Magnetic particle tin-zinc matrix composite solder and preparation method thereof

A magnetic particle, composite welding technology, applied in welding equipment, welding/cutting media/materials, welding media, etc., can solve the problems of weak bonding force and difficulty in joining, and achieve increased fluidity, improved wettability, and improved Beneficial effects on mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

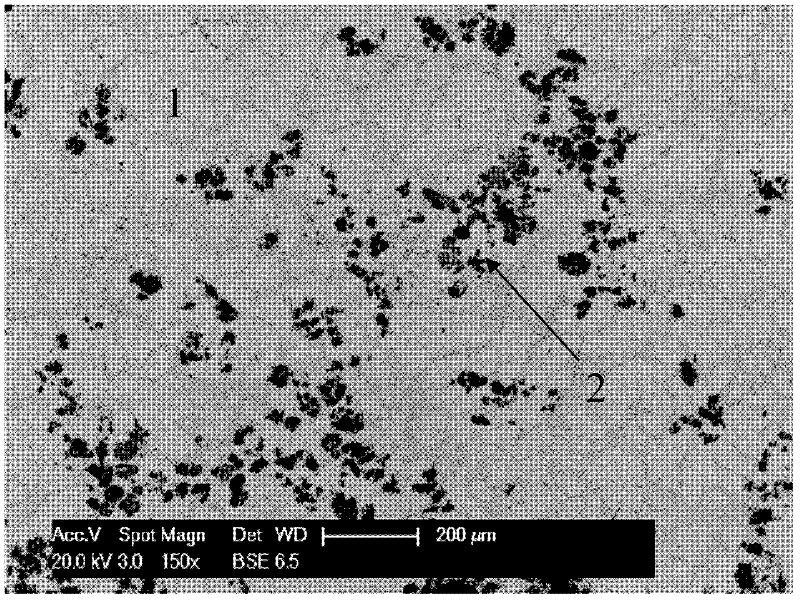

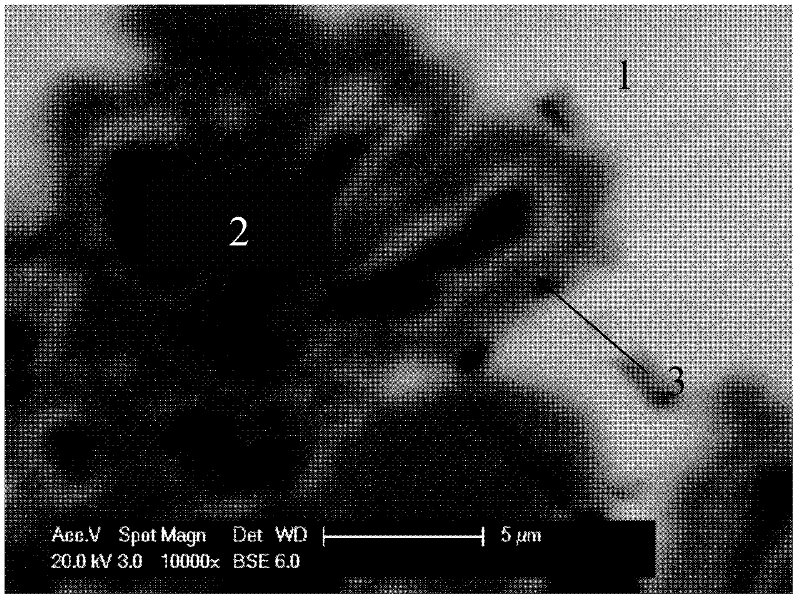

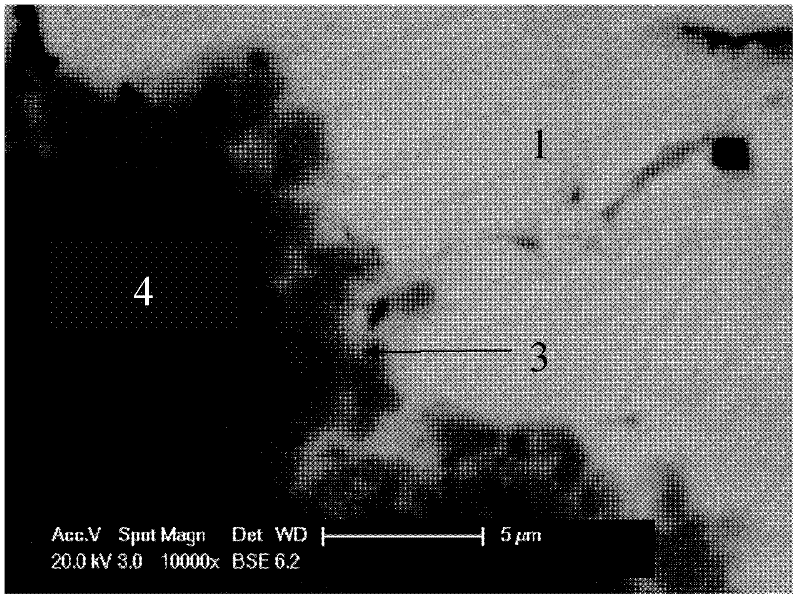

Image

Examples

Embodiment 1

[0035] Embodiment 1: The tin-zinc based composite solder of the present invention, the weight percentage of each component is: 99% of tin-zinc solder matrix, 1% of magnetic particles. The Zn content in the tin-zinc solder matrix is 8% by weight of the tin-zinc-based solder matrix, the balance is Sn, and the magnetic particles are Fe particles with a particle size of 10um. The Ni plating layer obtained by keeping the temperature at 90°C for 5min in the plating solution is about 1um magnetic particles.

Embodiment 2

[0036] Embodiment 2: In the tin-zinc based composite solder of the present invention, the weight percentage of each component is: tin-zinc solder matrix 95%, magnetic particles 5%. The Zn content in the tin-zinc solder matrix is 9% by weight of the tin-zinc-based solder matrix, the balance is Sn, and the magnetic particles are Fe particles with a particle size of 20um. The Ni plating layer obtained by keeping the temperature at 90°C for 8 minutes in the plating solution is about 2um magnetic particles.

Embodiment 3

[0037] Embodiment 3: The tin-zinc based composite solder of the present invention, the weight percentage of each component is: 95% of tin-zinc solder matrix, 5% of magnetic particles. The Zn content in the tin-zinc solder matrix is 9% by weight of the tin-zinc-based solder matrix, the balance is Sn, and the magnetic particles are Fe particles with a particle size of 20um. The Ni plating layer obtained by keeping the temperature at 90°C for 10min in the plating solution is about 3um magnetic particles.

[0038] : Embodiment 4: tin-zinc based composite solder of the present invention, the percentage by weight of each component is: 90% of tin-zinc solder matrix, 10% of magnetic particles. The Zn content in the tin-zinc solder matrix is 10% by weight of the tin-zinc-based solder matrix, the balance is Sn, and the magnetic particles are Fe particles with a particle size of 30um. The Ni plating layer obtained by keeping the temperature at 90°C for 10min in the plating solution is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com