Graphene/copper composite and preparation method thereof

A composite material and graphene technology, which is applied in the field of graphene-reinforced copper-based composite materials and its preparation, can solve the problems of easy oxidation and inability to realize mass production of materials, so as to avoid copper powder oxidation, excellent physical properties, and improve the interface The effect of wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The basic operation steps of present embodiment 1 preparation graphene / copper composite material are as follows:

[0046] Ⅰ) Material composition of graphene / copper composites

[0047] The material composition of graphene / copper composite material is mainly metal copper and graphene, and wherein metal copper adopts ball-milled flake copper alloy powder, nickel is a matrix alloy element, and the mass fraction of nickel in copper alloy is 5wt%; Wherein graphene The raw material is few-layer graphene prepared by mechanical exfoliation method, which accounts for 10wt% of the composite material, and the balance is 90wt% of the metal matrix.

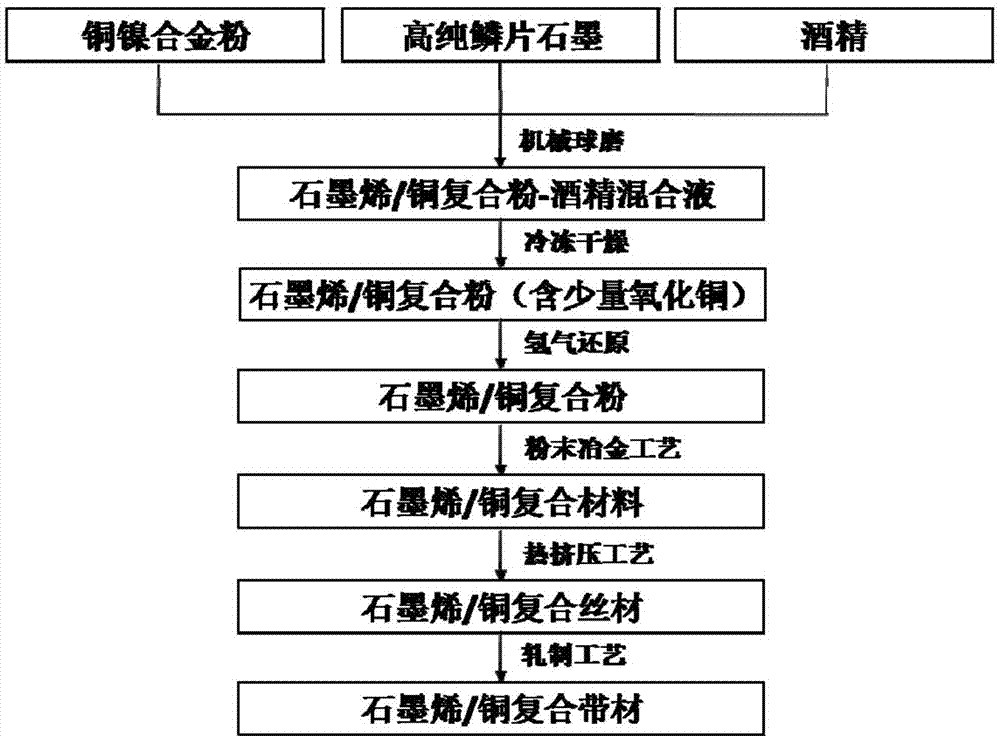

[0048] Ⅱ) The basic steps of preparing graphene / copper composites (see attached figure 1 )

[0049] 1) take by weighing the copper-nickel alloy powder of 50g and the high-purity flake graphite of 5.5g;

[0050] 2) According to the ball-to-material ratio of 20:1, put the balls, copper-nickel alloy powder, flake graphite and alcohol in...

Embodiment 2

[0055] The main difference from Example 1 is that: Example 2 adds a hot extrusion process to obtain a graphene / copper composite wire.

[0056] The basic operation steps of present embodiment 2 preparation graphene / copper composite material are as follows:

[0057] Ⅰ) Material composition of graphene / copper composites

[0058] The material components of the graphene / copper composite material are mainly metallic copper and graphene, wherein the metallic copper adopts ball-milled flake copper alloy powder, nickel is a matrix alloy element, and the mass fraction of nickel in the copper alloy is 0.3wt%; wherein graphene The raw material is few-layer graphene prepared by mechanical exfoliation method, which accounts for 0.5wt% in the composite material, and the balance is 99.5wt% of the metal matrix.

[0059] Ⅱ) The basic steps of preparing graphene / copper composites (see attached figure 1 )

[0060] 1) Weigh 50g of copper-nickel alloy powder and 0.25g of high-purity flake graphi...

Embodiment 3

[0067] The main difference from Example 2 is that: this Example 3 adds an annealing and rolling process to obtain a graphene / copper composite strip.

[0068] The basic operation steps of present embodiment 3 preparation graphene / copper composite material are as follows:

[0069] Ⅰ) Material composition of graphene / copper composites

[0070] The material components of the graphene / copper composite material are mainly metallic copper and graphene, wherein the raw materials and contents of metallic copper and graphene are the same as in Example 1.

[0071] Ⅱ) The basic steps of preparing graphene / copper composites (see attached figure 1 )

[0072] 1) take by weighing the copper-nickel alloy powder of 50g and the high-purity flake graphite of 0.25g;

[0073] 2) According to the ball-to-material ratio of 20:1, put the balls, copper-nickel alloy powder, flake graphite and alcohol into the ball mill tank, and the ball mill time is 12 hours. With the progress of ball milling, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com