Gradient laminated porous scaffold based on microsphere selective laser sintering and preparation method thereof

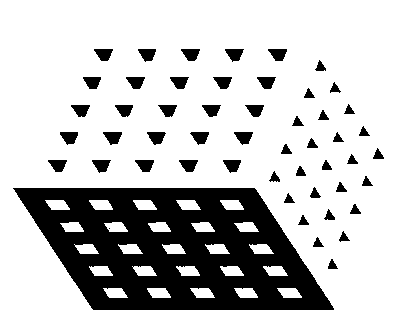

A porous scaffold and gradient technology, used in prostheses, bone implants, medical science, etc., can solve the problems of low sintering accuracy and difficult to control microstructure, and achieve the effect of good osseointegration and high mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dissolve 1.0g of polycaprolactone (PCL, Mw=50000) in 15ml of dichloromethane (DCM), and then use a magnetic stirrer to fully stir until it is completely dissolved to obtain a clear solution. Then 0mg, 50mg, 100mg, 150mg, 200mg, 250mg, 300mg, 350mg, 400mg of nano-hydroxyapatite were dispersed in dichloromethane, and added to the above clear solution under stirring to obtain a white suspension. Add the above suspension into the polyvinyl alcohol (PVA) solution containing 0.1% (w / v) at a stirring speed of 600rpm, disperse into tiny droplets, keep stirring, wait until the organic solvent dichloromethane volatilizes, filter, freeze After drying, composite microspheres with a mass content of 0%, 5%, 10%, 15%, 20%, 25%, 30%, 35%, and 40% hydroxyapatite were obtained, and the diameter of the microspheres was 150 μm. Then import the 3D computer model of the designed porous support into the computer terminal of the selective laser sintering equipment in stl file format, select th...

Embodiment 2

[0028] Dissolve 1.0g of polylactic acid (PLA, Mw=100000) in 12ml of dichloromethane (DCM), and then use a magnetic stirrer to fully stir until it is completely dissolved to obtain a clear solution. Then 0 mg, 100 mg, 200 mg, 300 mg, 400 mg of nano-hydroxyapatite were dispersed in dichloromethane, and added to the above clear solution under stirring to obtain a white suspension. Add the above suspension into the gelatin solution containing 0.15% (w / v) at a stirring speed of 600rpm, disperse into tiny droplets, keep stirring, and wait for the organic solvent to volatilize, filter, and freeze-dry to obtain 0%, 10 wt %, 20 wt %, 30 wt %, 40 wt % hydroxyapatite content of composite microspheres, with an average size of 100 μm. Then import the designed three-dimensional computer model into the computer terminal of the selective laser sintering equipment in stl file format, select the single-layer manufacturing mode, select the laser power as 10w, and the scanning rate as 1000mm / s, a...

Embodiment 3

[0030] Dissolve 1.5g of polyethylene / lactide (PLGA, Mw=80000) in 15ml of acetone (Acetone), and then use a magnetic stirrer to stir until it is completely dissolved to obtain a clear solution. Then 0mg, 50mg, 100mg, 150mg, 200mg, 250mg, 300mg, 350mg, 400mg of tricalcium phosphate were dispersed in acetone, and added to the above clear solution with stirring to obtain a white suspension. Add the above suspension into the gelatin solution containing 0.1% (w / v) at a stirring speed of 400rpm, disperse into tiny droplets, and keep stirring until the organic solvent is volatilized, filtered, and freeze-dried to obtain 0%, 5 wt %, 10 wt %, 15 wt %, 20 wt %, 25 wt %, 30 wt %, 35 wt %, 40 wt % tricalcium phosphate content of composite microspheres, the diameter of the microspheres is 300 μm. Then import the designed three-dimensional computer model into the computer terminal of the selective laser sintering equipment in stl file format, select the single-layer manufacturing mode, selec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com