3D Curved ultrathin glass bending and forming device and manufacturing method

A technology of ultra-thin glass and bending forming, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problems of lower pass rate in the production process, poor bending accuracy, cracking of ultra-thin glass, etc., and achieve saving Effect of working time, reducing stress, ensuring light transmission and cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

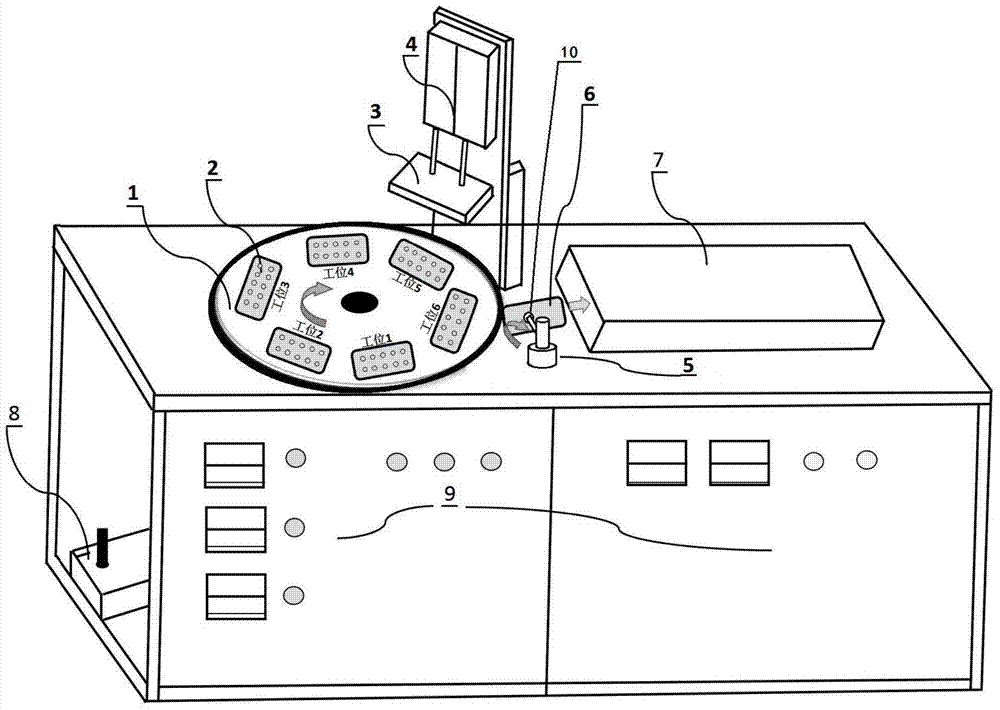

[0031] The present invention provides such figure 1 A 3D curved ultra-thin glass bending forming device shown includes a turntable 1 , a die 2 , a punch 3 , a cylinder 4 , a glass transfer mechanism 5 , a tunnel furnace 7 , a vacuum system 8 and an electrical control operating system 9 .

[0032] Described die 2 is arranged evenly around the turntable 1; Described punch 3 is arranged on the corresponding top of the die 2 of turntable 1 station, and cylinder 4 is set above punch 3; Described turntable 1, The glass transfer mechanism 5 and the tunnel furnace 7 are sequentially connected; the electrical control operating system 9 is arranged on the side of the device; the vacuum system 8 is arranged in the casing of the molding device.

[0033] The turntable 1 is made of quartz glass, and a rotating mechanism is arranged in the housing of the molding device corresponding to the turntable 1; the turntable 1 is evenly provided with 6 concave molds 2 made of quartz glass material, a...

Embodiment 2

[0039] Based on the device of embodiment 1, a manufacturing method of a 3D curved ultra-thin glass is as follows:

[0040] (1) Automatically controlled by the temperature controller, die 2 is raised to 450°C at a rate of 30°C / min, and then raised to 650°C at a rate of 50°C / min, and the temperature of punch 3 is raised to 50°C / min Speed up to 650°C.

[0041] (2) The ultra-thin glass 6 with a thickness of 0.3 mm is cut to a size of 154.6×74.8 mm in length and width, and is ground and chamfered by a CNC machine tool. ° on the die 2, and turn on the turntable 1 to rotate clockwise.

[0042] (3) When the die 2 on the turntable 1 rotates to the position corresponding to the punch 3, press the punch 3 down, and when the temperature reaches the softening temperature of ultra-thin glass 650 °C, vacuumize to -0.15 Pa, and use a negative Press to preform the ultra-thin glass 6 for 10 seconds, then apply a pressure of 0.2 Pa on the punch 3 and keep the pressure for 5 seconds, then fil...

Embodiment 3

[0045] Based on the device of embodiment 1, a manufacturing method of a 3D curved ultra-thin glass is as follows:

[0046] (1) Automatically controlled by the temperature controller, die 2 is raised to 500°C at a rate of 10°C / min, and then raised to 680°C at a rate of 100°C / min, and the temperature of punch 3 is raised to 100°C / min Speed up to 680°C.

[0047] (2) The ultra-thin glass 6 with a thickness of 0.2 mm is cut to a size of 154.6×74.8 mm in length and width, and is ground and chamfered by a CNC machine tool, and then the ultra-thin glass 6 is placed 2.6 mm inwards from the two long sides in turn. On the die 2 bent at 5°, turn on the turntable 1 and turn it clockwise.

[0048] (3) When the die 2 on the turntable 1 rotates to the position corresponding to the punch 3, press the punch 3 down, and when the temperature reaches the softening temperature of ultra-thin glass at 680 °C, vacuumize to -0.1 Pa, and use a negative Press to preform the ultra-thin glass 6 for 8 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com