Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Play a role in enhancing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Unbalanced ship classification method based on deep convolutional neural network

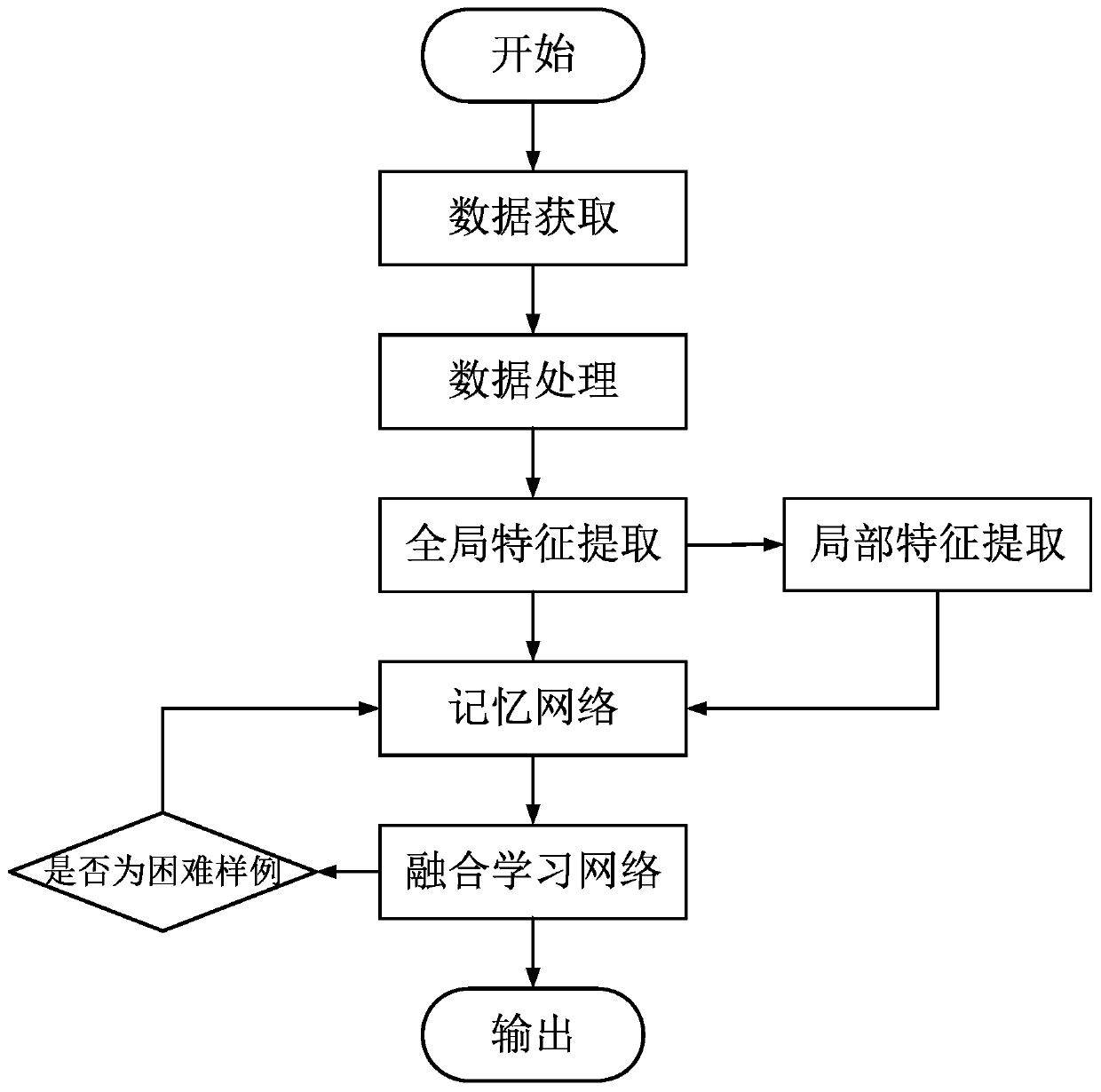

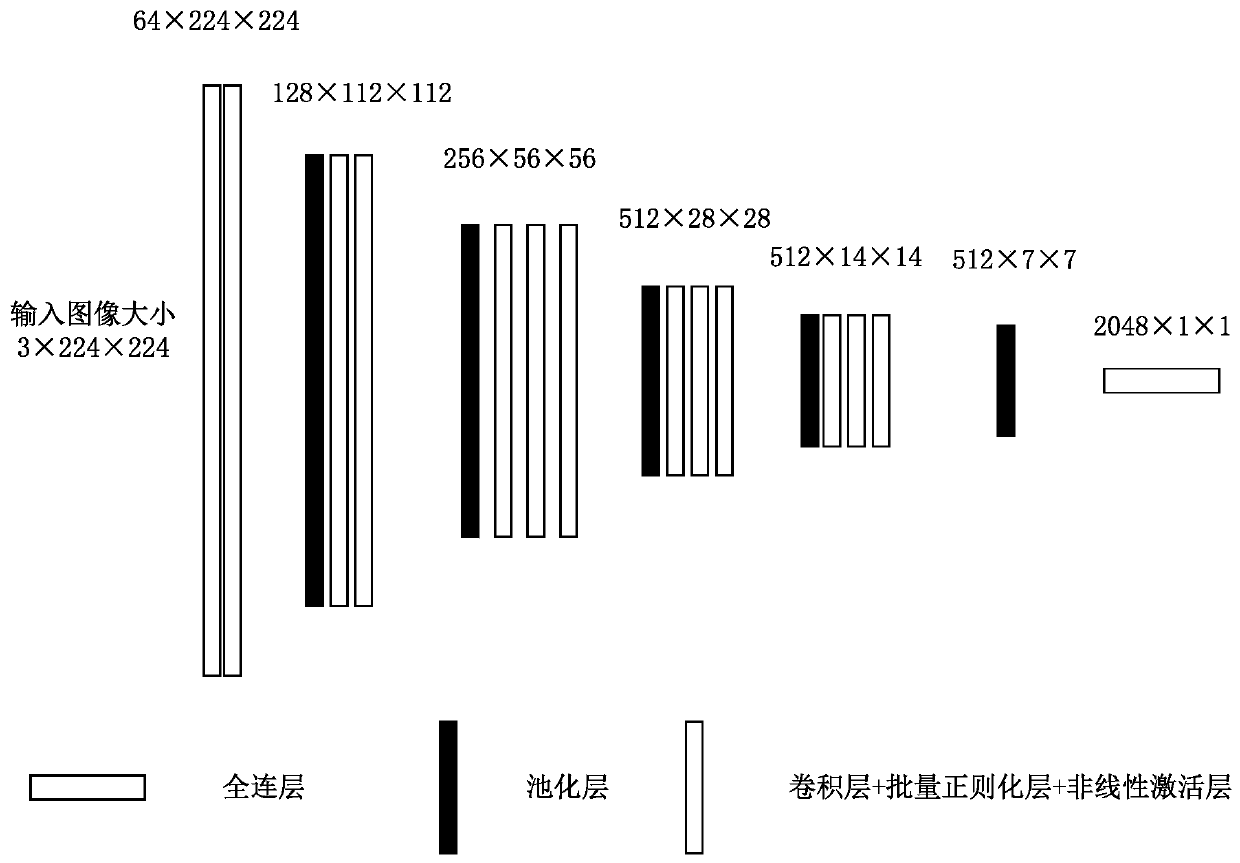

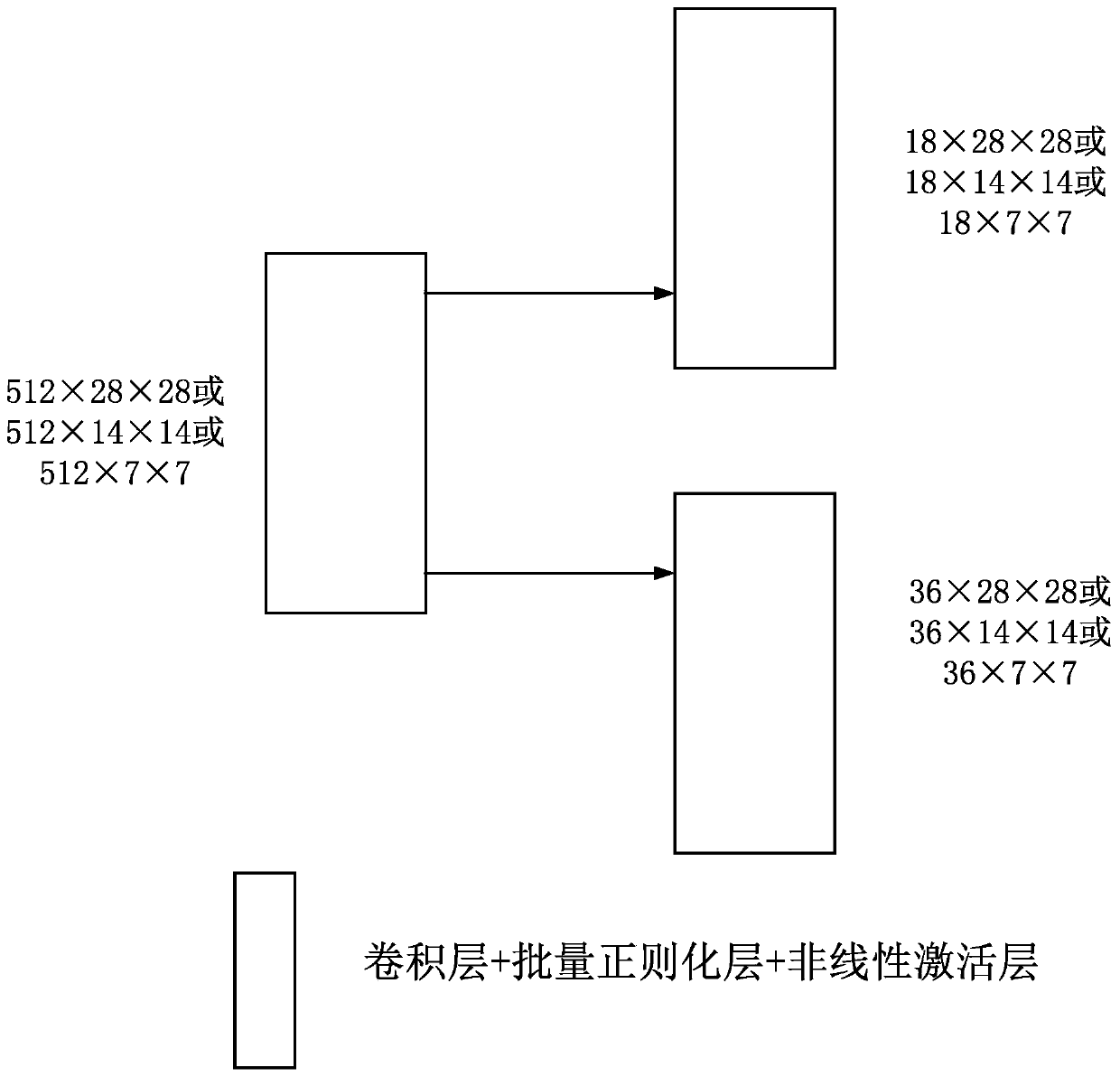

ActiveCN111461190AStrong application valueAccuracy close toCharacter and pattern recognitionNeural architecturesModel learningClassification result

The invention discloses an unbalanced ship classification method based on a deep convolutional neural network. The method comprises the steps of 1) obtaining basic data; 2) carrying out data processing; 3) constructing a model; 4) defining a loss function; 5) training a model; 6) applying the model. According to the invention, fine classification of ships and solving of the problem of unbalanced category data distribution are combined; on the basis of extracting the global features of the ship, the local features with category discrimination of the ship are introduced, so that the model learnsdetails of the ship, and the classification result is more accurate; a memory network and a fusion learning network are used for storing and emphatically learning samples which are difficult to learn; the learning of the samples is improved while the new samples are learned, the effect of rebalancing the category data distribution is also achieved, and the adverse effect on model training causedby unbalanced category data distribution in an actual scene is effectively avoided.

Owner:SOUTH CHINA UNIV OF TECH

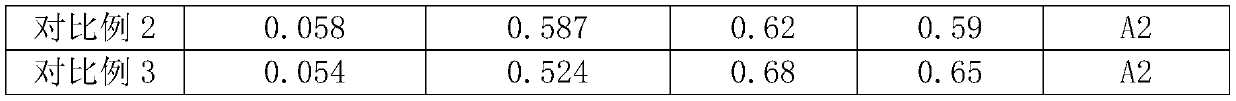

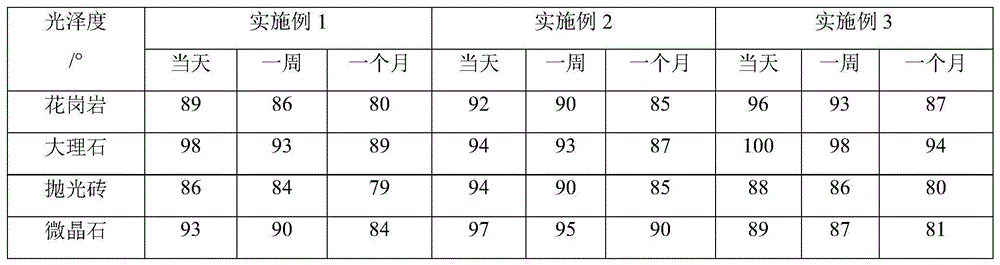

Stone surface treating agent, preparation method thereof and stone surface treating method

The invention discloses a stone surface treating agent, which comprises an A component and a B component, wherein the A component comprises the following raw materials in parts by weight: 150-400 parts of alkali metal silicate solution with the concentration of 5-40 percent by weight, 150-400 parts of acid saline solution with the concentration of 1-20 percent by weight and 3-80 parts of high polymer emulsion; and the B component comprises the following raw materials in parts by weight: 200-400 parts of silica gel, 50-400 parts of alkali metal silicate solution with the concentration of 5-40 percent by weight and 2-80 parts of high polymer emulsion. The invention further discloses a preparation method of the treating agent and a stone surface treating method. The stone surface treating agent prepared with the preparation method is a polishing material which takes an inorganic components as major components, is weakly acidic or weakly alkaline, has small chemical corrosion on stone, contains a small quantity of organic components, can overcome the defect of a pure wax organic material film and can achieve a mirror effect. The stone surface treating agent can be applied to stone surface polishing together with any electric tool and a universal cushion, and can be used for polishing polished tiles, microlite and the like.

Owner:WANFENG COMPOUND STONE TECH

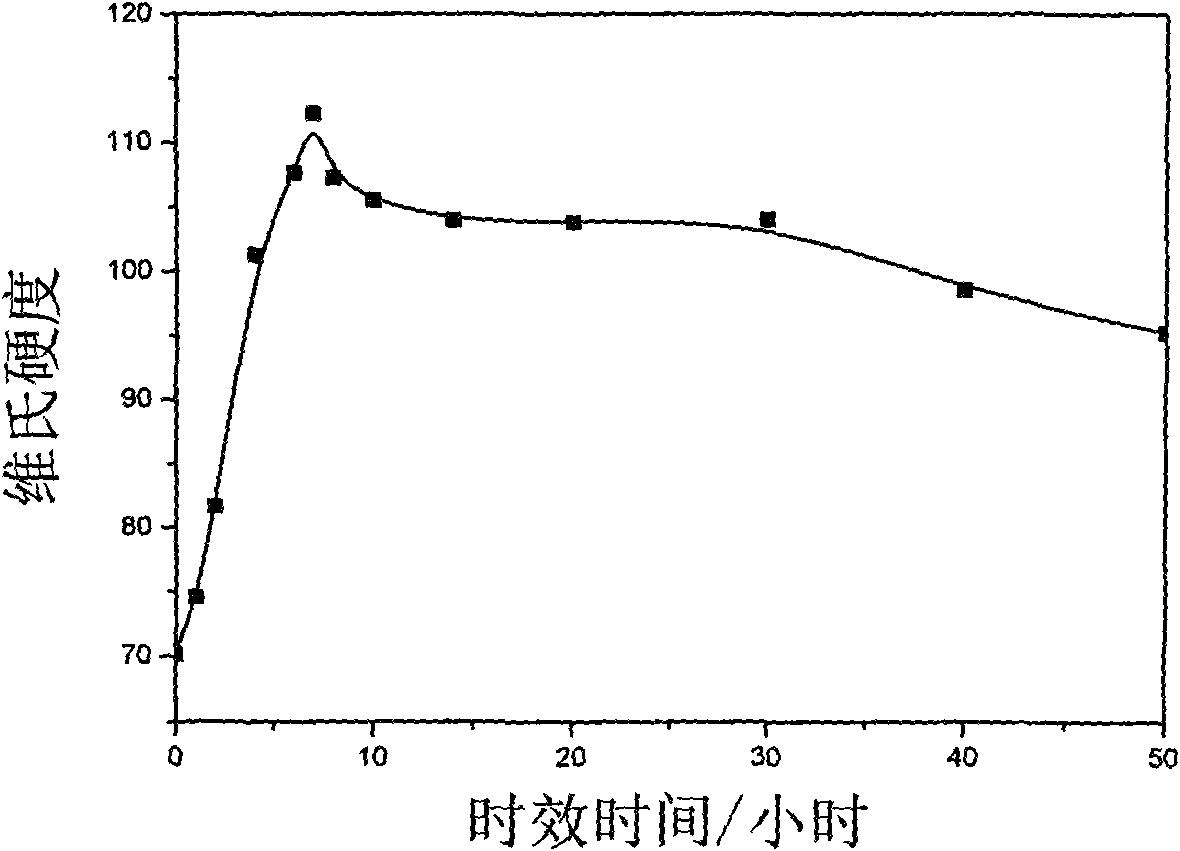

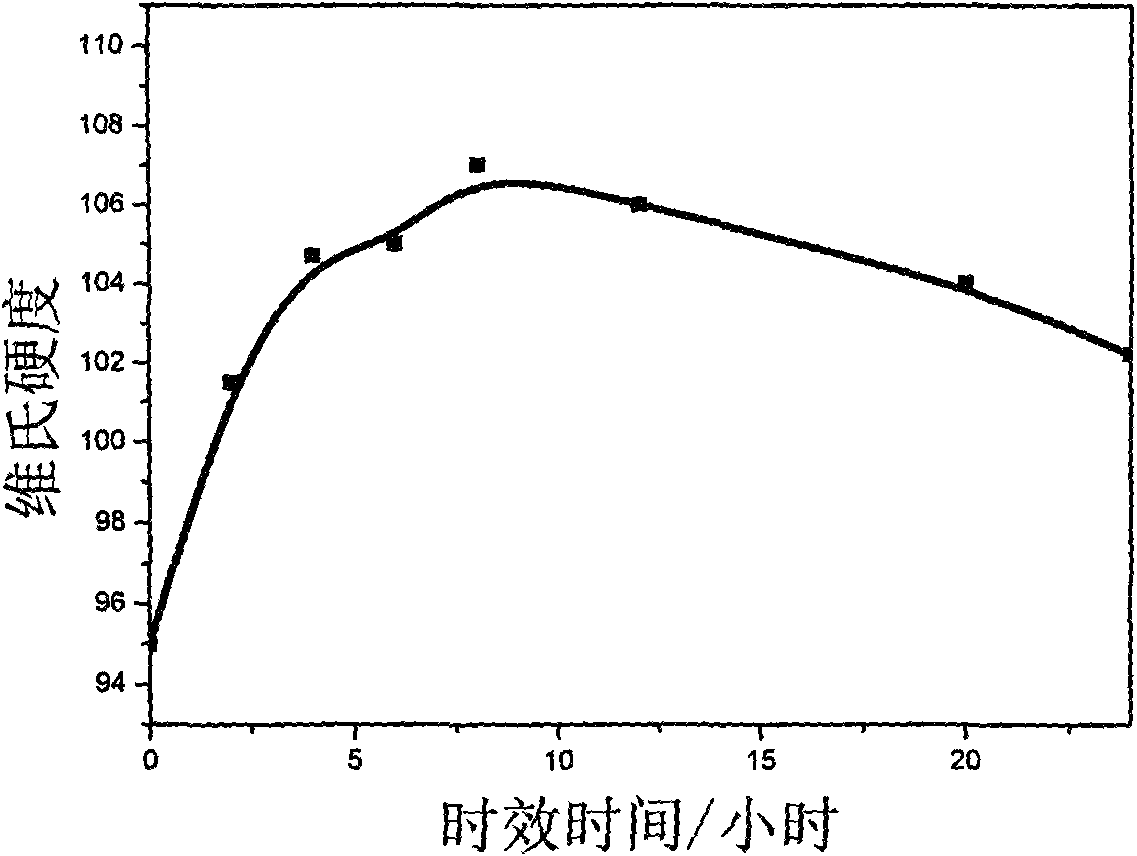

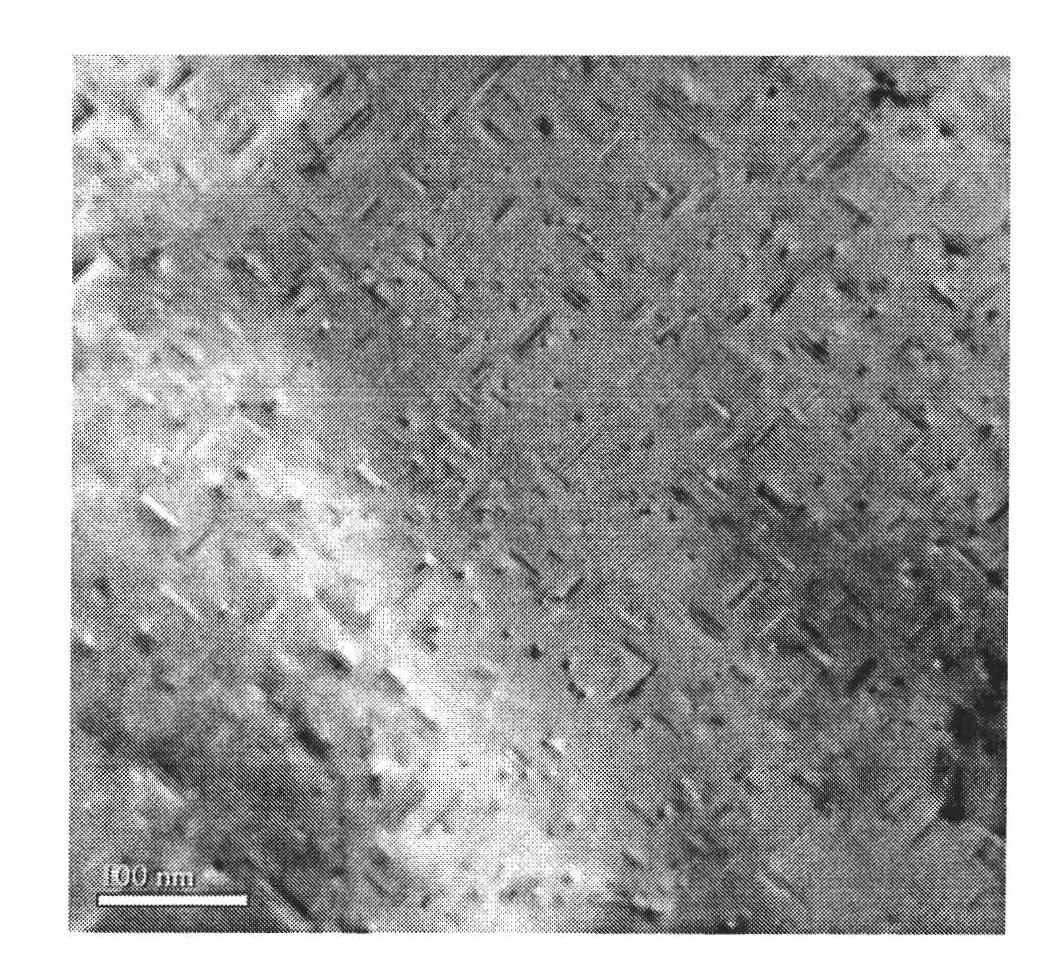

Preparation and ageing treatment process for novel Al-Mg-Si-Er aluminum alloy plate material

The invention discloses preparation and an ageing treatment process for a Al-Mg-Si-Er aluminum alloy plate material, belonging to the technical field of metal alloy. The preparation method comprises the following steps: preparing metal ingots by adopting a semi-continuous casting method; homogenizing the metal ingots; respectively performing hot rolling and cold rolling on a rolling mill of 310*480mm, wherein the heating temperature of the hot rolling is 450 DEG C; and preserving the temperature for 2 hours, wherein the final rolling thickness is about 2mm. One process condition is that: 1 to 50 hours of ageing heat treatment is performed at 180 DEG C after solution treatment; and the other process condition is that: 1 hour of regression heat treatment is performed at 220 DEG C based on 7 hours of ageing at 180 DEG C, and the alloy is re-aged for 1 to 24 hours at 150 DEG C after regression treatment. The alloy treated by the process has higher strength, the 230MPa using performance requirement of the alloy can be well fulfilled, and the corrosion resistance and plasticity of the alloy can be improved.

Owner:BEIJING UNIV OF TECH

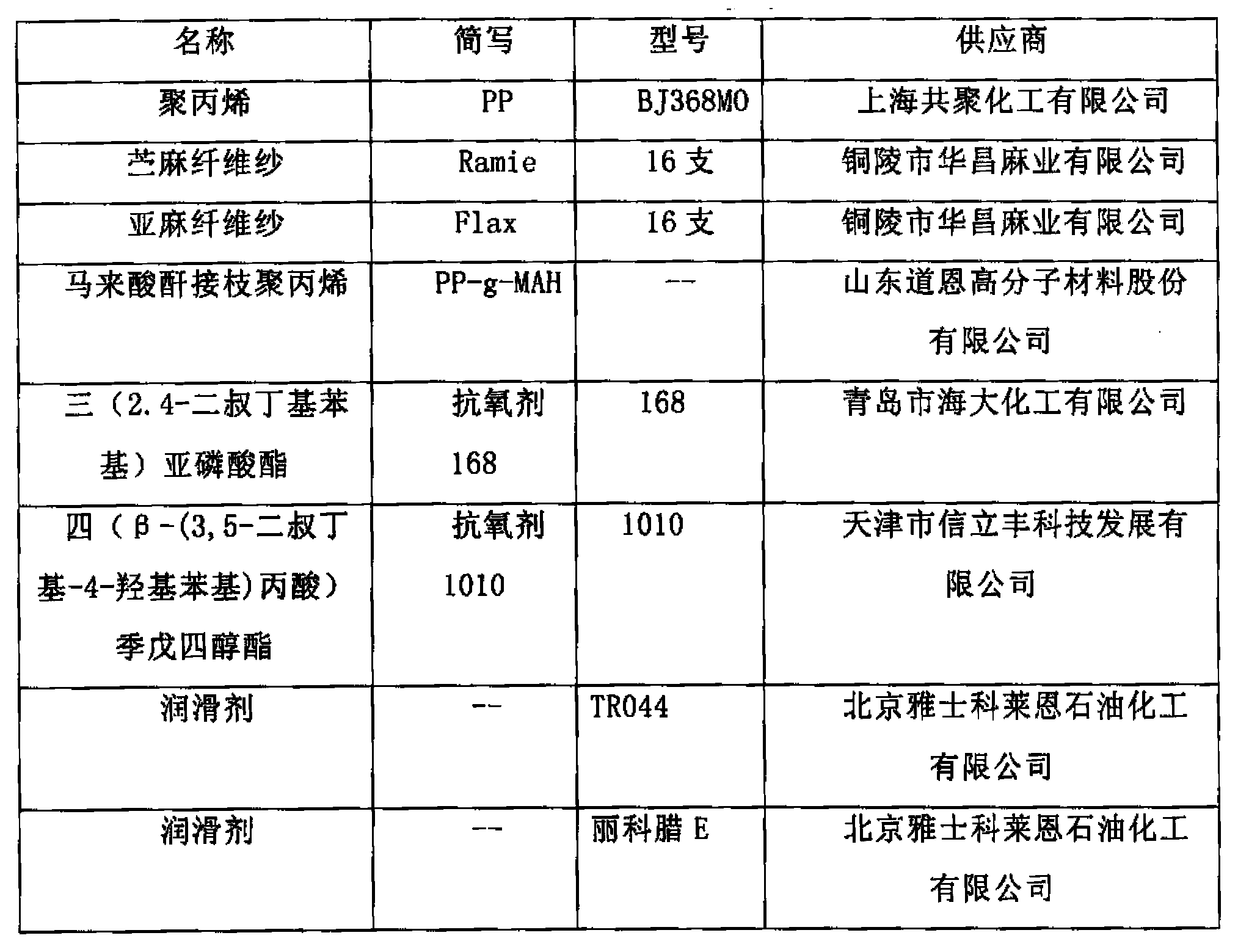

Fibrilia-reinforced polypropylene as well as preparation method thereof

The invention relates to fibrilia-reinforced polypropylene which is prepared from the following components in parts by weight: 100 parts of polypropylene, 10-150 parts of fibrilia and 0-50 parts of an assistant. A preparation method of fibrilia-reinforced polypropylene comprises the following steps: adding weighed100 parts of polypropylene and 0-50 parts of assistant into a twin-screw extruder; mixing, extruding and granulating with 10-150 parts of fibrilia at 160-205 DEG C to prepare fibrilia-reinforced polypropylene. Compared with the prior art, the preparation method has the advantages that the melt index of polypropylene adopted by the preparation method is greater than or equal to 80, and the number of fibrilia is greater than or equal to 6; on one hand, the excellent flowing property of polypropylene can be ensued; on the other hand, fibrilia is fine enough, and easy to cut and disperse; the processing temperature of fibrilia-reinforced polypropylene provided by the invention is controlled within 160-205 DEG C, and the rotational speed of a main machine is greater than or equal to 100r / m, so that the original performance of fibrilia can be better maintained, and the fibrilia better achieves the reinforcing effect.

Owner:HEFEI GENIUS NEW MATERIALS

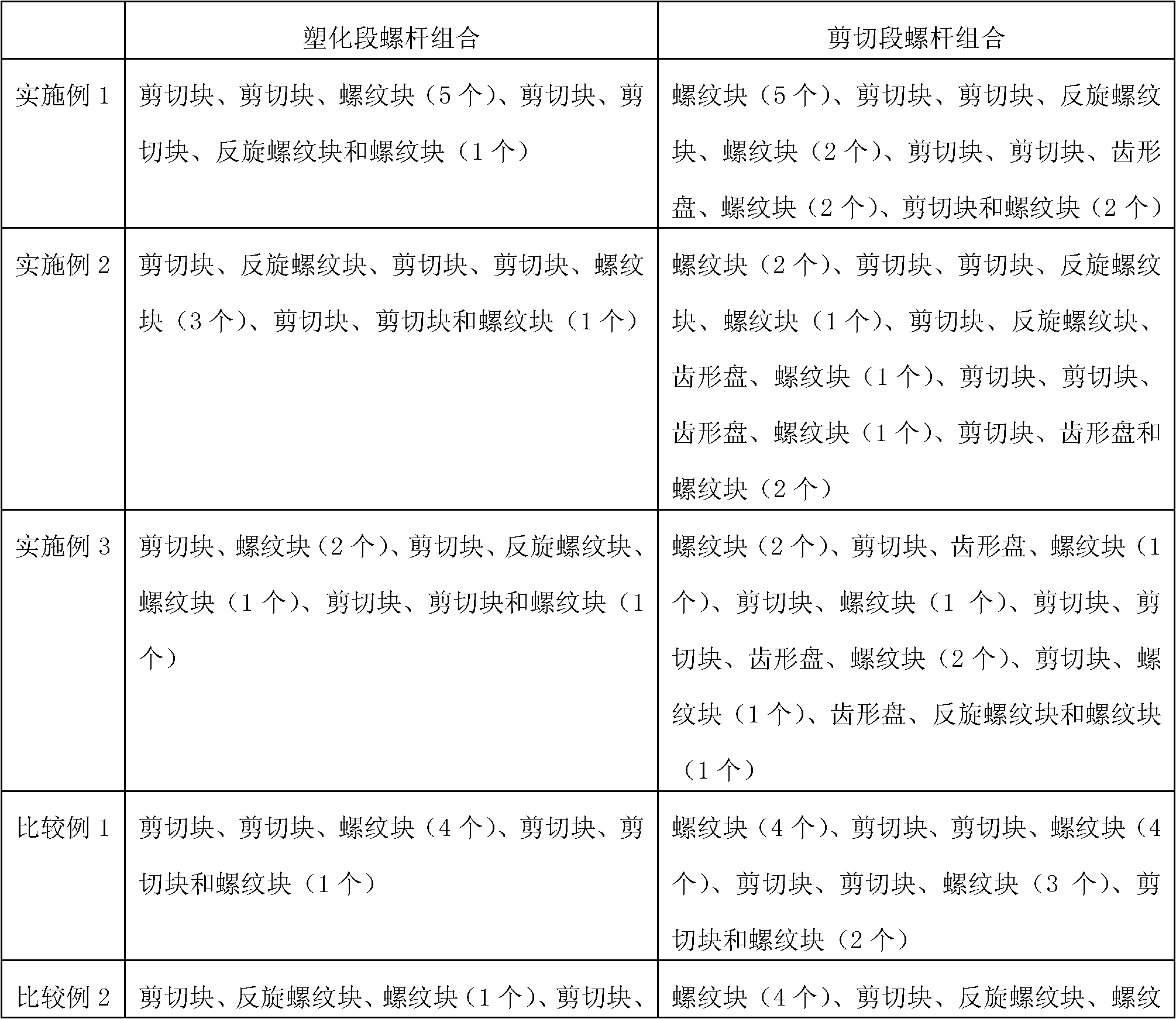

Preparation method for glass fiber reinforced AS (acrylonitrile-styrene) resin

The invention provides a preparation method for a glass fiber reinforced AS (acrylonitrile-styrene) resin, which comprises the following step: inputting raw materials into a double-screw extruder to carry out blending extrusion. A screw combination from a plasticizing section to a shearing section of the double-screw extruder comprises a threaded block, 9-21 shearing blocks, 2-4 left-handed threaded blocks and 1-3 tooth-shaped discs, and the raw materials comprise 63-86.4 wt% (weight percent) of the AS resin, 13-35 wt% of glass fiber, 0.1-0.6 wt% of coupling agent, 0.2-0.6 wt% of antioxidant and 0.3-0.8 wt% of lubricating agent. The glass fiber reinforced AS resin prepared by the preparation method has more uniform density and higher intensity.

Owner:株洲时代工程塑料制品有限责任公司

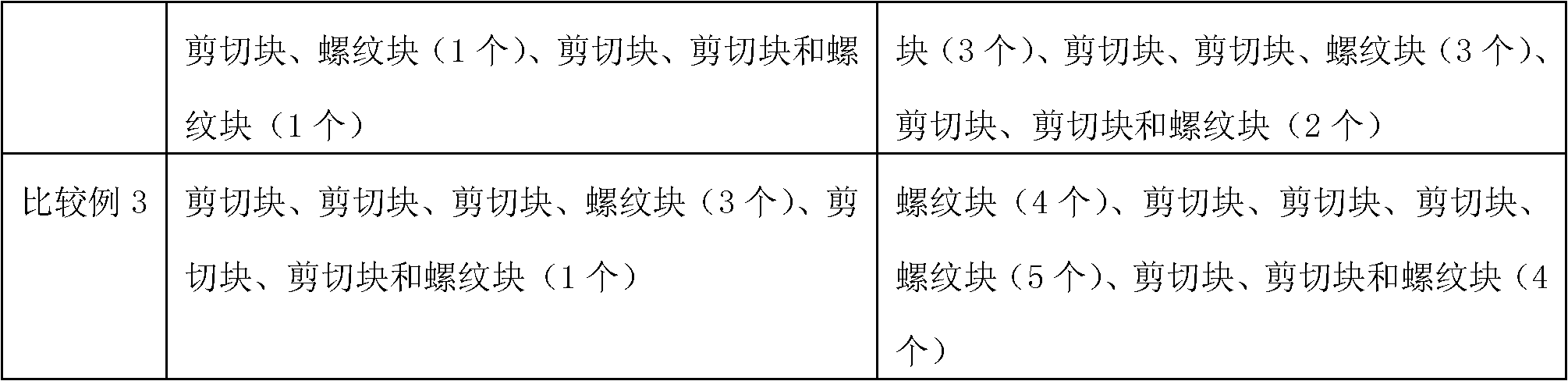

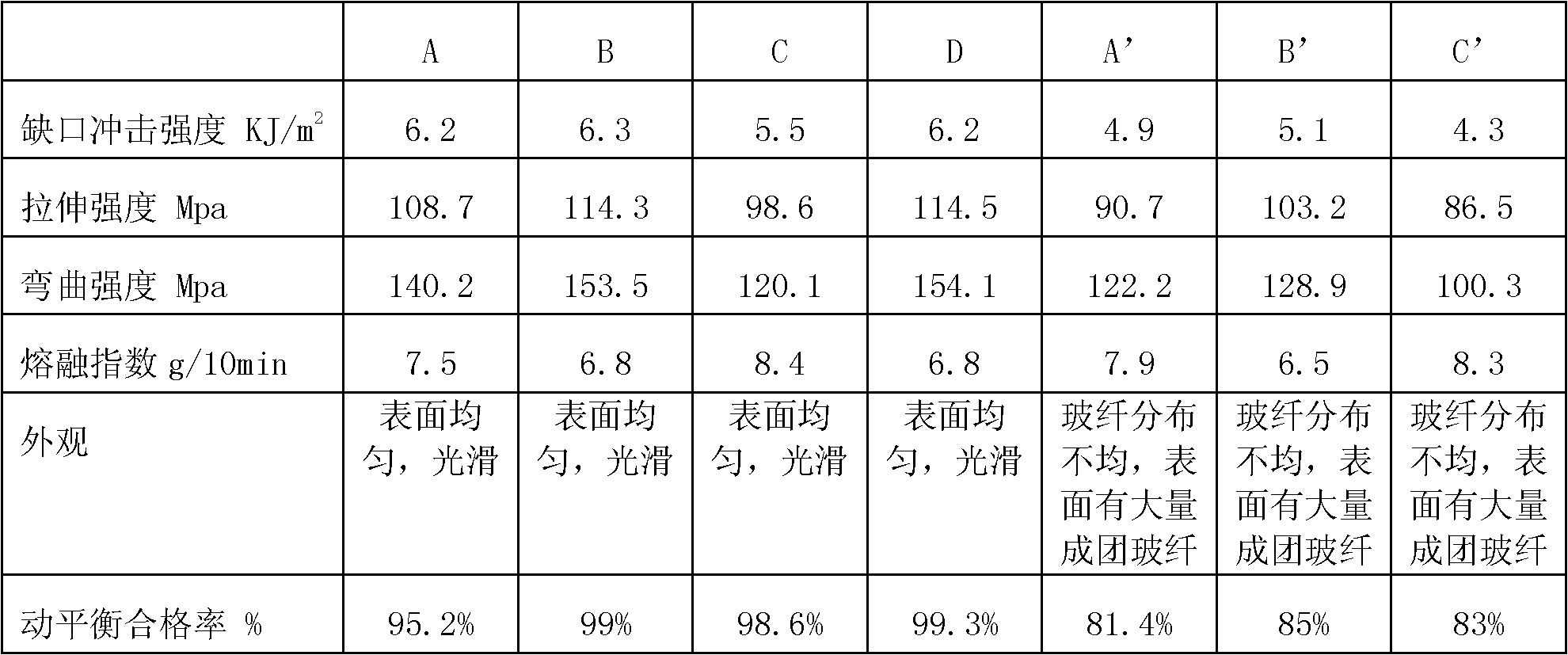

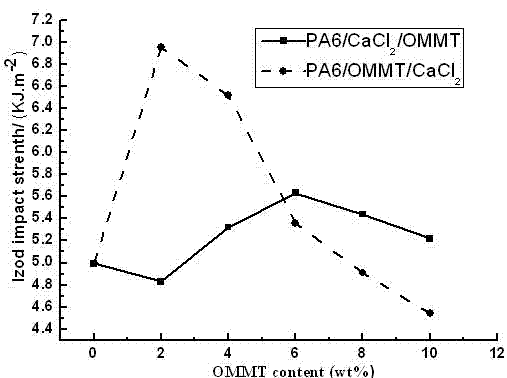

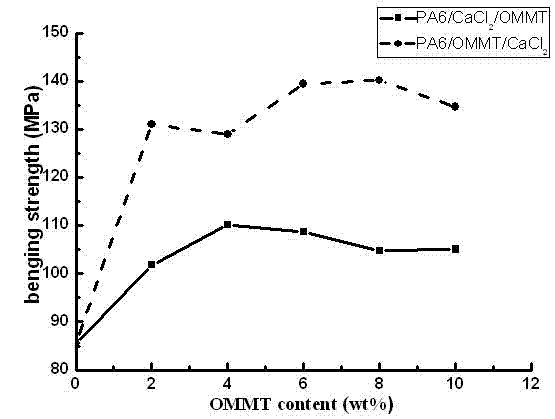

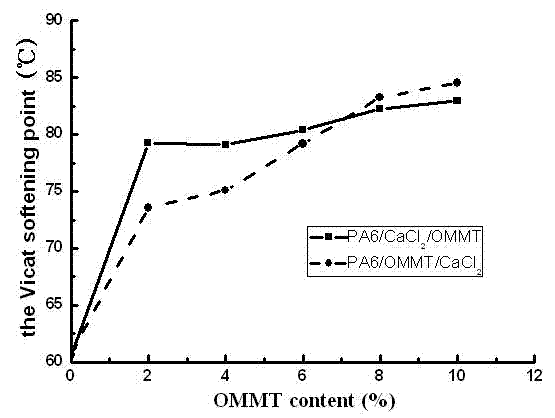

Formula and preparation method of composite low melting point nylon 6

The invention discloses a formula of composite low-melting-point nylon 6, comprising the following components in part by weight: 90-98 parts of nylon 6, 5-6 parts of anhydrous calcium chloride and 2-10 parts of organic montmorillonite. In the invention, the mode of firstly blending the nylon 6 and the organic montmorillonite for extrusion and granulation and then blending the obtained mixture with the anhydrous calcium chloride for extrusion and granulation to manufacture the low-melting-point nylon 6 is adopted, and the problem that calcium ions react with silicate in the organic montmorillonite to inhibit the dispersion of the organic montmorillonite in the low-melting-point nylon 6 is solved, so that the organic montmorillonite can be fully dispersed in the low-melting-point nylon 6, and further the mechanical property of the low-melting-point nylon 6 is improved. In addition, the invention is simple and is easy to implement, the production cost is low, and the service effect is ideal.

Owner:国家复合改性聚合物材料工程技术研究中心

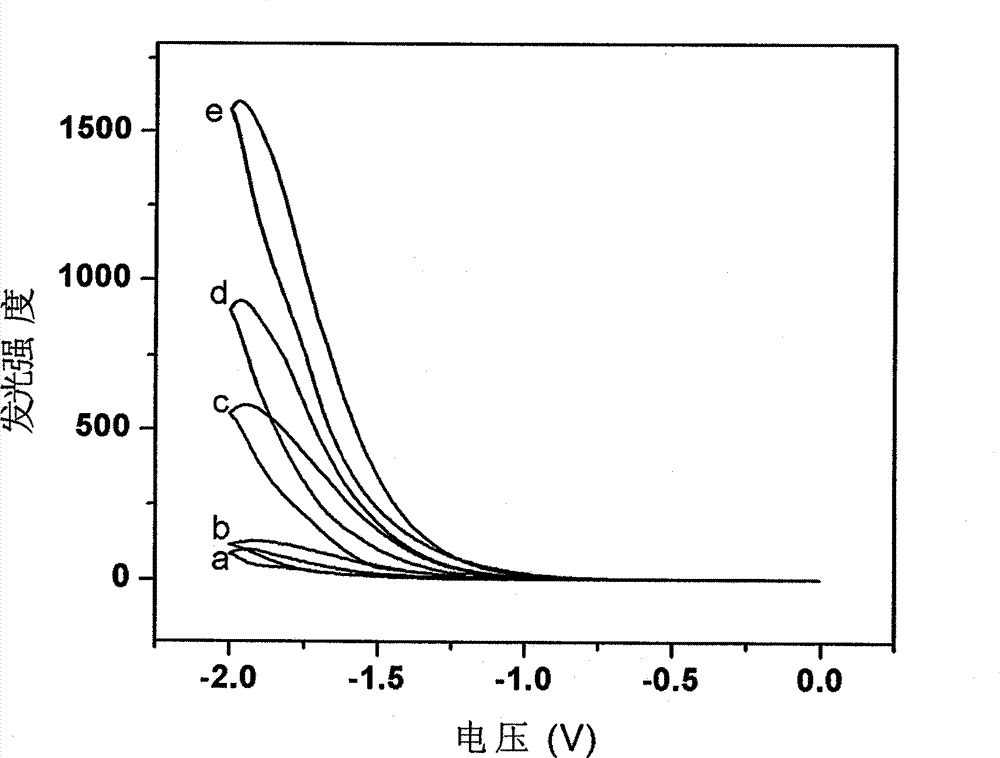

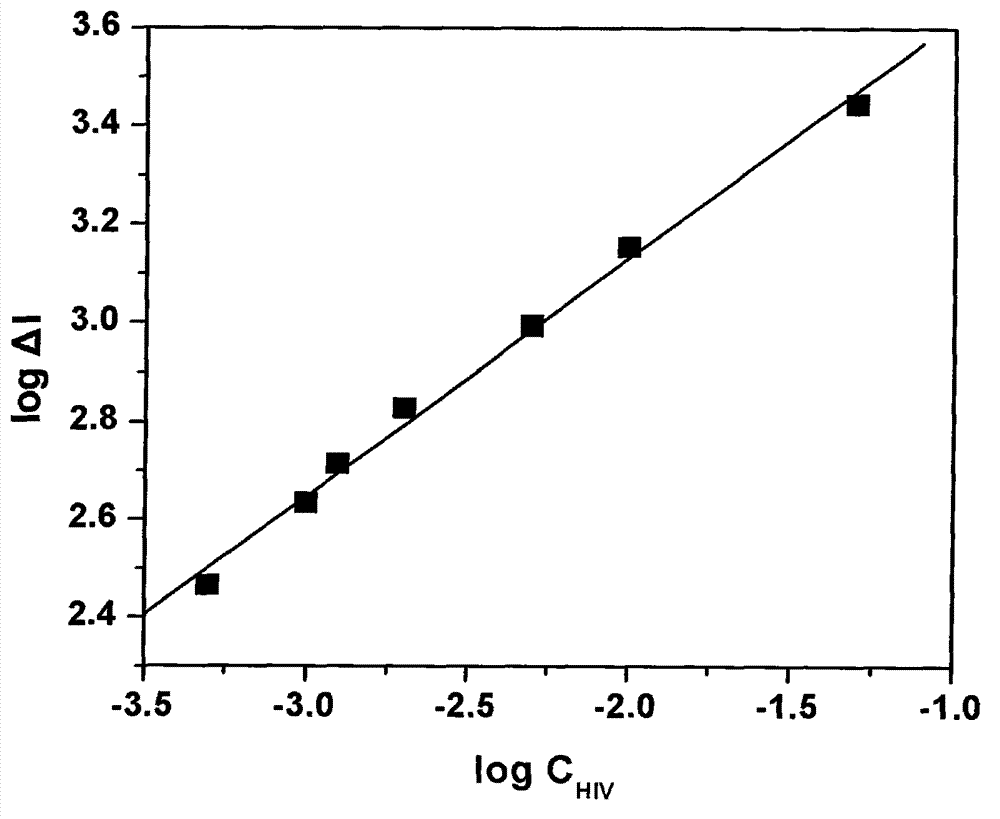

Electrochemical luminescence immune sensor built by mesoporous material loading quantum dots and coated by nanogold, and detection method of HIV (human immunodeficiency virus)

InactiveCN103048314AIncrease loadIncreased biocompatibilityChemiluminescene/bioluminescenceImmune complex depositionBiocompatibility Testing

The invention relates to the field of analysis tests, and discloses an electrochemical luminescence immune sensor built on the basis of a mesoporous material which loads quantum dots and is coated by nanogold, and a sandwich immunoassay method for detecting an HIV (human immunodeficiency virus) antibody. The electrochemical luminescence immune sensor takes the mesoporous material which loads the quantum dots and is coated by the nanogold as a signal label; and immune complex is formed by a biological immune method and decorated to the surface of an electrode, so as to form the electrochemical luminescence immune sensor. By adopting the mesoporous material which loads the quantum dots and is coated by the nanogold, a lot of quantum dots are loaded on the basis of the mesoporous material; a substance of a signal source is increased; the coated nanogold can be used for a method signal, and also can increase the biocompatibility; and the detection method is simple in sample pretreatment, and can adapt to high-sensitivity detection and analysis of the content of the HIV antibody in a serum sample.

Owner:NINGBO UNIV

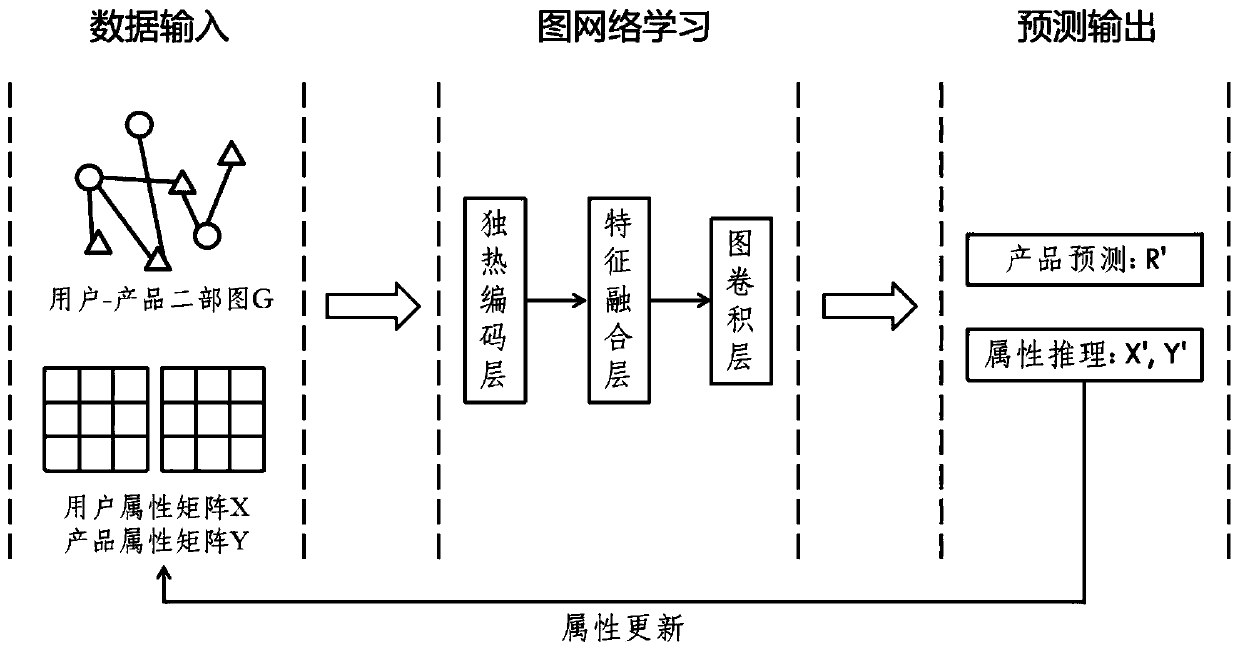

Attribute reasoning and product recommendation method based on adaptive graph convolutional network

ActiveCN111291270AHigh precisionIncrease data dimensionDigital data information retrievalCharacter and pattern recognitionTheoretical computer scienceData mining

The invention discloses an attribute reasoning and product recommendation method based on an adaptive graph convolutional network. The method comprises the following steps: 1, constructing heterogeneous data: a scoring matrix of a user to a product, a user attribute matrix, a product attribute matrix, a user attribute index matrix and a product attribute index matrix; 2, performing missing value filling preprocessing on the user attribute matrix and the product attribute matrix; 3, obtaining a cooperative matrix through one-hot coding; 4, constructing a feature fusion layer according to the attribute matrix and the collaborative matrix; 5, carrying out feature propagation through a graph convolution layer; 6, constructing a prediction layer to perform attribute reasoning and product recommendation; 7, updating the node attribute matrix according to the output result of the prediction layer; and 8, repeating the steps 4-7 until the attribute reasoning and product recommendation effectsare optimal. According to the method, the high-order structure information of the graph, the internal interaction between the node attributes and the potential association between the node attributesand the link relationship can be fully mined, so that more accurate attribute reasoning and product recommendation are realized.

Owner:HEFEI UNIV OF TECH

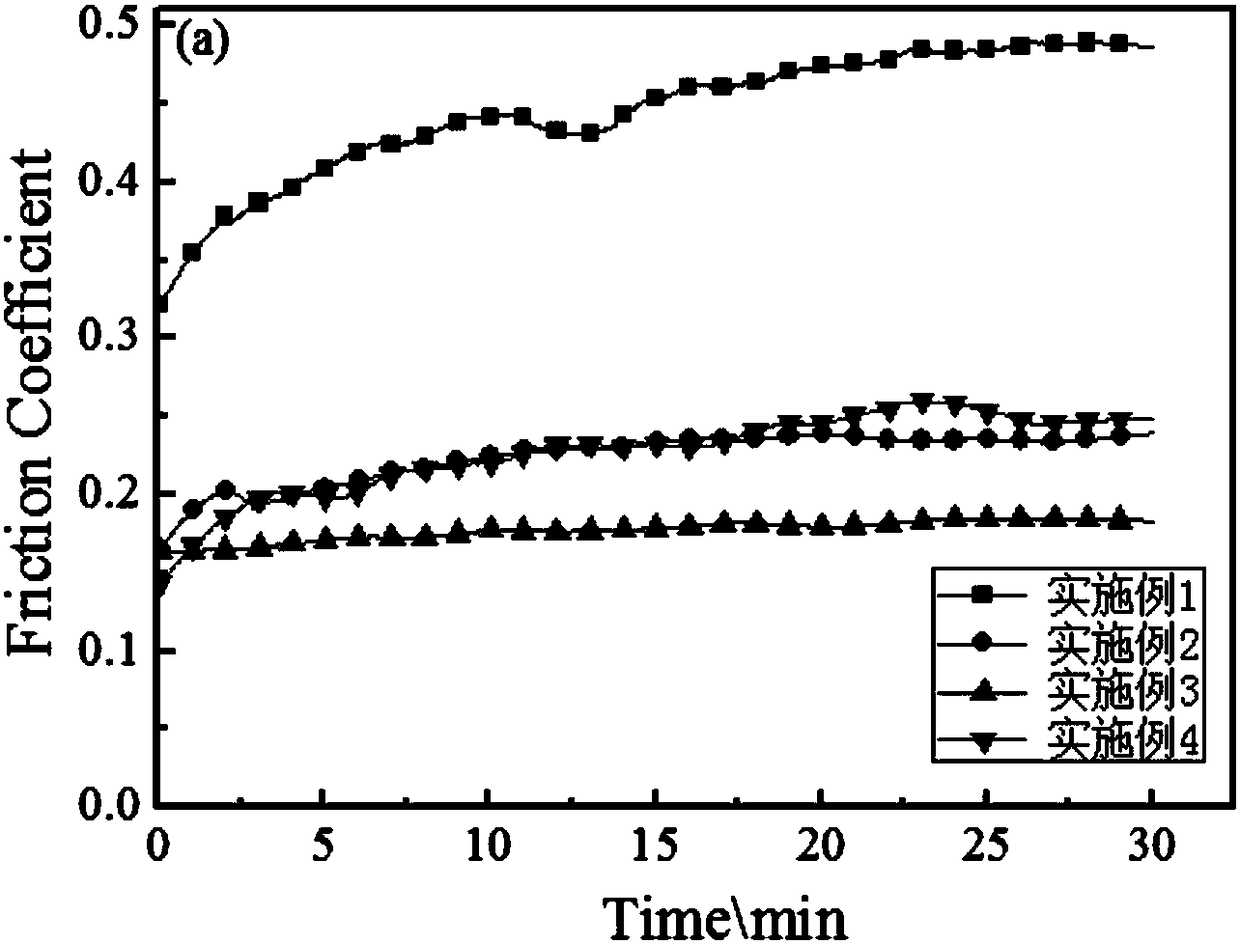

Copper-based powder metallurgy brake pad material as well as preparation method and application thereof

The invention discloses a copper-based powder metallurgy brake pad material as well as a preparation method and application thereof. The copper-based powder metallurgy brake pad material is prepared from the following raw materials in percentage by weight: 54 weight percent to 67 weight percent of copper powder, 13 weight percent of graphite, 4 weight percent to 17 weight percent of iron powder, 8weight percent to 14 weight percent of a ferrochrome alloy, 1 weight percent to 4 weight percent of silicon carbide and 1 weight percent to 4 weight percent of silicon dioxide; the preparation methodof the copper-based powder metallurgy brake pad material comprises the following steps: 1) weighing the raw materials according to the ratio and putting the raw materials into a mixer and uniformly mixing; 2) filling the mixed raw materials into a mold; carrying out hot pressing sintering or spark plasma sintering under the protection of a vacuum atmosphere or nitrogen gas to obtain the brake padmaterial with excellent comprehensive performance. The prepared brake pad material has high density and rigidity, stable friction coefficient, abrasion resistance and excellent comprehensive performance, and can meet the requirements on braking friction plates of high-speed rail trains. The copper-based powder metallurgy brake pad material disclosed by the invention can be used for preparing a brake pad; the preparation method comprises the following steps: taking Q235 as a base material, and compounding and sintering the raw materials for preparing the copper-based powder metallurgy brake pad material and the base material through a hot pressing sintering technology, so as to obtain the brake pad.

Owner:SOUTHEAST UNIV

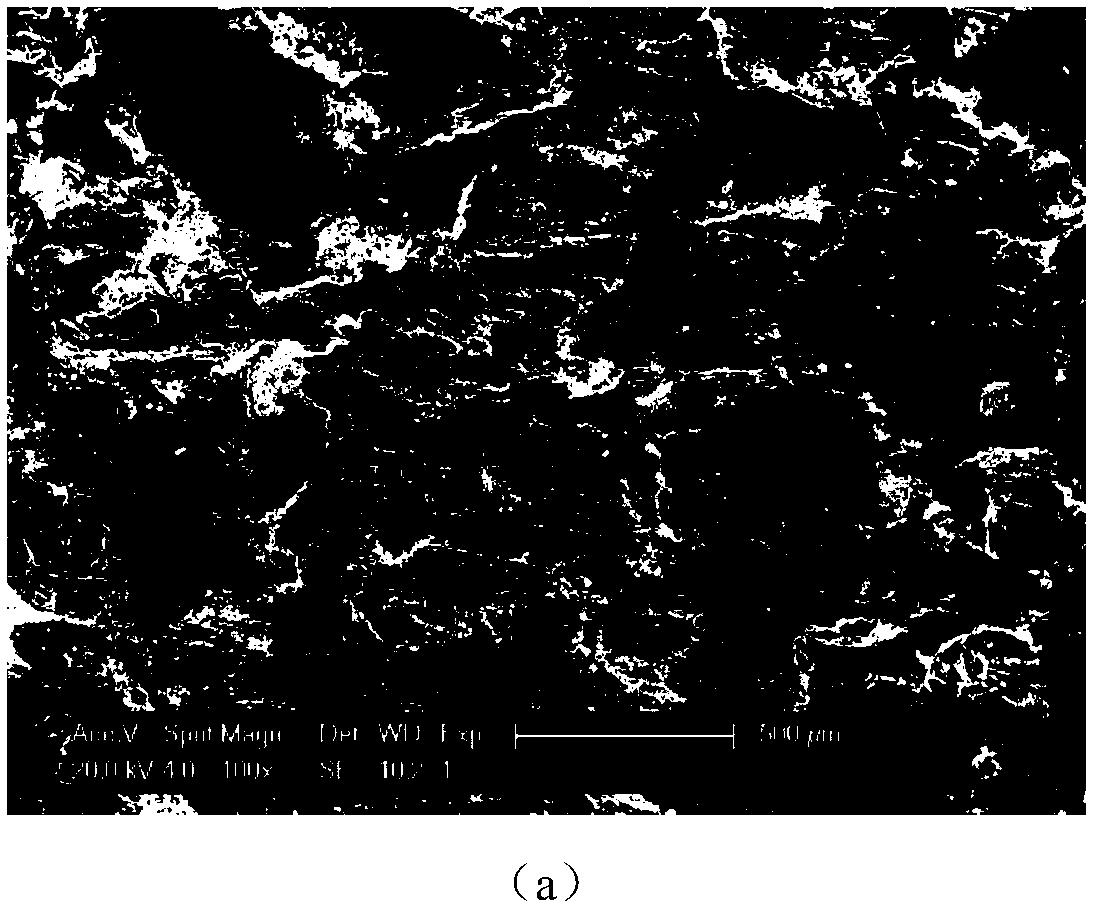

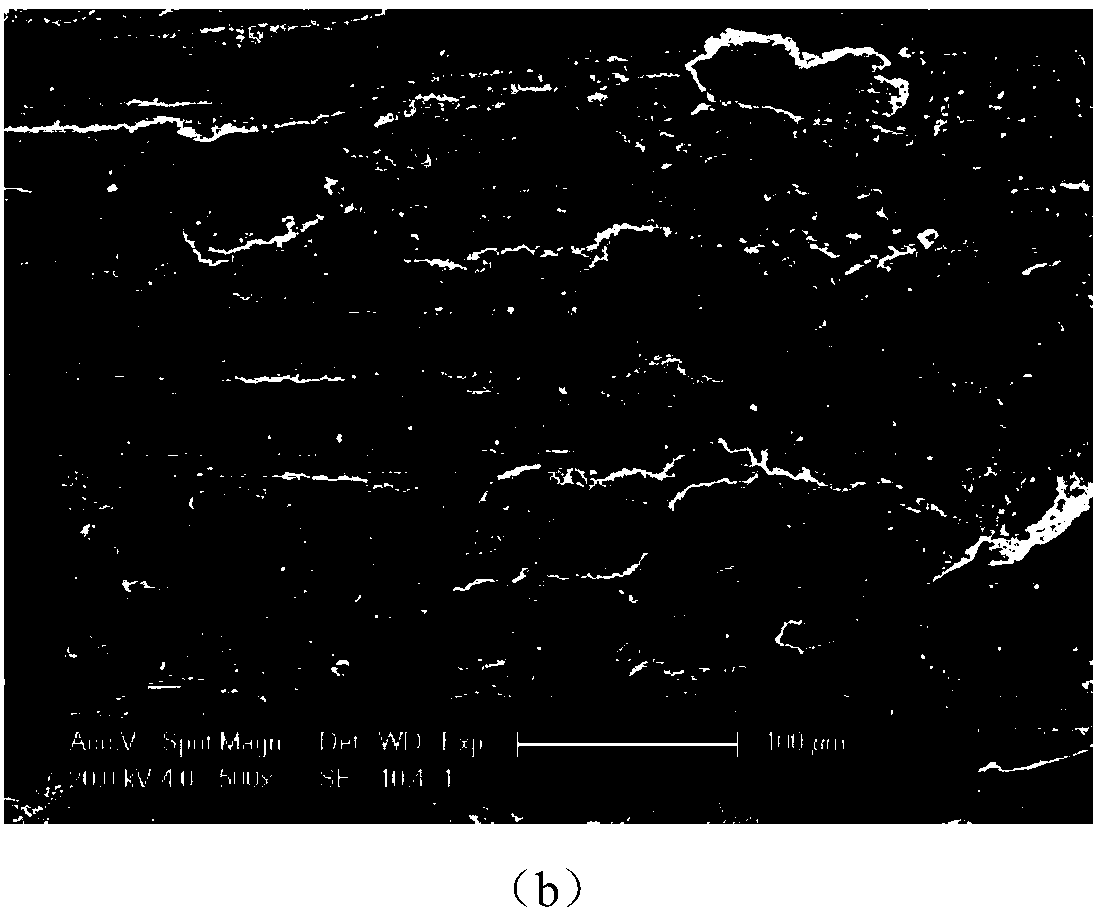

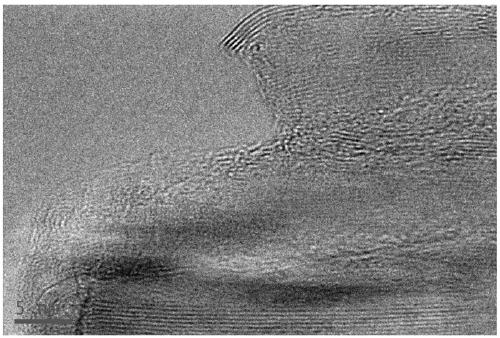

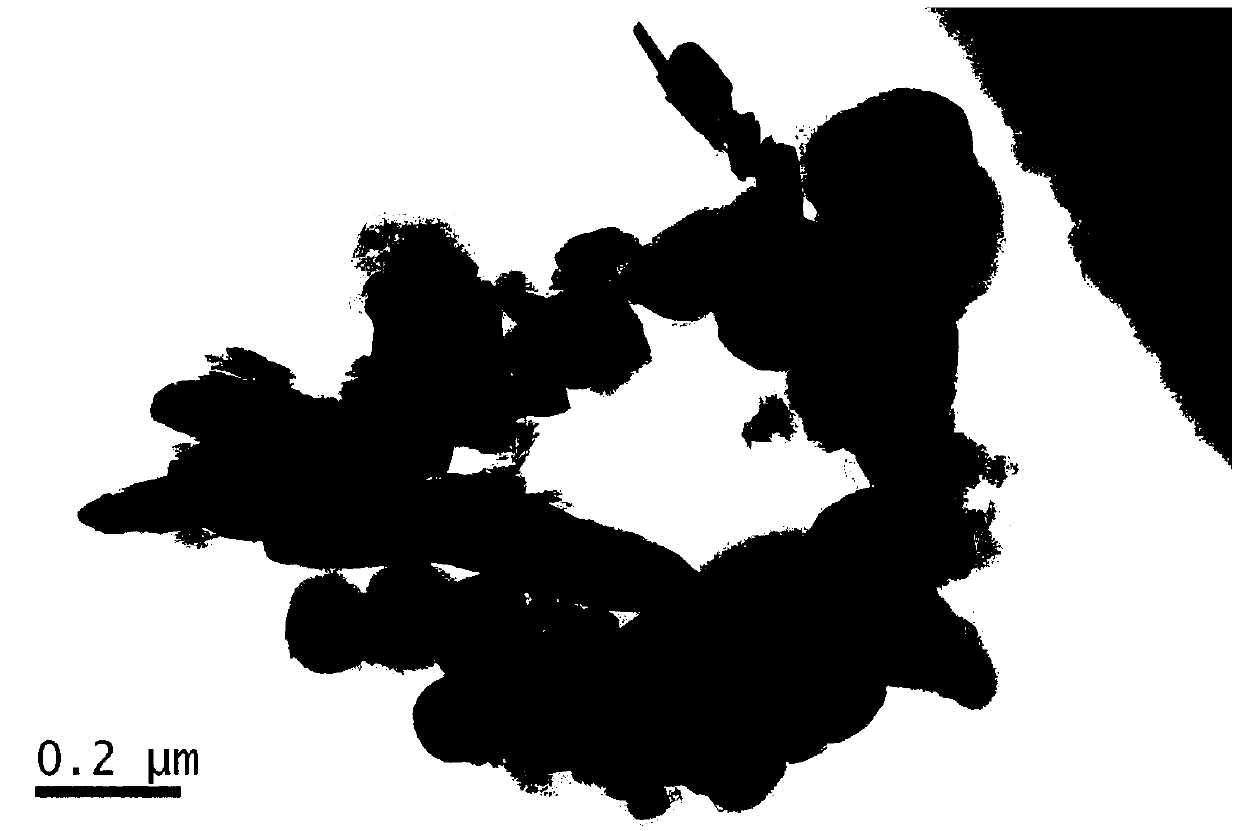

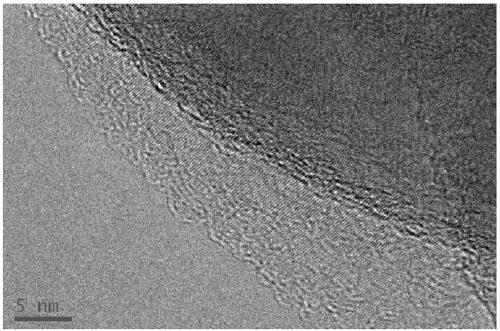

Preparation method of carbon/carbon-boron nitride anti-friction composite material

ActiveCN109665855AImprove mechanical propertiesImprove friction and wear propertiesFiberCarbon fibers

The invention discloses a preparation method of a carbon / carbon-boron nitride anti-friction composite material. The preparation method comprises acidizing a graphitized C / C blank, washing the acidizedC / C blank to be neutral to obtain a preprocessed C / C blank, immersing the preprocessed C / C blank into a solution containing modifier for reaction to obtain a functionalized C / C blank, impregnating the functionalized C / C blank with h-BN (hexagonal boron nitride) slurry, then drying the impregnated C / C blank to obtain a C / C-BN precursor, and performing carbonizing densification and graphitization on the C / C-BN precursor with a carbon source to obtain the C / C-BN anti-friction composite material; the modifier is selected from silane coupling agent or polyvinyl alcohol (PVA). According to the preparation method of the carbon / carbon-boron nitride anti-friction composite material, a slurry impregnation method is applied for the first time to produce a BN matrix, and after the C / C blank is functionalized, a slurry impregnation process can effectively introduce BN powder into the C / C blank. The preparation method of the carbon / carbon-boron nitride anti-friction composite material can effectively avoid damage of carbon fiber and ensure excellent structural strength of the C / C-BN composite material; the prepared C / C-BN composite material has excellent friction-wear properties.

Owner:CENT SOUTH UNIV

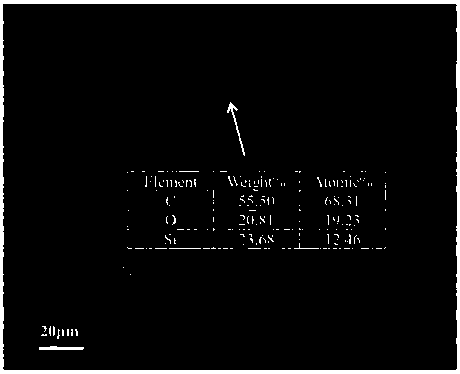

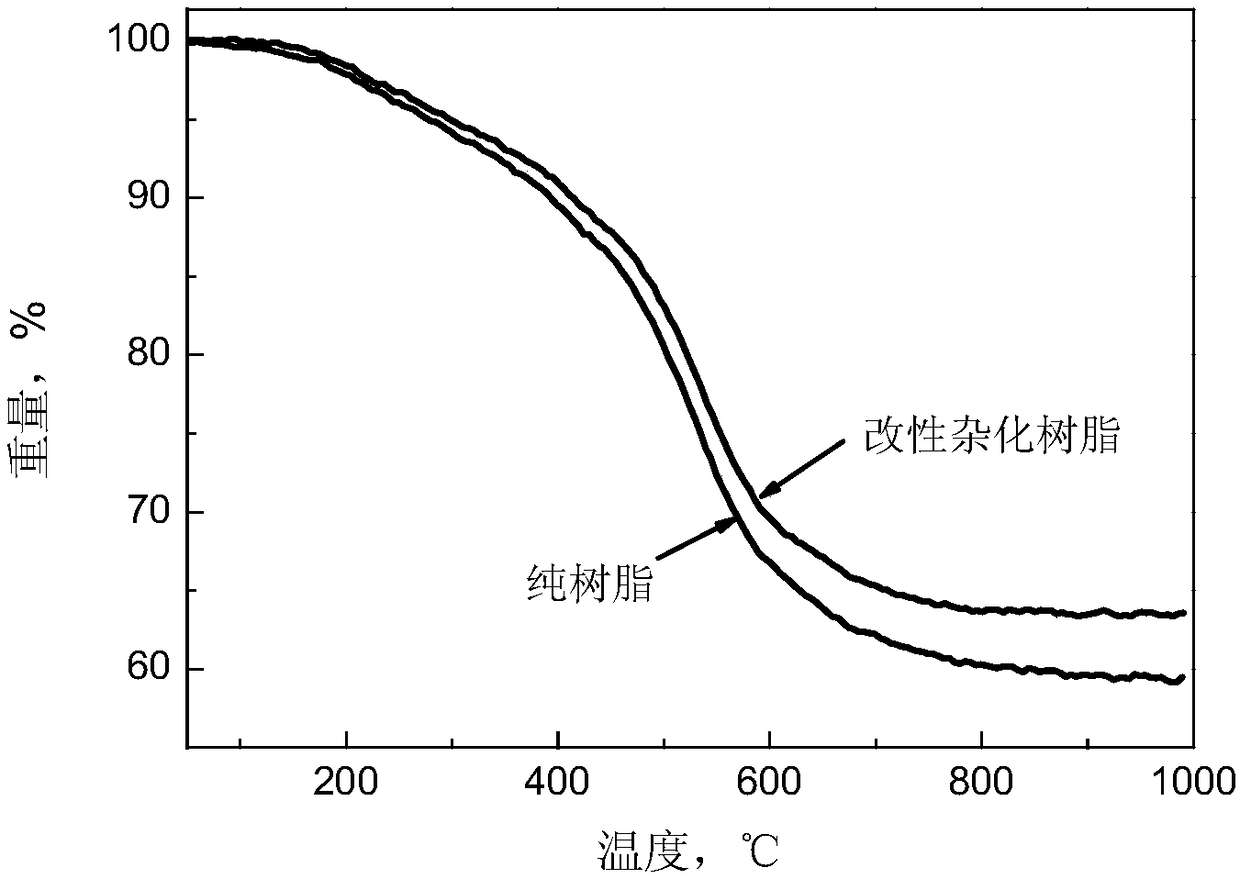

Silsesquioxane-modified hybrid phenolic resin, and preparation method and application thereof

The invention relates to a silsesquioxane-modified hybrid phenolic resin, and a preparation method and an application thereof, and belongs to the field of high-performance resin matrix composite materials. The silsesquioxane-modified hybrid phenolic resin provided by the embodiment of the invention is a hybrid phenolic resin cured product with a POSS molecule as a chemical crosslinking point, formed through reacting the POSS molecule represented by formula (1) with phenolic resin, and the addition of a POSS hybrid molecule strengthens nanoparticles, so the initial maximum decomposition temperature of the resin is improved to about 580 DEG C from 450 DEG C of pure resin, the residual weight is increased to about 65% from 58%, and the ablation resistance of the material is remarkably improved; and the POSS-modified hybrid phenolic resin provided by the invention has potential application prospects in the field of aerospacecraft resin-based advanced thermal protection materials.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

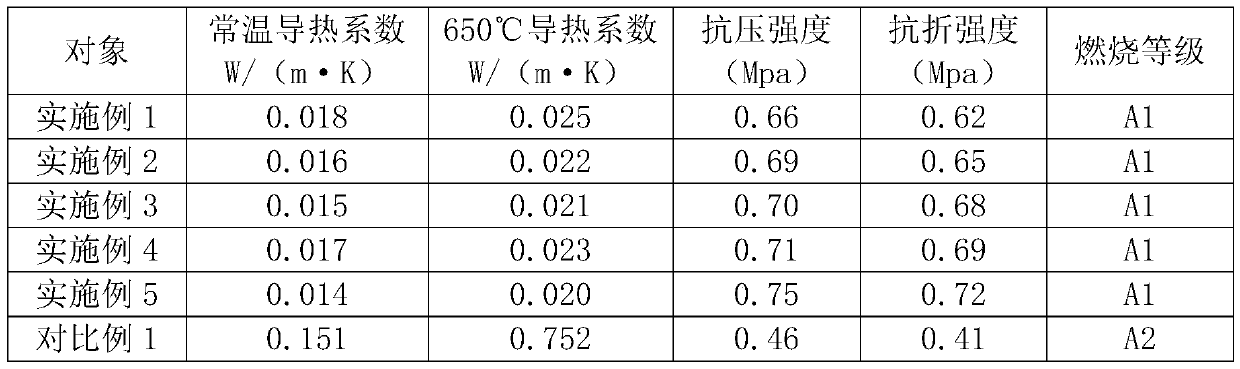

Basalt fiber thermal insulation decorative integrated plate and preparation method thereof

ActiveCN110357566AReduce convective heat transferImprove insulation effectCarbon fibersThermal insulation

The invention discloses a basalt fiber thermal insulation decorative integrated plate and a preparation method thereof, belonging to the technical field of building materials. According to the invention, carbon fiber and basalt fiber are taken as framework structural materials, modified SiO2 aerogel is taken as a heat insulation functional material, and inorganic fillers, adhesives and additives are combined to form the basalt fiber heat insulation decorative integrated plate. The basalt fiber thermal insulation decorative integrated plate can be used below 650 DEG C, has a thermal conductivity of about 0.02 W / (mK), is three to five times that of the traditional inorganic thermal insulation material, and can greatly improve the thermal insulation effect and high-temperature resistance.

Owner:中科华坤(北京)科技有限公司

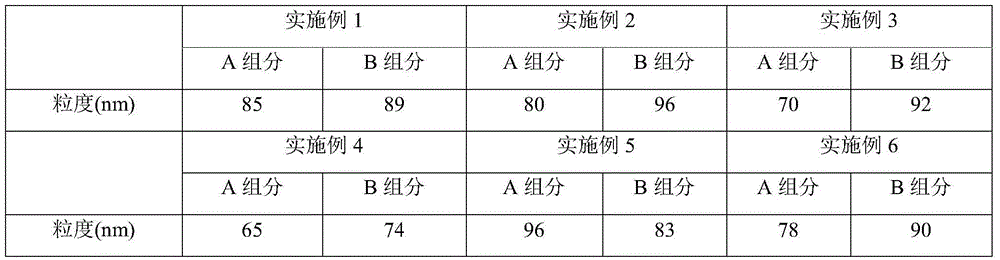

Nano stone surface treating agent and preparation method thereof

InactiveCN104356827AImprove durabilityGood penetration and adhesionCoatingsMicrocrystalline waxAcrylic resin

The invention discloses a nano stone surface treating agent which comprises a component A and a component B. The component A comprises the following raw materials in parts by weight: 1-2 parts of 5-10 wt% oxalate solution, 3-5 parts of 5-10 wt% fluosilicate solution, 6-9 parts of 30-50 wt% pure acrylic emulsion and 4-9 parts of water. The component B comprises the following raw materials: 3-5 parts of 15-20 wt% acrylic resin isopropanol solution, 1-2 parts of polyethylene wax or microcrystalline wax and 3-6 parts of solvent. The components A and B in the nano stone surface treating agent are both nano materials, and have favorable permeation and adhesion properties. The component A and component B are sequentially subjected to grinding treatment, so that the blend crystallizing layer formed by the component A and the specular layer formed by the component B form a firm and hard surface, thereby greatly enhancing the glossiness and being beneficial to enhancing the durability of the high glossiness of the stone surface.

Owner:HUAZHONG NORMAL UNIV

Preparation method of hollow silicon carbide microspheres

PendingCN112047343AMeet lightweight requirementsReduce dosageSilicon carbideMicrosphereCarbon nanotube

The invention relates to a preparation method of hollow silicon carbide microspheres. The preparation method is characterized by comprising the following steps: 1) preparing aerogel microspheres fromgraphene oxide and carbon nanotubes; 2) coating the aerogel microspheres with a phenolic resin or sucrose solution, and carrying out spray drying to obtain spherical powder; 3) preparing porous graphite microspheres by taking pyrolytic carbon as a coating film through curing and carbonizing processes; (4) coating the porous graphite microspheres with silica sol, heating and curing the porous graphite microspheres, heating the cured porous graphite microspheres and asphalt or other organic carbon in a vacuum furnace to 2000 DEG C, and carrying out heat preservation for 1-2 hours to carry out reaction sintering. 5) obtaining microspheres for generating silicon carbide coated porous graphite; 6) decomposing redundant organic carbon in an oxidizing furnace to obtain the silicon carbide microspheres with porous graphite as an inner core. and (7) mixing powder formed by mixing silicon nitride and silicon carbide micro-powder with the prepared silicon carbide microspheres, sintering at the high temperature of 1,600-2,000 DEG C under argon, and carrying out floating separation with water to obtain the compact hollow silicon carbide microspheres with the reinforced surfaces.

Owner:峨眉山市鑫锐新材料有限公司

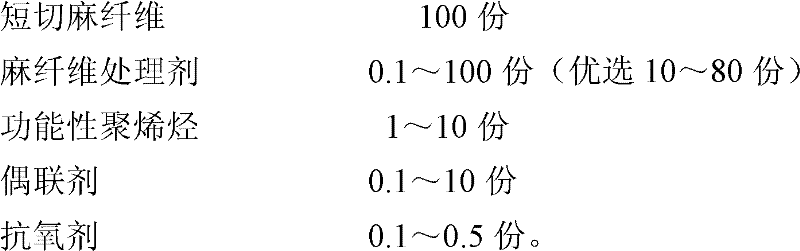

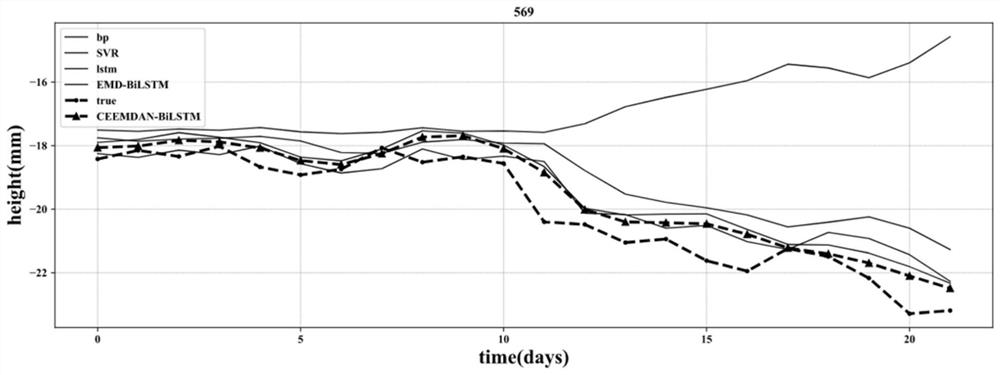

Fibrilia for plastic reinforcing and method for manufacturing the same

InactiveCN102232099AReduce surface polarityLow water absorptionVegetal fibresThin material handlingFiberPolyolefin

The present invention discloses a fibrilia for plastic reinforcing and a method for manufacturing the same. The fibrilia contains the following components in part by weight: 100 chopped fibrilias, 0.1 to 100 fibrilia agents, 1 to 10 functional polyolefins, 0.1 to 10 coupling agents and 0.1 to 0.5 antioxygens. The method comprises the steps of: cutting off the chopped fibrilias; immersing the cut chopped fibrilias into a sodium hydroxide solution and stirring the solution; washing out the chopped fibrilias after taking out them from the solution; drying the obtained chopped fibrilias; then immersing the dried chopped fibrilias into solution with the fibrilia agents; drying to obtain the chopped fibrilias with surface treatment; adding the chopped fibrilias, the coupling agents, the functional polyolefins and the antioxygens into a preheated kneader in order; and stirring to obtain the fibrilia for plastic reinforcing. The chopped fibrilias manufactured by the present invention has goodcolor, good rigidity, good heat resistance, and good compatibility with the plastic, thus the chopped fibrilias can be used for manufacturing chopped fibrilias / plastic composite materials with high performance, and can play a reinforcing role in plastic substrates.

Owner:BILIC FORTUNE TECH

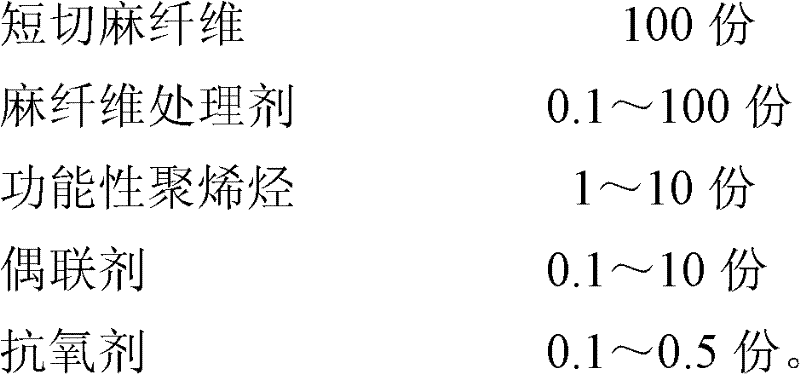

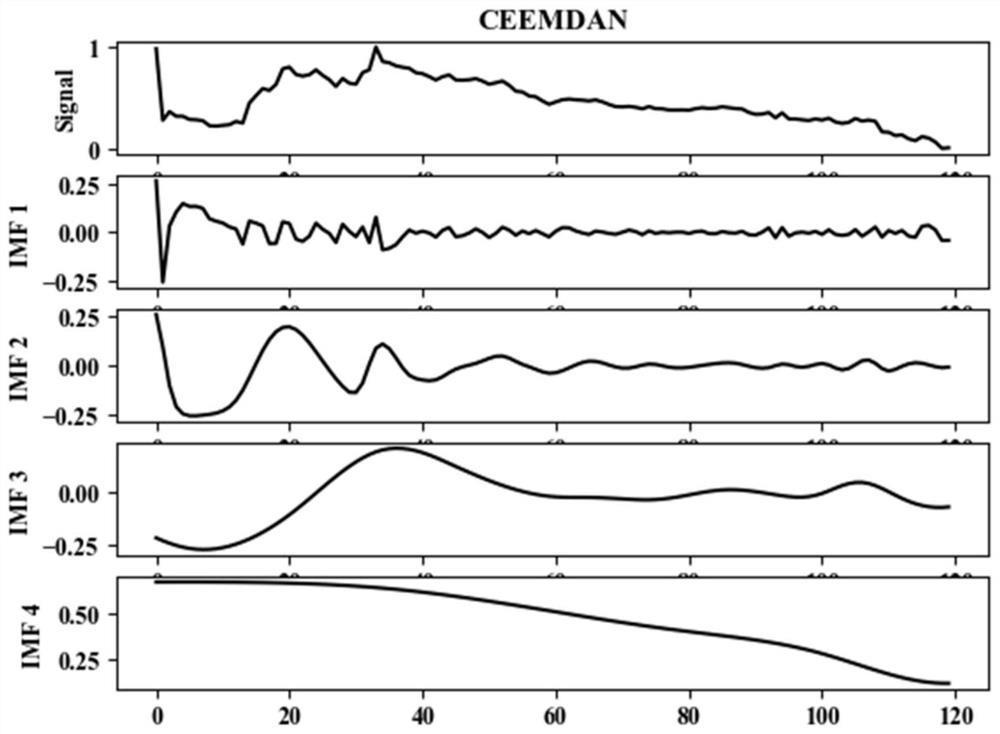

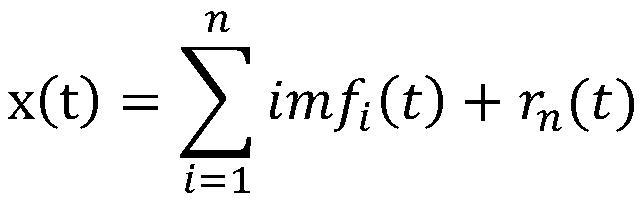

Tunnel settlement time sequence prediction method based on CEEMDAN-BiLSTM

PendingCN112434890APlay a role in enhancingGood prediction accuracyForecastingNeural architecturesAlgorithmEngineering

The invention discloses a tunnel settlement time sequence prediction method based on CEEMDAN-BiLSTM, and the method comprises the following steps: collecting ground surface settlement data above a tunnel, sequentially recording the settlement value of each collection point according to the time sequence, obtaining a single-dimensional tunnel settlement time sequence, and carrying out the preprocessing of the single-dimensional tunnel settlement time sequence; carrying out complete ensemble empirical mode decomposition of adaptive noise on the preprocessed tunnel settlement time sequence to obtain n stable intrinsic mode function IMF1-IMFn components with different scales and a residual error Res component; determining a time scale, reconstructing the decomposed IMF components and errors Res, normalizing unified dimensions, and determining a training set and a test set; establishing a bidirectional long-term and short-term memory network prediction model for each training set and each test set, and predicting a tunnel settlement subsequence; and reversely normalizing the tunnel settlement sub-sequences under different scales, superposing the tunnel settlement sub-sequences to obtaina final tunnel settlement result, and evaluating the prediction effect and stability of the model according to different evaluation indexes.

Owner:中国计量大学上虞高等研究院有限公司 +1

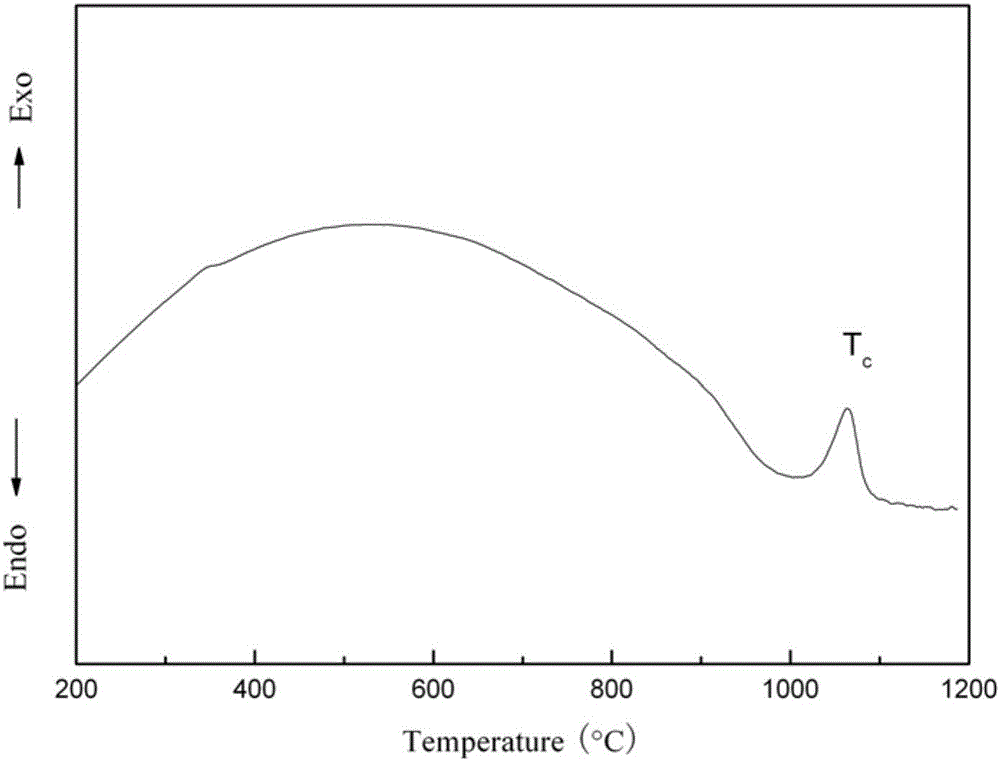

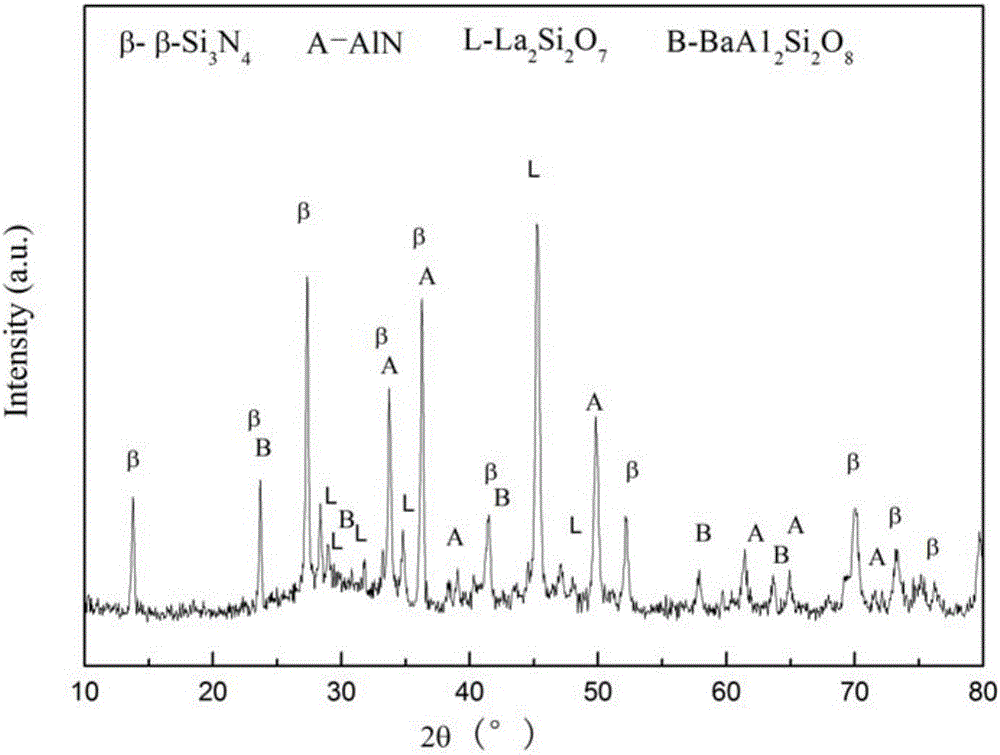

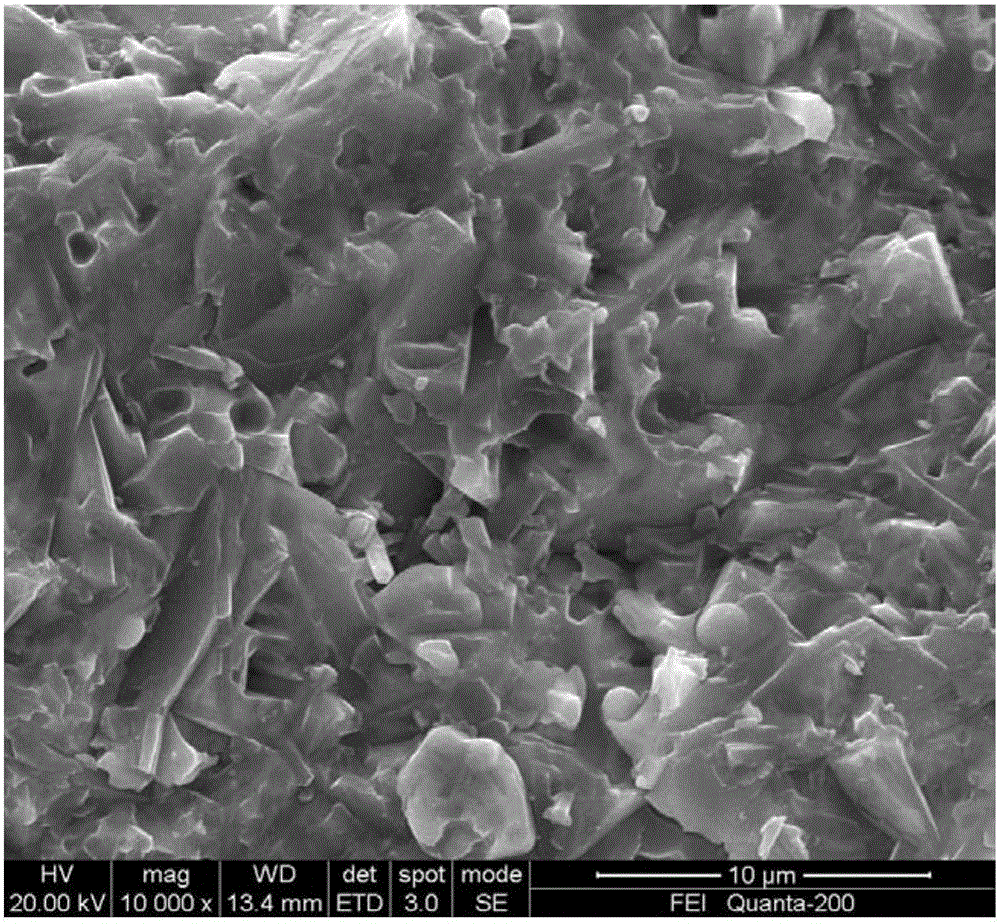

Self-enhancement-toughening silicon nitride/ aluminium nitride/ lanthanum barium silicate glass ceramics ternary composite material with self-enhancement-toughening and preparing method of ternary composite material

InactiveCN106830690ASmall coefficient of thermal expansionExcellent hot corrosion resistanceSilicon nitrideLanthanum

The invention discloses a self-enhancement-toughening silicon nitride / aluminum nitride / lanthanum barium silicate glass ceramics ternary composite material with self-enhancement-toughening and a preparing method of the ternary composite material. The ternary composite material adopts lanthanum barium silicate glass powder, aluminum nitride powder and alpha-silicon nitride powder as raw materials, is prepared through blanking and sintering, and contains beta-silicon nitride rod-like crystal. The silicon nitride / aluminum nitride / lanthanum barium silicate glass ceramics ternary composite material has the advantages of being low in density, high in strength, high in fracture characteristic, high in dielectric constant, low in inflation coefficient, high in conductivity and the like. The preparing method of the ternary composite material is simple in preparing process and low in the glass melting temperature and the composite material sintering temperature, and the ternary composite material is friendly to environment and low in production cost. The prepared ternary composite material has a good application prospect, can partially replace an existing high temperature structure material, and is applied in the fields of national defense and military industries, electronic devices, high thermal conductivity ceramic baseplates, high-end ceramic parts and the like.

Owner:CENT SOUTH UNIV

Preparation method of silicon carbide modified epoxy resin and silicon carbide modified epoxy resin composite material

The invention discloses a preparation method of silicon carbide modified epoxy resin and a silicon carbide modified epoxy resin composite material. The silicon carbide modified epoxy resin comprises the following raw materials: polyethylene fibers with a super-high molecular weight, 0.03-0.5g of Tris, 200ml of water, 0.1-0.8g of tannic acid, 3-8g of NaCl, silicon carbide, absolute ethanol, epoxy resin, and a 1,3-bis(aminomethyl)benzene curing agent. According to the method provided by the invention, the silicon carbide modified epoxy resin prepared by the method has a simple process and low costs, reagents used in the resin are conventional reagents, special equipment is not needed, and therefore the silicon carbide modified epoxy resin has the characteristic of easy industrialization implementation; and according to the silicon carbide modified epoxy resin prepared by the method, the silicon carbide is added into the epoxy resin, and the silicon carbide not only improves resin properties, but also improves interfacial bonding force by enhancing a cross network of the resin and the tannic acid.

Owner:江苏普泰克新材料科技有限公司

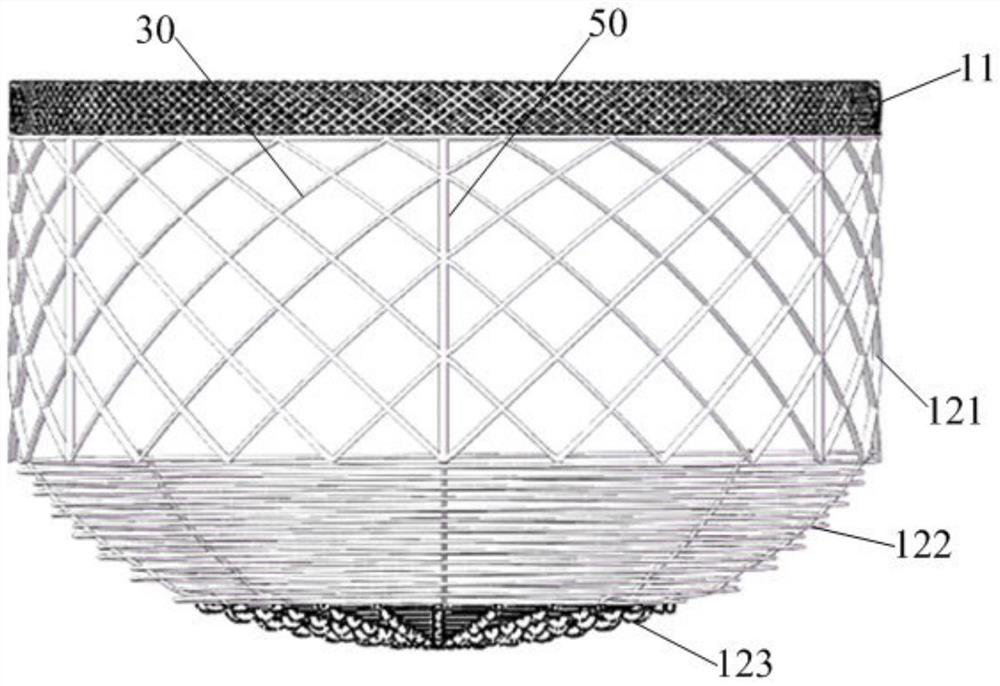

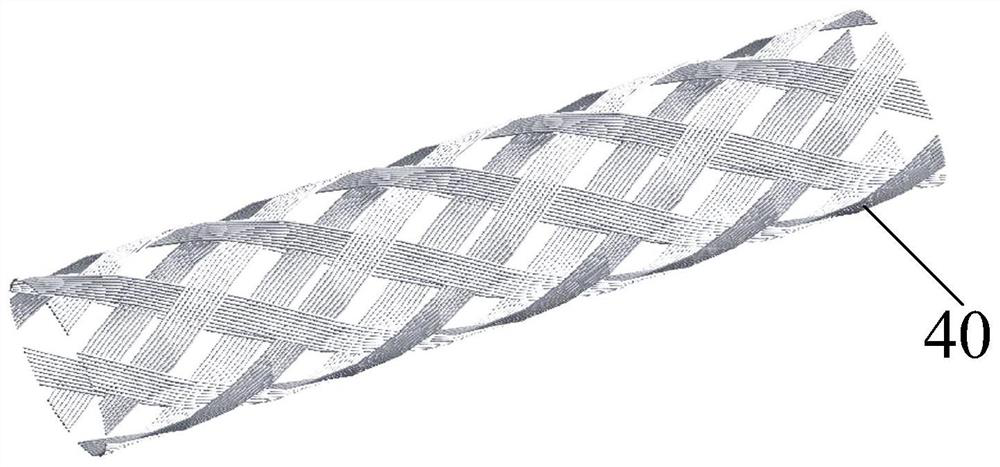

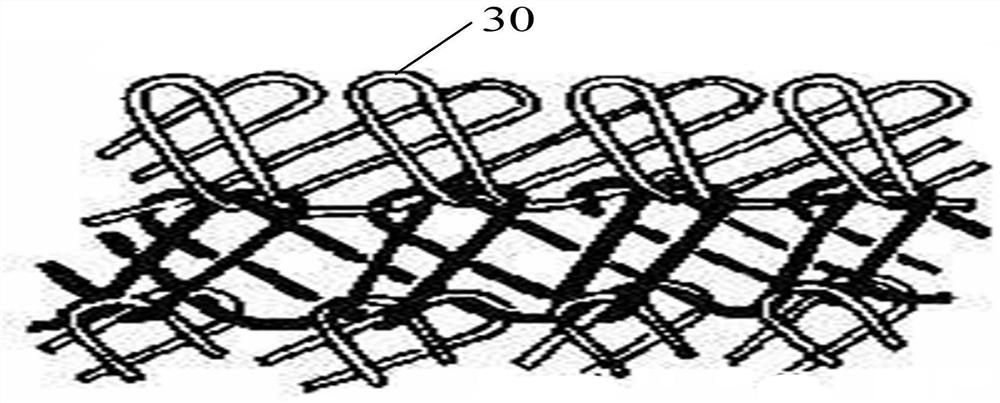

Integrally woven crucible preform and coated crucible prepared from same

PendingCN112176403AReduce processing wasteImprove plasticityPolycrystalline material growthBy pulling from meltFiberCarbon fibers

The invention provides an integrally-woven crucible prefabricated body which is a net-shaped body formed by weaving one or more carbon fiber ropes, and the crucible prefabricated body is formed by densely weaving an opening in the upper end and a compact weaving at the lower end. The crucible is formed by weaving one carbon fiber rope or a plurality of carbon fiber ropes, so that a prefabricated body is unnecessary and working hours are reduced. According to the crucible, straight carbon fiber ropes are adopted for weaving, so that a blank body does not need to be manufactured, the shape plasticity is high, limitation of the blank body is avoided, flexible design and batch production can be achieved, the delivery period is shortened, and material machining waste is little.

Owner:SHANGHAI QI JIE CARBON MATERIALS

Lake sediment curing agent

ActiveCN111675453AEasy curingFast curingFixation/solidifcation sludge treatmentContaminated waterways/lakes/ponds/rivers treatmentCelluloseAluminium chloride

The invention discloses a lake sediment curing agent, and relates to the technical field of sediment treatment. The lake sediment curing agent is prepared from the following raw materials in parts byweight: 3 to 5 parts of polymeric aluminum chloride, 1 to 2 parts of carboxymethyl cellulose, 25 to 35 parts of modified shell powder, 10 to 15 parts of polyacrylamide, 1 to 1.5 parts of N,N-methylenebisacrylamide, 0.5 to 1 part of acrylic acid and 5 to 10 parts of a promoter. The raw materials do not contain curing materials such as cement, lime, and the like, the pH value of cured sediment is neutral, and thus subsequent resource utilization is facilitated.

Owner:HANGZHOU XINGYUAN FILTER TECH +1

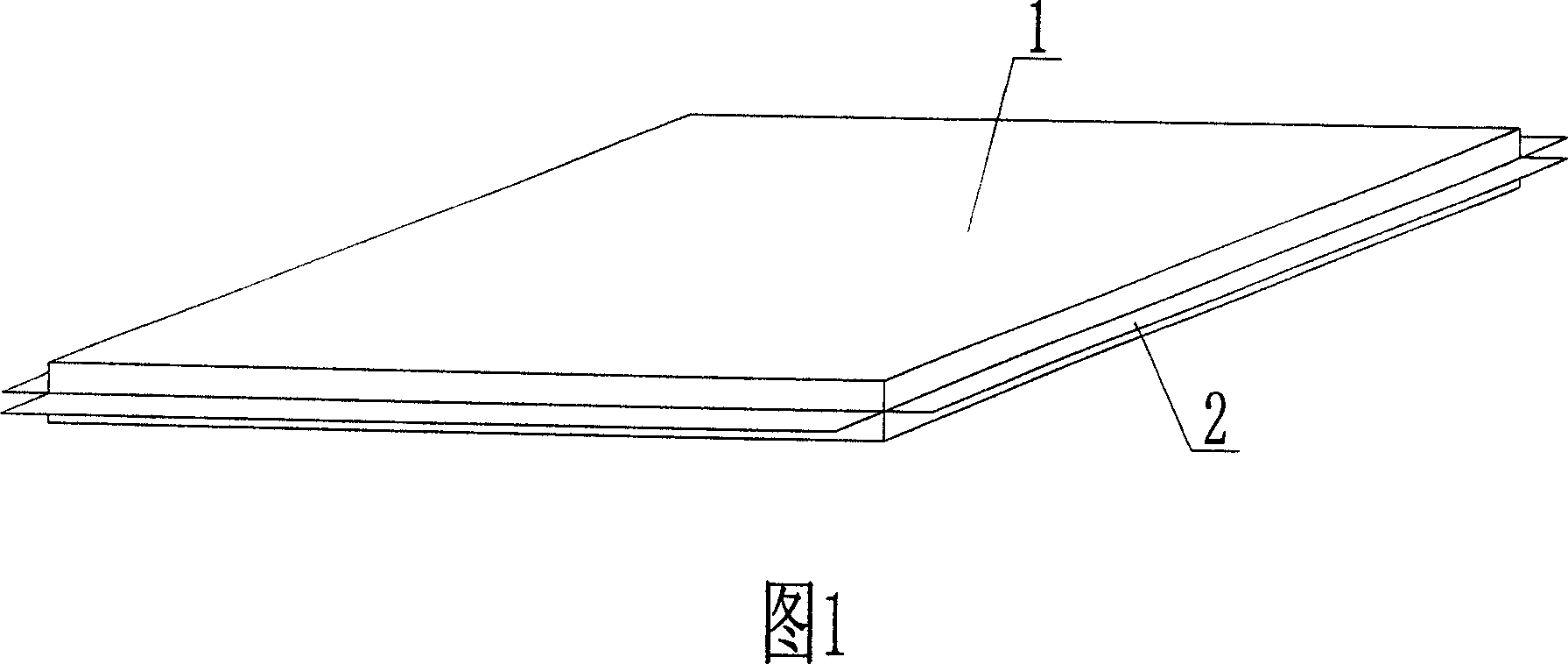

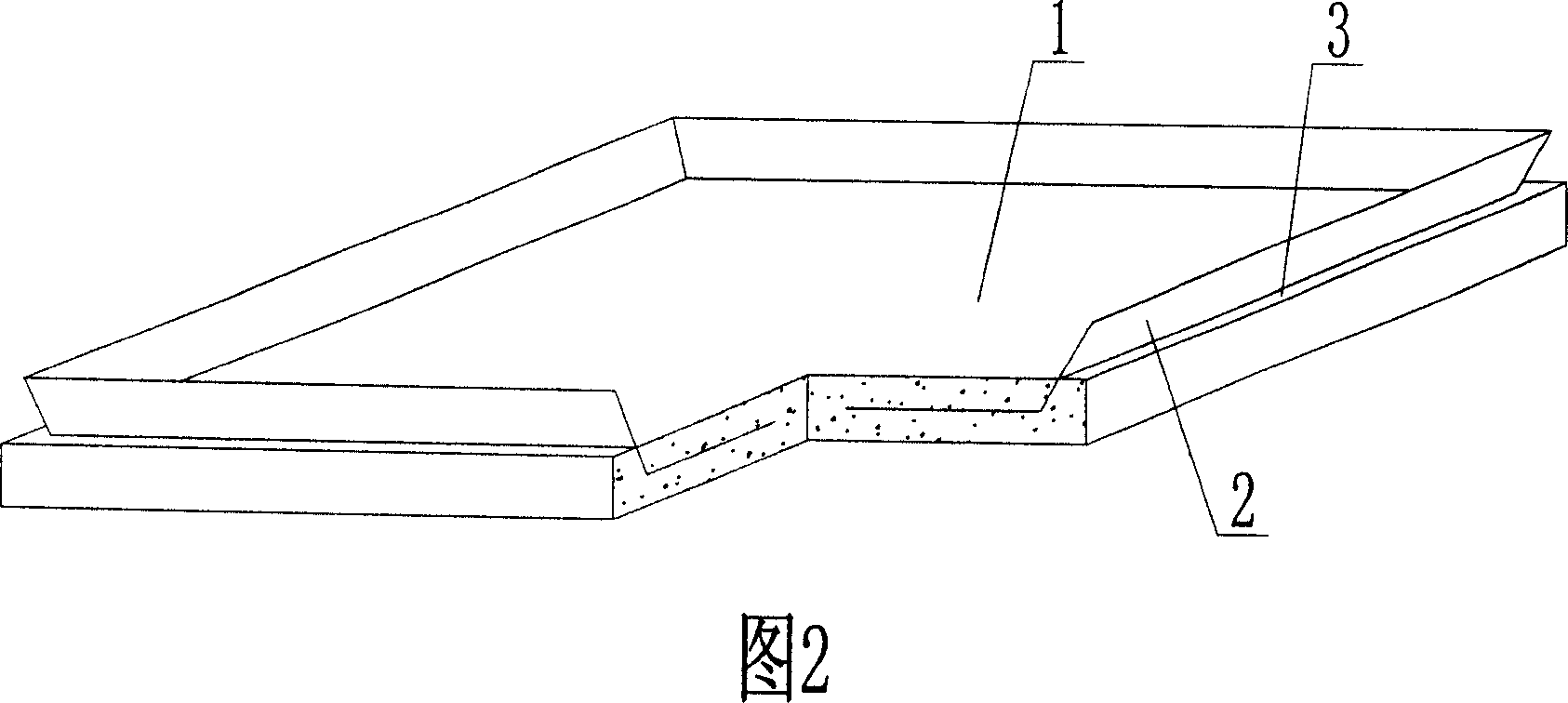

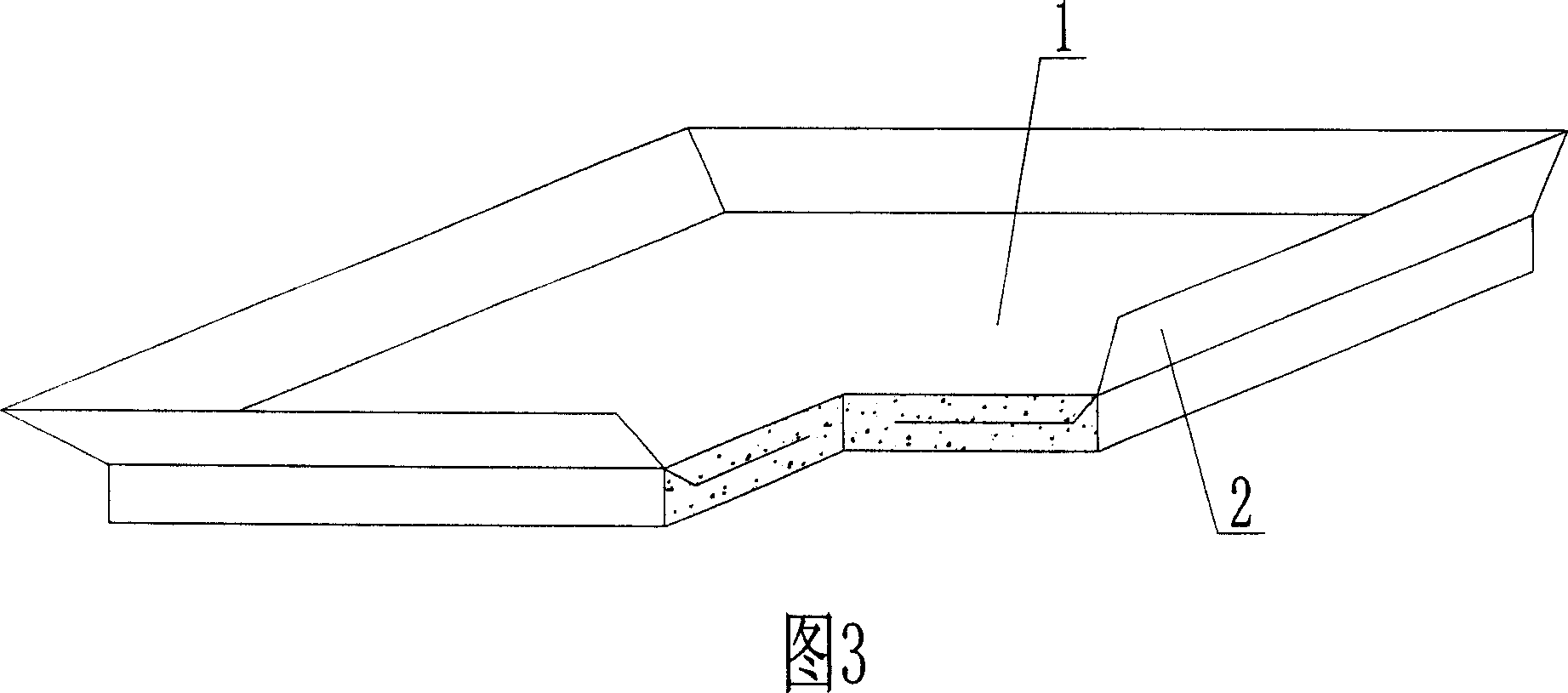

Reinforced concrete precast plate

Owner:湖南邱则有专利战略策划有限公司

Preparation method and application of composite toughened glass

PendingCN111533460AImprove mechanical propertiesHigh elastic modulusGlass furnace apparatusIon exchangeMolten glass

A preparation method of composite toughened glass comprises the following steps of: melting, clarifying and homogenizing all component raw materials of set glass to obtain molten glass without defectssuch as bubbles, stripes and the like; cooling the defect-free molten glass to a proper temperature, then adding a nanoscale ZrO2 crystal, and continuously stirring to obtain uniformly mixed molten glass; carrying out molding and annealing treatment on the uniformly mixed molten glass to obtain nanoscale ZrO2 crystal reinforced glass; carrying out efficient ion exchange chemical strengthening onthe reinforced glass to obtain composite toughened glass which is high in surface pressure stress, large in ion exchange layer depth and capable of meeting cover plate protection. The composite toughened glass provided by the invention has effectively-improved strength and toughness and improved mechanical properties, and can be widely applied to the fields of cover plates of electronic equipment,household appliances, display devices and the like.

Owner:CHANGSHU JIAHE DISPLAY TECH CO LTD

High-performance activated carbon paper and production method thereof

InactiveCN107724183ADense structureFiber bonded wellWater-repelling agents additionFiltration separationIodine valueActivated carbon

The invention discloses high-performance activated carbon paper. The high-performance activated carbon paper comprises activated carbon, plant celluloses, polyester fiber pulp, PE / PET composite chopped fibers and sizing agents. The high-performance activated carbon paper is obtained by the steps of preparation of plant cellulose pulp, preparation of the polyester fiber pulp, and preparing, dryingand forming of activated carbon pulp. The high-performance activated carbon paper, as a functional filter material, has an adsorption function of the activated carbon and functions of intercepting andfiltering out suspended particulate matters and filtering out residues; the iodine value of the filter material reaches 550-800mg / g, and benzene adsorption rate can reach 18-28%; the high-performanceactivated carbon paper is widely applied to various industries such as air purification and water treatment, filtration and purification, can remove residual chlorine, TOC (total organic carbon), chemical pollutants and the like in water effectively, has good decoloration effect, and can remove substances such as formaldehyde, benzene, ammonia and TVOC (total volatile organic compounds) in the air. The filter material in the form is convenient to cut, roll, fold and clean, and environment protection and rapidness are achieved.

Owner:南通三友环保科技有限公司

Preparation method of machine air filter paper

ActiveCN109355978AHigh activityImprove adsorption capacityPaper coatingPaper/cardboardChemical LinkagePolymer resin

The invention relates to the technical field of filter paper, and discloses a preparation method of machine air filter paper. The preparation method includes the steps: soaking raw paper into trimesoyl chloride solution; soaking the raw paper into oil-phase solution; soaking the raw paper into 1, 2, 6-hexanetriol water-phase solution; performing interfacial polymerization reaction on the raw paperin the water-phase solution to generate polyurethane polymer resin; covering the surface of the raw paper with a polyurethane resin protection layer. The resin protection layer is connected with theraw paper through the bonding action force of a chemical bond, the resin protection layer and the raw paper cannot be easily separated under the influence of outside conditions, so that the raw paperis protected for a long time, and the service life of the machine air filter paper is prolonged.

Owner:马鞍山华旺新材料科技有限公司

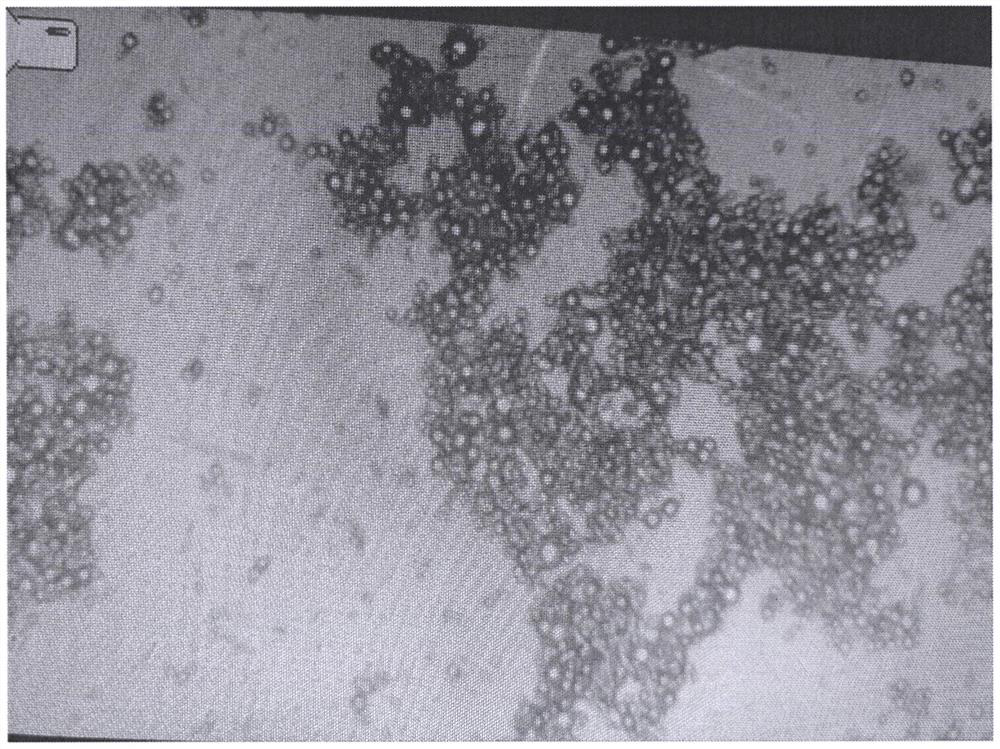

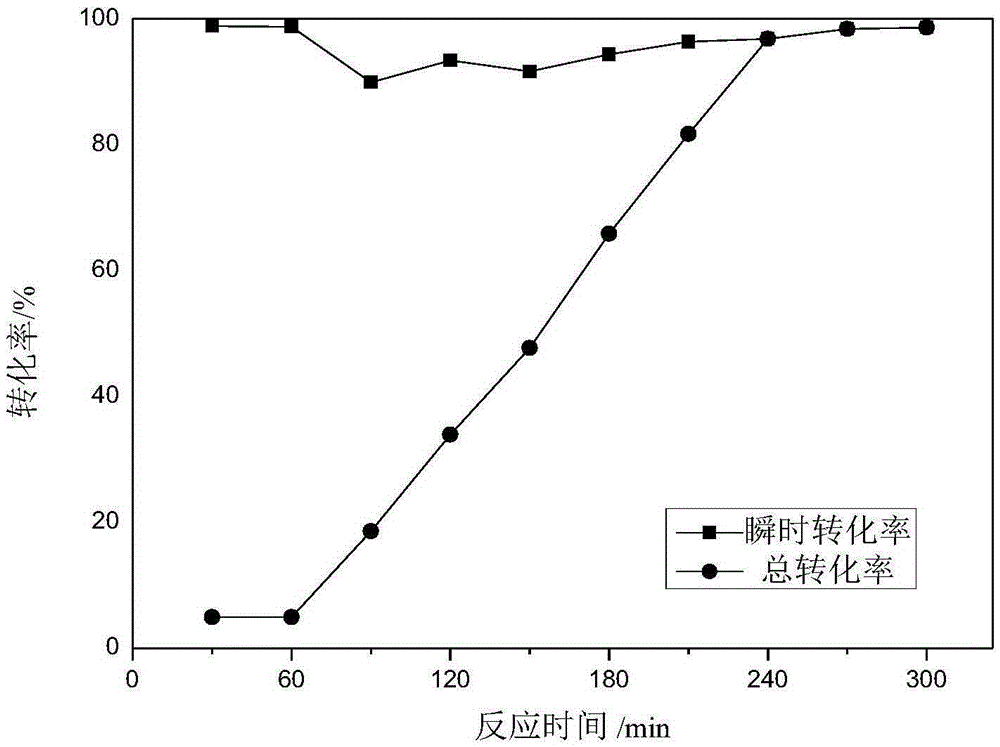

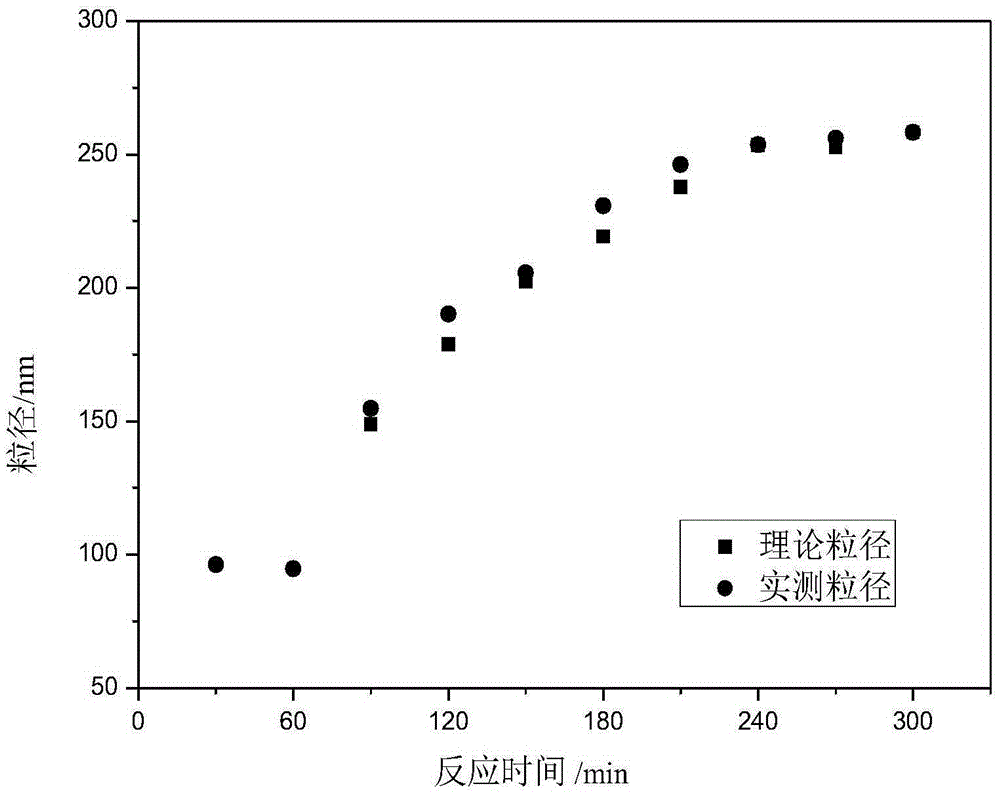

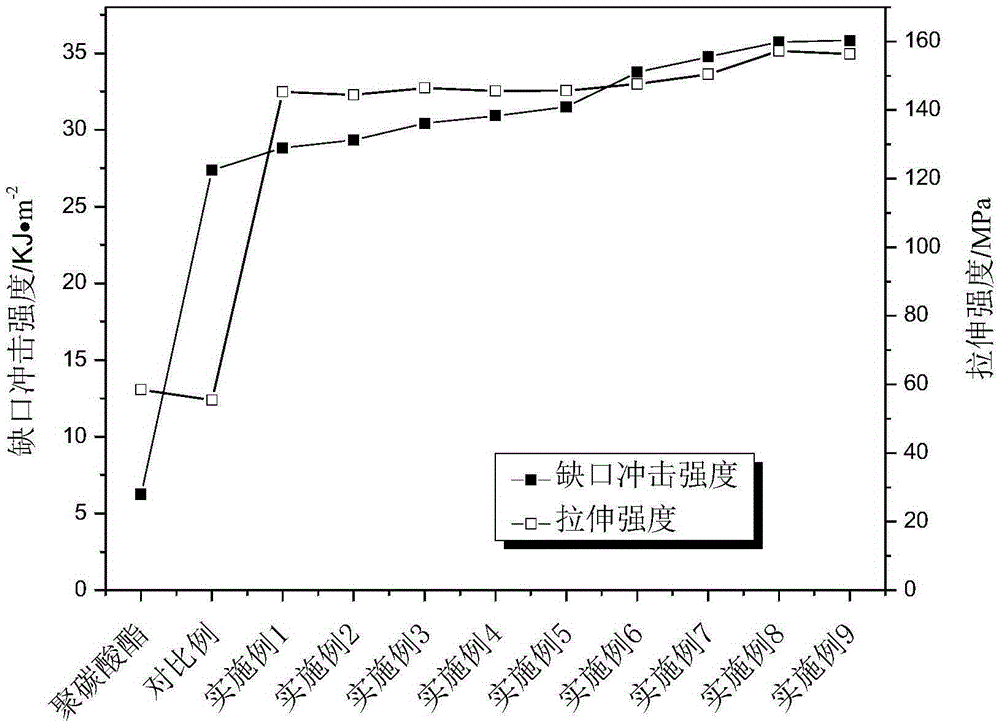

Preparation method of acrylate polymer/montmorillonite composite particles for toughening makrolon

The invention discloses a preparation method of acrylate polymer / montmorillonite composite particles for toughening makrolon. The preparation method comprises the steps that emulsifier dosage at a seed stage and a polymeric monomer of an elastomer are selected, a seed emulsion polymerization technology is utilized, the elastomer at the seed stage is prepared, the growth of particle size of the elastomer and the in-situ coating of a plastic outer layer are realized, an adding mode of an initiator is regulated, then emulsified montmorillonite dispersion liquid is added into emulsion, so that montmorillonite layers are uniformly dispersed among emulsion particles, and acrylate polymer / montmorillonite composite particles are obtained by demulsification. 1.96 percent of acrylate polymer / montmorillonite composite particles are blended with makrolon, the notch impact strength of a composite material at low temperature is increased by 3 times compared with that of purified makrolon, meanwhile the tensile strength of the composite material is increased by 1 time or more compared with that of the purified markrolon, and the aims of toughening and enhancing at the same time are realized.

Owner:天津瑞宏汽车配件制造有限公司

Preparation method of epoxy resin nano-grade composite material

The invention provides a preparation method of an epoxy resin nano-grade composite material. The method is characterized in comprising the steps that: nano-particles processed through a surface treatment are added into acetone while stirring; the mixture is subjected to an ultrasonic treatment for tens of minutes; the obtained solution is uniformly mixed with epoxy resin while stirring, and solvent is removed; the mixture is heated to 130 DEG C and is subjected to a reaction for th; The obtained material is dispersed for 20min in a high-speed homogenization dispersion machine; the obtained material is cooled, a proper amount of a curing agent is added into the material, and the mixture is uniformly mixed; vacuum pumping and degassing are carried out, and the material is poured into a steel mold which is applied with a demolding agent and which is already preheated; the material is completely cured for 5h under a temperature of 130 DEG C and 5h under a temperature of 150 DEG C; and the material is cooled and demolded.

Owner:费金华

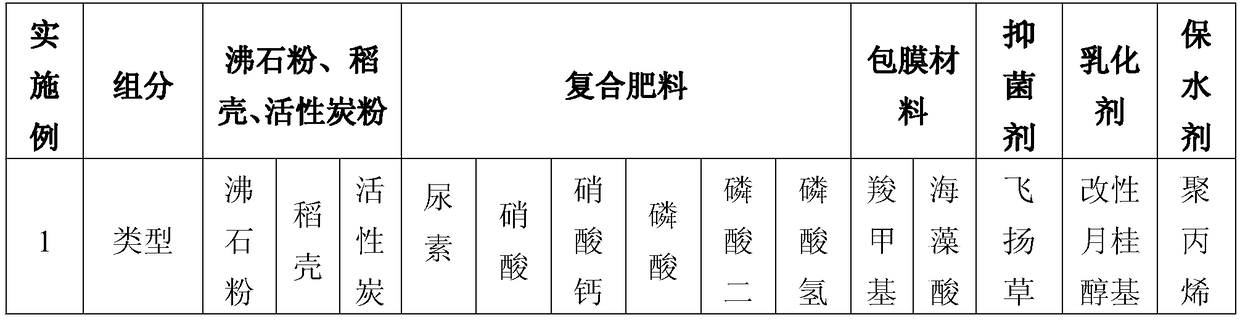

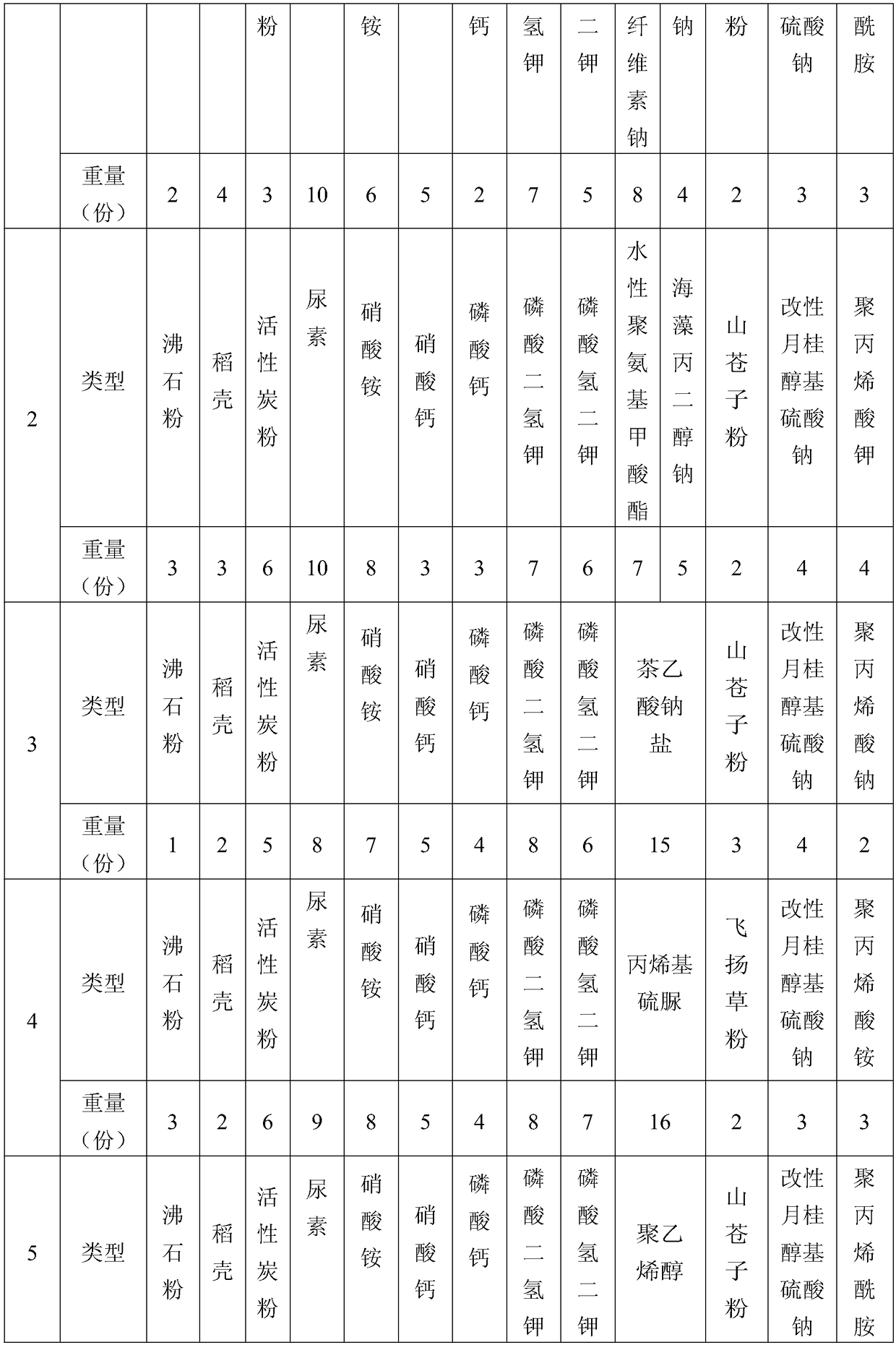

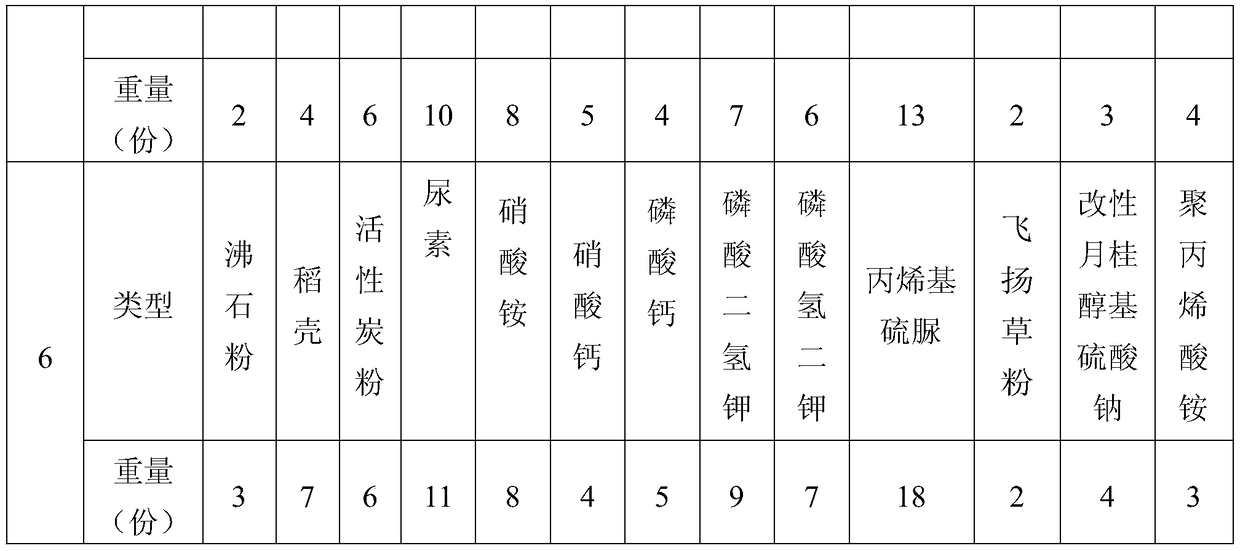

Slow-release compound fertilizer and preparation method thereof

InactiveCN108821895ALow costGood coating effectAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDipotassium hydrogen phosphateMonopotassium phosphate

The invention provides a slow-release compound fertilizer. The slow-release compound fertilizer comprises the following components: 1-4 parts of zeolite powder, 2-10 parts of rice husks, 2-8 parts ofactivated carbon powder, 30-50 parts of a compound fertilizer, 10-20 parts of a coating material, 1-3 parts of a bacteriostatic agent, 1-4 parts of a binder, 1-6 parts of an emulsifier, and 2-5 partsof a water retention agent, wherein the compound fertilizer is composed of the following materials: 8-12 parts of urea, 6-10 parts of ammonium nitrate, 3-6 parts of calcium nitrate, 2-5 parts of calcium phosphate, 6-10 parts of potassium dihydrogen phosphate, and 5-7 parts of dipotassium hydrogen phosphate; the bacteriostatic agent is one of euphorbia hirtapowder and litsea cubeba powder; and a mass ratio of the zeolite powder to the rice husks to the activated carbon powder is 3:7:4. The slow-release compound fertilizer provided by the invention has the advantages of an adjustable nutrient ratio, remarkable effects of slow release and yield increasing, and antibacterial water-retention functions, and can solve the technical problems that a slow-release effect of a compound fertilizer in the prior art is not ideal and a function is single; and the production process of the slow-release compound fertilizer is simple and has better demonstration and promotion effects.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

High-strength environment-friendly regenerated plastic particles

The invention discloses high-strength environment-friendly regenerated plastic particles characterized in that the particles are prepared from the following raw materials in parts by weight: 50-100 parts of waste polyvinyl chloride, 10-15 parts of 2-amino-1,3,5-triazine-4,6-dithiol / diallyl isocyanurate polycondensate, 5-10 parts of walnut shell powder, 2-5 parts of nano boron fibers, 1-3 parts ofpolyvinyl chloride fibers, 3-6 parts of alpha-amino functionalized styrene-butadiene thermoplastic rubber, 1-3 parts of titanium bis(triethanolamine)diisopropoxide, 0.5-1.5 parts 4,4'-(phenylphosphinidene)bis(benzenesulfonic acid) dipotassium salt hydrate, 0.5 to 2 parts of a plasticizer, 0.5 to 2 parts of a compatilizer and 0.5 to 2 parts of an antioxidant. The invention further discloses a regeneration method of the high-strength environment-friendly regenerated plastic particles. The high-strength environment-friendly recycled plastic particles disclosed by the invention are high in strength, sufficient in toughness, good in stability and excellent in weather resistance.

Owner:界首市圣通无纺布有限公司

Preparation method of autoclaved aerated concrete block and autoclaved aerated concrete block

The invention discloses a preparation method of an autoclaved aerated concrete block. The preparation method comprises the following steps: S1, preparing an additive A from aluminum powder paste, sodium sulfate and sodium abietate; and preparing fly ash, bagasse, juncus roemerianus powder, lime powder, gypsum powder and the additive A into ball billets, and curing to obtain lightweight aggregate; s2,preparing fly ash, ceramic tile waste, glass waste, quicklime and gypsum powder into a mixture; s3, preparing sodium hydroxide, rosin powder, triethanolamine and sodium silicate into an additive B; and S4, preparing a brick blank from the lightweight aggregate, the mixture, cement and the additive B, and maintaining the brick blank to obtain the autoclaved aerated concrete block. The invention further discloses the autoclaved aerated concrete block which is prepared by the preparation method of the autoclaved aerated concrete block. According to the autoclaved aerated concrete block, the construction waste, the household waste and the industrial waste are reasonably utilized, waste is turned into wealth, resource waste and environmental pollution are reduced, and the autoclaved aerated concrete block which is high in compressive strength and breaking strength and light in weight is prepared.

Owner:广西建工集团建筑产业投资有限公司

Heating cable with high weather resistance

InactiveCN108034152AEasy to useImprove structural strengthHeating element shapesHeating element materialsFiberInsulation layer

The invention relates to the technical field of cables, in particular to a heating cable with high weather resistance. The heating cable comprises cable core wires, heat conduction insulation layers and sheaths. The heat conduction insulation layers and the sheaths are sequentially coated outside the cable core wires from the inside to the outside; the heat conduction insulation layers comprise heat conduction insulation inner layers and heat conduction insulation outer layers; the sheaths comprise 80-100 parts of chlorinated polyethylene rubber, 8-15 parts of nitrile rubber, 5-15 parts of inorganic reinforcing fillers, 1-5 parts of ceramic fibers, 1-5 parts of carbon fibers, 6-10 parts of silane coupling agents, 0.01-0.5 part of antioxidants, 0.1-1 part of ultraviolet absorbents and 0.03-0.8 part of hydrolysis-resistant agents. The heating cable has the advantages that blending modification is carried out on the chlorinated polyethylene rubber and the nitrile rubber in the sheaths, accordingly, the heating cable is temperature-resistant, flame-retardant, high-low-temperature-resistant and oil-resistant, and the structural strength of the heating cable can be improved; the heatingcable with the heat conduction insulation inner layers is impact-resistant and accordingly can be assuredly reliably used in extreme environments.

Owner:曹结宾

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com