Low thermal expansion coefficient NaMxAlySiz high entropy alloy and preparation method thereof

A low thermal expansion coefficient, high entropy alloy technology, applied in the field of superalloy materials, can solve the problems of large expansion rate, limited service temperature, steep expansion curve, etc., and achieve the effect of lower thermal expansion coefficient, lower thermal expansion coefficient change rate, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

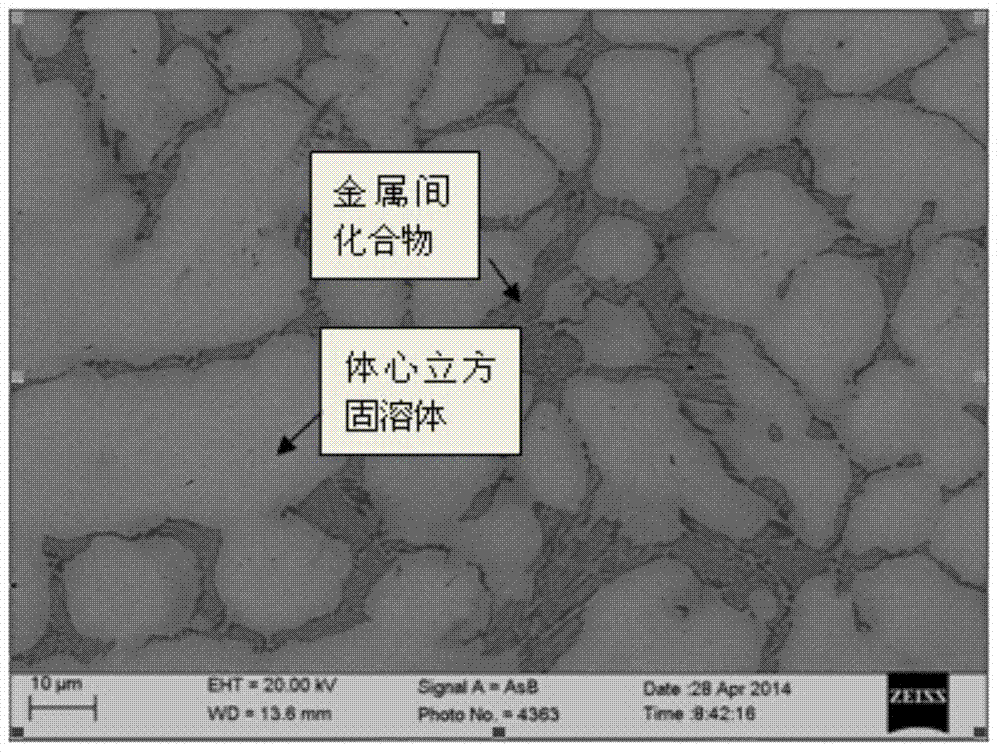

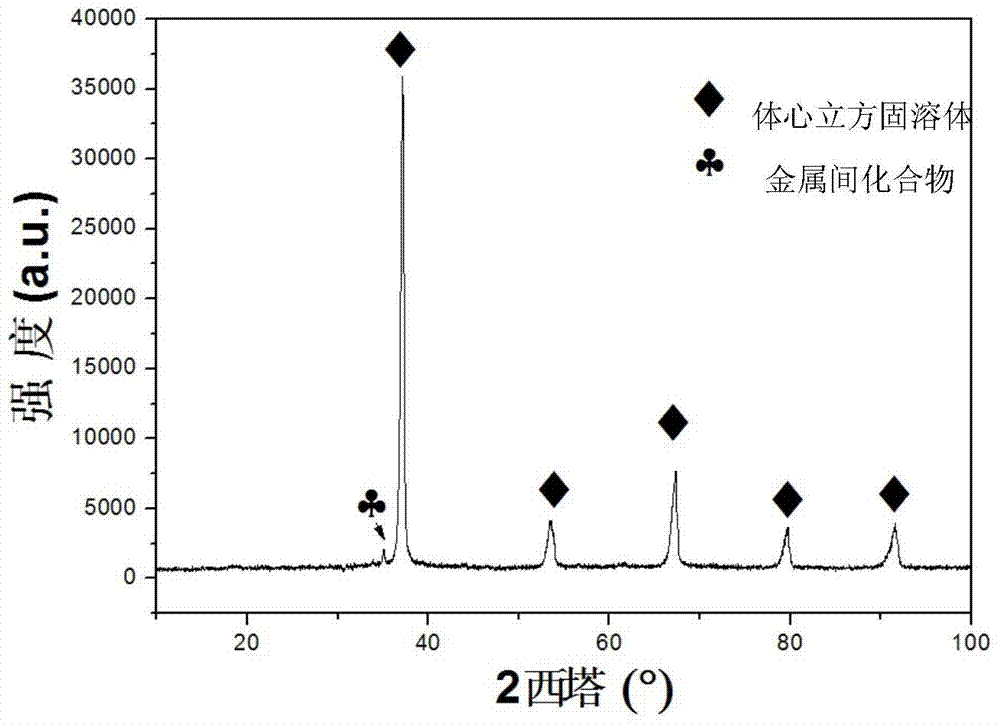

Embodiment 1

[0035] 1. Alloy composition

[0036] The alloy composition of embodiment 1 is Ta 5 Nb 17.5 f 17.5 Zr 17.5 Ti 17.5 Mo 5 W 5 Al 10 Si 5 .

[0037] 2. Alloy melting

[0038] Alloy melting involves the following steps:

[0039] Step 1: The atomic percentage expression of the design alloy composition is Ta 5 Nb 17.5 f 17.5 Zr 17.5 Ti 17.5 Mo 5 W 5 Al 10 Si 5 , then convert the atomic percentage of the determined raw materials into a mass ratio and weigh each raw material respectively;

[0040] Step 2: Set Mo and Ti as a group, W and Hf as a group, and Ta, Nb and Zr as a group, respectively add them to a vacuum arc melting furnace, place them in a crucible at an angle of 20°-40° to the horizontal plane The included angle is smelted twice to obtain a pre-alloyed ingot of two metals, and then all the pre-alloyed ingots of two metals are melted together to obtain a pre-alloyed ingot containing N;

[0041] Step 3: Put the Si and Al weighed in step 1 together with th...

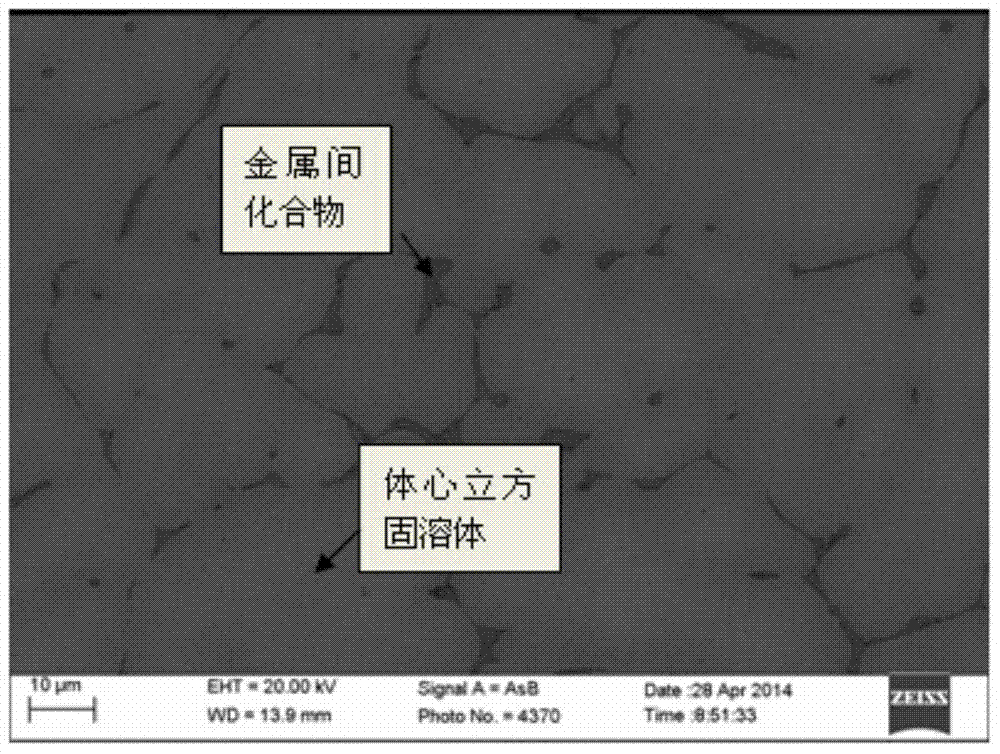

Embodiment 2

[0045] 1. Alloy composition

[0046] The alloy composition of embodiment 2 is Ta 10 Nb 19 f 5 Zr 5 Ti 7 Mo 8 W 35 V 10 Si 1 .

[0047] 2. Alloy melting

[0048] Alloy melting involves the following steps:

[0049] Step 1: The atomic percentage expression of the design alloy composition is Ta 10 Nb 19 f 5 Zr 5 Ti 7 Mo 8 W 35 V 10 Si 1 , and then convert the determined atomic percentage of raw materials into mass ratio and weigh each raw material respectively;

[0050] Step 2: Set Mo and Ti as a group, W and Hf as a group, and Ta, Nb and Zr as a group, respectively add them to a vacuum arc melting furnace, place them in a crucible at an angle of 20°-40° to the horizontal plane The included angle is smelted twice to obtain a pre-alloyed ingot of two metals, and then all the pre-alloyed ingots of two metals are melted together to obtain a pre-alloyed ingot containing N;

[0051] Step 3: Put the V weighed in step 1 and the pre-alloyed ingot containing N obtaine...

Embodiment 3

[0056] 1. Alloy composition

[0057] The alloy composition of embodiment 3 is Ta 8 Nb 5 f 35 Zr 12 Ti 5 Mo 15 W 15 co 1 Al 1 Si 3 .

[0058] 2. Alloy melting

[0059] Alloy melting involves the following steps:

[0060] Step 1: The atomic percentage expression of the design alloy composition is Ta 8 Nb 5 f 35 Zr 12 Ti 5 Mo 15 W 15 co 1 Al 1 Si 3 , and then convert the determined atomic percentage of raw materials into mass ratio and weigh each raw material respectively;

[0061] Step 2: Set Mo and Ti as a group, W and Hf as a group, and Ta, Nb and Zr as a group, respectively add them to a vacuum arc melting furnace, place them in a crucible at an angle of 20°-40° to the horizontal plane The included angle is smelted twice to obtain a pre-alloyed ingot of two metals, and then all the pre-alloyed ingots of two metals are melted together to obtain a pre-alloyed ingot containing N;

[0062] Step 3: Put the Co weighed in Step 1 and the N-containing pre-alloye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com