Lead-free compound solder by Ni particle strengthening tin and silver group and preparing method thereof

A composite brazing filler metal and particle-enhanced technology, which is applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problem of little research on brazing technology, and achieve improved thermal fatigue resistance, fewer components, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

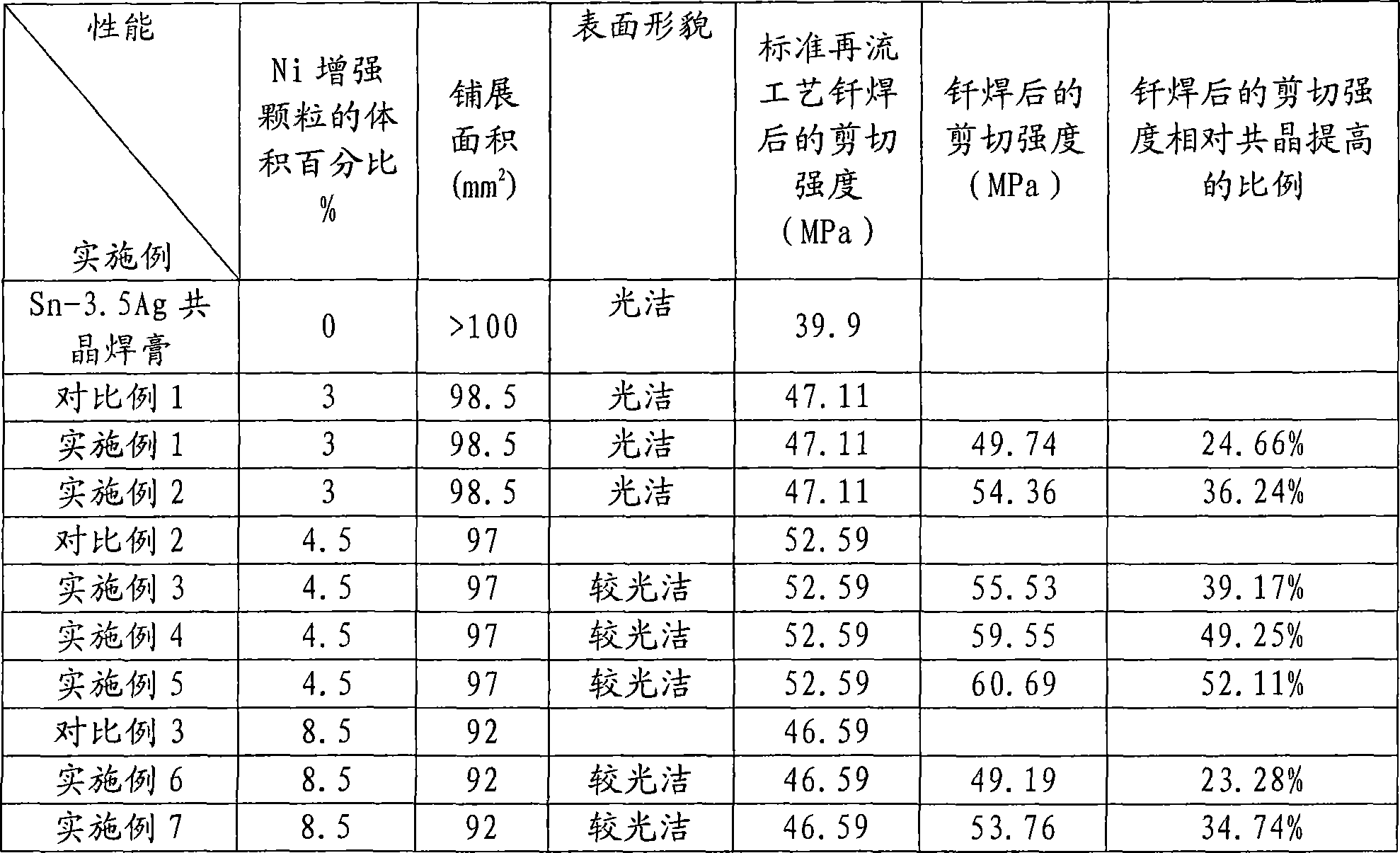

Embodiment 1

[0032] 1) Same as step 1) in Comparative Example 1;

[0033] 2) Braze the Ni (3vol%) particle-reinforced composite solder paste prepared in step 1), and keep heating at 330℃. When the composite solder paste slowly reaches 220.2℃ to melt, keep heating at 1.4℃ / sec. When the temperature of the composite solder paste reaches the peak temperature of 280℃, it will be cooled to a solid state at a cooling rate of 5.5℃ / sec. When the temperature drops to 60℃, the brazing ends, the structure is stable and reliable, and the shear strength value is 49.74MPa.

Embodiment 2

[0035] 1) Same as step 1) in Comparative Example 1;

[0036] 2) Braze the Ni (3vol%) particle-reinforced composite solder paste prepared in step 1), keep the furnace temperature at 330°C, and when the composite solder paste slowly reaches 220.2°C to melt, keep the temperature rising rate of 0.8°C / sec Heating, when the temperature of the composite solder paste reaches the peak temperature of 280°C, it begins to cool to a solid state. The cooling rate is 5.5°C / sec. After the solder solidifies, its structure will slowly develop, but it does not affect the overall performance. When the temperature drops to 60°C, the brazing ends, the structure is stable and reliable, and the shear strength value is 54.36MPa.

Embodiment 3

[0042] 1) Same as step 1) in Comparative Example 2;

[0043] 2) Braze the Ni (4.5vol%) particle-reinforced composite solder paste prepared in step 1), keep the furnace temperature at 330℃, and when the composite solder paste slowly reaches 220.2℃ to melt, keep the heating rate of 1.4℃ / sec Heating, when the temperature of the composite solder paste reaches the peak temperature of 280°C, it begins to cool to a solid state. The cooling rate is 5.5°C / sec. After the solder solidifies, its structure will slowly develop, but it does not affect the overall performance. When the temperature drops to 60°C, the brazing ends, the structure is stable and reliable, and the shear strength value is 55.53MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com