Manufacturing method of wavelength conversion device

一种波长转换装置、制造方法的技术,应用在照明装置的零部件、放映装置、照明装置等方向,能够解决刮涂工艺要求很高、制作周期长、制造难度大等问题,达到降低制备难度、缩短生产周期、提高热稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

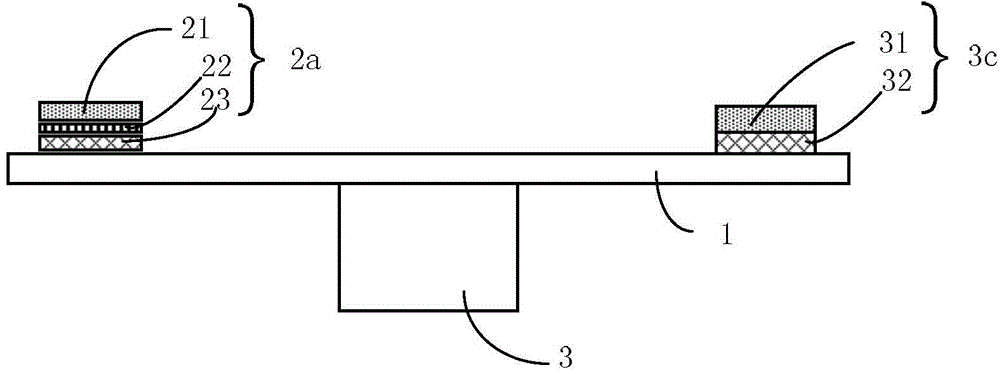

[0042] refer to figure 1 and image 3 , the manufacturing method of the wavelength conversion device is: first prepare three wavelength conversion modules 2a, 2b, 2c respectively, and then install and fix the three wavelength conversion modules on one side surface of a bottom plate 1.

[0043] The manufacturing steps of each wavelength conversion module 2a / 2b / 2c are divided into:

[0044] S1. Prepare diffuse reflection paste and phosphor paste;

[0045] S2. Brushing the diffuse reflection slurry on the ceramic substrate and sintering to form a diffuse reflection layer;

[0046] S3. Apply phosphor paste on the diffuse reflection layer and sinter to form a phosphor layer to obtain a wavelength conversion module.

[0047] wavelength conversion module 2a such as figure 2 As shown, it includes a ceramic substrate 23 , a diffuse reflection layer 22 and a phosphor layer 21 , and the three are stacked in sequence and closely attached in pairs.

[0048] In step S1, the diffuse re...

Embodiment 2

[0076] The difference between this embodiment and the first embodiment is that the steps of manufacturing each wavelength conversion module are different, and for other features not described, please refer to the first embodiment.

[0077] like Figure 4 As shown, in this embodiment, the manufacturing steps of the wavelength conversion module are divided into:

[0078] P1. Prepare diffuse reflection paste and phosphor paste;

[0079] P2. Apply phosphor paste on a substrate and sinter to form a phosphor layer;

[0080] P3. Apply diffuse reflection slurry on the phosphor layer and sinter it to form a diffuse reflection layer;

[0081] P4. Demoulding the substrate, taking out a diffuse reflection layer with a phosphor layer attached to one surface, and bonding or sintering the other side of the diffuse reflection layer to the ceramic substrate to obtain a wavelength conversion module.

[0082] Each step is described in detail below.

[0083] For step P1, reference may be made...

Embodiment 3

[0089] The difference between this embodiment and Embodiments 1 and 2 is that some but not all of the wavelength conversion modules are replaced by fluorescent ceramic modules. Therefore, this embodiment is as follows Figure 5 As shown, a part of the wavelength conversion modules are performed according to the steps of the first or second embodiment, as shown in the flow on the left, and the other part is replaced with a fluorescent ceramic module as shown in the flow on the right.

[0090] Correspondingly, the steps for preparing the fluorescent ceramic module are as follows:

[0091] Q1. Obtain fluorescent ceramic blocks;

[0092] Q2. Coating a total reflection dielectric film on the bottom surface of the fluorescent ceramic block.

[0093] Further, step Q3 may also be included:

[0094] Q3: Coating a metal protective film on the outer surface of the total reflection dielectric film.

[0095] like figure 2 As shown, the fluorescent ceramic module 3c thus produced inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com