Graphene/silver composite material and preparation method thereof

A composite material and graphene technology, applied in the direction of metal/alloy conductor, cable/conductor manufacturing, metal rolling, etc., can solve complex composite process, poor controllability of preparation process, can not guarantee uniform composite of graphene and metal, etc. Problems, to achieve good composite effect, avoid agglomeration and damage, excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The basic operation steps of present embodiment 1 preparation graphene / silver composite material are as follows:

[0043] Ⅰ) Material composition of graphene / silver composites

[0044] The material components of the graphene / silver composite material are mainly metallic silver and graphene, wherein the metallic silver is prepared by chemical reduction method, the particle size is 0.1μm-5μm, and the proportion of the composite material is 94wt%; the raw material of graphene is The single-layer or few-layer graphene oxide prepared by the Hummers method accounts for 6wt% in the composite material.

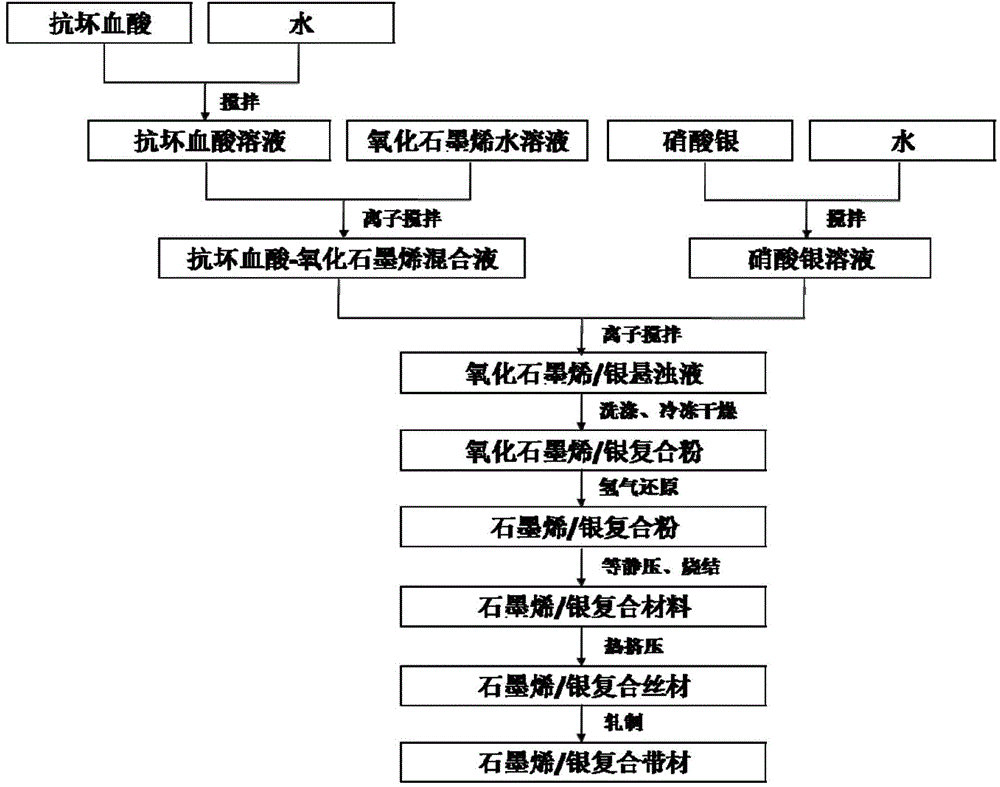

[0045] Ⅱ) Basic steps for preparing graphene / silver composites (see attached figure 1 )

[0046] 1) Prepare 0.1mol / L silver nitrate solution and 0.1mol / L ascorbic acid solution (or one or more of glucose, citric acid or oxalic acid);

[0047] 2) adding graphene oxide into deionized water, stirring and dispersing the ions for 0.5 hours to uniformly disperse the graphene oxide...

Embodiment 2

[0053] The main difference from Example 1 is that: Example 2 adds a hot extrusion process to obtain a graphene / silver composite wire.

[0054] The basic operation steps of present embodiment 2 preparing graphene / silver composite wire material are as follows:

[0055] Ⅰ) Material composition of graphene / silver composites

[0056] The material components of the graphene / silver composite material are mainly metallic silver and graphene, wherein the metallic silver is prepared by chemical reduction method, the particle size is 0.1μm-5μm, and the proportion of the composite material is 97wt%; the raw material of graphene is The single-layer or few-layer graphene oxide prepared by the Hummers method accounts for 3wt% in the composite material.

[0057] Ⅱ) Basic steps for preparing graphene / silver composites (see attached figure 1 )

[0058] 1) Prepare 0.25mol / L silver nitrate solution and 0.25mol / L ascorbic acid solution;

[0059] 2) adding graphene oxide into deionized water, s...

Embodiment 3

[0066] The difference from Example 2 is that this Example 3 adds an annealing and rolling process on the basis of Example 2 to obtain a graphene / silver composite strip.

[0067] The basic operation steps of present embodiment 3 preparation graphene / silver composite strips are as follows:

[0068] Ⅰ) Material composition of graphene / silver composites

[0069] The material components of the graphene / silver composite material are mainly metallic silver and graphene, wherein the raw materials and contents of metallic silver and graphene are the same as in Example 2.

[0070] Ⅱ) Basic steps for preparing graphene / silver composites (see attached figure 1 )

[0071] 1) Prepare 0.25mol / L silver nitrate solution and 0.25mol / L ascorbic acid solution;

[0072] 2) adding graphene oxide into deionized water, stirring and dispersing the ions for 0.5 hours to uniformly disperse the graphene oxide to obtain a graphene oxide solution with a mass concentration of 0.9%.

[0073] 3) Mix 2.5L ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com