High-composite performance benzimidazole-containing aromatic polymer fiber and preparation method thereof

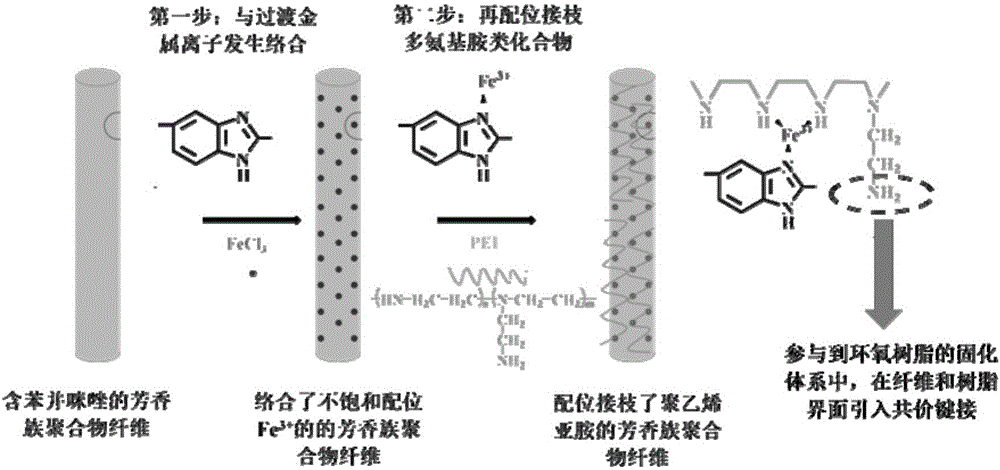

An aromatic polymer and benzimidazole technology, which is applied in the field of aromatic polymer fiber and its preparation, can solve the problems of damaged fiber body mechanical properties, chain scission, etc., achieve high composite performance and improve the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

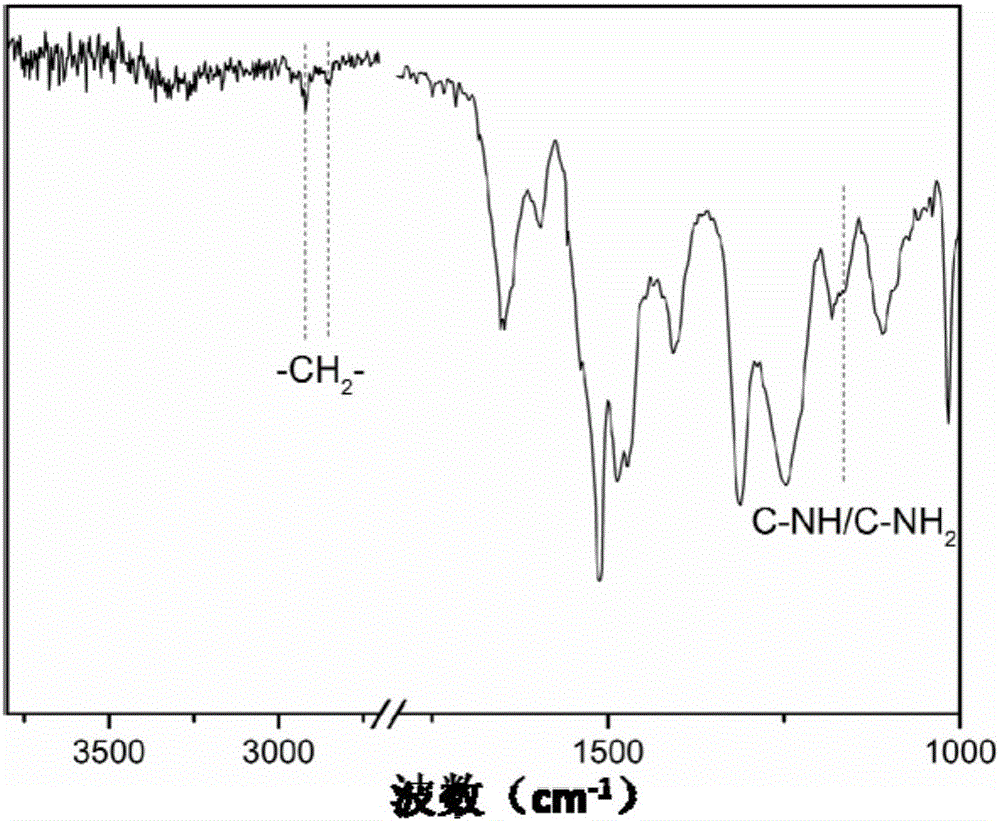

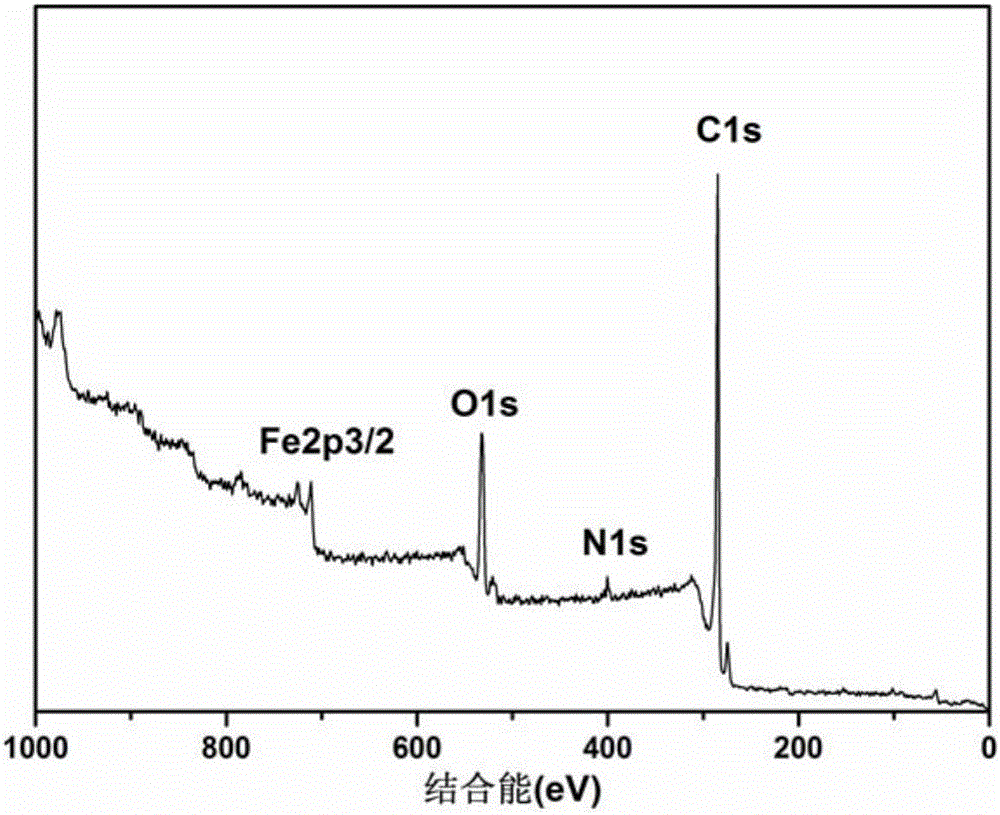

Method used

Image

Examples

Embodiment 1

[0025] First soak the aramid III fiber statically in 0.03% Fe at 50°C 3+ In the mixed solution that the mixed solvent of ethanol and water (wherein the volume fraction of water is 7%) made reacts 30min and dries, then the obtained unsaturated coordination Fe 3+ The fibers are soaked in ethanol solvent of polyethyleneimine with a concentration of 0.006% at 50°C for 10 minutes and then dried.

[0026] Add the obtained aramid III fiber with high composite performance into the epoxy resin matrix to prepare the corresponding composite material. The relevant properties of the obtained fiber and composite material are shown in the attached table.

Embodiment 2

[0028] First soak the aramid III fiber statically in 0.01% Cu at 10°C 2+ isopropanol and water mixed solvent (wherein the volume fraction of water is 3%) in the mixed solution that is made of reacting 5min and then drying, then the obtained unsaturated coordination Cu 2+ The fibers are soaked in ethanol solvent of polyvinylamine with a concentration of 0.001% at 70°C for 60 minutes and then dried.

[0029] Add the obtained aramid III fiber with high composite performance into the epoxy resin matrix to prepare the corresponding composite material. The relevant properties of the obtained fiber and composite material are shown in the attached table.

Embodiment 3

[0031] First soak the aramid III fiber statically in 0.1% Ni at 70°C 2+ isopropanol and water mixed solvent (wherein the volume fraction of water is 1%) in the mixed solution that is made of reacting 60min and drying, then the obtained unsaturated coordination Ni 2+ The fiber is soaked in ethylenediamine ethanol solvent with a concentration of 0.01% at 10°C for 60 minutes and then dried.

[0032] Add the obtained aramid III fiber with high composite performance into the epoxy resin matrix to prepare the corresponding composite material. The relevant properties of the obtained fiber and composite material are shown in the attached table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com