Fibrilia-reinforced polypropylene as well as preparation method thereof

A hemp fiber and polypropylene technology, which is applied in the field of hemp fiber reinforced polypropylene and its preparation, can solve the problems of poor polymer fluidity and uneven mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

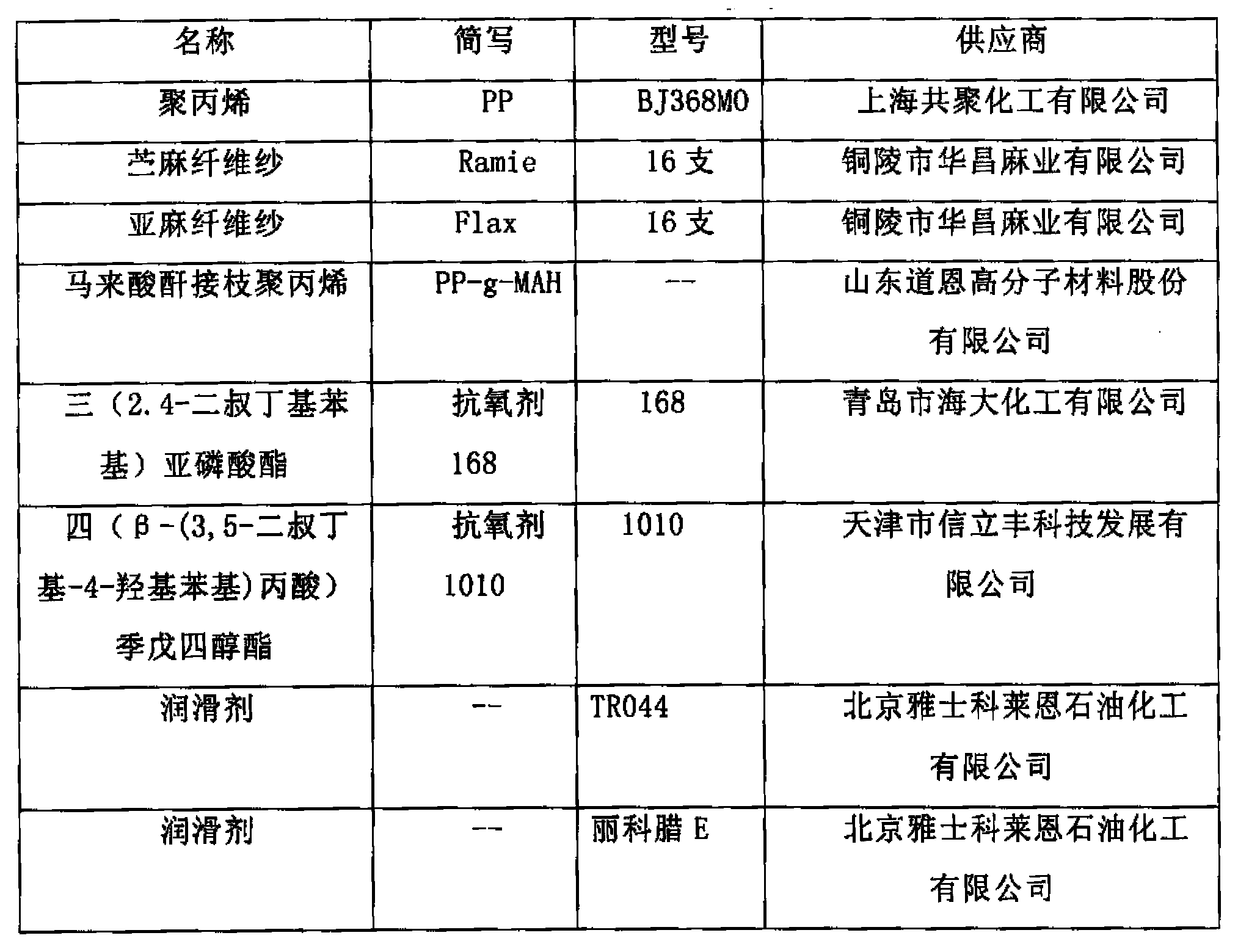

Image

Examples

Embodiment 1

[0030] Weigh 100 parts of PP of BJ368MO, 2 parts of antioxidant 1010, 2 parts of antioxidant 168, and 2 parts of lubricant TR044, and mix them in a high-speed mixer for 3 minutes. Extrude pellets in a screw extruder.

[0031] The temperature of the extruder is set as: Zone I 160°C, Zone II 170°C, Zone III 175°C, Zone IV 180°C, Zone V 190°C, Zone VI 200°C, Head 205°C. After the material is extruded, it is cooled by water, Pelletize, dry the pellets at 100°C for 3 hours, make a sample by an injection molding machine, and perform a mechanical performance test. The performance test results are shown in Table 2.

Embodiment 2

[0033] Weigh 100 parts of PP of BJ368MO, extrude and granulate together with 10 parts of ramie fiber in a twin-screw extruder.

[0034] The extruder temperature setting is: 160°C in zone I, 170°C in zone II, 175°C in zone III, 180°C in zone IV, 190°C in zone V, 200°C in zone VI, and 205°C at the head. Pelletize, dry the pellets at 100°C for 3 hours, make a sample by an injection molding machine, and perform a mechanical performance test. The performance test results are shown in Table 2.

Embodiment 3

[0036] Weigh 100 parts of PP of BJ368MO, 2 parts of antioxidant 1010, 2 parts of antioxidant 168, and 2 parts of lubricant TR044, and mix them in a high-speed mixer for 3 minutes. Extrude pellets in a screw extruder.

[0037] The temperature setting of the extruder is: 160°C in zone I, 170°C in zone II, 175°C in zone III, 180°C in zone IV, 190°C in zone V, 00°C in zone VI2, and 205°C at the head. After the material is extruded, it is cooled by water, Pelletize, dry the pellets at 100°C for 3 hours, make a sample by an injection molding machine, and perform a mechanical performance test. The performance test results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com