Silicon carbide granule enhancement type tin-silver-zinc compound solder and manufacture method thereof

A silicon carbide particle and enhanced technology, which is applied in welding equipment, welding/cutting media/materials, welding media, etc., can solve problems such as not being able to meet environmental protection, and achieve good mechanical properties, simple preparation methods, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

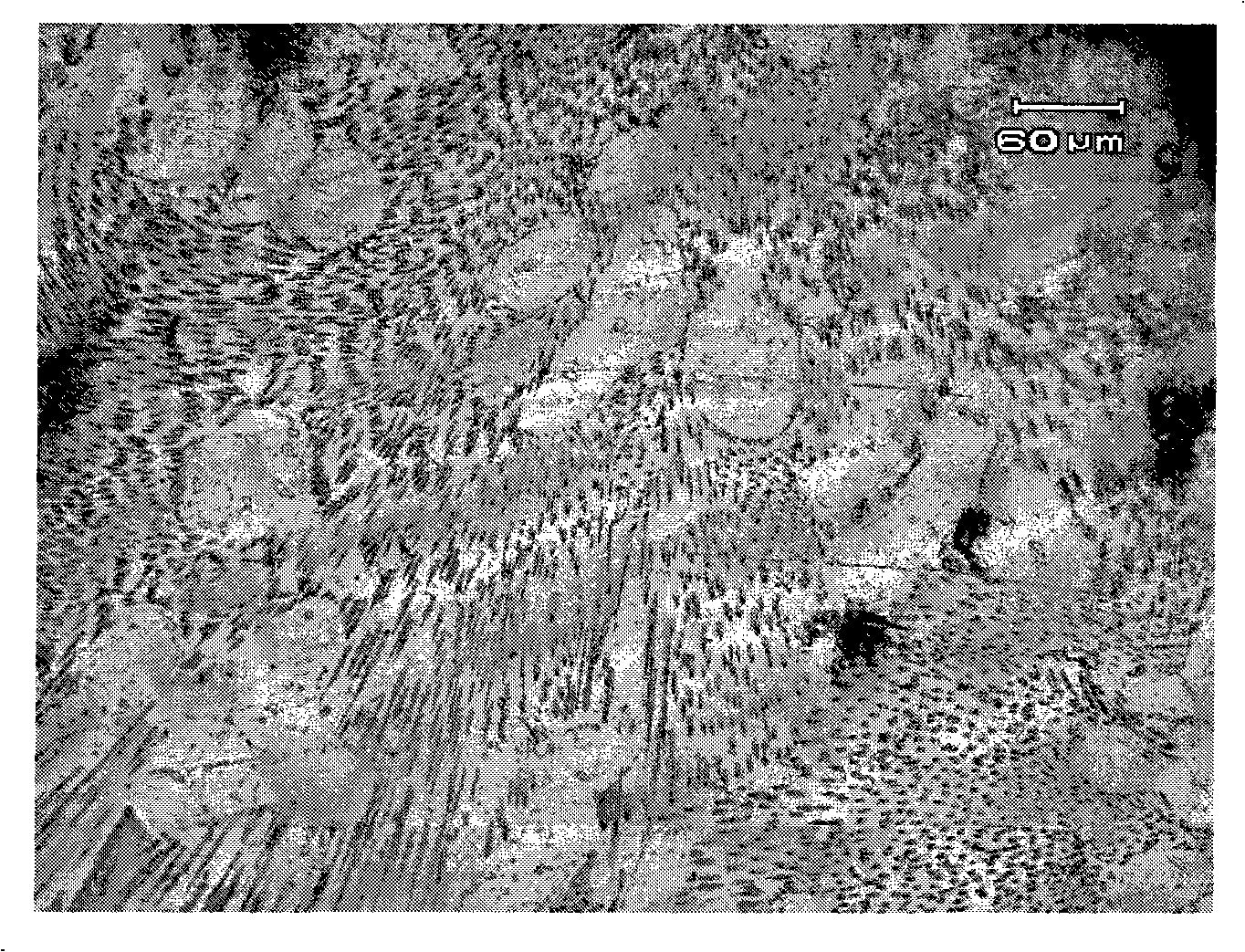

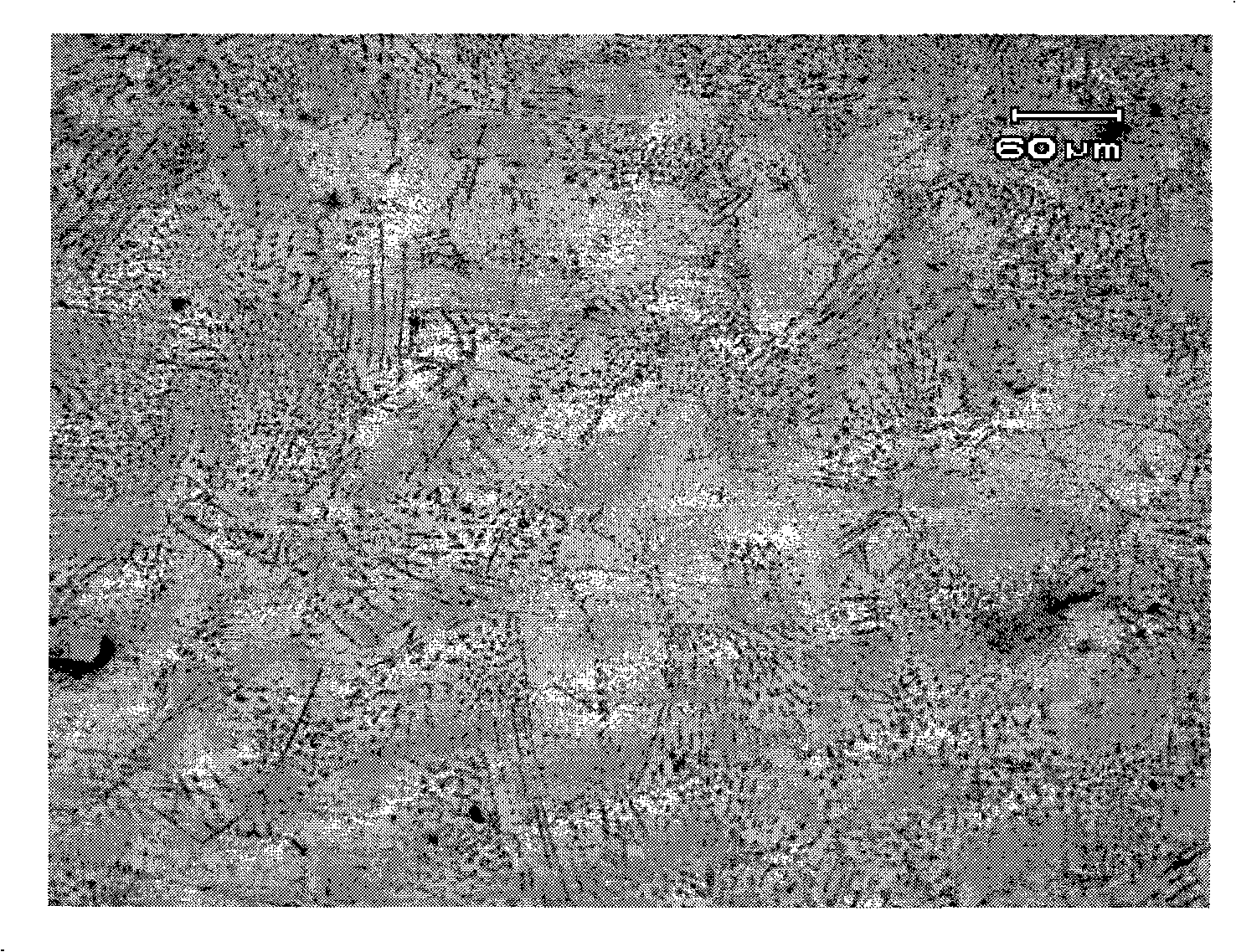

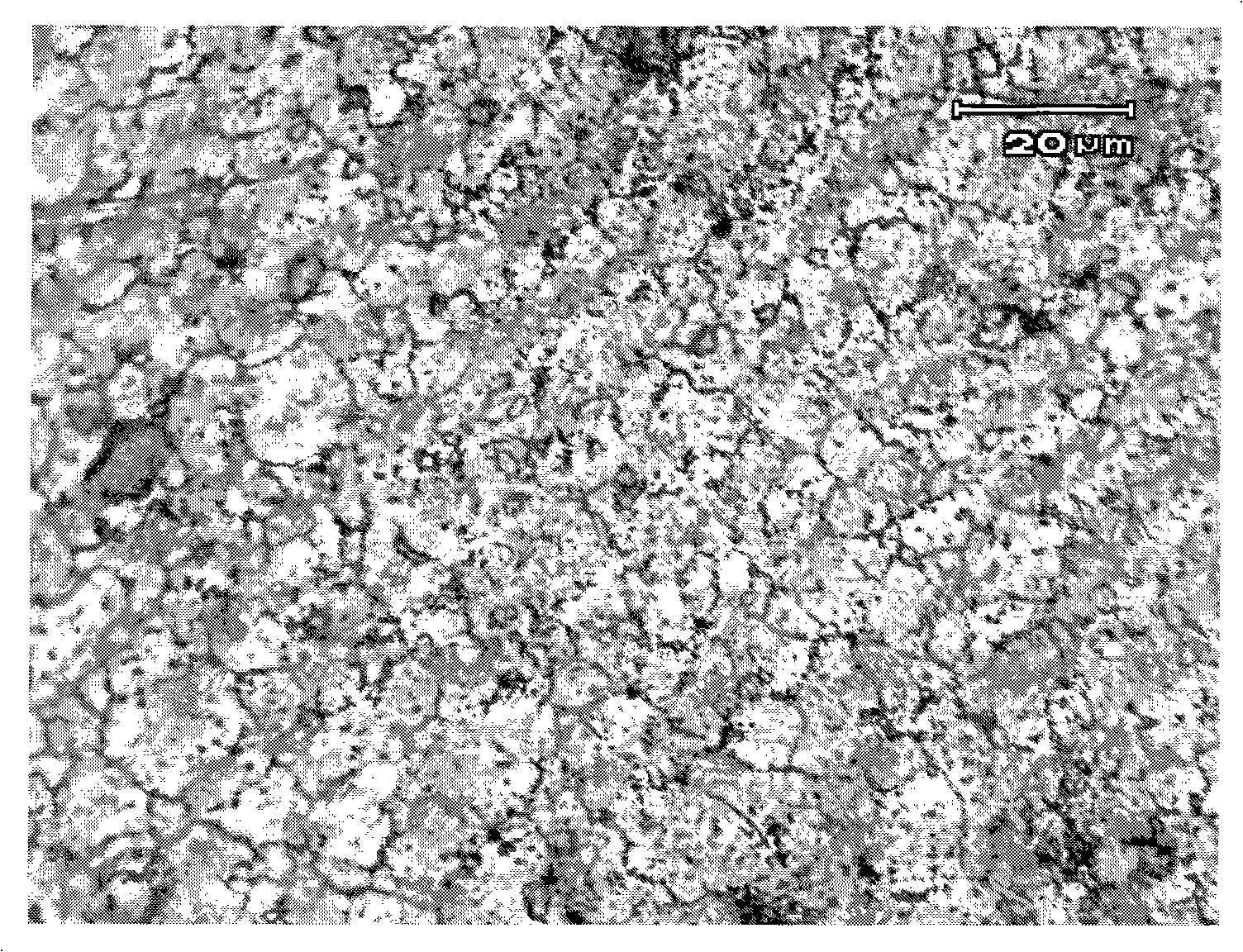

Image

Examples

Embodiment 1

[0026] The formula of the silicon carbide particle-reinforced tin-silver-zinc composite solder according to this embodiment is: tin-silver-zinc solder and 0.3% silicon carbide particles. The average size of silicon carbide particles is 10 μm, and in the tin-silver-zinc solder, the mass ratio of tin, silver, and zinc is 96.1:3:0.9.

[0027] The solder of this example is recorded as: 0.3% SiC reinforced Sn-3% Ag-0.9% Zn, and its preparation process is as follows:

[0028] ①. Heat the tin, silver and zinc with a purity of 99.99% to 1200°C in a vacuum melting furnace under the protection of argon according to the formula ratio, and at the same time add magnetic stirring to make the alloy composition uniform, then water-cool and solidify, and then melt the alloy After turning over, reheat to 1200°C to melt, and at the same time, add magnetic stirring and water cooling, repeat this at least five times, and obtain a button-shaped tin-silver-zinc solder with a diameter of 3.0 to 3.5 c...

Embodiment 2

[0031] The silicon carbide particle-reinforced tin-silver-zinc composite solder according to this embodiment includes tin-silver-zinc solder and 0.1% silicon carbide particles. The silicon carbide particles have an average size of 10 μm. The tin-silver-zinc solder is composed of tin, silver, zinc and indium in a mass ratio of 95:3.5:0.5:1.

[0032] The solder in this example is marked as: 0.1% SiC reinforced Sn-3.5% Ag-0.5% Zn-1% In, and its preparation process is as follows:

[0033] ①. The tin, silver, zinc and indium with a purity of 99.99% are heated to 1200°C in a vacuum melting furnace under the protection of argon according to the formula ratio, and magnetically stirred at the same time to make the alloy composition uniform, and then water-cooled and solidified. Turn the alloy over and reheat it to 1200°C to melt, and at the same time add magnetic stirring and water cooling, so repeat at least five times to get a button-shaped tin-silver-zinc solder with a diameter of ...

Embodiment 3

[0036] The silicon carbide particle-reinforced tin-silver-zinc composite solder according to this embodiment includes tin-silver-zinc solder and 0.5% silicon carbide particles. The silicon carbide particles have an average size of 10 μm. The tin-silver-zinc solder is composed of tin, silver, zinc and gallium with a purity of 99.99% in a mass ratio of 94.6:3.7:1.2:0.5.

[0037] The solder in this example is marked as: 0.5% SiC reinforced Sn-3.7% Ag-1.2% Zn-0.5% Ga, and its preparation process is as follows:

[0038] ①. The tin, silver, zinc and gallium with a purity of 99.99% are heated to 1200°C in a vacuum melting furnace under the protection of argon according to the formula ratio, and magnetically stirred at the same time to make the alloy composition uniform, and then water-cooled and solidified. Turn the alloy over and reheat it to 1200°C to melt, and at the same time add magnetic stirring and water cooling, so repeat at least five times to get a button-shaped tin-silver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com