Foamed aluminum sandwich structure composite material and preparing method thereof

A composite material and sandwich structure technology, applied in the field of materials, can solve problems such as interface debonding damage, and achieve the effects of improving the interface bonding strength, reducing the preparation cost and improving the preparation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The closed-cell foamed aluminum with a thickness of 20mm and a density of 0.30g / cm3 is treated with potassium dichromate etching solution, rinsed with tap water, then thoroughly cleaned with deionized water, and dried in an oven at 60°C for use.

[0049] Epoxy resin E51: epoxy nitrile prepolymer: glycidyl acrylate: glass microspheres: chopped aramid fiber: m-phenylenediamine: boron trifluoride monoethylamine by weight ratio 100:10:10: 70:10:10:1, using mechanical stirring to evenly fill the prepared resin system in the pores on the surface of aluminum foam by scraping.

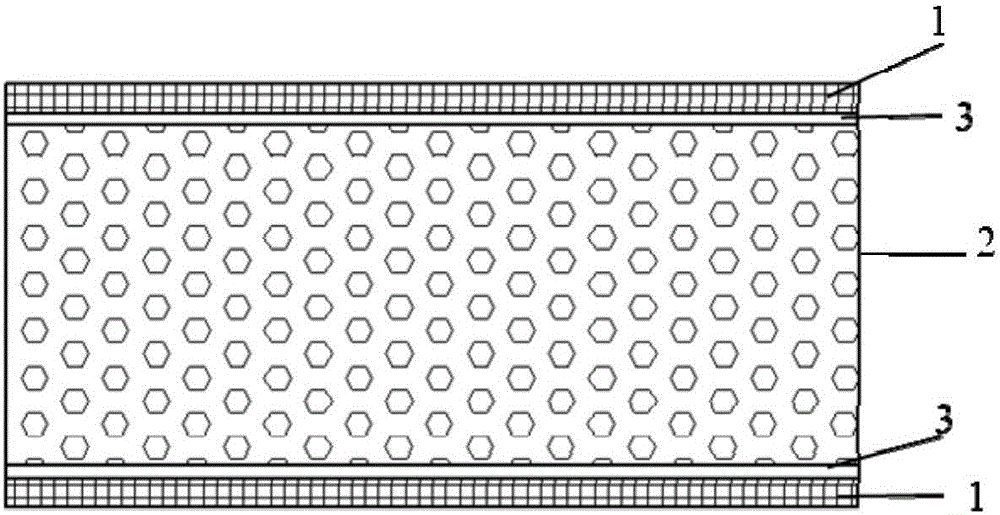

[0050] The upper and lower surfaces of the processed aluminum foam are sequentially covered with aluminum fiber mesh impregnated with resin, 2 layers of carbon fiber prepreg and 2 layers of glass fiber prepreg, and put into a flat mold for hot pressing and curing. The curing process is that the hot press heats up from room temperature to 80°C at an average heating rate of 3°C / min, then heats it for 30 m...

Embodiment 2

[0057] The closed-cell aluminum foam with a thickness of 10mm and a density of 0.47g / cm3 is treated with potassium dichromate etching solution, rinsed with tap water, then thoroughly cleaned with deionized water, and dried in an oven at 60°C for use.

[0058] 10 parts of Expancle microspheres, 5 parts of nitrile rubber, 2 parts of chopped basalt fiber, 10 parts of Al 2 o 3 Add the microspheres to 100 parts of epoxy resin TED-85 and 10 parts of glycerol triglycidyl ether and mix well, then add 30 parts of 4,4-diaminodiphenylmethane and 1 part of 2-ethyl-4 -Methylimidazole is fully stirred evenly by mechanical stirring. Under the action of ultrasound, soak the foamed aluminum in the resin system for 10 minutes and lift it out, and scrape off the excess resin on the surface.

[0059] Copper fiber mesh impregnated with resin, carbon fiber prepreg, aramid fiber prepreg and high-strength glass fiber prepreg are sequentially laid on the upper and lower surfaces of the treated foame...

Embodiment 3

[0062] The closed-cell aluminum foam with a thickness of 20mm and a density of 0.70g / cm3 is treated with potassium dichromate etching solution, rinsed with tap water, then thoroughly cleaned with deionized water, and dried in an oven at 60°C for use.

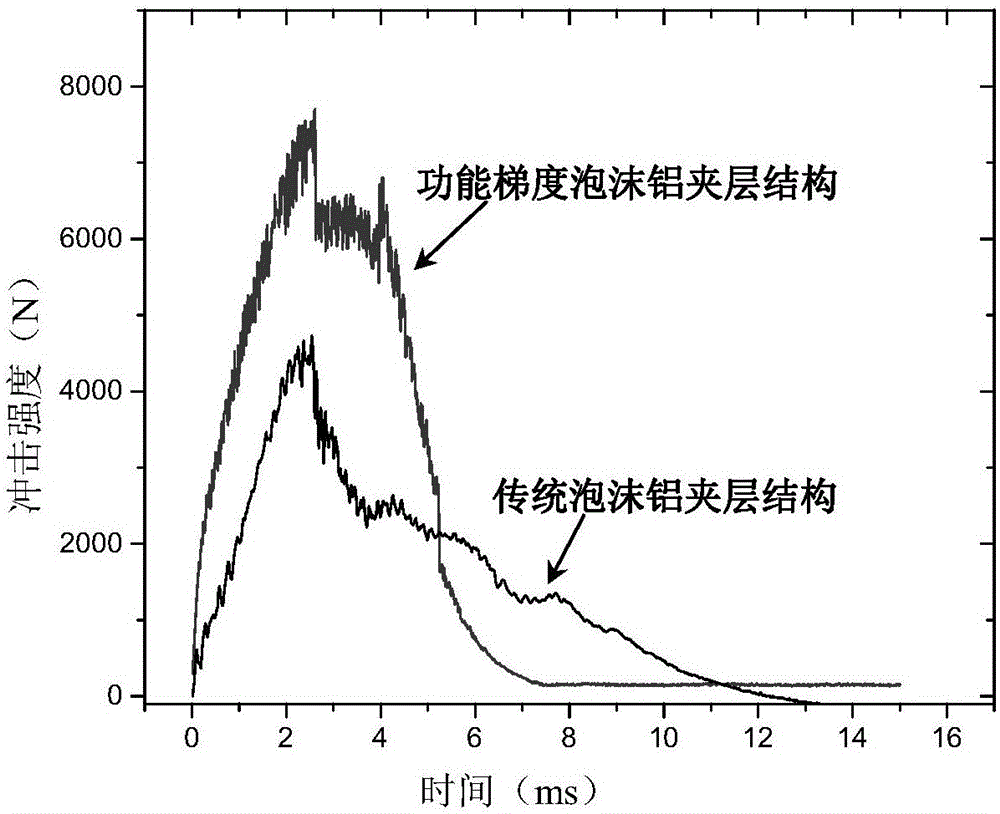

[0063] Add 30 parts of 4,4 -Diaminodiphenyl sulfone and 2 parts of 2-phenylimidazoline are stirred evenly, and the resin system is filled into the surface pores of the foamed aluminum by the pouring method, and the resin-impregnated stainless steel fiber mesh and basalt are sequentially laid on the upper and lower surfaces of the treated foamed aluminum The fiber prepreg is put into the mold for vacuum bag pressure curing molding, the curing temperature is 120 ° C, the curing pressure is 0.1 MPa, and it is kept for 30 minutes and then cooled to 80 ° C. Compared with polyurethane foam commonly used in traditional closed-cell foam core materials, the aluminum foam sandwich composite material prepared in this example has a smooth s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com