High-abrasion-resistant metal ceramic composite roller sleeve and preparation method thereof

A metal-ceramic composite and metal-ceramic technology, which is applied in the field of wear-resistant materials, can solve the problems of easy existence of holes in the joint surface, shortened service life of the composite roller sleeve, complicated technical process, etc., and achieves low production cost, good interface bonding and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

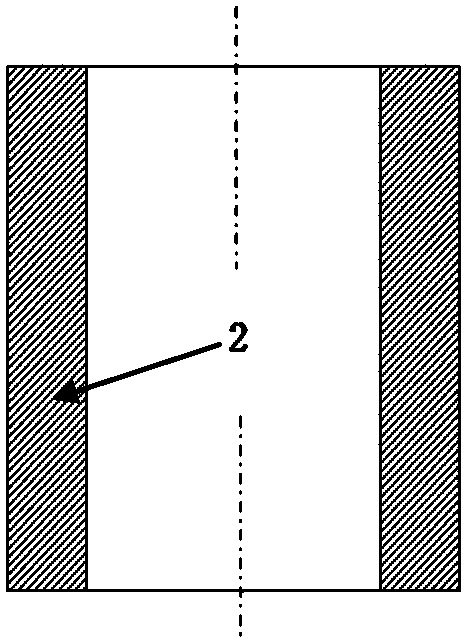

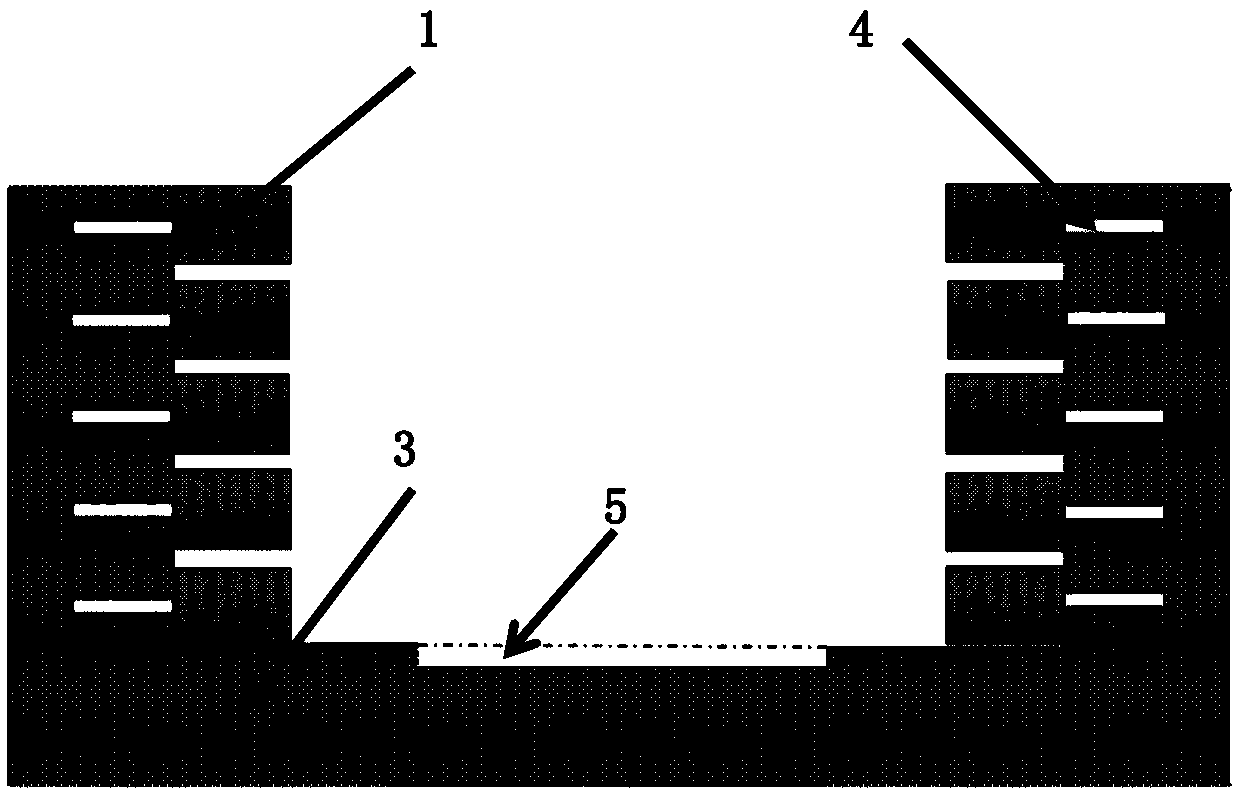

[0071] A high-wear-resistant metal-ceramic composite roller sleeve is a high-wear-resistant metal-ceramic composite tapered roller sleeve for vertical mills, which includes a preset inner sleeve 2 and an outer sleeve, and the material of the preset inner sleeve It is 20 steel, and the pouring material of the jacket is a high-wear-resistant alloy and metal-ceramic composite reinforced block; the wall thickness of the jacket is 1 / 2 of the overall wall thickness of the high-wear-resistant metal-ceramic composite roller sleeve;

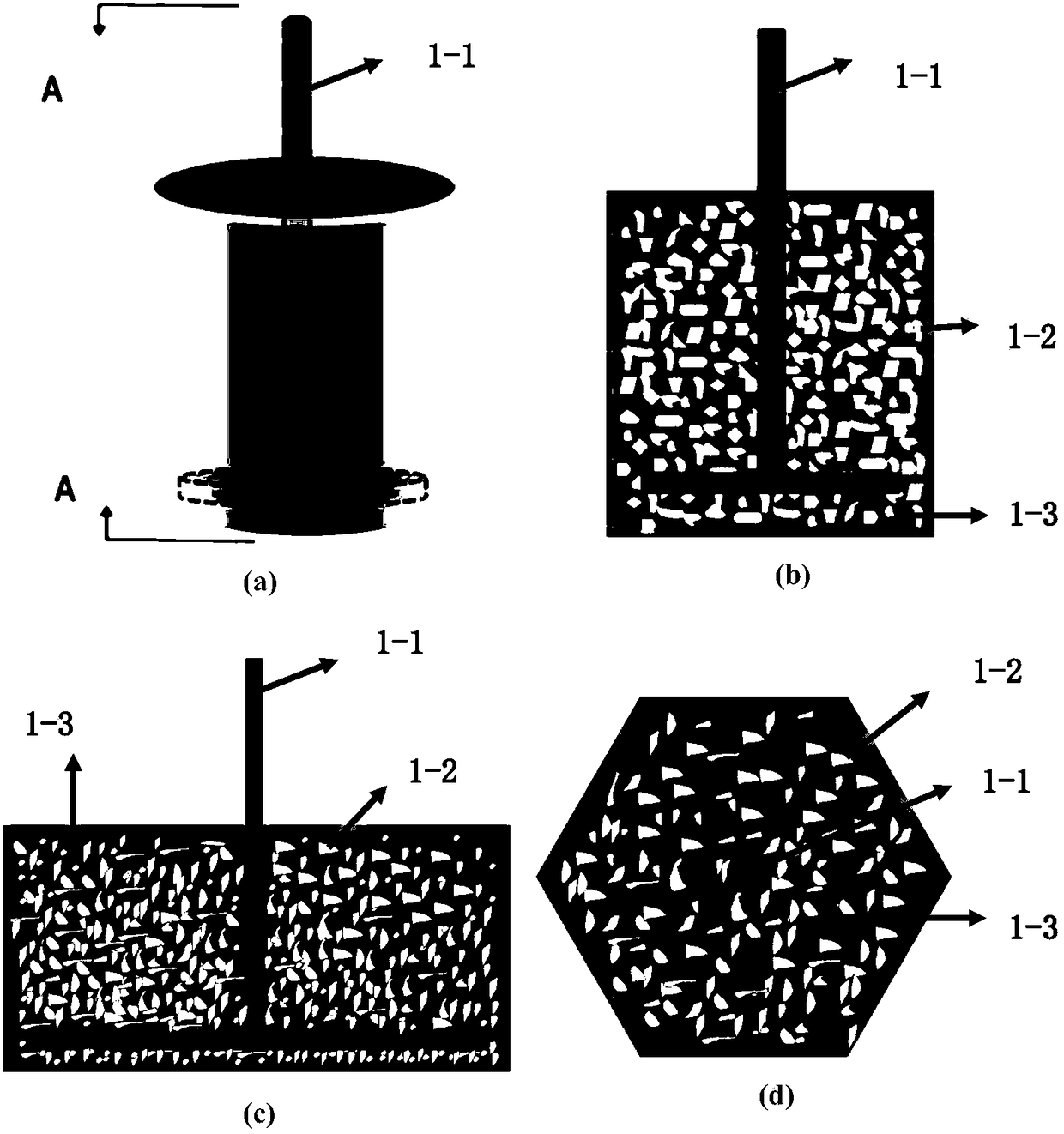

[0072] The metal-ceramic composite reinforced block 1 includes reinforcing particles 1-2, Cr, C wear-resistant alloy powder 1-3 and "T" type stainless steel parts 1-1; the WC particles are used as a reinforcing phase, and the The Cr, C wear-resistant alloy powder is used as the matrix, and according to the mass ratio, WC particles: wear-resistant alloy powder = 1:4; the "T" type stainless steel part is a fixed part, specifically 316L type;

[0073] The ma...

Embodiment 2

[0100] A high-wear-resistant metal-ceramic composite roll sleeve is a high-wear-resistant metal-ceramic high-pressure roller mill roll sleeve, which is used in a high-pressure roll mill. It includes a preset inner sleeve and an outer sleeve. The material of the preset inner sleeve is 20 steel, the casting material of the jacket is high wear-resistant alloy and metal-ceramic composite reinforced block; the wall thickness of the jacket is 1 / 3 of the overall wall thickness of the high-wear-resistant metal-ceramic composite roller sleeve;

[0101] The metal-ceramic composite reinforced block includes reinforcing particles, Cr, Mn wear-resistant alloy powder and "T" type stainless steel parts; the ZTA ceramic particles are used as a reinforcing phase, and the Cr, Mn wear-resistant alloy powder is used as a The matrix, according to the mass ratio, ZTA ceramic particles: wear-resistant alloy powder = 1:4; the "T" type stainless steel parts are fixed parts, specifically type 316L;

[...

Embodiment 3

[0129] A high-wear-resistant metal-ceramic composite roller sleeve is a high-wear-resistant metal-ceramic composite high-pressure roller mill roller sleeve, which is used in a high-pressure roller mill. It includes a preset inner sleeve and an outer jacket, and the material of the preset inner sleeve It is 20 steel, and the pouring material of the jacket is a high-wear-resistant alloy and metal-ceramic composite reinforced block; the wall thickness of the jacket is 1 / 4 of the overall wall thickness of the high-wear-resistant metal-ceramic composite roller sleeve;

[0130] The metal-ceramic composite reinforced block includes reinforced particles, Cr, Mo wear-resistant alloy powder and "T" type stainless steel parts; the Al 2 o 3 White corundum+Al 2 o 3 Brown corundum is used as a reinforcing phase, and the Cr and Mo wear-resistant alloy powders are used as a matrix. According to the mass ratio, Al 2 o 3 White corundum: Al 2 o 3 Brown corundum: wear-resistant alloy powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com