Ceramic granule reinforced composite material

A ceramic particle, reinforced composite technology, applied in welding/cutting media/materials, welding media, manufacturing tools, etc., to achieve the effect of reducing requirements, enhancing life, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

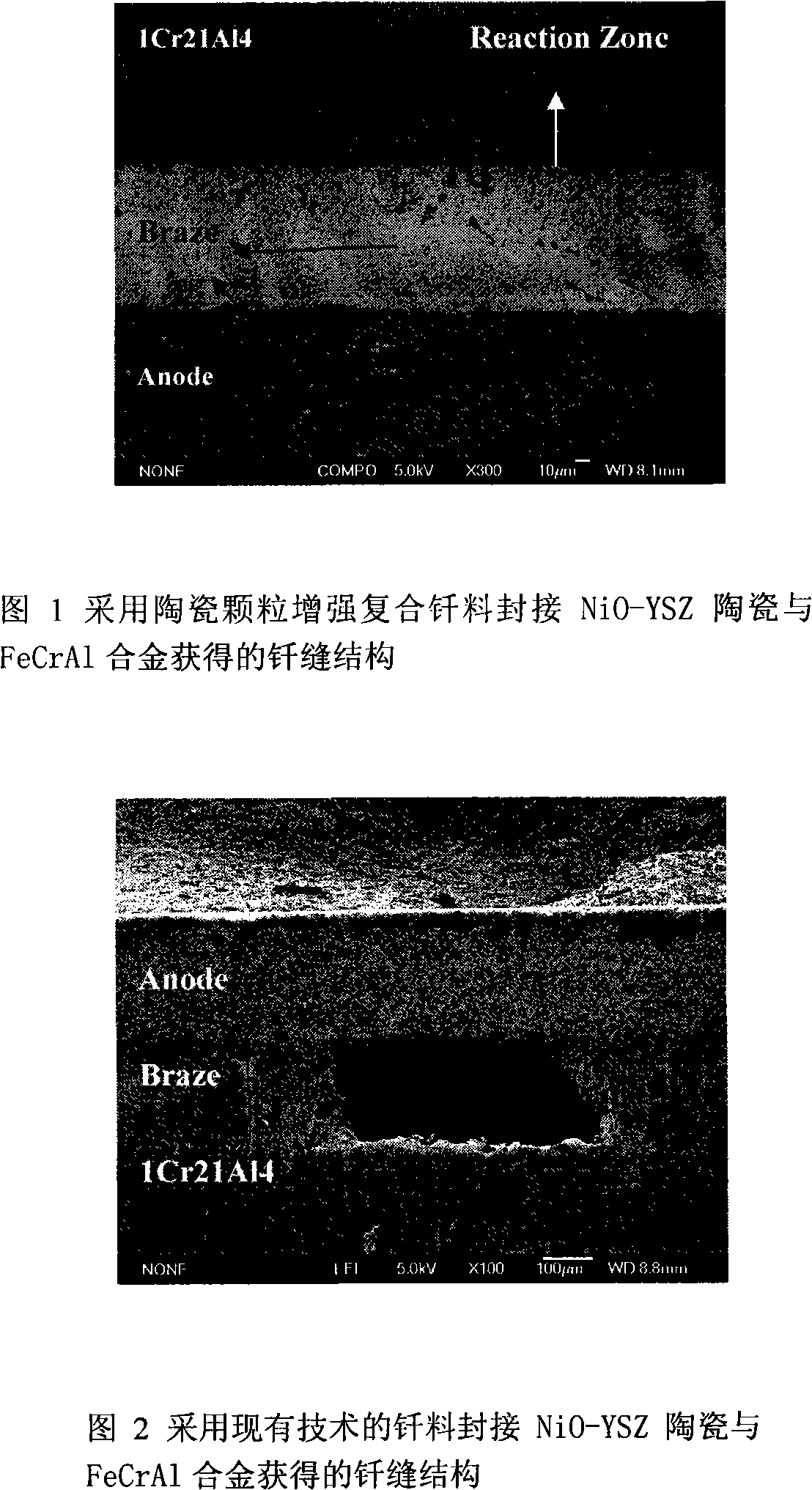

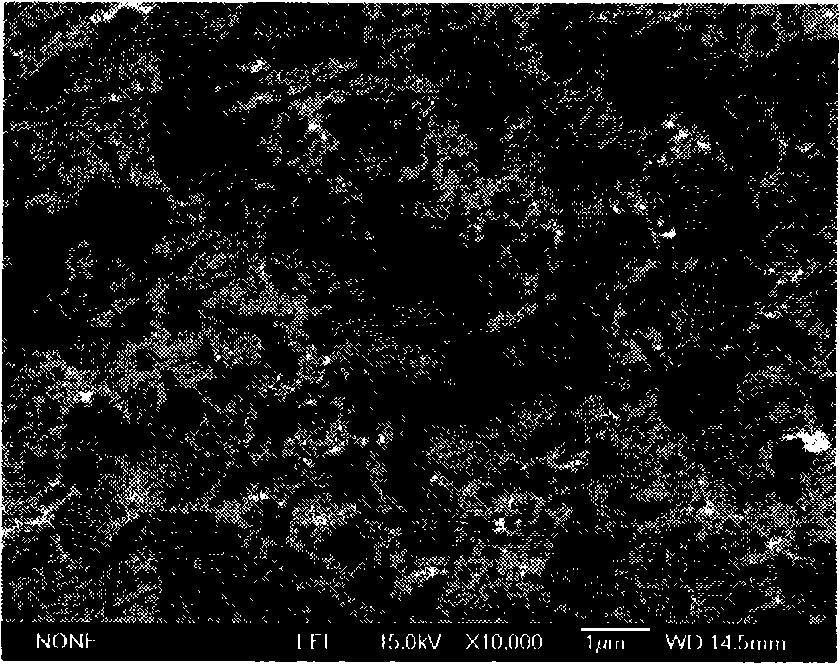

[0022] The ceramic particle reinforced composite brazing filler metal used for ceramic / ceramic or ceramic / metal brazing is composed of Ag powder and Cu powder mixed with metal powder A and ceramic particles B in a mass ratio; the average particle size of Ag powder is 1 μm, The average particle size of Cu powder is 0.5 μm, and the average particle size of reinforcement YSZ ceramic powder is 0.5 μm. It is brazing through solder in the air, using Cu to form CuO and intermetallic compounds during the brazing process to enhance the welding strength, and adding ceramic particles to the generation of pores. The preparation is as follows: firstly, Ag powder and Cu powder are mixed in a molar ratio (Ag: 92 mol%; Cu: 8 mol%) to form Ag-8Cu metal powder. Then 2% (mass ratio) of YSZ particles relative to the total mass was added. Use a mixer to mix evenly. Then pour the mixed brazing filler metal into a mortar, add a binder (terpineol solution of ethyl cellulose) at a solid content of 8...

Embodiment 2

[0024] The ceramic particle reinforced composite brazing filler metal was prepared in the same way as in Example 1, except that the ceramic particles were ZrO 2 , with an average particle size of 1 μm.

Embodiment 3

[0026] The ceramic particle reinforced composite brazing filler metal is prepared in the same way as in Example 1, except that the ceramic particles are Al 2 O 3 , with an average particle size of 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com