Fibrilia for plastic reinforcing and method for manufacturing the same

The technology of hemp fiber and jute fiber is applied in the field of hemp fiber for plastic reinforcement and its preparation. Good rigidity and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

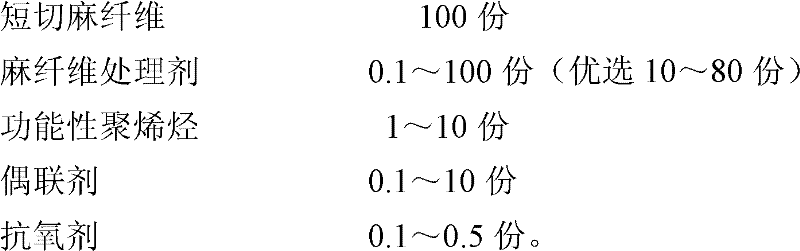

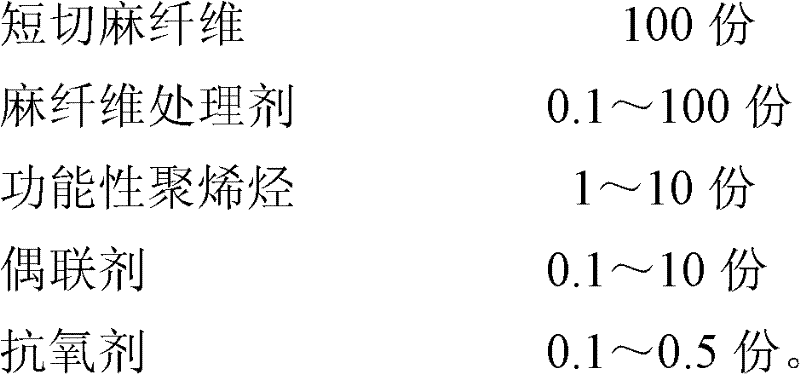

Method used

Image

Examples

Embodiment 1

[0023] (1) 100 parts by weight of ramie fibers are cut to 1-20 mm to obtain chopped hemp fibers; the chopped hemp fibers are soaked in aqueous sodium hydroxide solution (1% by mass concentration) and stirred for 20 minutes, then rinsed with water To pH 7.0, centrifuged to dry the water, then soaked in the temperature of 80 ℃ hemp fiber treatment agent (80 parts by weight of urea-formaldehyde resin prepolymer) aqueous solution (mass percentage concentration is 30%) for 30min, the hemp fiber After exhausting the aqueous solution of the hemp fiber treatment agent, vacuum drying at a temperature of 110°C until the moisture content of the hemp fiber mass is less than 1%, to obtain surface-treated chopped hemp fibers;

[0024] (2) with surface-treated chopped hemp fiber, 2 parts by weight of silane coupling agent, 9 parts by weight of functional polyolefin (5 parts by weight of metallocene polyethylene wax and 4 parts by weight of metallocene polyolefin wax-maleic anhydride Graft mi...

Embodiment 2

[0026] (1) Cut 100 parts by weight of flax fibers to 1-20 mm to obtain chopped hemp fibers; soak and stir the chopped hemp fibers in aqueous sodium hydroxide solution (10% by mass) for 2 minutes, then rinse with water To pH 9.0, centrifuged to dry the water, then soaked in the hemp fiber treatment agent (90 parts by weight of trimethylol melamine resin) aqueous solution (mass percentage concentration is 20%) at a temperature of 90 ℃ for 30min, until the hemp fiber is exhausted After the hemp fiber treatment agent aqueous solution, adopt the temperature 150 ℃ of vacuum drying to the hemp fiber moisture content is less than 1%, obtain the chopped hemp fiber through surface treatment;

[0027] (2) With surface-treated chopped hemp fiber, 8 parts by weight coupling agent (4 parts by weight titanate coupling agent mixed with 4 parts by weight rare earth coupling agent), 4 parts by weight functional polyolefin (2 parts by weight Part metallocene polypropylene mixed with 2 parts by w...

Embodiment 3

[0029] (1) 100 parts by weight of sisal fibers are cut to 1 to 20 mm to obtain chopped hemp fibers; the chopped hemp fibers are soaked and stirred in aqueous sodium hydroxide solution (5% by mass) and then rinsed with clear water Rinse to pH 8.0, centrifugally dry the water, then soak in the hemp fiber treatment agent (100 parts by weight of hexamethylol melamine resin) aqueous solution (10% by mass concentration) at a temperature of 85°C for 20 minutes, and treat the hemp fiber After exhausting the aqueous solution of the hemp fiber treatment agent, vacuum drying at a temperature of 120°C until the moisture content of the hemp fiber mass is less than 1%, to obtain surface-treated chopped hemp fibers;

[0030] (2) With surface-treated chopped hemp fiber, 7 parts by weight of coupling agent (5 parts by weight of aluminate coupling agent and 2 parts by weight of isocyanate coupling agent), 7 parts by weight of functional polyolefin (5 parts by weight of Metallocene polyolefin an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com