Aluminum alloy composite material with solid self-lubrication and preparation method thereof

A solid self-lubricating and composite material technology, applied in the field of materials, can solve the problems of not meeting the requirements of drill pipe use, environmental pollution of electrolyzer waste liquid, short service life, etc., and achieve excellent self-lubrication, excellent wear resistance, and service life long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

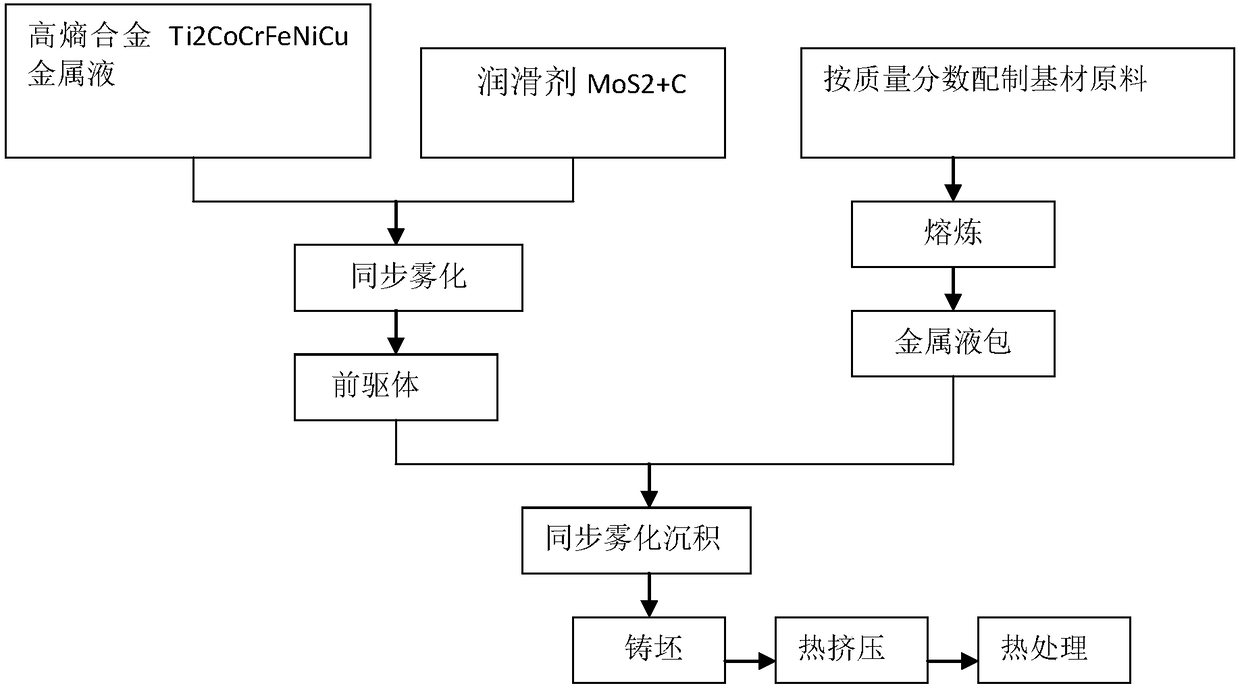

[0023] Embodiment 1: A method for preparing an aluminum alloy drill pipe material with solid self-lubricating properties, the specific steps are as follows:

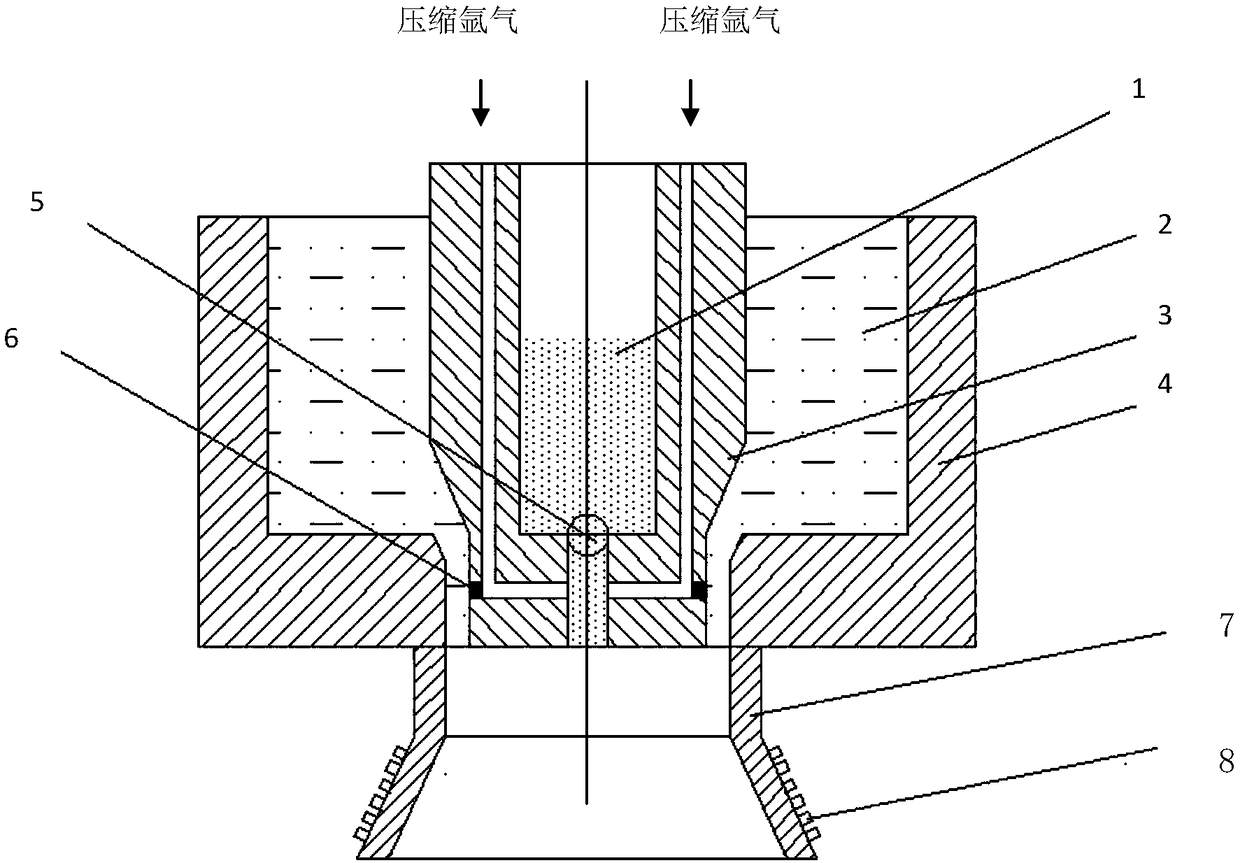

[0024] 1): Precursor preparation, first prepare Ti, Co, Cr, Fe, Ni, Cu metals according to the atomic ratio to prepare the raw materials, place them in the crucible melting furnace to be heated to melting, and then fill the melt into the metal in the spray deposition machine At the same time, the MoS2+C mixture with a particle size of 10μm is injected into the solid fluidized conveyor, and 0.85MPa high-pressure argon is passed into the metal liquid ladle and the solid fluidized conveyor to make the high-entropy alloy metal liquid and MoS2+C particles are atomized synchronously to form solid-liquid mixed droplets, and the droplets solidify rapidly under the action of the cooler at the lower end of the atomization chamber, and are deposited on the substrate to obtain precursor particles with a deposition distance of 900mm;

[0...

Embodiment 2

[0031] Embodiment 2: A method for preparing an aluminum alloy drill pipe material with solid self-lubricating properties, the specific steps are as follows:

[0032] 1): Precursor preparation, first prepare Ti, Co, Cr, Fe, Ni, Cu metals according to the atomic ratio to prepare the raw materials, place them in the crucible melting furnace to be heated to melting, and then fill the melt into the metal in the spray deposition machine At the same time, the MoS2+C mixture with a particle size of 10μm is injected into the solid fluidized conveyor, and 0.85MPa high-pressure argon is passed into the metal liquid ladle and the solid fluidized conveyor to make the high-entropy alloy metal liquid and MoS2+C particles are atomized synchronously to form solid-liquid mixed droplets, and the droplets solidify rapidly under the action of the cooler at the lower end of the atomization chamber, and are deposited on the substrate to obtain precursor particles with a deposition distance of 900mm;

[0...

Embodiment 3

[0039] Embodiment 3: A method for preparing an aluminum alloy drill pipe material with solid self-lubricating properties, the specific steps are as follows:

[0040] 1): Precursor preparation, first prepare Ti, Co, Cr, Fe, Ni, Cu metals according to the atomic ratio to prepare the raw materials, place them in the crucible melting furnace to be heated to melting, and then fill the melt into the metal in the spray deposition machine At the same time, the MoS2+C mixture with a particle size of 10μm is injected into the solid fluidized conveyor, and 0.85MPa high-pressure argon is passed into the metal liquid ladle and the solid fluidized conveyor to make the high-entropy alloy metal liquid and MoS2+C particles are atomized synchronously to form solid-liquid mixed droplets, and the droplets solidify rapidly under the action of the cooler at the lower end of the atomization chamber, and are deposited on the substrate to obtain precursor particles with a deposition distance of 900mm;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com