Corrosion resistant low noise semi-metallic brake pad

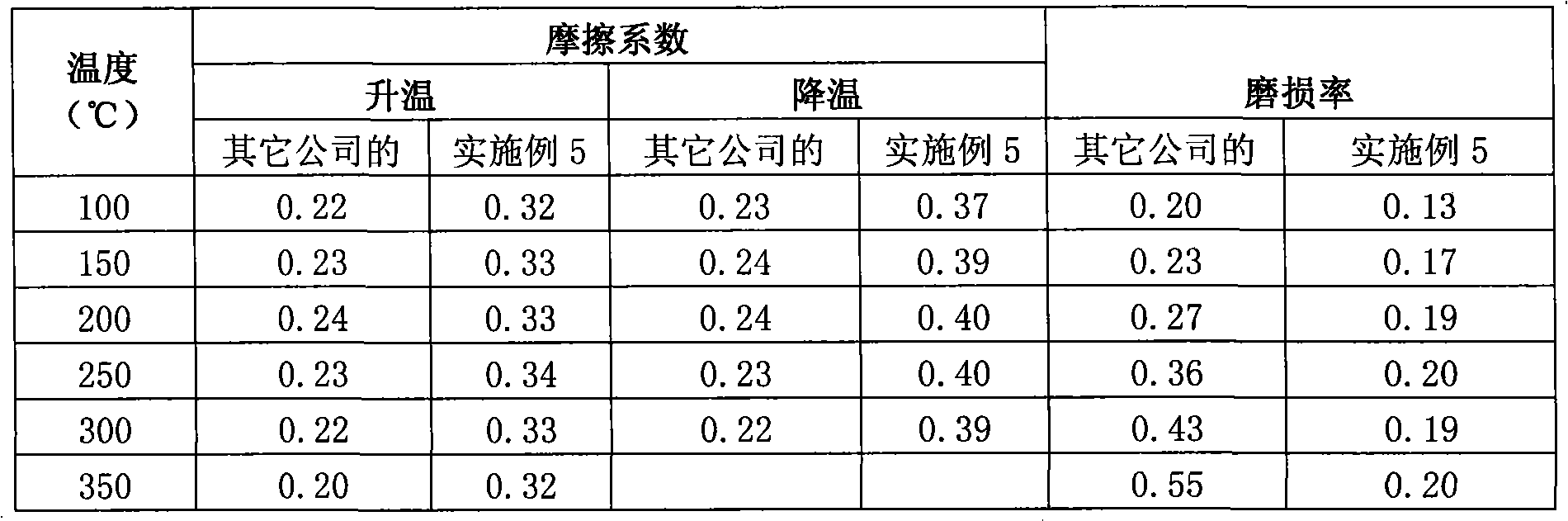

A low-noise, semi-metal technology, applied in the field of metal brake pads, can solve the problems of large damage to brake drums or brake discs, easy corrosion of semi-metal brake pads, and high thermal conductivity, and achieves good resistance to high temperature thermal recession and noise. Small, high coefficient of friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: by weight percentage with nitrile rubber powder 2%, tire powder 5%, expanded graphite 4%, boron phenolic resin 13%, stainless short fiber (4-7mm) 15%, red copper fiber (length is 3-5mm ) 5%, cashew nut oil friction powder 2%, graphite particles 5%, superfine iron oxide powder (300-325 mesh) 8%, diatomite 3%, acicular wollastonite fiber 9%, barite (600 mesh) 10%, chromite powder (300-350 mesh) 5%, sepiolite fiber 5%, zinc stearate 0.5%, zircon powder 3%, boron nitride 3%, molybdenum disulfide powder 2.5% After mixing, put it into a high-speed disperser, stir it into powder, take it out, put it into a forming mold for pressing, and then compound it with a steel back and put it into a flat vulcanizer at a high temperature of 270°C and a pressure of 18MPa for 15 minutes. , and then take out the brake pads and remove the burrs to become the finished product.

Embodiment 2

[0016] Embodiment 2: by weight percentage with nitrile rubber powder 4%, tire powder 3%, expanded graphite 5%, boron phenolic resin 10%, stainless short fiber (4-7mm) 11%, red copper fiber (length is 3-5mm ) 3.8%, cashew nut oil friction powder 3%, graphite particles 3%, superfine iron oxide powder (300-325 mesh) 7%, diatomite 5%, acicular wollastonite fiber 10%, barite (600 mesh) 15%, chromite powder (300-350 mesh) 3%, sepiolite fiber 8%, zinc stearate 0.2%, zircon powder 2%, boron nitride 5%, molybdenum disulfide powder 2% After mixing, put it into a high-speed disperser, stir it into powder, take it out, put it into a forming mold for pressing, and then compound it with a steel back and put it into a flat vulcanizer at a high temperature of 270°C and a pressure of 18MPa for 15 minutes. , and then take out the brake pads and remove the burrs to become the finished product.

Embodiment 3

[0017] Embodiment 3: by weight percentage with nitrile rubber powder 3%, tire powder 4%, expanded graphite 3%, boron phenolic resin 9%, stainless short fiber (4-7mm) 14%, red copper fiber (length is 3-5mm ) 6.4%, cashew nut oil friction powder 2.3%, graphite particles 4%, superfine iron oxide powder (300-325 mesh) 10%, diatomite 3%, acicular wollastonite fiber 12%, barite (600 mesh) 11%, chromite powder (300-350 mesh) 4%, sepiolite fiber 4%, zinc stearate 0.3%, zircon powder 3%, boron nitride 4%, molybdenum disulfide powder 3% After mixing, put it into a high-speed disperser, stir it into powder, take it out, put it into a forming mold for pressing, and then compound it with a steel back and put it into a flat vulcanizer at a high temperature of 270°C and a pressure of 18MPa for 15 minutes. , and then take out the brake pads and remove the burrs to become the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com