Preparation method of acrylate polymer/montmorillonite composite particles for toughening makrolon

A technology of acrylate and polycarbonate, which is applied in the field of preparation of acrylate polymer/montmorillonite composite particles for polycarbonate toughening, and can solve the problems of poor processing performance and decreased tensile strength of the blend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

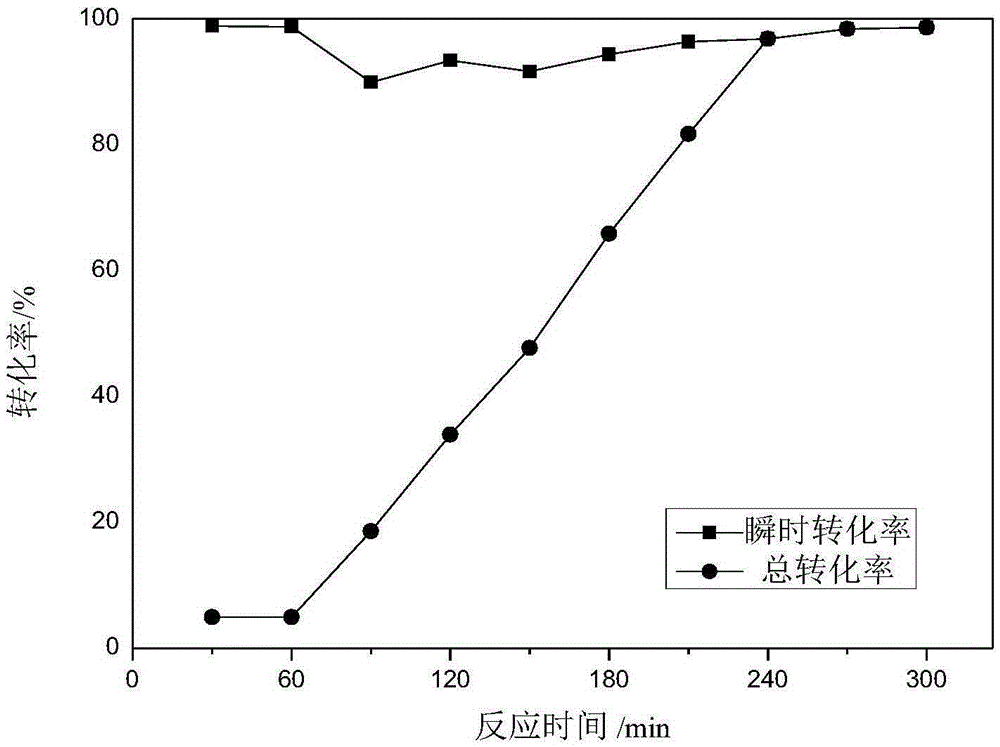

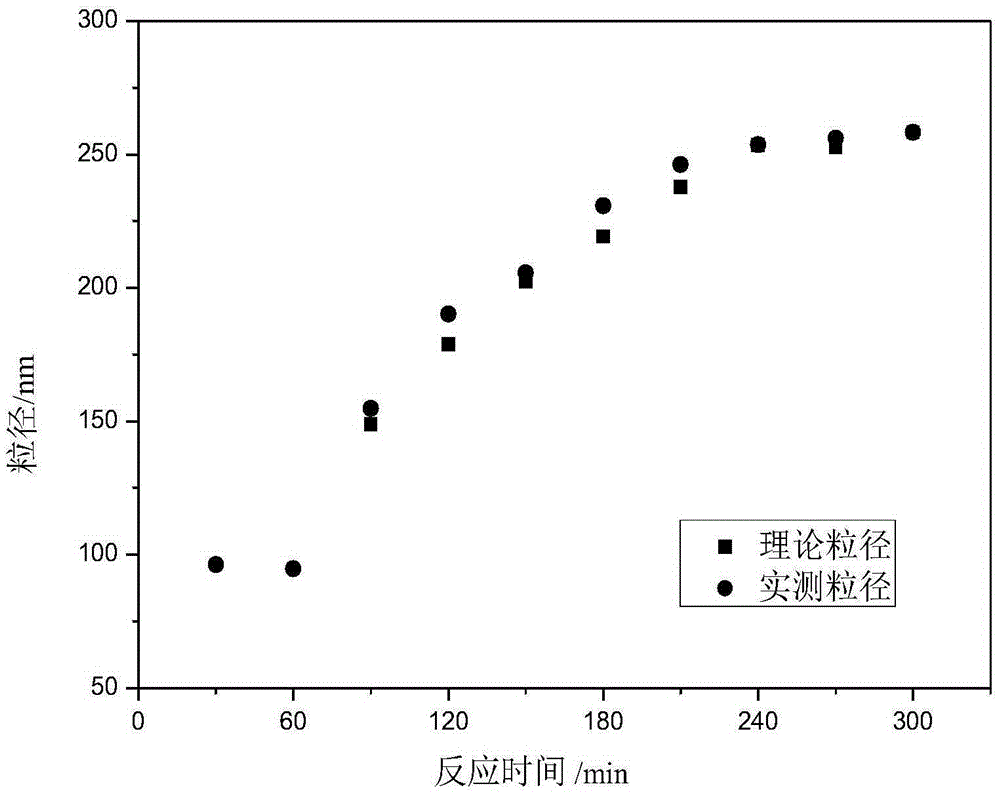

Examples

Embodiment 1

[0046] a. Pre-emulsification of seed monomer

[0047] First, add 0.71g of anionic emulsifier sodium dihexyl adipate sulfonate and 150g of deionized water into a 500ml four-neck flask, and mix and stir for 30 minutes; then add 12g of 2-ethyloctyl acrylate to the reactor The monomer and 0.04g of cross-linking agent 1,4-butanediol diacrylate were placed on an electromagnetic stirrer and stirred for 20 minutes to obtain a seed monomer pre-emulsion for later use;

[0048] b. Pre-emulsification of monomers in the growth phase of the nuclear layer

[0049] Add 2.13g of anionic emulsifier sodium dihexyl adipate sulfonate, 168g of 2-ethyloctyl acrylate monomer and 0.85g of crosslinking agent 1,4-butanediol diacrylate into a 400ml beaker, then Place it on an electromagnetic stirrer and mix and stir for 20 minutes to obtain a monomer pre-emulsion in the growth stage of the nuclear layer, which is set aside;

[0050] c. Pre-emulsification of the outer monomer

[0051] Add 0.40g of anio...

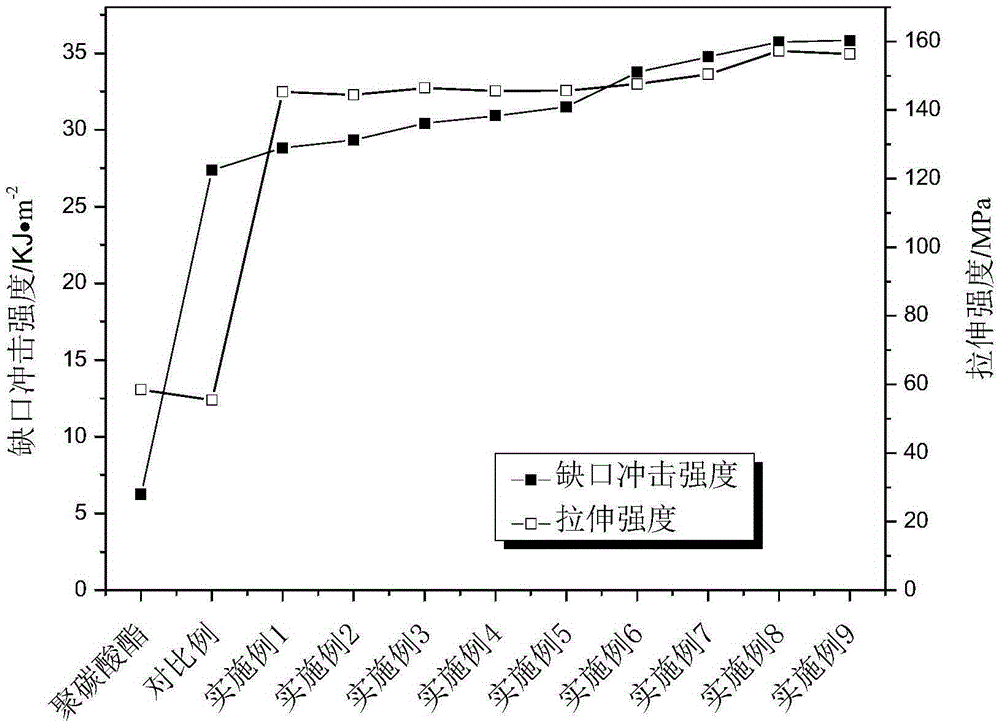

Embodiment 2~9

[0083] The other steps are the same as in Example 1, but the changes in the quality of emulsifier 1 at the seed stage in step a, the quality of montmorillonite in step d and the quality of emulsifier 2 used in Examples 2 to 9 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com