Preparation and ageing treatment process for novel Al-Mg-Si-Er aluminum alloy plate material

An aluminum alloy sheet and aging treatment technology, applied in the field of metal alloys, can solve the problems of reducing the precipitation time of aging precipitates, stress corrosion, and limiting the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Put the pre-prepared high-purity aluminum ingot into the graphite crucible. After the aluminum ingot is completely melted, add aluminum-silicon and aluminum-erbium alloys in sequence, and finally add high-purity magnesium ingot. At the same time, wrap the magnesium ingot with aluminum foil. After all the metals are melted After adding hexachloroethane (the content is 2% of the mass of the metal raw material) and stirring evenly, let it stand still, remove the slag, and finally pour the molten metal into an iron mold whose inner wall is coated with a mixed solution of zinc oxide and water glass. After the ingot was homogenized in an air circulation furnace at 560°C for 6 hours, the surface scale and defects were milled on a machine tool to prepare for rolling. Before rolling, the metal ingot is heated to 450°C for 2 hours, hot-rolled and cold-rolled on a 310×480mm twin-roll rolling mill, with about 13 passes in between, and the final thickness is about 2mm. ℃ for 40 minu...

Embodiment 2

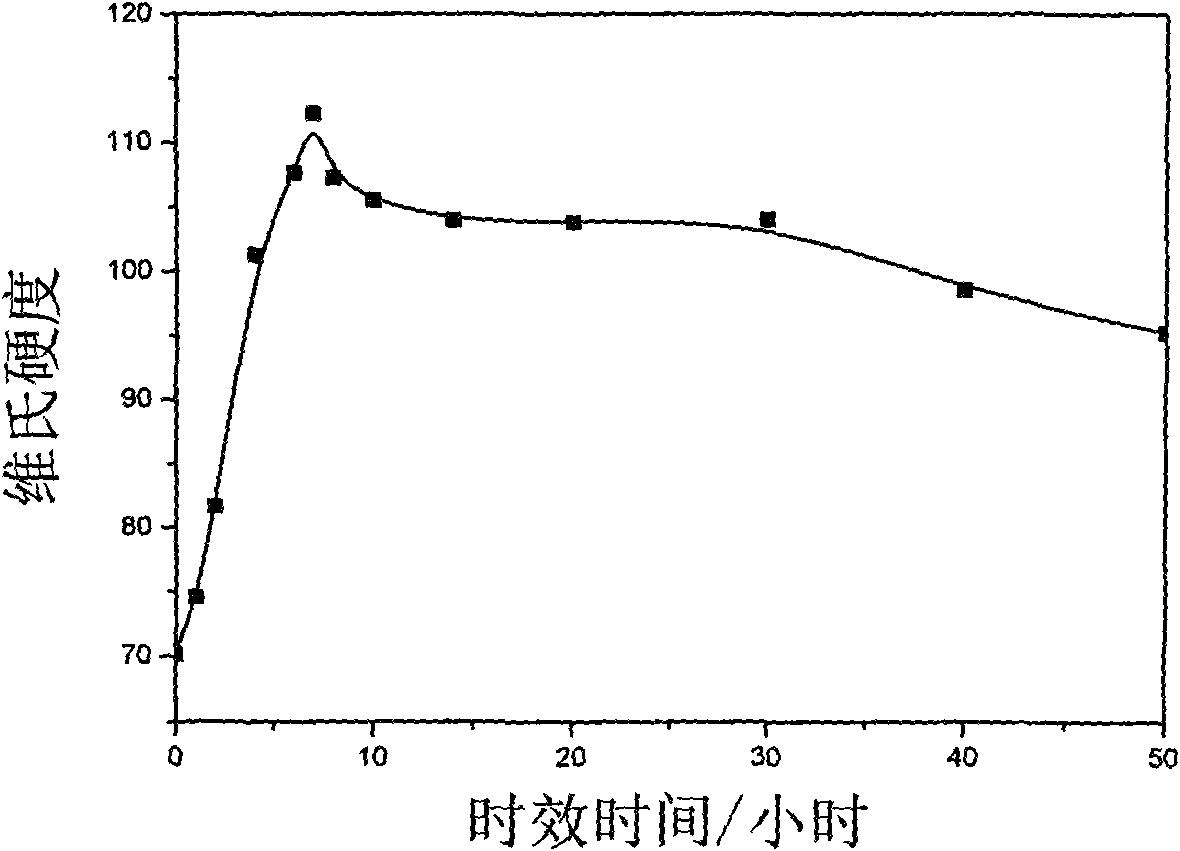

[0020] Al-Mg-Si-Er alloy plates were aged at 180°C for different times, figure 1 It is the age hardening curve of Al-Mg-Si-Er alloy at 180°C. Through different aging times at 180°C, it can be seen that as the aging time prolongs, the microhardness of the alloy first increases and then decreases. When the aging time is 7h, the microhardness of the alloy is the highest, which means that the aging time can reach fully aged condition.

Embodiment 3

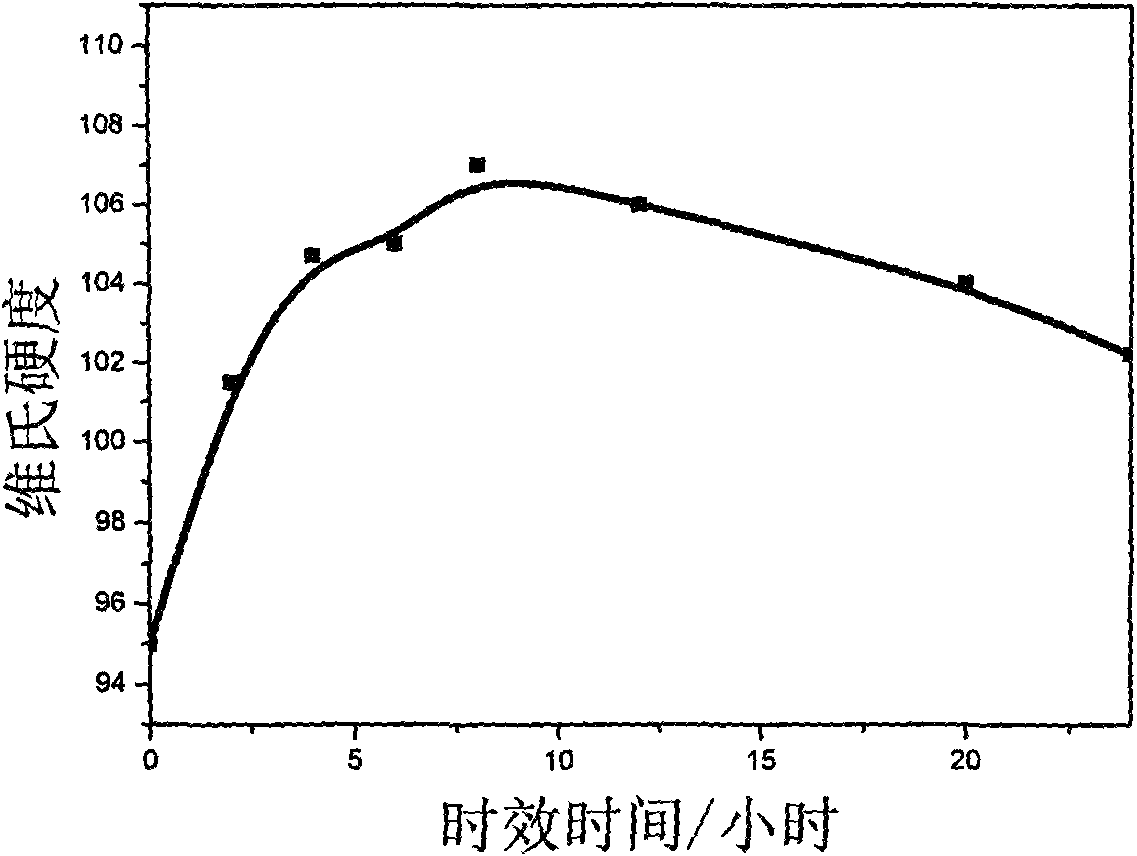

[0022] The Al-Mg-Si-Er alloy plate was aged at 180°C for 7 hours, then regressed at 220°C for 1 hour, and finally aged at a lower temperature of 150°C for different times. The age hardening curve is shown in figure 2 .

[0023] From figure 2 It can be seen that the alloy reached the peak aging state after aging at 180°C for 7 hours, and then regressed at 220°C for 1 hour to dissolve the second phase particles that precipitated first into the collective, and finally re-aged at a lower temperature of 150°C Microhardness change curve, the hardness value of the alloy is the highest at 8 hours.

[0024] Table 1 lists the tensile mechanical properties of Al-Mg-Si-Er alloys after peak aging after different heat treatment processes.

[0025]

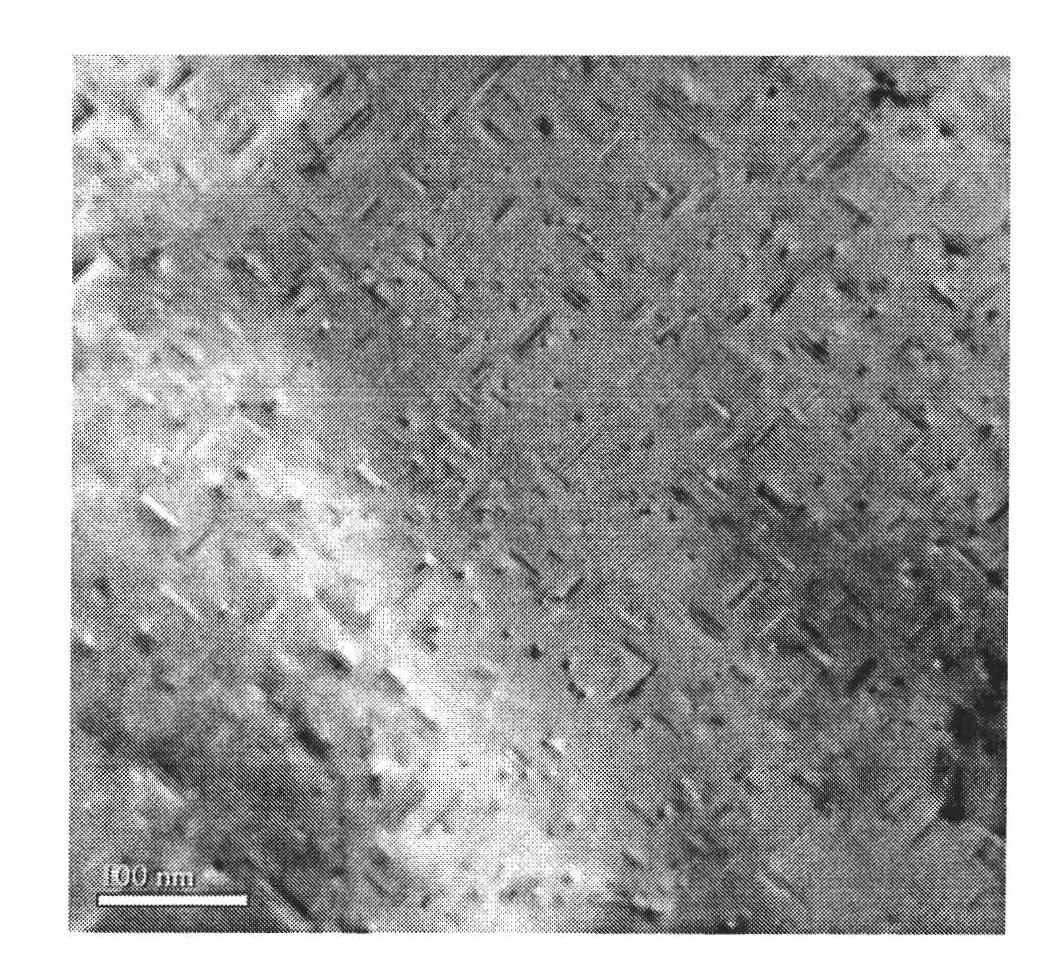

[0026] image 3 The microstructure of the alloy reflects that the needle-shaped second phase particles β″ mainly appeared in the alloy under the peak aging state, and a small amount of spherical particles also appeared, which may be unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com