased short circuit between turns of the magnetic pole coil, burning of copper compacts and induction coils, and uneven dissolution of silver solder pieces, etc. The effect of reducing unit cost, good welding joint quality, and expanding the design size range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

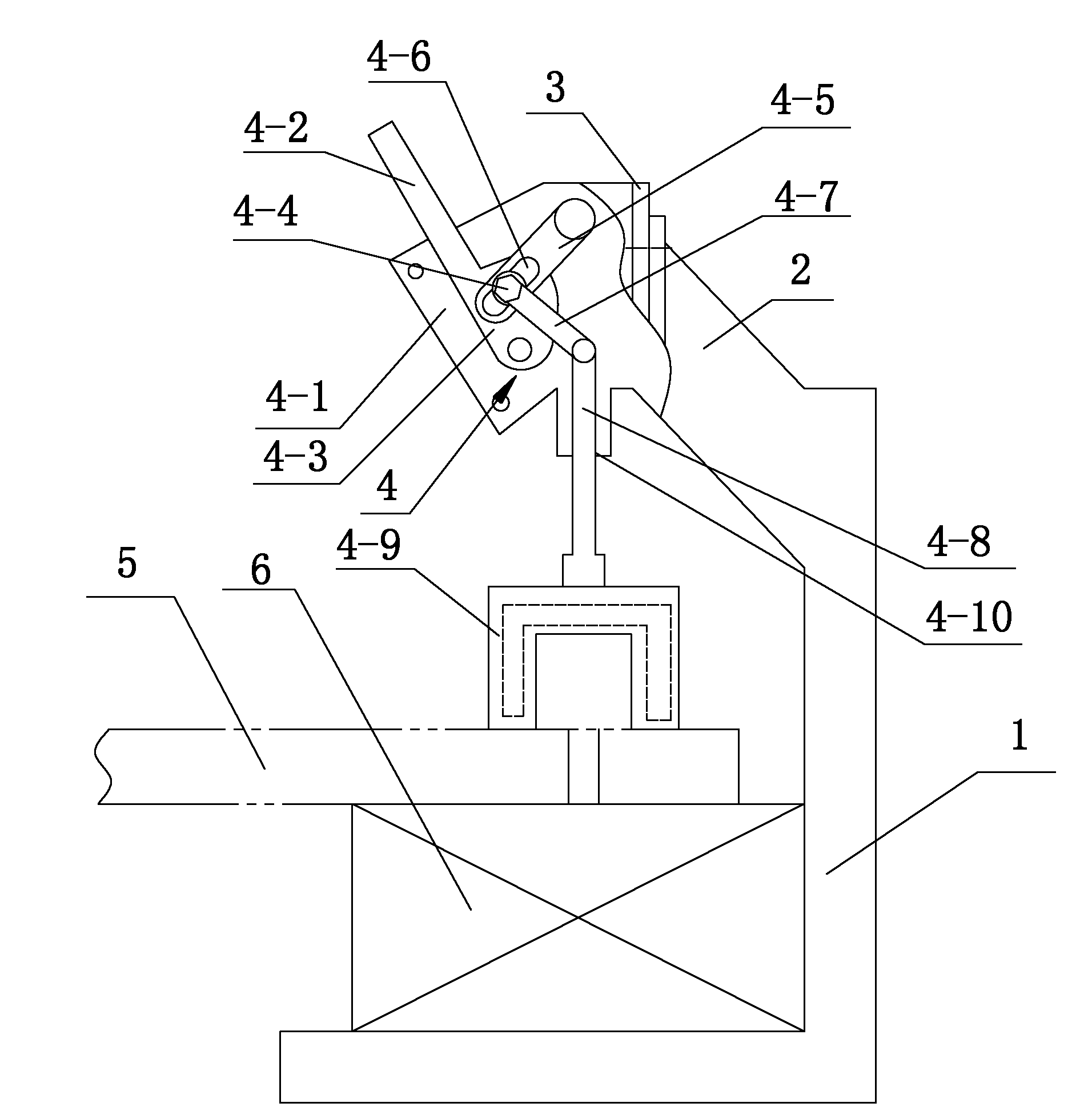

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0016] see figure 1 ,

[0017] A method of manufacturing a magnetic pole coil:

[0018] 1. First, install the tightening and positioning device according to claim 1 on the brazing machine, and adjust its position to detect whether the power supply is turned on and whether the cooling system is operating normally;

[0019] 2. Place the solder piece between the welding ports of the two copper bars, and discharge the copper to be welded on the center of the induction coil. Adjust the adjustment plate horizontally to ensure that the U-shaped indenter is facing the center of the induction coil. After adjustment, manipulate the movable handle Press the U-shaped pressure head on the two copper bars to be welded;

[0020] 3. After adjusting the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com