Preparation method of Sn-base composite solder sheet based on porous Ni/Cu alloy

A hybrid welding and alloy technology, applied in welding equipment, metal processing equipment, welding/cutting media/materials, etc., can solve the problems of low coating adhesion, low welding efficiency, poor toughness, etc., and achieve strong performance adjustment and durability Good oxidation performance and controllable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

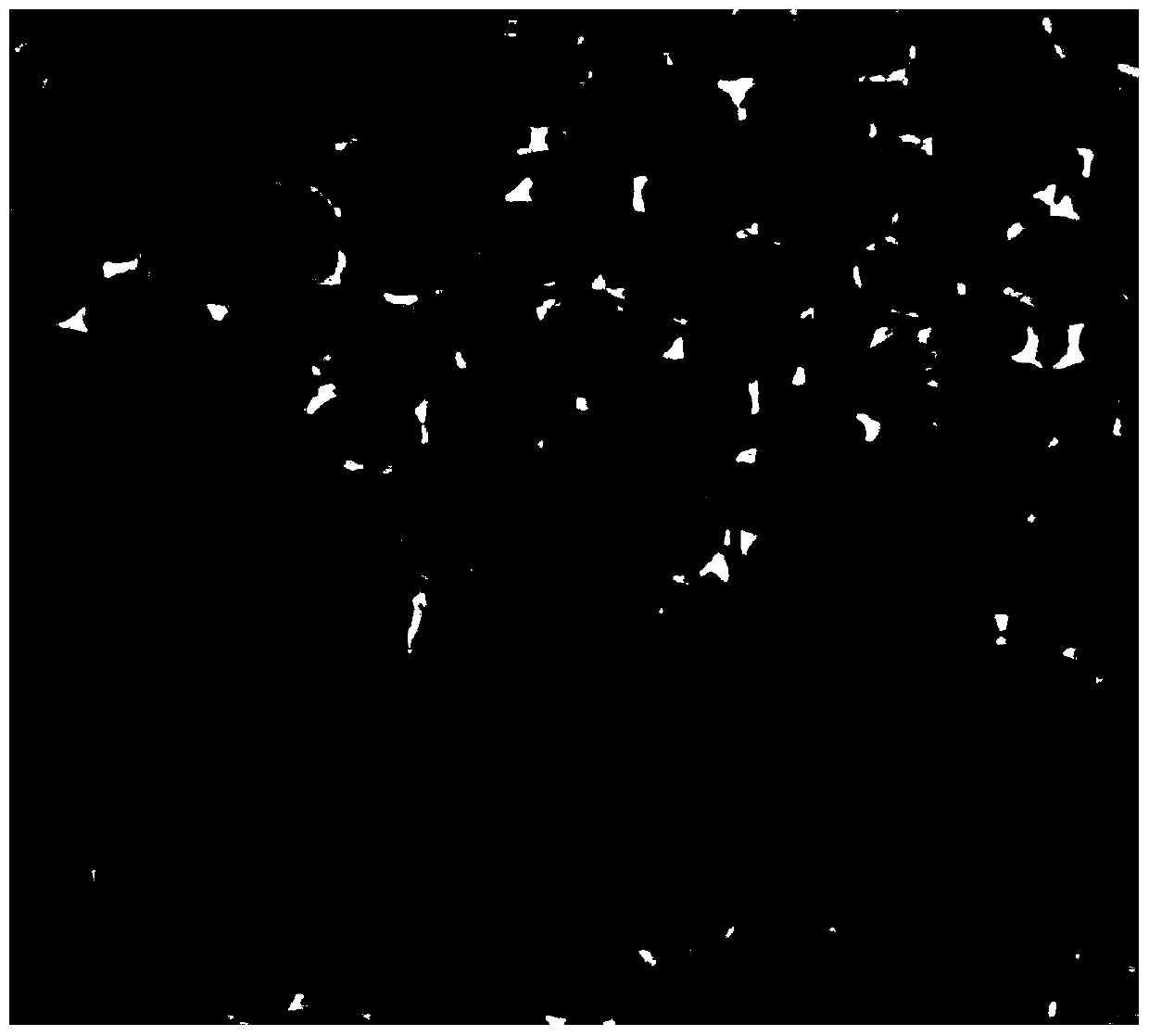

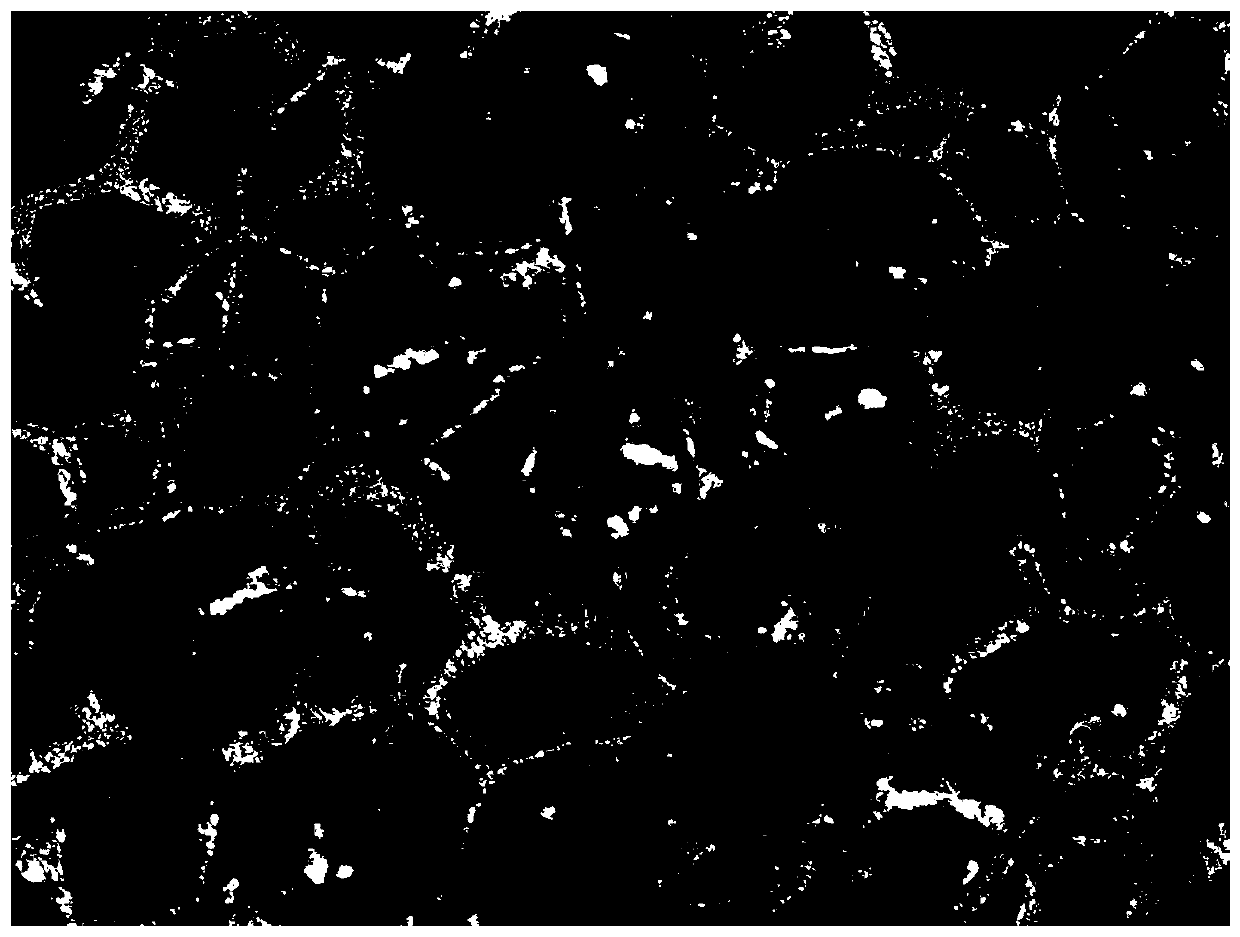

[0024] Put the porous Ni metal (porosity 98%) with a size of 40mm*25mm*1mm into dilute hydrochloric acid and alcohol with a concentration of 5% (volume fraction, the same below), take it out and put it into an ultrasonic cleaner for cleaning for about 5 minutes , electroplating after drying. The electroplating anode is pure copper plate, the cathode is porous Ni metal, the electroplating temperature is maintained at 40°C, the electroplating time is 30min, and the current density is 8A / dm 2 . After electroplating, the obtained porous Ni / Cu metal sheet was washed in deionized water and alcohol for 1 min, and then taken out and dried. Immediately transfer the porous metal sheet to a high-temperature sintering furnace, continuously pass in the protective gas Ar gas, heat at a heating rate of 10°C / min, the sintering peak temperature is 1000°C, and the holding time is 5h. After the sintering was completed, the furnace was cooled to 300°C, and the furnace was opened, and the porous...

Embodiment 2

[0027] Put the porous Ni metal (80% porosity) with a size of 40mm*25mm*1mm into dilute hydrochloric acid with a concentration of 5% and alcohol successively, take it out, put it into an ultrasonic cleaner for cleaning for about 5 minutes, blow it dry, and then perform electroplating. The electroplating anode is pure copper plate, the cathode is porous Ni metal, the electroplating temperature is maintained at 40°C, the electroplating time is 30min, and the current density is 4A / dm 2 . After electroplating, the obtained porous Ni / Cu metal sheet was washed in deionized water and alcohol for 1 min, and then taken out and dried. Immediately transfer the porous metal sheet to a high-temperature sintering furnace, continuously pass in protective gas Ar gas, heat at a heating rate of 10°C / min, the sintering peak temperature is 850°C, and the holding time is 2h. After the sintering was completed, the furnace was cooled to 300°C, and the furnace was opened, and the porous Ni / Cu alloy s...

Embodiment 3

[0030] Put the porous Ni metal (porosity 98%) with a size of 40mm*25mm*1mm into dilute hydrochloric acid and alcohol with a concentration of 5% successively, take it out, put it in an ultrasonic cleaner for cleaning for about 5min, blow it dry, and then perform electroplating. The electroplating anode is pure copper plate, the cathode is porous Ni metal, the electroplating temperature is maintained at 40°C, the electroplating time is 30min, and the current density is 12A / dm 2 . After electroplating, the obtained porous Ni / Cu metal sheet was washed in deionized water and alcohol for 1 min, and then taken out and dried. Immediately transfer the porous metal sheet to a high-temperature sintering furnace, continuously pass in protective gas Ar gas, heat at a heating rate of 10°C / min, the sintering peak temperature is 1000°C, and the holding time is 2h. After sintering, cool the furnace to 300°C and start the furnace, take out the porous Ni / Cu alloy sheet, and immediately immerse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com