Silsesquioxane-modified hybrid phenolic resin, and preparation method and application thereof

A technology of silsesquioxane and phenolic resin, which is applied in the field of hybrid phenolic resin and its preparation, can solve the problems of reduced ablation resistance, reduced carbon residue rate, and reduced ablation efficiency, so as to improve ablation resistance , low chemical toxicity, increased strength and ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The embodiment of the present invention also provides a preparation method of a silsesquioxane-modified hybrid phenolic resin, which includes the following steps:

[0042] Step 1. Dissolve silsesquioxane in an alcohol solvent to obtain a silsesquioxane solution;

[0043] Step 2. Add the phenolic resin solution to the silsesquioxane solution, stir and mix to obtain a hybrid resin solution;

[0044] Step 3. Exhaust the solvent in the hybrid resin solution in a vacuum at 50-70°C, and then heat up and cure to obtain a silsesquioxane-modified hybrid phenolic resin, wherein the silsesquioxane has the following The molecular structure:

[0045]

[0046] Among them, R is isobutyl, phenyl or isooctyl, R 1 For H or

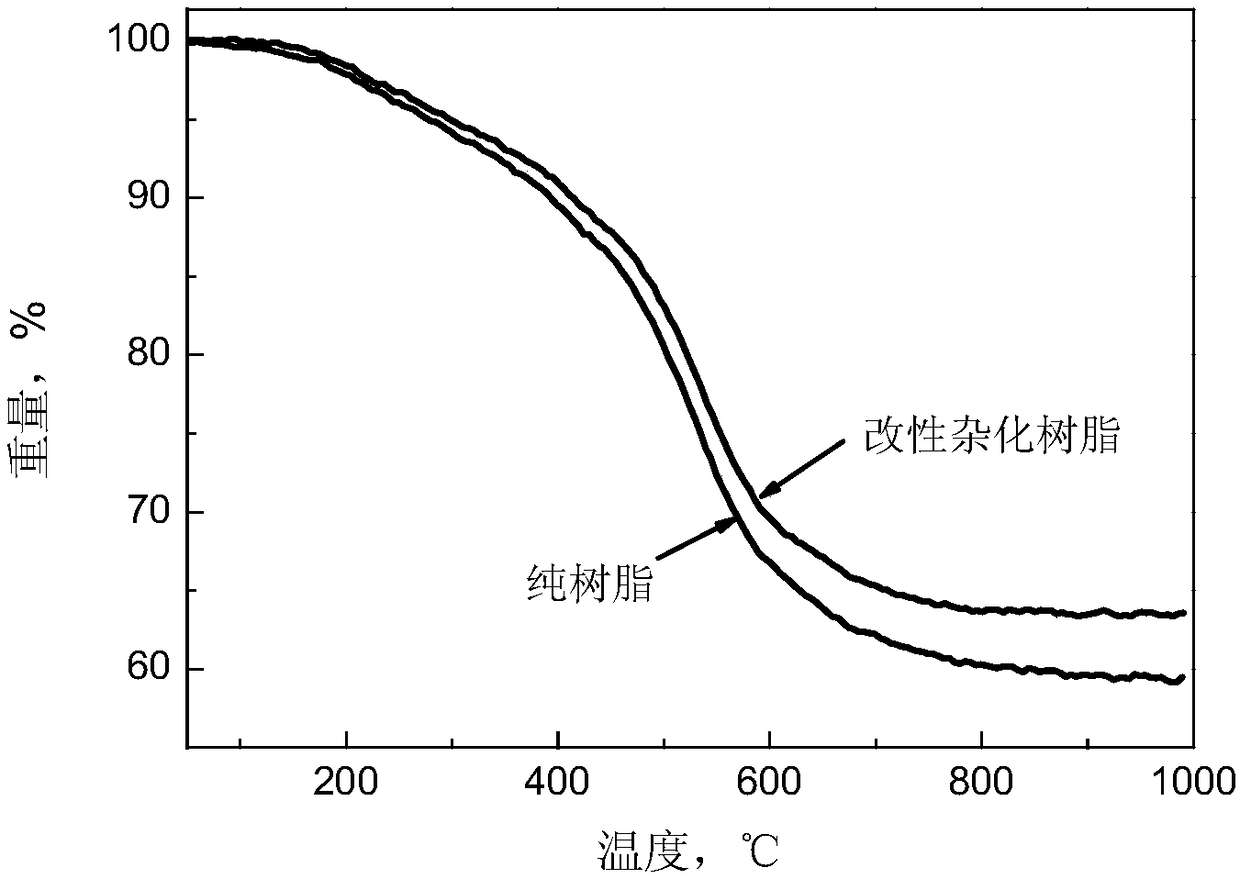

[0047] In the method for preparing a silsesquioxane-modified hybrid phenolic resin provided by the embodiment of the present invention, the POSS molecule represented by formula (1) is reacted with the phenolic resin to form a hybrid with POSS molecules as chemical crosslinki...

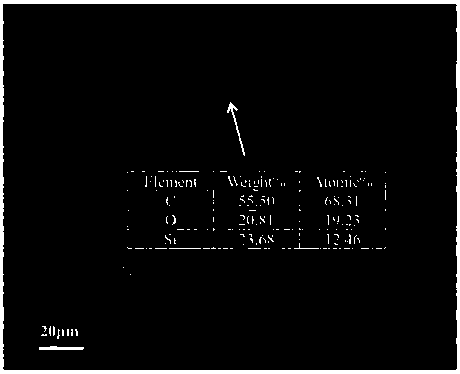

Embodiment 1

[0056] Weigh 10 g of trisilanol phenyl POSS molecules, dissolve them in 15 g of ethanol solvent, and stir thoroughly until completely dissolved into a transparent state to obtain a POSS solution with a concentration of 40 wt%. Weigh 120 g of an ethanol solution of barium phenolic resin with a solid content of 75%, add the POSS molecule solution to the barium phenolic solution, and mechanically stir at room temperature for 2 hours until it is uniformly mixed to obtain a hybrid resin solution. Then transfer the phenolic resin hybrid solution to a vacuum oven, evacuating at 50°C for half an hour, then raising it to 55°C for half an hour, and then raising to 60°C for about 45 minutes. Pour the hybrid resin solution from which the solvent has been drained into the mold, put it into the curing oven, and raise the temperature from room temperature to 90°C at a heating rate of 0.5°C / min, keep it for 1 hour, and then increase the temperature at 0.2°C / min The rate was increased to 120°C,...

Embodiment 2

[0058] Weigh out 5 g of trisilanol phenyl POSS molecules, dissolve them in 15 g of ethanol solvent, and stir thoroughly until completely dissolved into a transparent state to obtain a POSS solution with a concentration of 25 wt%. Weigh 136 g of an ethanol solution of a high-carbon phenolic resin with a solid content of 70%, add the POSS molecular solution to the barium phenolic solution, and mechanically stir for 2 hours at room temperature until it is uniformly mixed to obtain a hybrid resin solution. Then transfer the phenolic resin hybrid solution to a vacuum oven, evacuating at 50°C for half an hour, then raising it to 55°C for half an hour, and then raising to 60°C for about 45 minutes. Pour the hybrid resin solution from which the solvent has been drained into the mold, put it into the curing oven, and raise the temperature from room temperature to 90°C at a heating rate of 0.5°C / min, keep it for 1 hour, and then increase the temperature at 0.2°C / min The rate is increased...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com