Special lubricating grease composition for steel wire rope

A technology of grease composition and lithium stearate, which is applied in the field of grease, can solve problems such as the inability to use wire ropes for lubrication and protection, achieve improved adhesion and penetration, low production costs, and improved water resistance and protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

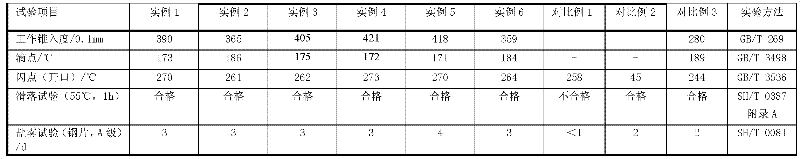

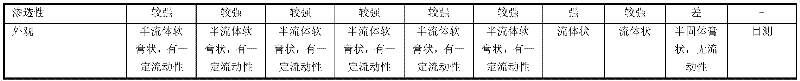

Examples

example 1

[0038] 310g of mineral base oil (100°C kinematic viscosity 5 ~ 20mm 2 / s) into the still, add 28.8g of 12-OH lithium stearate soap, 7.2g of lithium stearate soap. Heat up and stir, when the temperature rises to 210-220°C, stop heating and keep the temperature for 2 minutes. Stir and add 300g of mineral base oil for quenching. Add 4g of diphenylamine when the temperature is 140-150°C. When the temperature drops to 125-130°C, add 30 g of No. 75 microcrystalline wax and stir evenly. Stir again and add the extracted oil (100℃ kinematic viscosity 15~60mm 2 / s) 320g. Take it out of the kettle and grind it three times. The properties of the prepared grease are listed in Table 1.

example 2

[0040] 280g of mineral base oil (100 ° C kinematic viscosity 7 ~ 16mm 2 / s) into the kettle, add 45g of 12-OH lithium stearate soap and 10g of lithium stearate soap, heat up and stir, when the temperature rises to 210-220°C, stop heating and keep the temperature for 2 minutes. Stir and add 440g of mineral base oil for quenching. Add 10 g of diphenylamine when the temperature is 140-150°C. When the temperature drops to 125-130°C, add 50 g of No. 80 microcrystalline wax and stir evenly. Stir again and add the extracted oil (the kinematic viscosity at 100°C is 15-60mm 2 / s) 165g. Take it out of the kettle and grind it three times. The properties of the prepared grease are listed in Table 1.

example 3

[0042] 320g of mineral base oil (100°C kinematic viscosity 7 ~ 16mm 2 / s) into the still, add 22g of 12-OH lithium stearate soap, 4g of lithium stearate soap. Stir and heat up. When the temperature rises to 210-220°C, stop heating and keep the temperature for 4 minutes. Stir and add 260g of mineral base oil for quenching. Add 3 g of diphenylamine when the temperature is 140-150°C. When the temperature drops to 125-130°C, add 21g of No. 70 microcrystalline wax and stir evenly. Stir again and add the extracted oil (the kinematic viscosity at 100°C is 15-60mm 2 / s) 370g. Take it out of the kettle and grind it three times. The properties of the prepared grease are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com