Method for preparing regenerated high-shrinkage polyester by waste polyester alcoholysis method

A waste polyester, high shrinkage technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of large fluctuations in the content of diethylene glycol by-products, deterioration of the hue of recycled polyester, and difficult control of melting point, etc., to achieve stable alcohol Improve product quality, reduce by-products, and achieve high-value recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

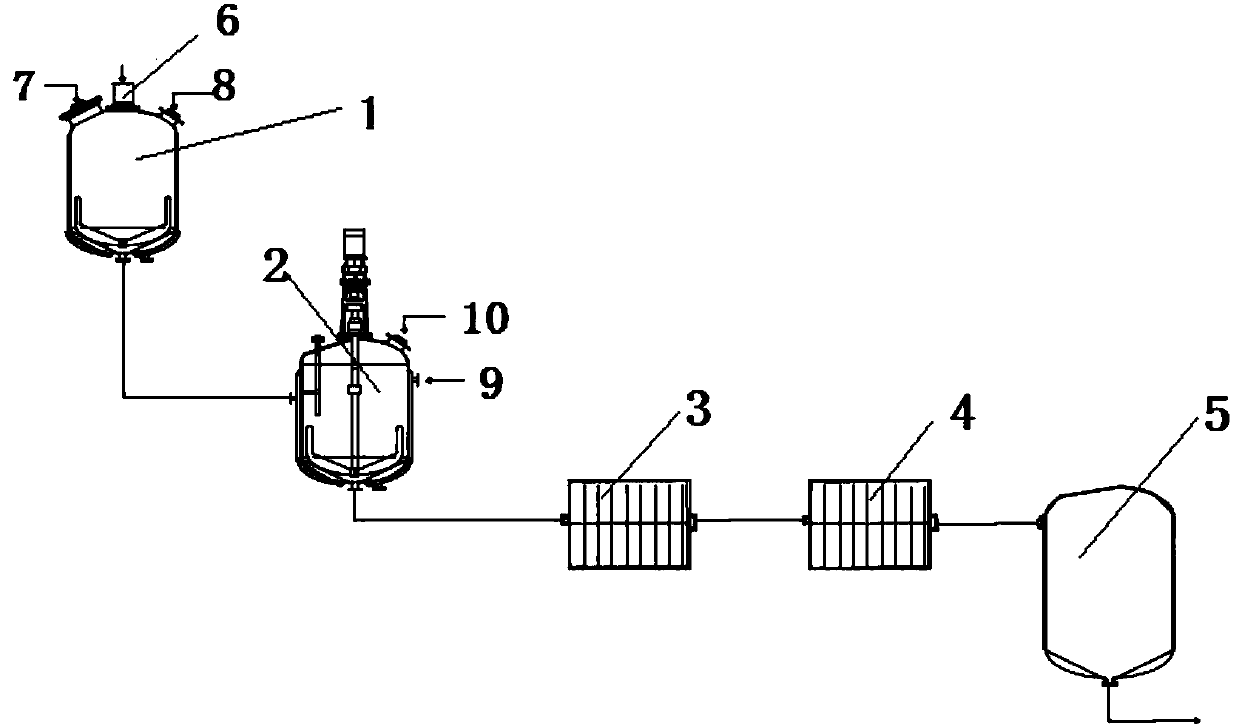

[0017] A kind of waste polyester alcoholysis method of the present embodiment prepares the method for regenerated high-shrinkage polyester, such as figure 1 As shown, it includes the following steps: 1) pretreatment of waste polyester, directly smashing the clean waste polyester blocks into the feed bin, cutting the clean waste polyester fibers into the feed bin, and waste polyester bottle flakes Sorting, cleaning, impurity removal, crushing, cutting, and then feeding into the silo, and then mixing ingredients for the next process; 2) alcoholysis of waste polyester, the pretreated waste polyester, according to waste polyester (waste polyester) The molar percentage ratio of 1:2 is put into the alcoholysis kettle 1, and the alcoholysis kettle 1 contains ethylene terephthalate and oligomer (mother liquor) (adding in the first additive inlet 8), wherein the addition of ethylene terephthalate and oligomer (mother liquor) accounts for 40% of the total mass percentage of dropping int...

Embodiment 2

[0020]As described in Example 1, the difference is: the molar percentage of waste polyester and ethylene glycol is 1:4, and the alcoholysis still contains ethylene terephthalate and oligomers (mother liquor), wherein the The addition amount of ethylene glycol diformate and oligomer (mother liquor) accounted for 30% of the total mass percentage of input waste polyester, the reaction temperature was 200° C., and the reaction time was 4 hours. Add 0.2‰ (accounting for the mass percent of the product obtained) of phosphorous acid stabilizer; the esterification reaction temperature is 230 ° C, the reaction time is 1.5 hours, and simultaneously add 10% (accounting for the mass percent of the product obtained) of isophthalic acid (IPA), 0.3% (accounting for the mass percent of the obtained product) of DEG, so that the DEG content (accounting for the obtained product mass percent) of the esterified product is 2.5%. The temperature of polycondensation-I and polycondensation-II is contr...

Embodiment 3

[0023] As described in Example 1, the difference is: the molar percentage of waste polyester and ethylene glycol is 1:6, and the alcoholysis still contains ethylene terephthalate and oligomers (mother liquor), wherein the The addition amount of ethylene glycol diformate and oligomer (mother liquor) accounted for 20% of the total mass percentage of input waste polyester, the reaction temperature was 190° C., and the reaction time was 2 hours. Add 0.2‰ (accounting for the mass percent of the product obtained) of trimethyl phosphate stabilizer; the esterification reaction temperature is 220 ° C, the reaction time is 1 hour, and simultaneously add 15% (accounting for the mass percent of the product obtained) of isophthalic acid (IPA), 0.2% (accounting for the mass percent of the obtained product) of DEG, so that the DEG content (accounting for the obtained product mass percent) of the esterified product is 2.4%. The temperature of polycondensation-I and polycondensation-II is cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com