Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

505results about "Cleaning heat-transfer devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

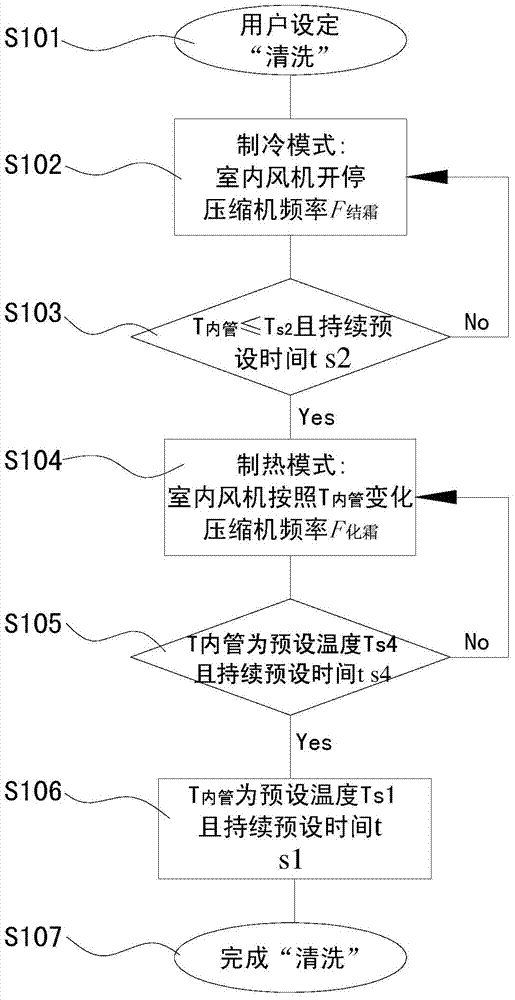

Cleaning method and device for indoor heat exchanger of air conditioner

ActiveCN104848738AAchieve high temperature sterilization functionImprove comfortCleaning heat-transfer devicesSpace heating and ventilation safety systemsFrostEngineering

The invention discloses a cleaning method and device for an indoor heat exchanger of an air conditioner. The cleaning method for the indoor heat exchanger of the air conditioner comprises the steps that 1, the air conditioner is controlled to operate in a refrigerating mode, an indoor draught fan is switched off, the surface of the indoor heat exchanger is frosted, and whether frosting is completed is judged; 2, after frosting is completed, the air conditioner is controlled to operate in a heating mode, the indoor draught fan is switched on, the frost on the surface of the indoor heat exchanger is converted into water, and whether defrosting is completed is judged; 3, after defrosting is completed, the temperature T of an inner tube of the indoor heat exchanger is controlled to be a first preset temperature TS1, the temperature TS1 of the inner tube of the indoor heat exchanger is kept for a first preset time tS1, and cleaning is completed. By the adoption of the cleaning method for the indoor heat exchanger of the air conditioner, cleaning of the indoor heat exchanger of the air conditioner can be achieved, no part is additionally arranged, cost is not increased, the high-temperature sterilizing function is achieved, and the comfort and health of a user are further improved.

Owner:GREE ELECTRIC APPLIANCES INC

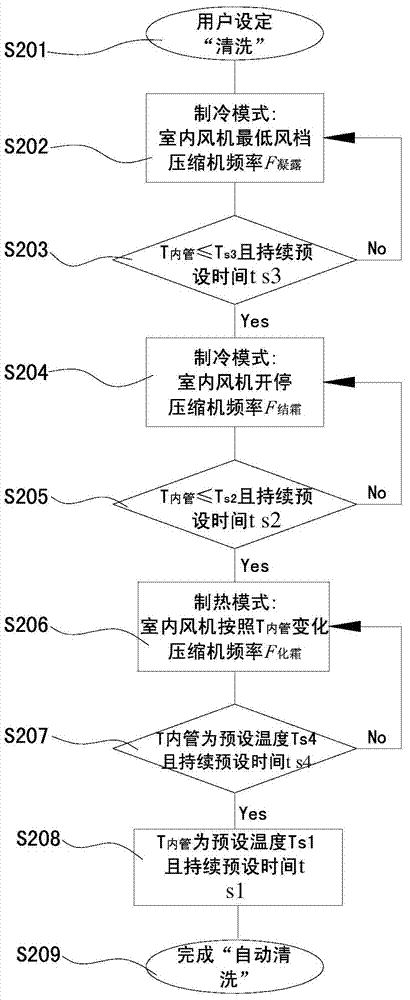

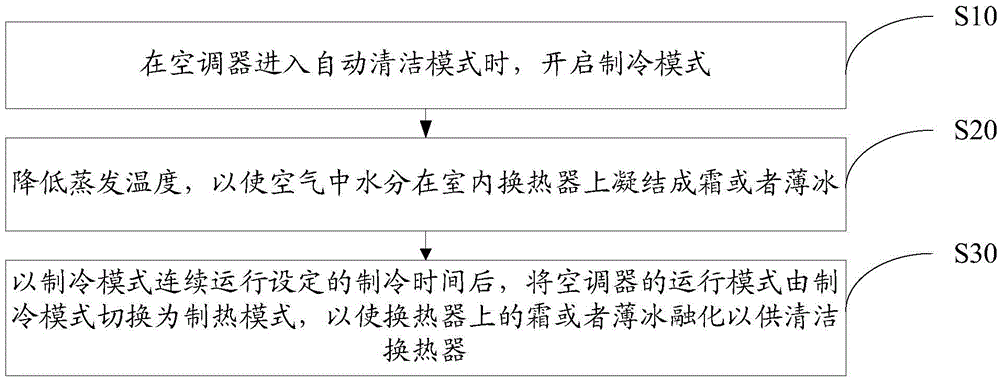

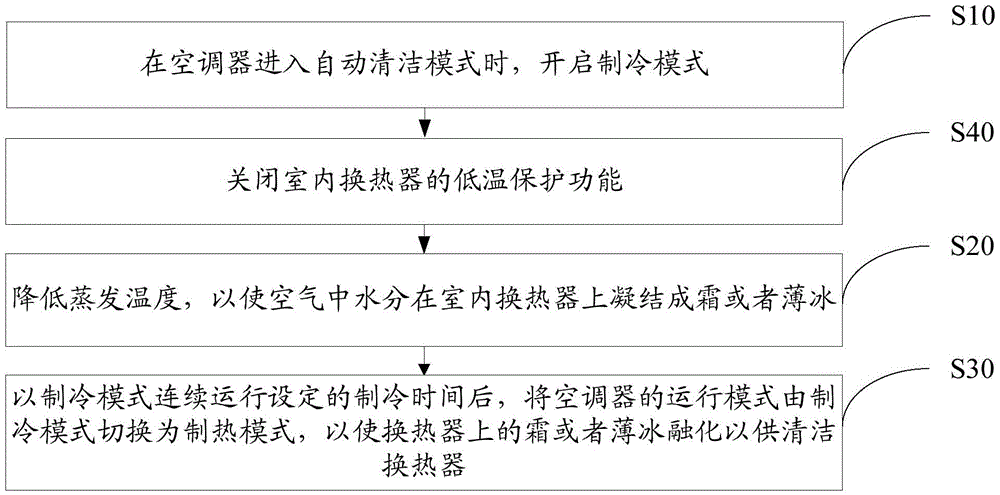

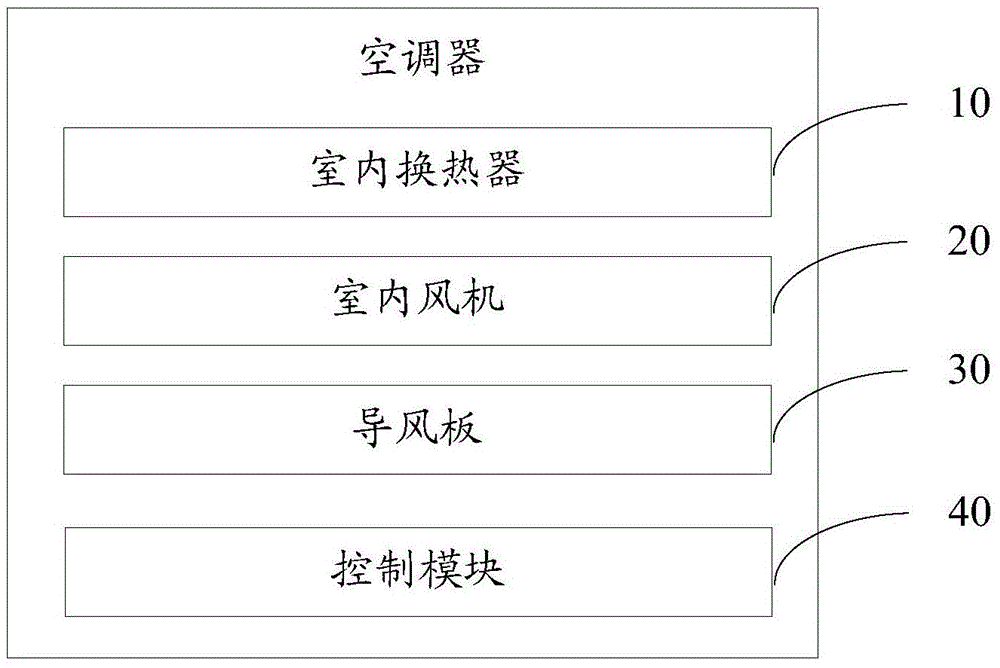

Cleaning control method for indoor heat exchanger of air conditioner and air conditioner

InactiveCN105486164AExpand the scope of cleaningRealize automatic cleaningMechanical apparatusCleaning heat-transfer devicesFrostEngineering

The invention discloses a cleaning control method for an indoor heat exchanger of an air conditioner. The cleaning control method includes the steps that when the air conditioner gets into the automatic cleaning mode, the refrigeration mode is started; evaporating temperature is reduced to enable water in air to be condensed into frost or thin ice on the indoor heat exchanger; after the air conditioner continuously runs in the refrigeration mode for set refrigeration time, the running mode of the air conditioner is switched to the heating mode from the refrigeration mode so that the frost or the thin ice on the heat exchanger can be thawed to clean the heat exchanger. The invention further discloses the air conditioner. By means of the cleaning control method and the air conditioner, automatic cleaning of the indoor heat exchanger of the air conditioner can be achieved, and therefore it can be avoided that the heat exchange efficiency of the heat exchanger is reduced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

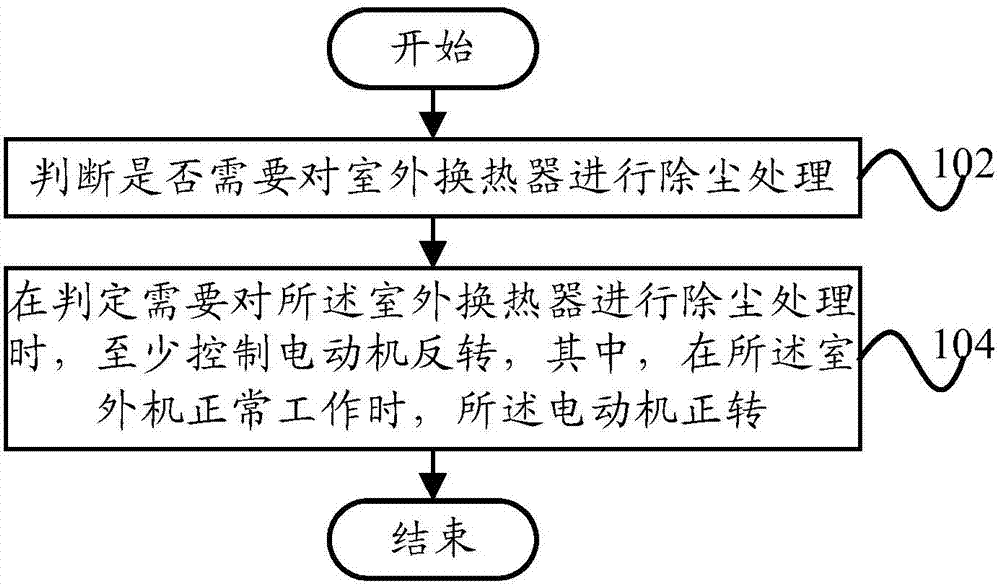

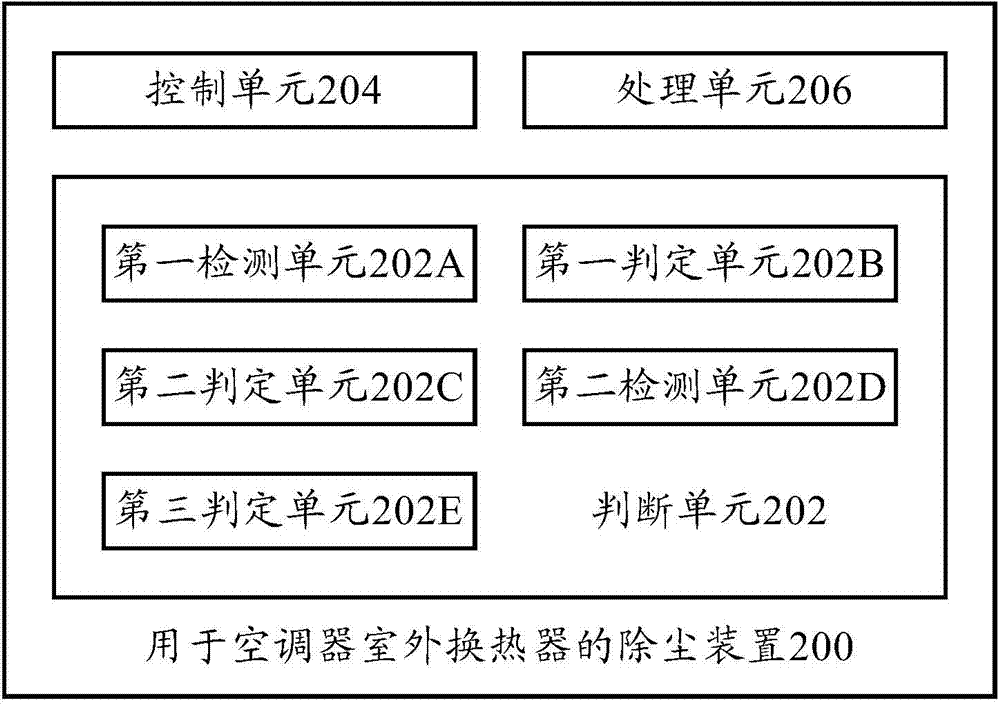

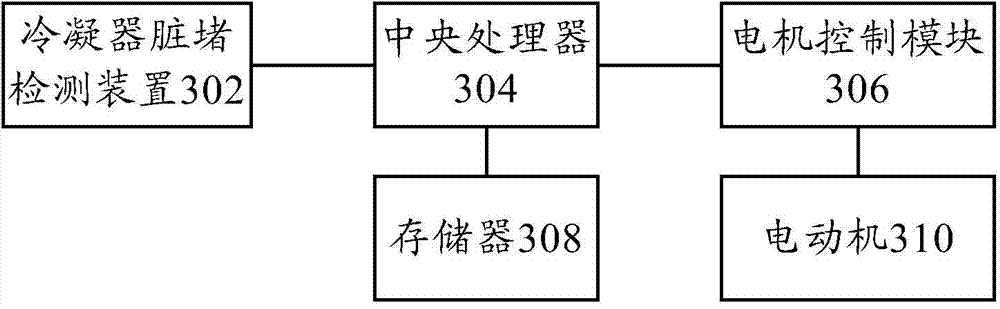

Dust removal method and device applied to air conditioner outdoor heat exchanger

InactiveCN104729016AAchieve dust removal effectEfficient removalMechanical apparatusCleaning heat-transfer devicesEngineeringHigh heat

The invention provides a dust removal method and device applied to an air conditioner outdoor heat exchanger. An outdoor unit of an air conditioner comprises the outdoor heat exchanger and an air duct system composed of a motor and vanes. The dust removal method includes the following steps that whether dust removal processing needs to be carried out on the outdoor heat exchanger is judged; when it is judged that the outdoor heat exchanger needs dust removal processing, at least the motor is controlled to rotate reversely, and when the outdoor unit works normally, the motor rotates forwards. By means of the technical scheme, the effect that the air conditioner automatically carries out dust removal on the outdoor heat exchanger is realized, a higher heat exchange efficiency of a condenser is guaranteed, and the complex operation of detaching the outdoor unit when the condenser is cleaned manually is avoided.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

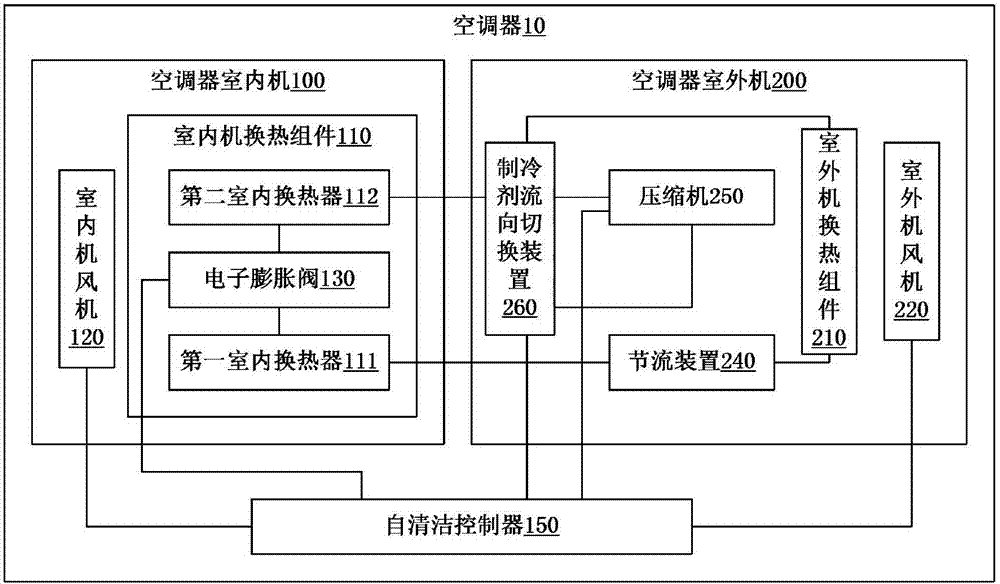

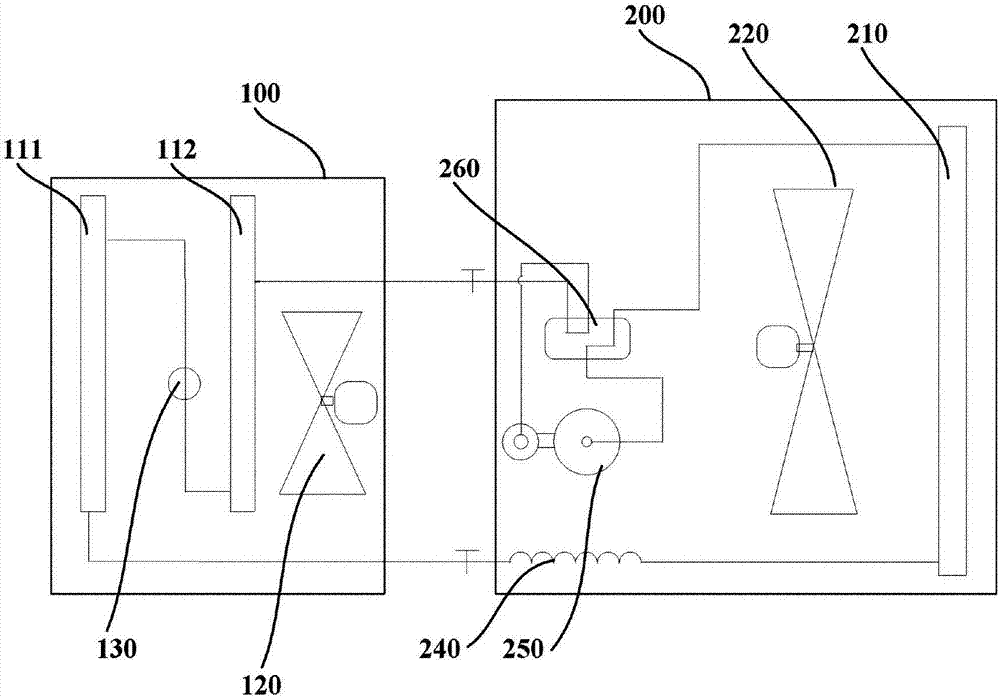

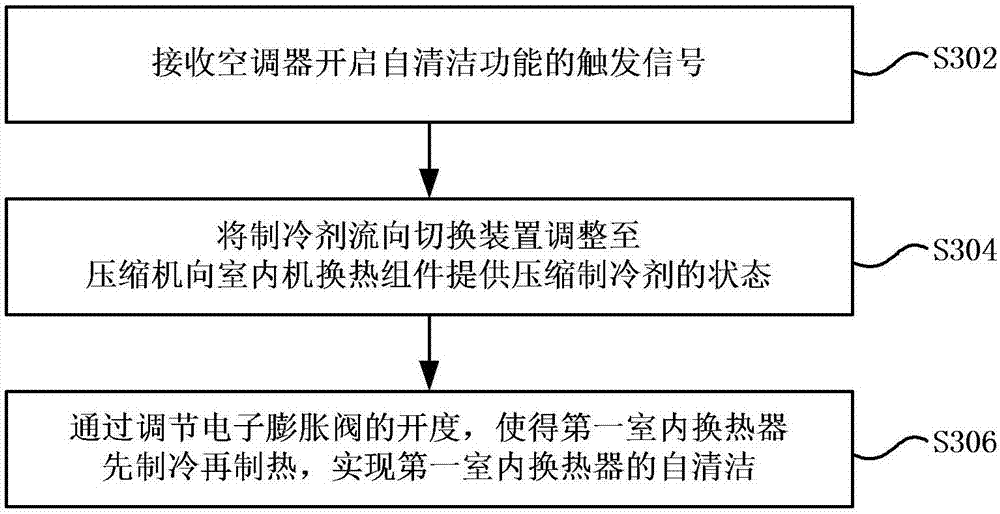

Air conditioner and self-cleaning control method of indoor unit of air conditioner

ActiveCN107514683AReduce the impactAvoid wild swingsMechanical apparatusCleaning heat-transfer devicesEngineeringElectronic expansion valve

The invention provides an air conditioner and a self-cleaning control method of an indoor unit of the air conditioner. An indoor unit heat exchanging assembly of the air conditioner comprises a first indoor heat exchanger and a second indoor heat exchanger which are in tandem connection. The second indoor heat exchanger is connected to a compressor through a refrigerant flow direction switching device. An electronic expansion valve is arranged between the first indoor heat exchanger and the second indoor heat exchanger. The control method comprises the following steps that a trigger signal that the air conditioner starts a self-cleaning function is received, and the refrigerant flow direction switching device is adjusted to a state that the compressor provides a compress refrigerant for the indoor unit heat exchanging assembly; by adjusting the opening degree of the electronic expansion valve, the first indoor heat exchanger is made to conduct refrigerating firstly and then heating so as to constantly frost on the surface of the first indoor heat exchanger in a refrigerating stage; and defrosting is conducted in a heating stage, attached contaminants are taken away by water formed by defrosting, and self cleaning of the first indoor heat exchanger is achieved. According to the scheme, drastic fluctuation of temperature is avoided, and better using experience is brought to users.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

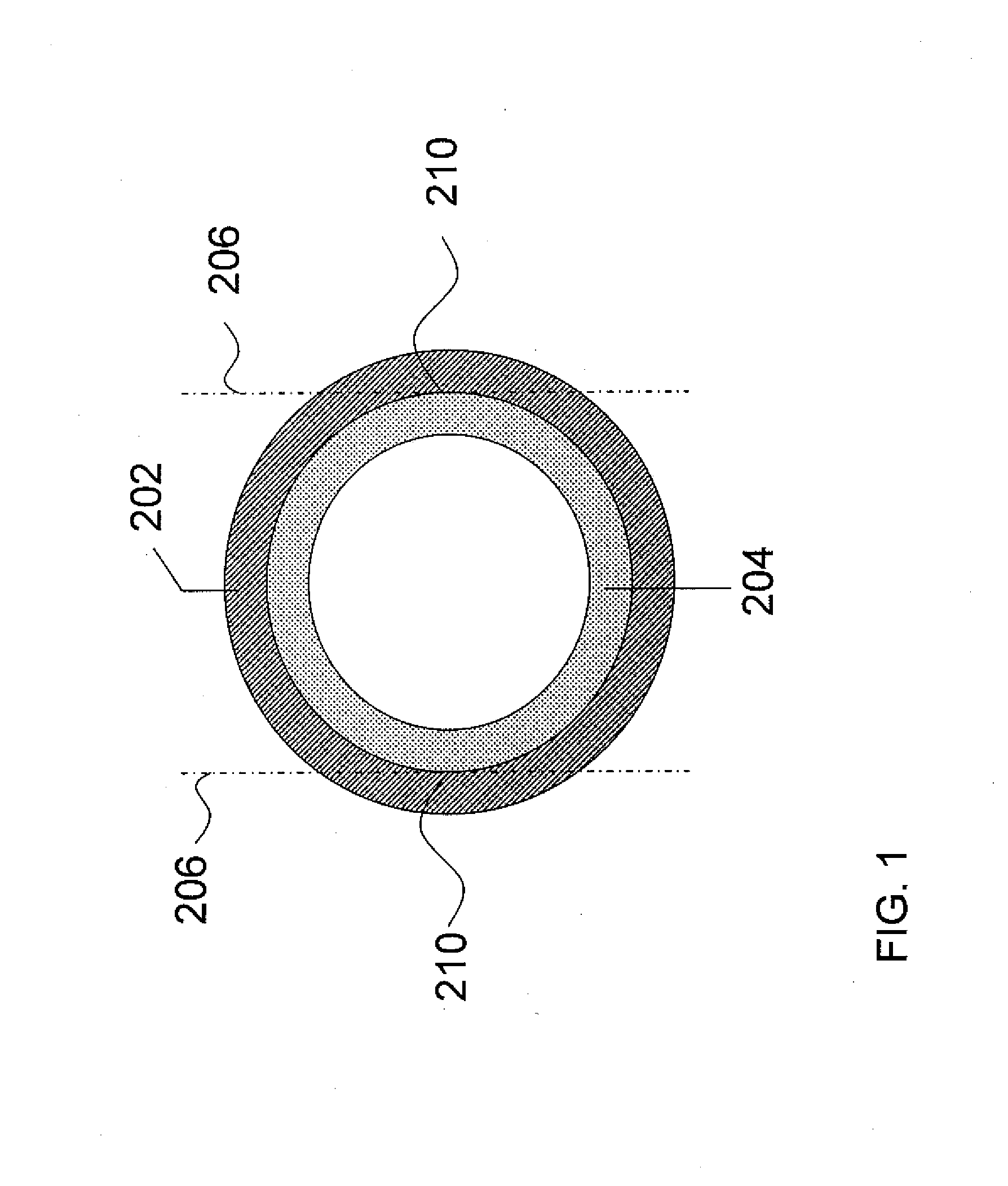

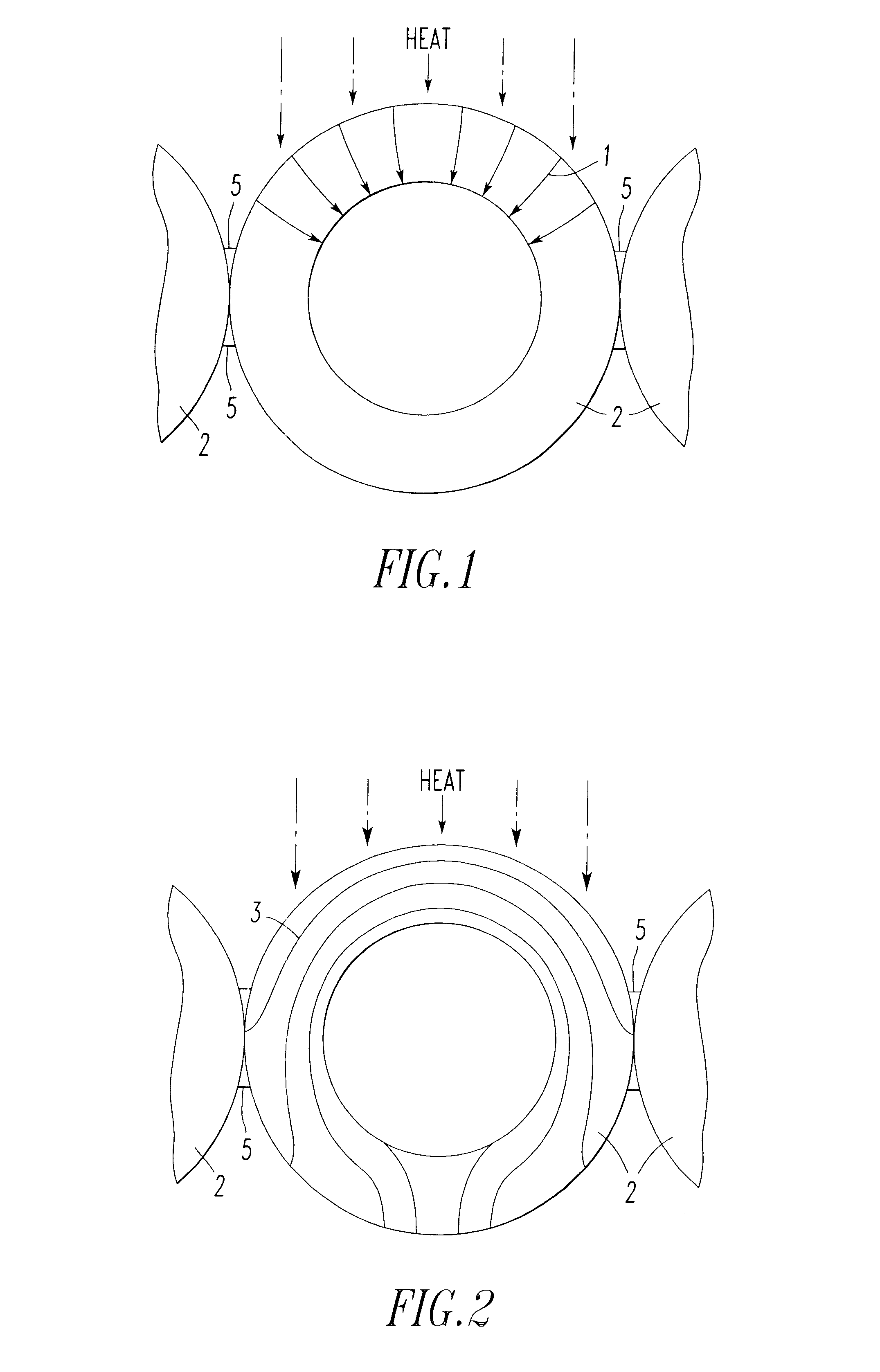

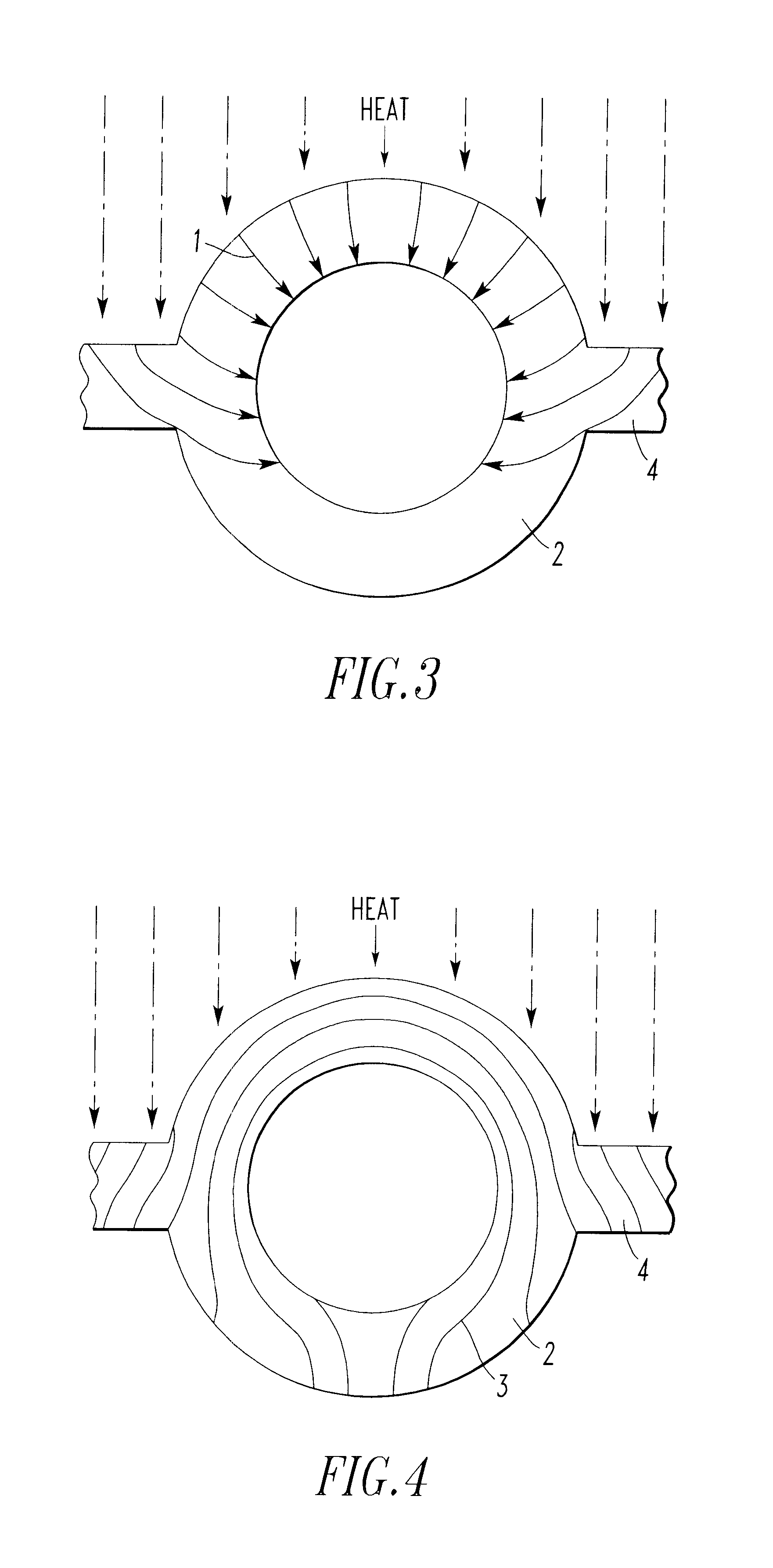

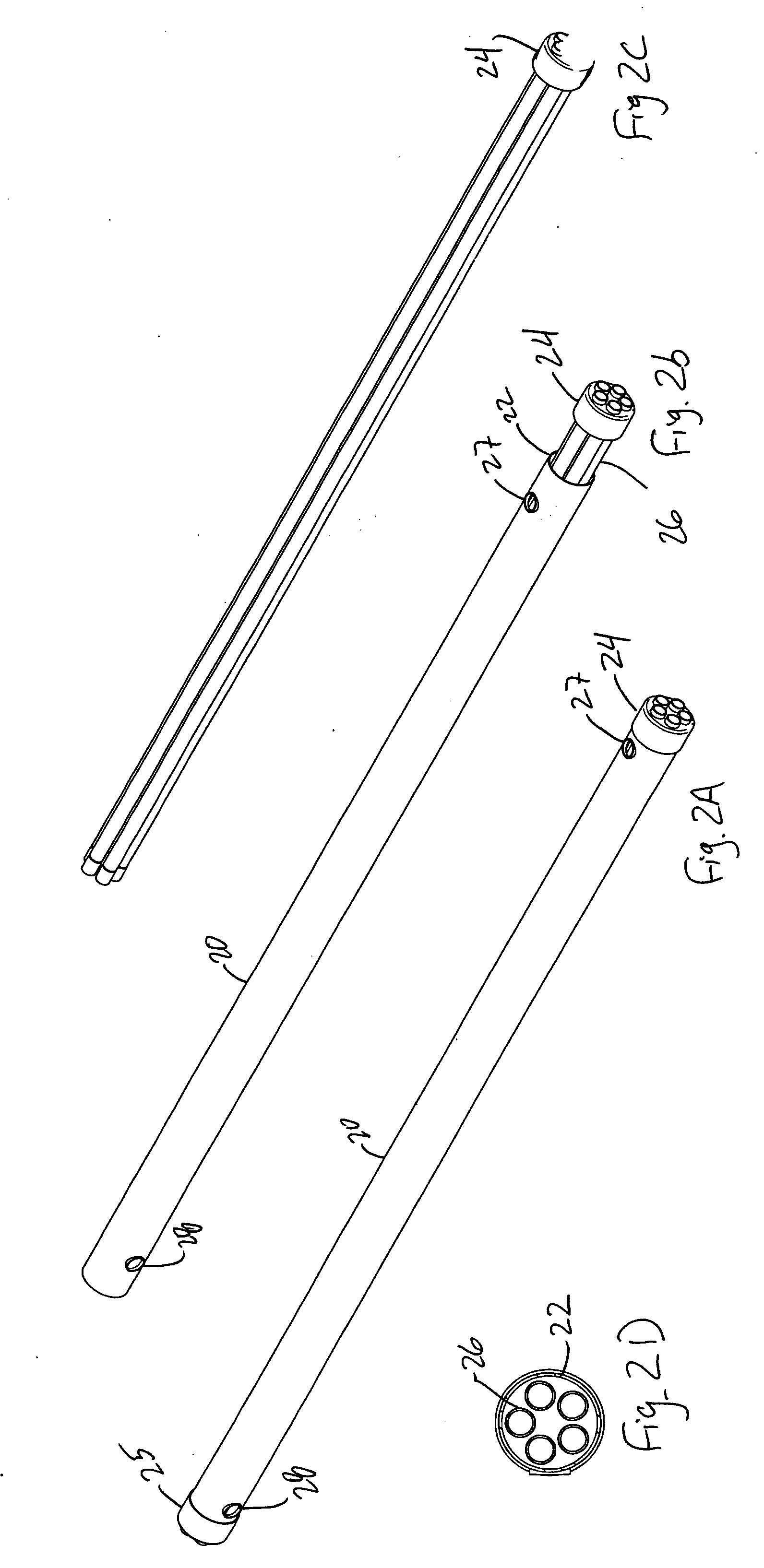

Method for removing oilfield mineral scale from pipes and tubing

A method for removing mineral scale from tubing is disclosed. The method may include the steps of making a first longitudinal cut along a length of the tubing, making a second longitudinal cut along a length of tubing, and removing a plurality of sections of tubing, wherein the sections of tubing are defined by the first and second longitudinal cuts.

Owner:EXKAL LTD

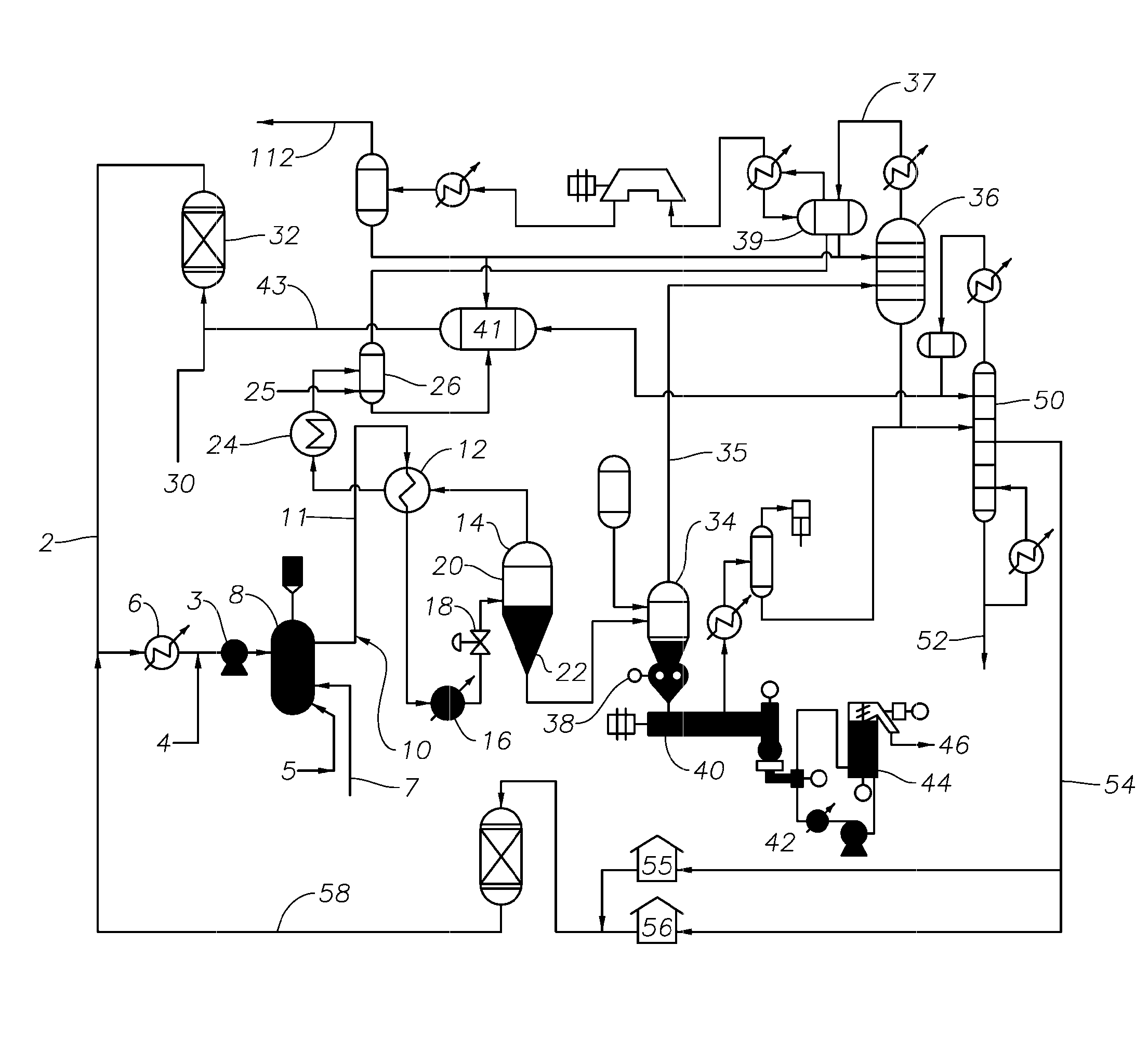

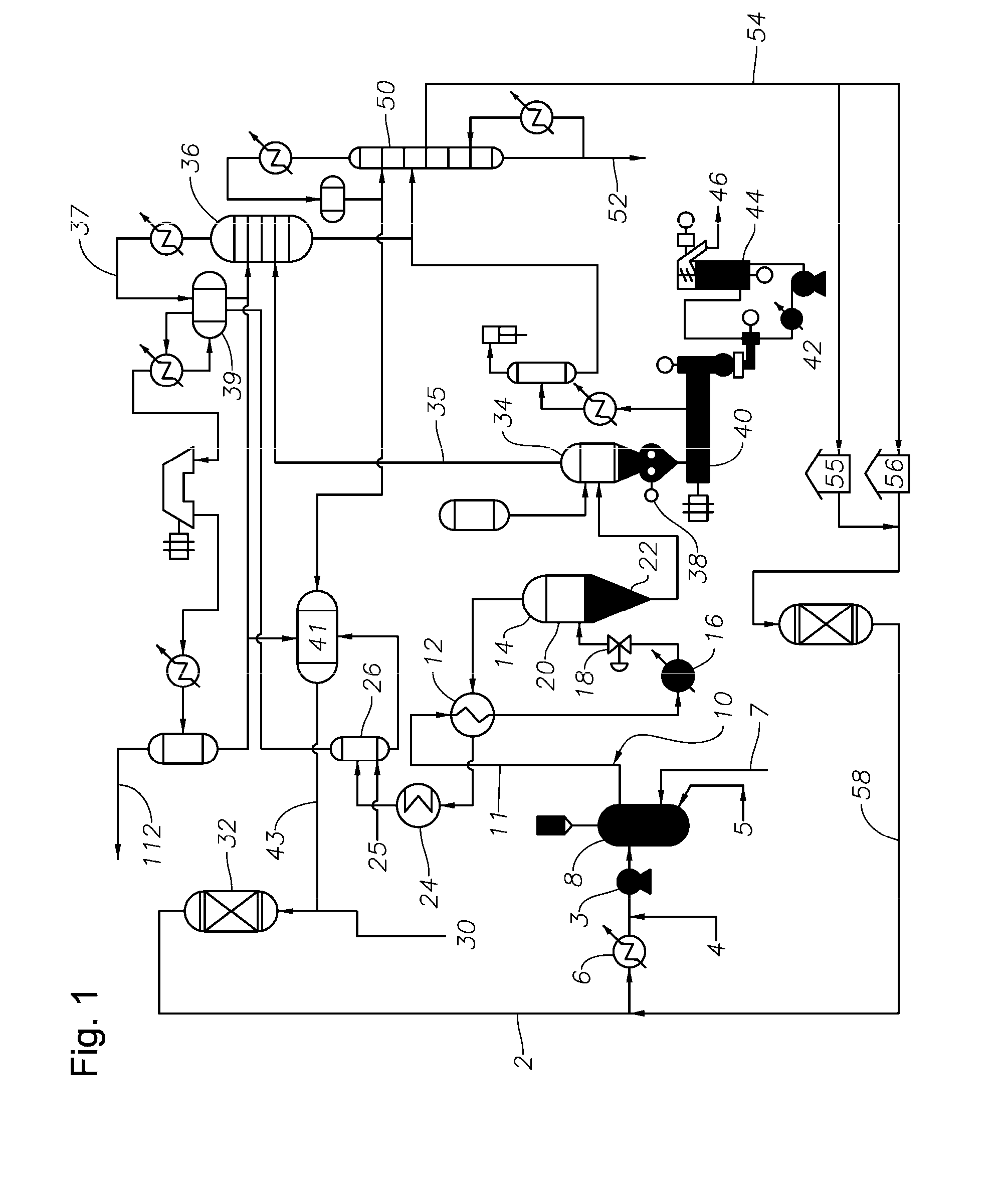

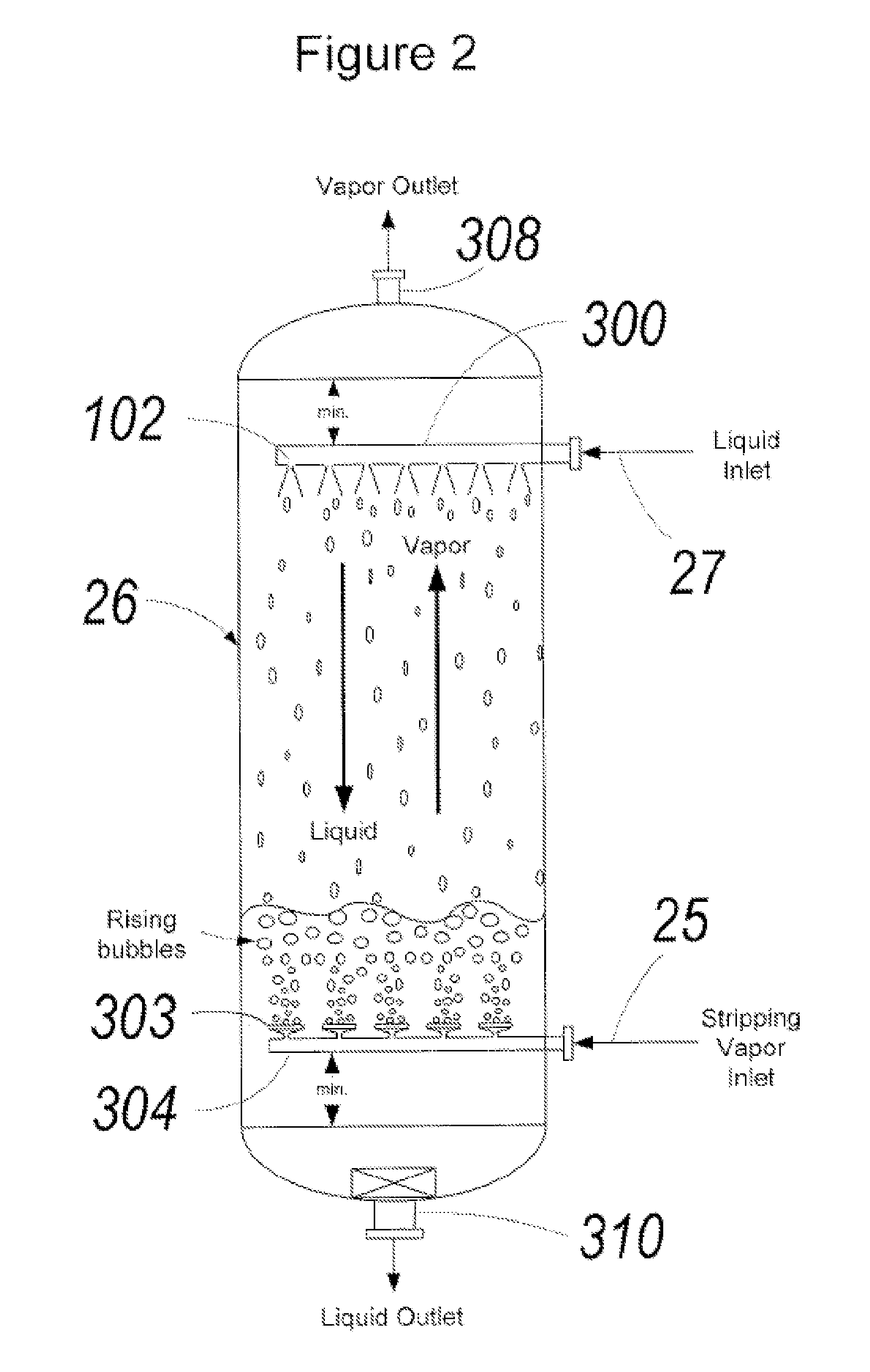

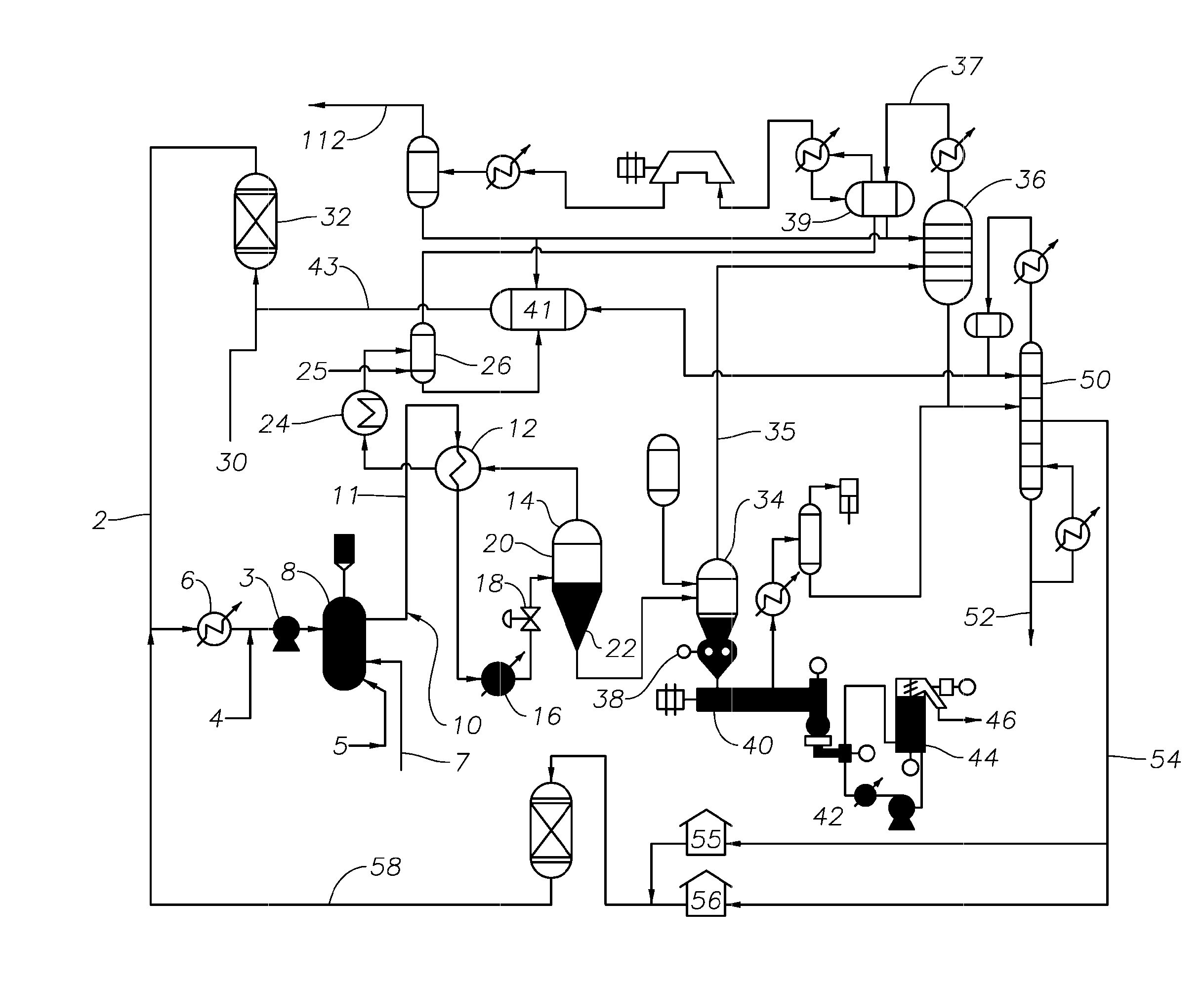

Processes And Apparatus For Continuous Solution Polymerization

InactiveUS20110172375A1Process control/regulationCleaning heat-transfer devicesHydrocarbon solventsThree stage

Described herein in one embodiment is a plant for the continuous solution polymerization of one or more monomers in a solvent, e.g., a hydrocarbon solvent. In one aspect, the plant comprises a high pressure pump and at least one heat exchanger downstream of the pump. In another aspect a feed is cooled by three heat exchangers which are refrigerated by means of a common three stage compressor. In another aspect, the plant comprises a primary reactor and a secondary reactor arranged to operate in parallel, in which the ratio of volume of the primary reactor to the secondary reactor is in the range of 60:40 to 95:5. In another aspect, a method of defouling a heat exchanger is provided in which the level of liquid refrigerant in the heat exchanger is temporarily lowered.

Owner:EXXONMOBIL CHEM PAT INC

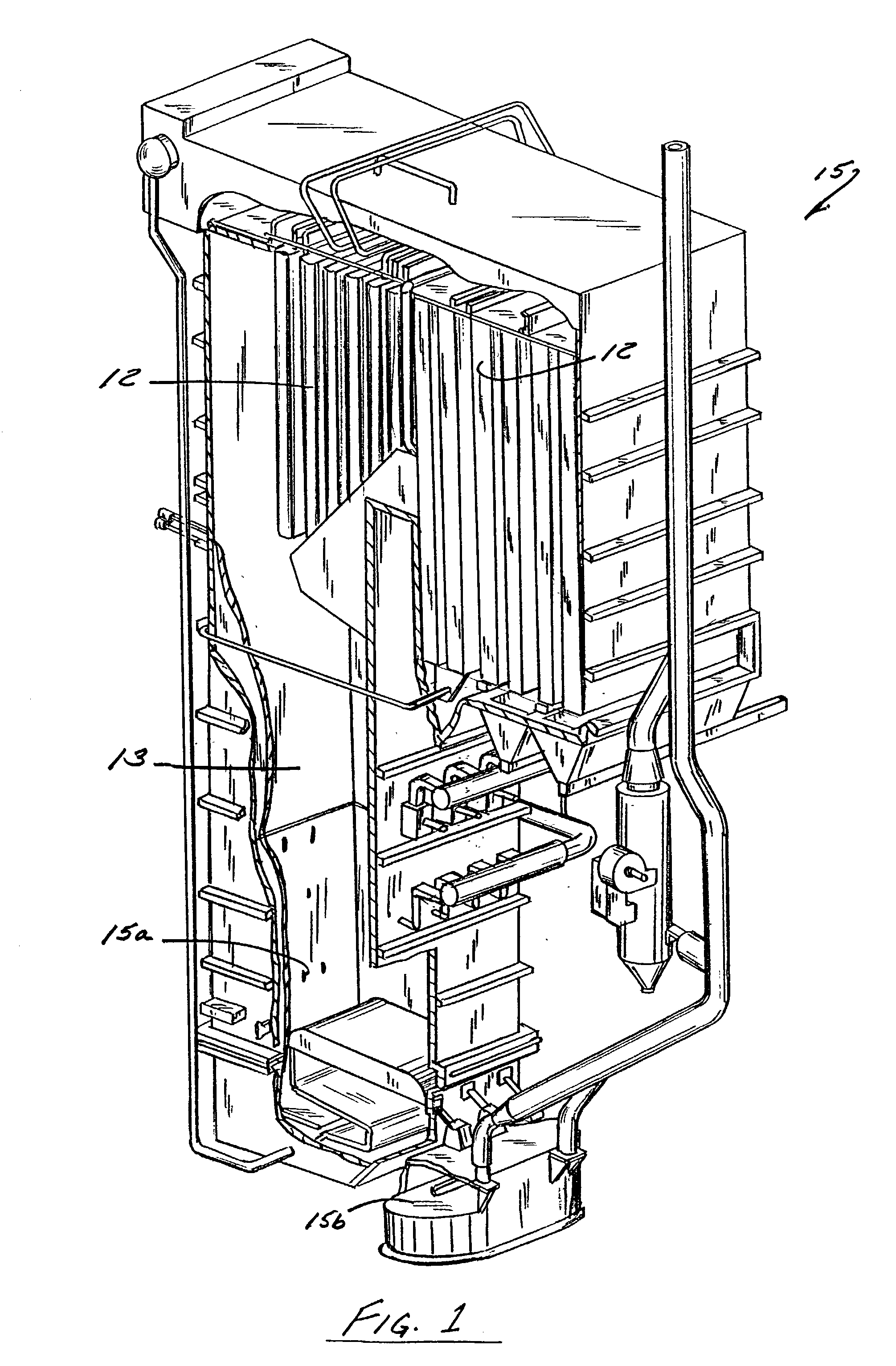

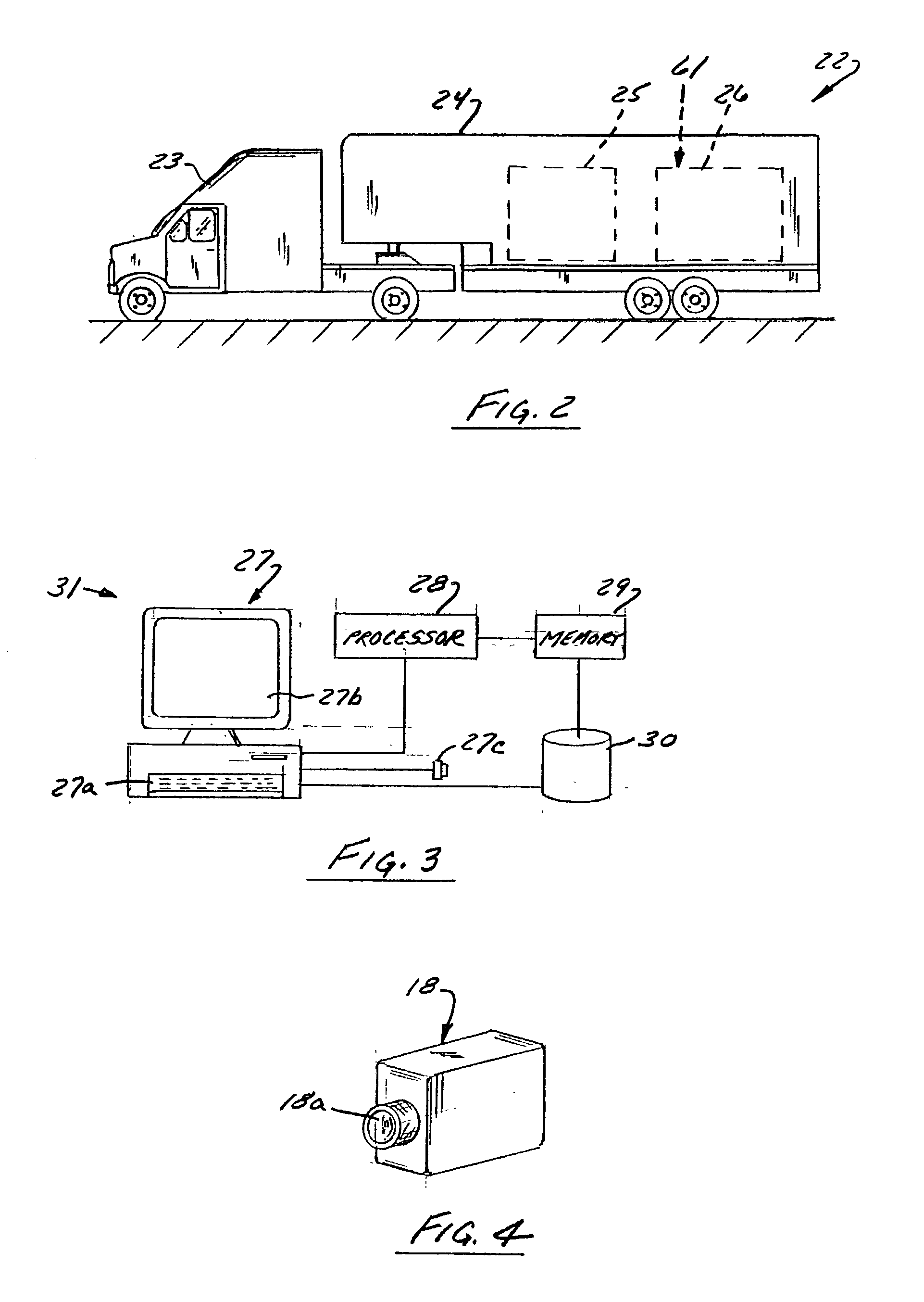

Laser system for slag removal

InactiveUS6710285B2Eliminates slagConsiderable riskCleaning heat-transfer devicesHollow article cleaningFiberSlag

A system for removing slag from a boiler includes a laser, a targeting system, and a computer system for controlling the operation of the laser and targeting system. Preferably, the laser includes chemicals contained in a mixing pre-chamber. A pump connects to the pre-chamber, and an iodine laser diode connects to the pump. The laser unit also has a power source, cooling system, and a raw beam laser. The targeting system is driven by targeting software and includes an optical targeting system. Preferably, the system also includes a mobile trailer with a computer control room, a main laser operating unit, and a portable optical targeting system connected to the laser unit. Fiber optic cable connects the targeting system and the laser. The online deslagging method includes transporting and setting-up the system, relaying set-up information, feeding targeting information, activating and operating the laser to remove slag from within the boiler.

Owner:FIRST CALL EXPLOSIVE SOLUTIONS

Laser system slag removal

InactiveUS20030222062A1Removal from surfaceEliminates slagCleaning heat-transfer devicesHollow article cleaningFiberSlag

A system for removing slag from a boiler includes a laser, a targeting system, and a computer system for controlling the operation of the laser and targeting system. Preferably, the laser includes chemicals contained in a mixing pre-chamber. A pump connects to the pre-chamber, and an iodine laser diode connects to the pump. The laser unit also has a power source, cooling system, and a raw beam laser. The targeting system is driven by targeting software and includes an optical targeting system. Preferably, the system also includes a mobile trailer with a computer control room, a main laser operating unit, and a portable optical targeting system connected to the laser unit. Fiber optic cable connects the targeting system and the laser. The online deslagging method includes transporting and setting-up the system, relaying set-up information, feeding targeting information, activating and operating the laser to remove slag from within the boiler.

Owner:FIRST CALL EXPLOSIVE SOLUTIONS

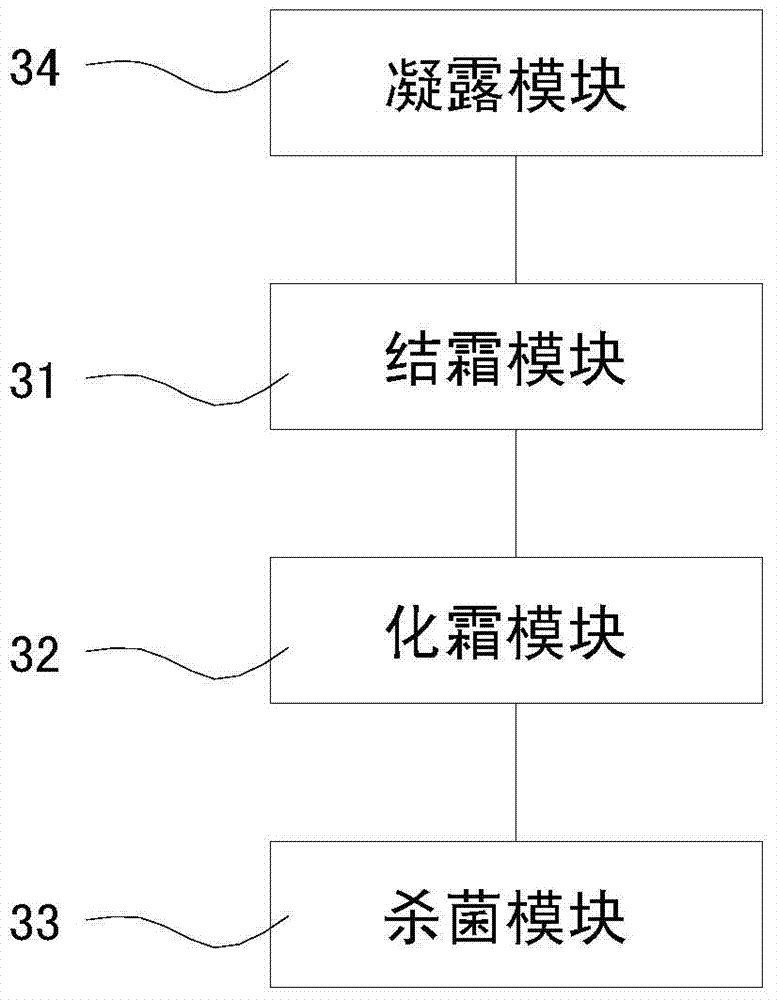

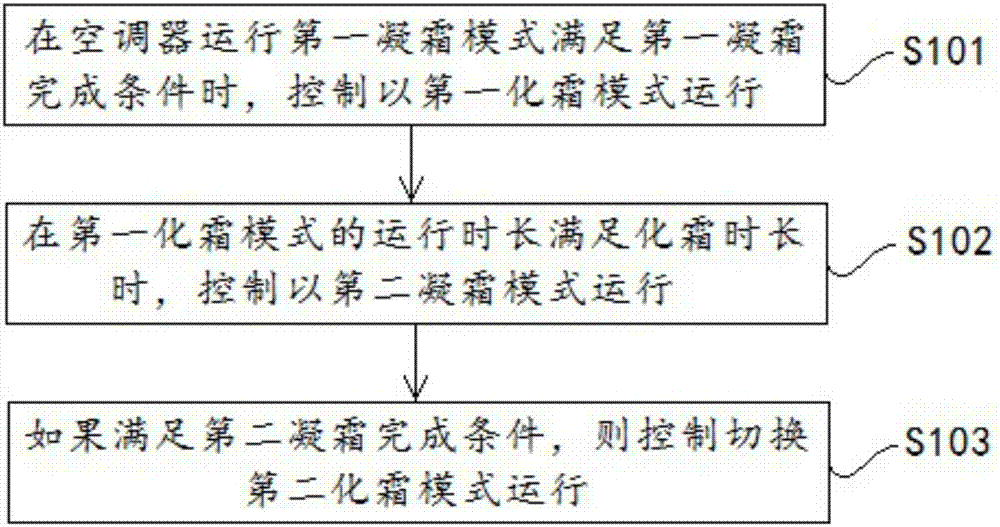

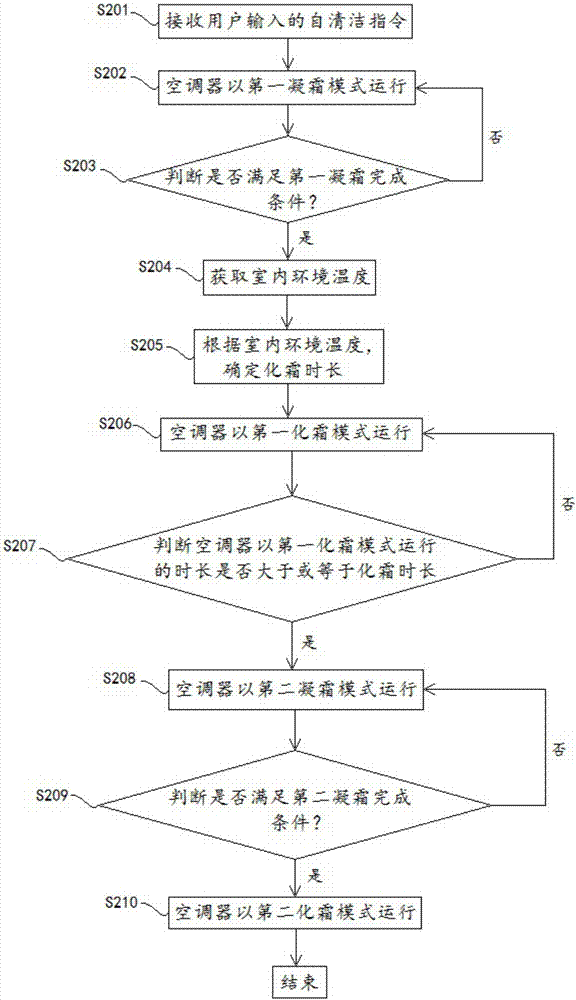

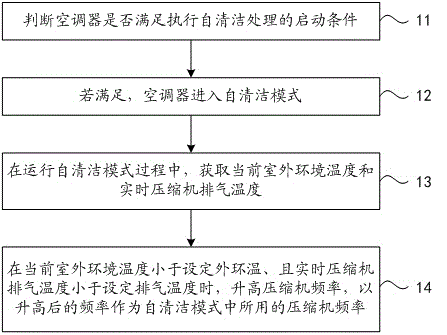

Self-cleaning control method and device for air conditioner

ActiveCN107166670AEasy to cleanReduce accumulationMechanical apparatusCleaning heat-transfer devicesFrostControl theory

The invention discloses a self-cleaning control method and device for an air conditioner, and belongs to the technical field of self cleaning of air conditioners. The control method comprises the steps that when the air conditioner operates in a first frosting mode and meets a first frosting completion condition, the air conditioner is controlled to operate in a first defrosting mode; when operation time of the first defrosting mode meets defrosting time, the air conditioner is controlled to operate in a second frosting mode; and if a second frosting completion condition is met, the air conditioner is controlled to operate in a second defrosting mode. According to the control method, a two-time continuous frosting and defrosting self-cleaning process is adopted, the time for first-time defrosting is set within the specified defrosting time, and therefore condensed water which is melted in the first-time defrosting process can flow to deep-layer parts such as fin gaps, and the condensed water cannot completely break away from a heat exchanger; frost condensation and dust stripping of the condensed water at positions such as the fin gaps is achieved by means of second-time frosting, the overall cleaning effect of the air conditioner is improved, and accumulation of dust at the deep-layer parts of the heat exchanger is reduced.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Method of removing solid carbon dioxide

The invention provides a method of removing solid carbon dioxide from cryogenic equipment, including the steps of: (a) introducing a stream including ethane to the cryogenic equipment to convert solid carbon dioxide to liquid form whereby a mixture of liquid ethane and liquid carbon dioxide is formed; and (b) removing the mixture of liquid ethane and liquid carbon dioxide from the cryogenic equipment. In particular, the method can be used in a liquefied natural gas (LNG) plant wherein cryogenic equipment contains LNG, and the method includes the steps of: (a′) removing the LNG from the cryogenic equipment; (a) introducing a stream including ethane to convert solid carbon dioxide to liquid form whereby a mixture of liquid ethane and liquid carbon dioxide is formed; and (b) removing the mixture of liquid ethane and liquid carbon dioxide from the cryogenic equipment. The result is an effective cleaning method for fouled LNG equipment.

Owner:SHELL OIL CO

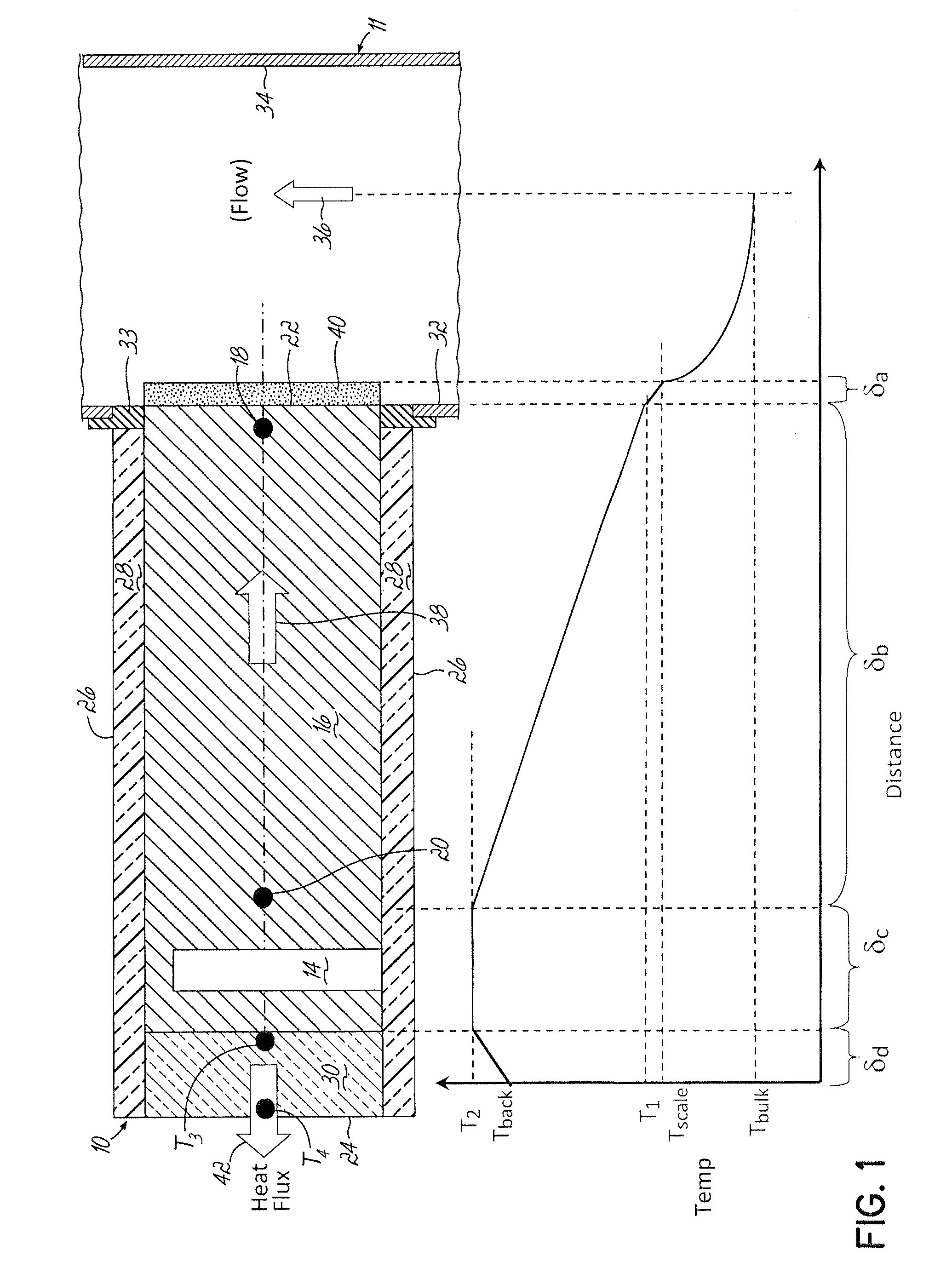

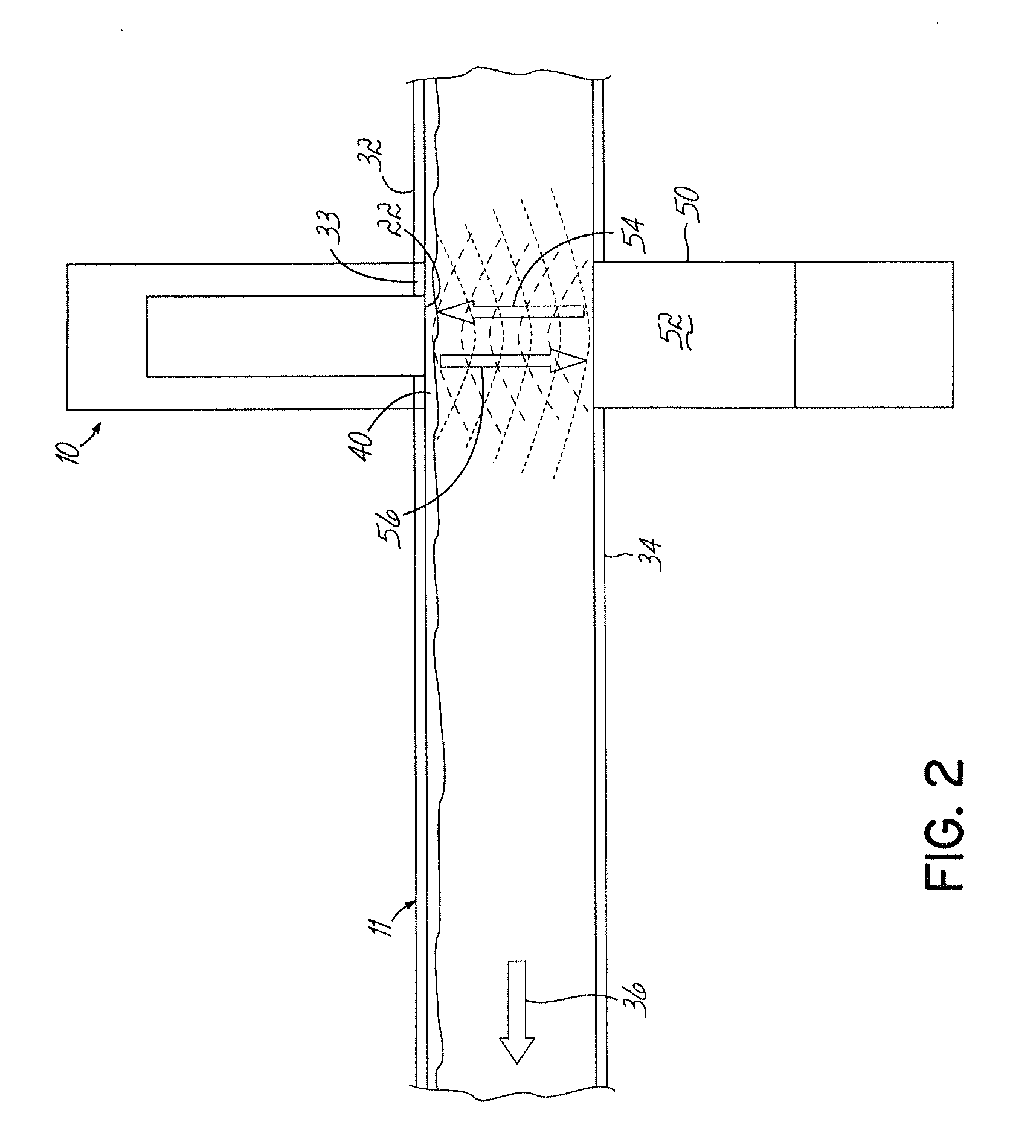

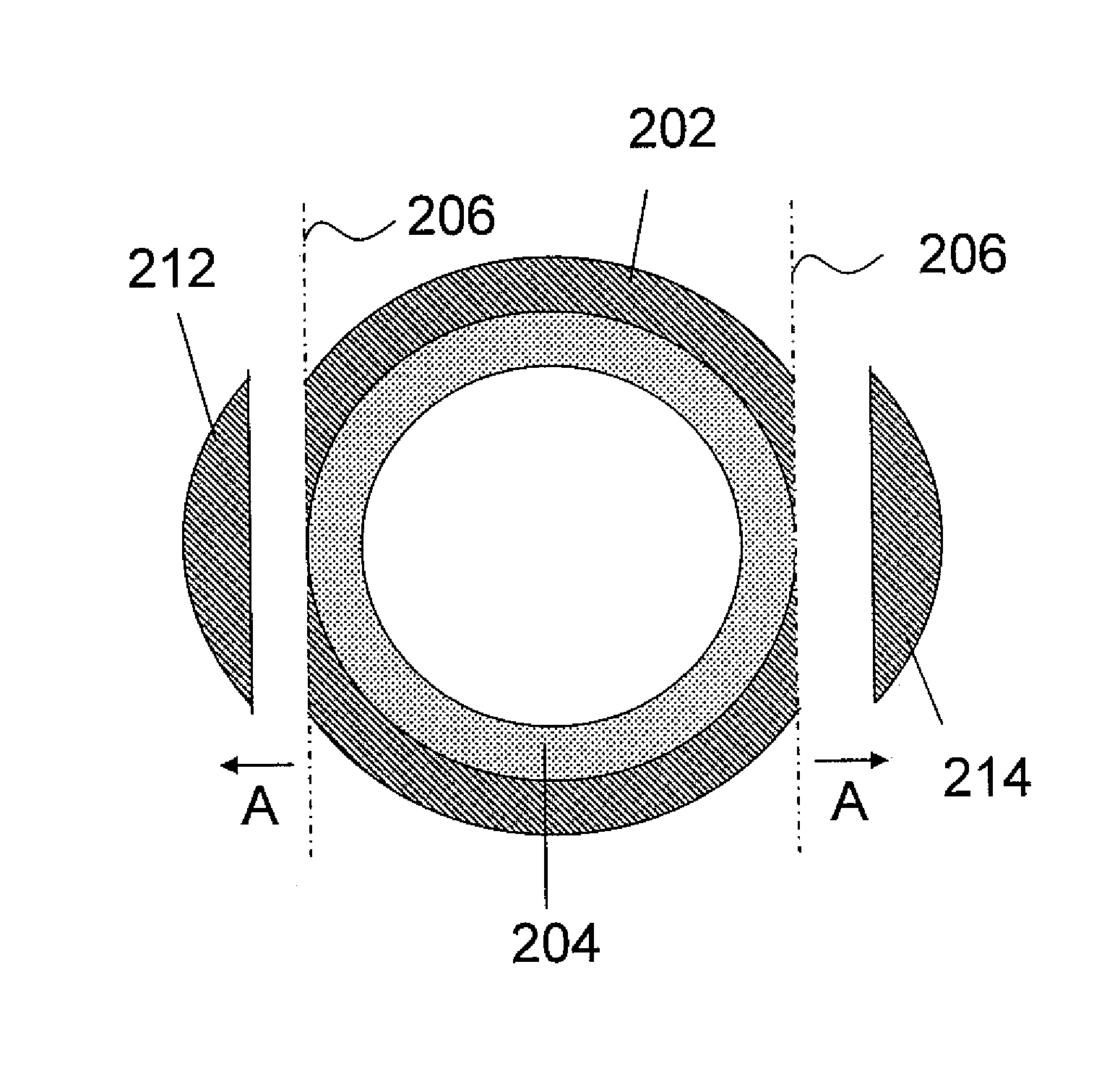

Method and apparatus for estimating fouling factor and/or inverse soluble scale thickness in heat transfer equipment

ActiveUS20140177673A1Accurately indicatedUseful insight natureThermometer detailsAir-treating devicesHeat fluxHeat flow

Scale deposition on a heat transfer surface in a liquid system such as a heat exchanger is estimated by directing of small portion of the liquid flow through a test cell, consisting of a sensor positioned on and projecting through a conduit wall. The sensor consists of a conductive block containing a heater and having a heated wetted test surface that is flush with the inside of the conduit wall and in contact with the flow through the conduit. Within the conductive block are two temperature sensors which are at different distances from the heated wetted test surface and the heater. The periphery of the apparatus is designed to reduce heat flow through the periphery and allow greater heat flow through the heated wetted test surface. By comparing the temperature differential between the two temperature sensors to the differential when no scale is present, the presence of and amount of scale can be determined, based on reduced heat transfer through the heated wetted surface caused by the accumulated scale. The change in the temperature differential is directly proportional to the scale thickness for a given type of scale. When the thickness of the scale is determined by another means, the nature of the scale can be implied. The sensitivity of the measurement can be adjusted to accommodate a very wide range of bulk liquid or ambient temperature via adjustment of the heat flux through the provided secondary heat flux path.

Owner:SOLENIS TECH CAYMAN

Method for removing oilfield mineral scale from pipes and tubing

A method for removing mineral scale from tubing is disclosed. The method may include the steps of making a first longitudinal cut along a length of the tubing, making a second longitudinal cut along a length of tubing, and removing a plurality of sections of tubing, wherein the sections of tubing are defined by the first and second longitudinal cuts.

Owner:EXKAL LTD

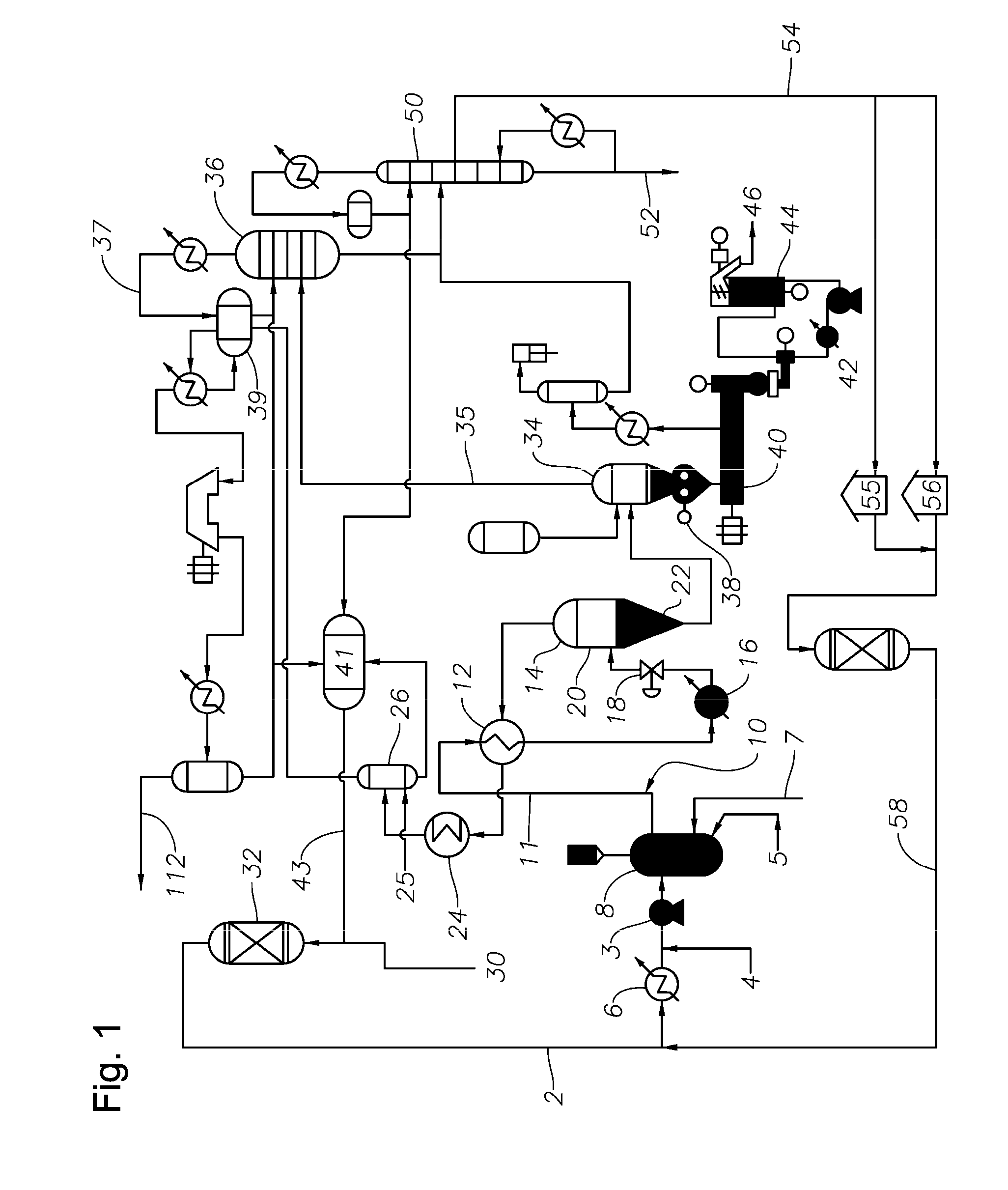

Processes And Apparatus For Polymer Finishing And Packaging

ActiveUS20110172382A1Process control/regulationCleaning heat-transfer devicesSolution polymerizationResidence time

Provided are apparatus and methods relating to the finishing line of a continuous solution polymerization plant. In one aspect, an apparatus includes a pelletizer having cooling liquid, e.g., water or aqueous solution, into which is added a pelletization aid. In another aspect, the apparatus comprises means to remove residual polymer particles from the pelletizer cooling liquid. In a further aspect, the apparatus comprises conduits of at least 50 m in length for carrying propellant cooling liquid from the pelletizer to a drying apparatus. The residence time of the pellets in the cooling liquid may be 10 seconds or more. In a further aspect, a drying apparatus is provided for the pellets which comprises first and second drying zones. In a further aspect, a pneumatic conveyor is provided for carrying pellets to a packaging apparatus. In a further aspect, a packaging apparatus is provided comprising a blender silo.

Owner:EXXONMOBIL CHEM PAT INC

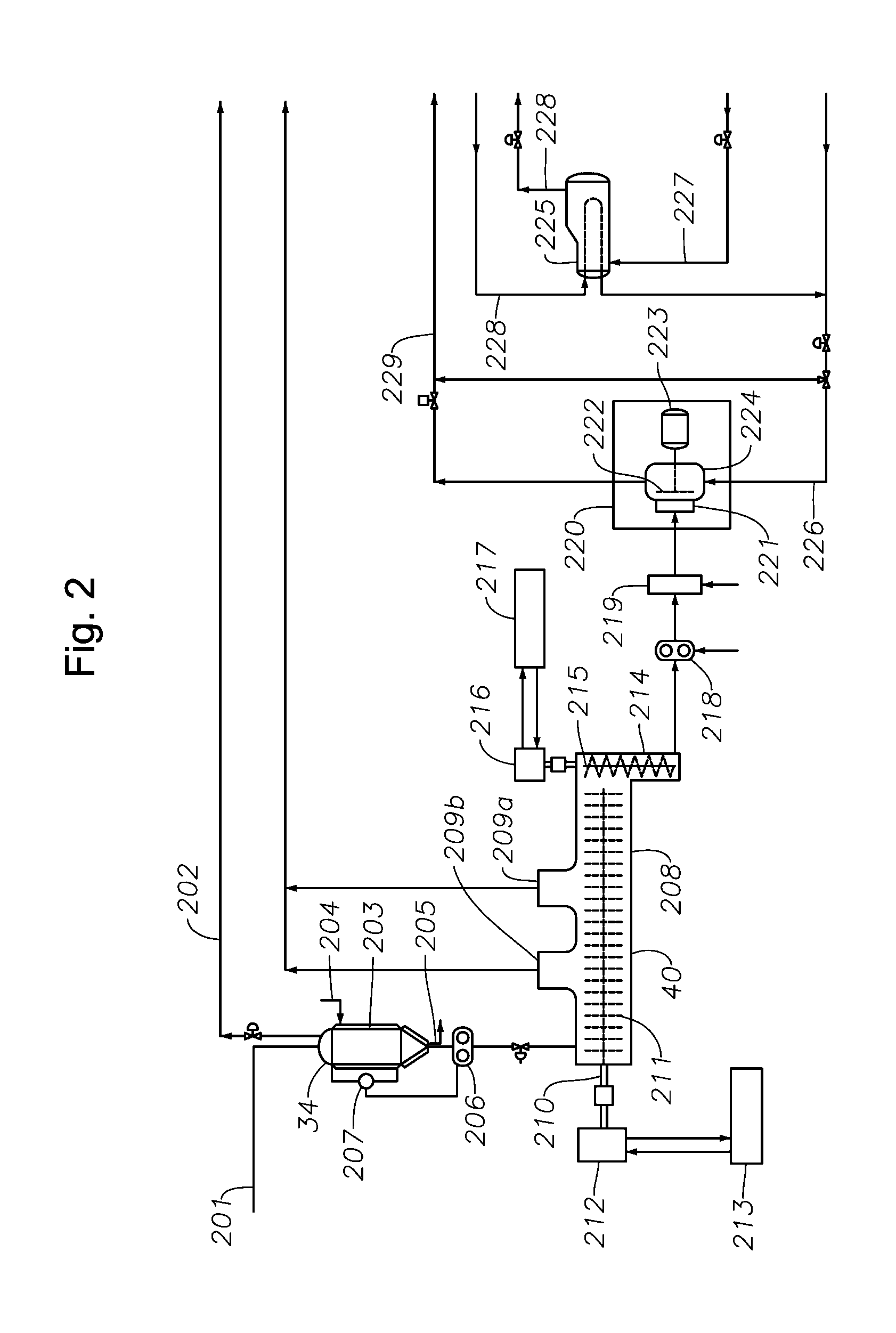

Self-cleaning method of indoor unit of air conditioner

ActiveCN106705376AIncrease exhaust temperatureAvoid the problem of not being able to perform self-cleaningMechanical apparatusCleaning heat-transfer devicesEngineeringHeat exchanger

The invention discloses a self-cleaning method of an indoor unit of an air conditioner. The self-cleaning method comprises the following steps: whether the air conditioner meets the starting condition required for performing self-cleaning treatment is judged, if so, the air conditioner enters a self-cleaning mode and performs self-cleaning treatment of a heat exchanger; and in a process of running the self-cleaning mode, a current outdoor environment temperature and a real-time compressor exhaust temperature are acquired, if the current outdoor environment temperature is less than the set outdoor environment temperature and the real-time compressor exhaust temperature is less than the set exhaust temperature, the compressor frequency is raised, and the raised frequency acts as the compressor frequency used in the self-cleaning mode. With the application of the self-cleaning method, the problem that the self-cleaning purpose can not be achieved due to air conditioner outage resulting from a failure of too low exhaust temperature can be solved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

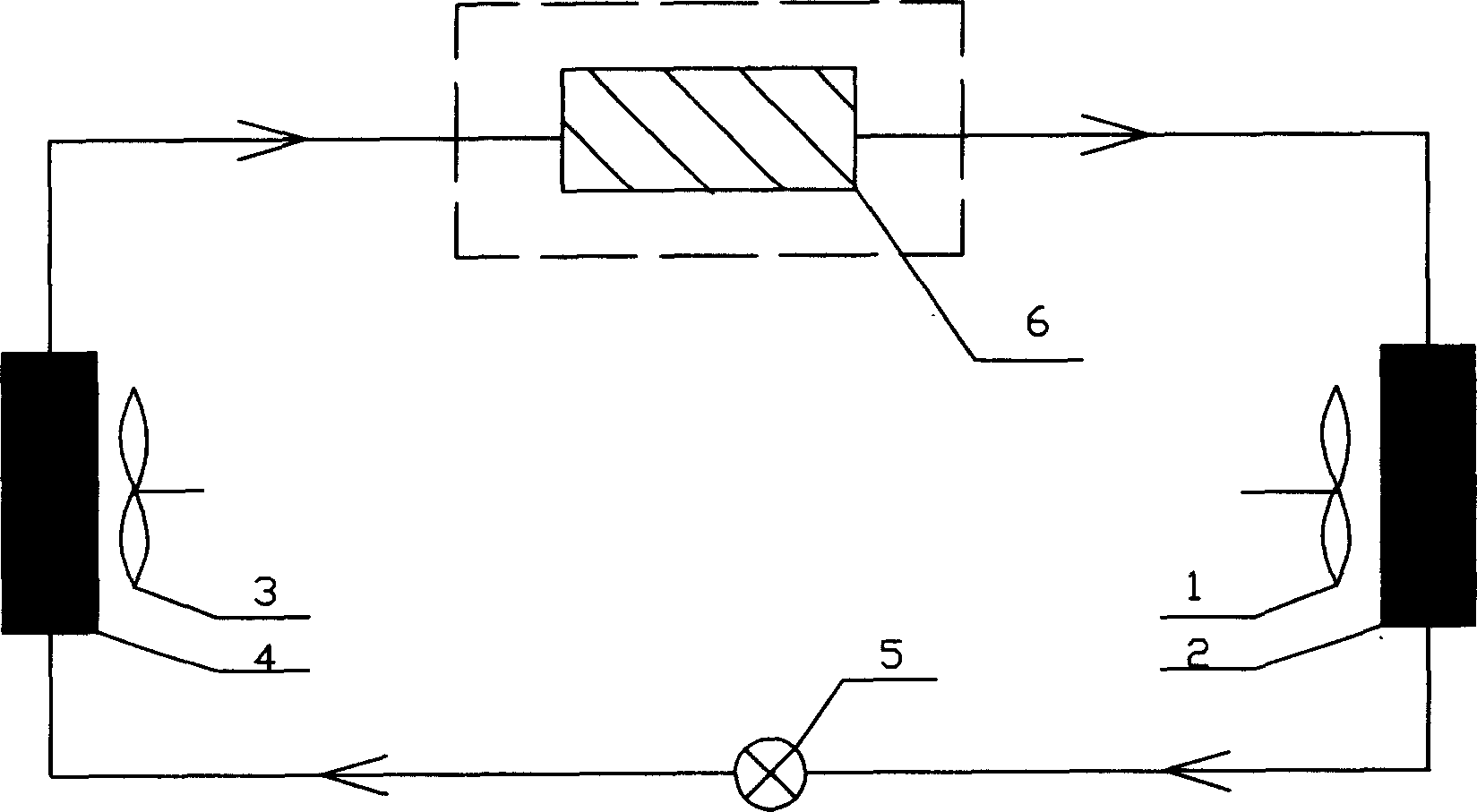

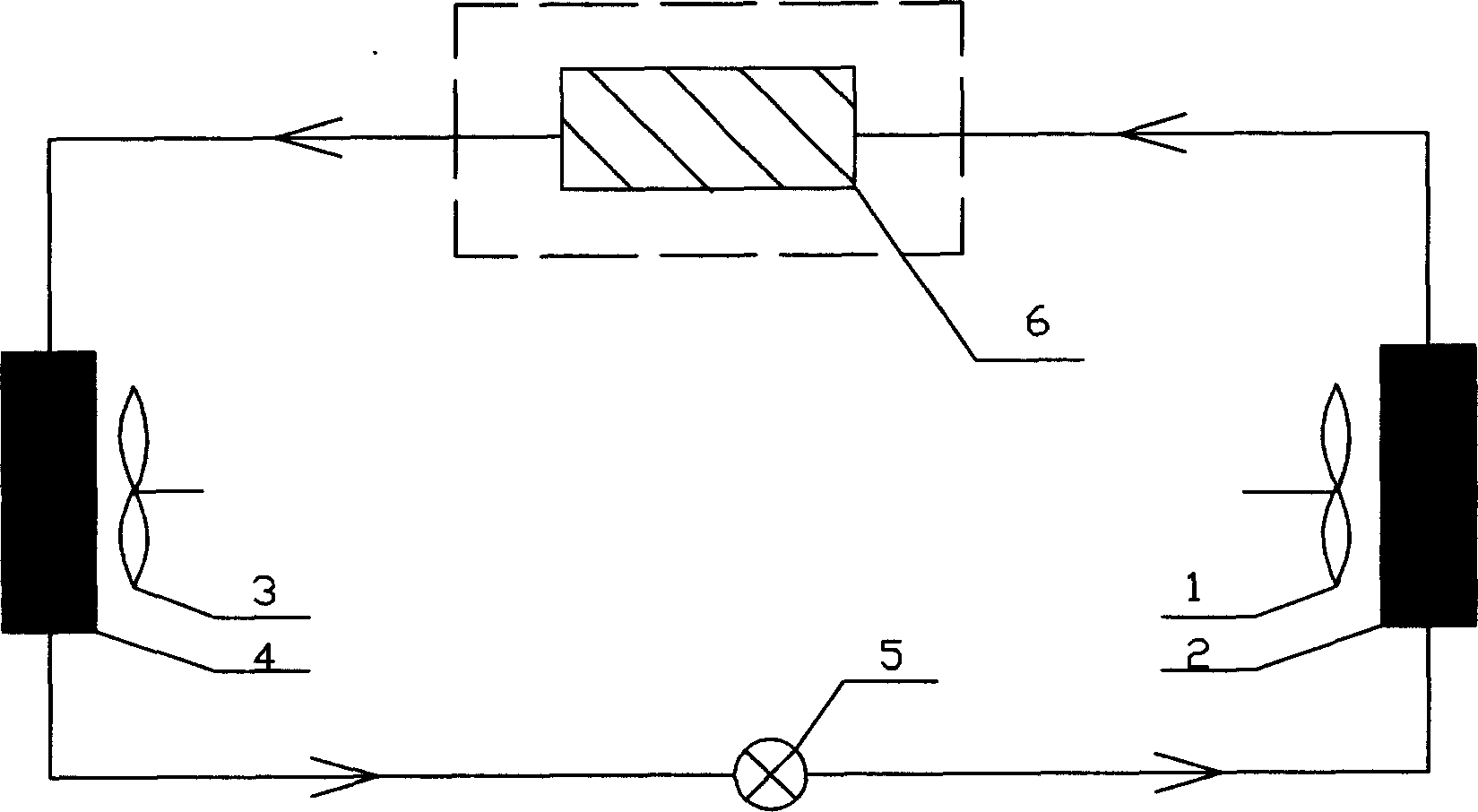

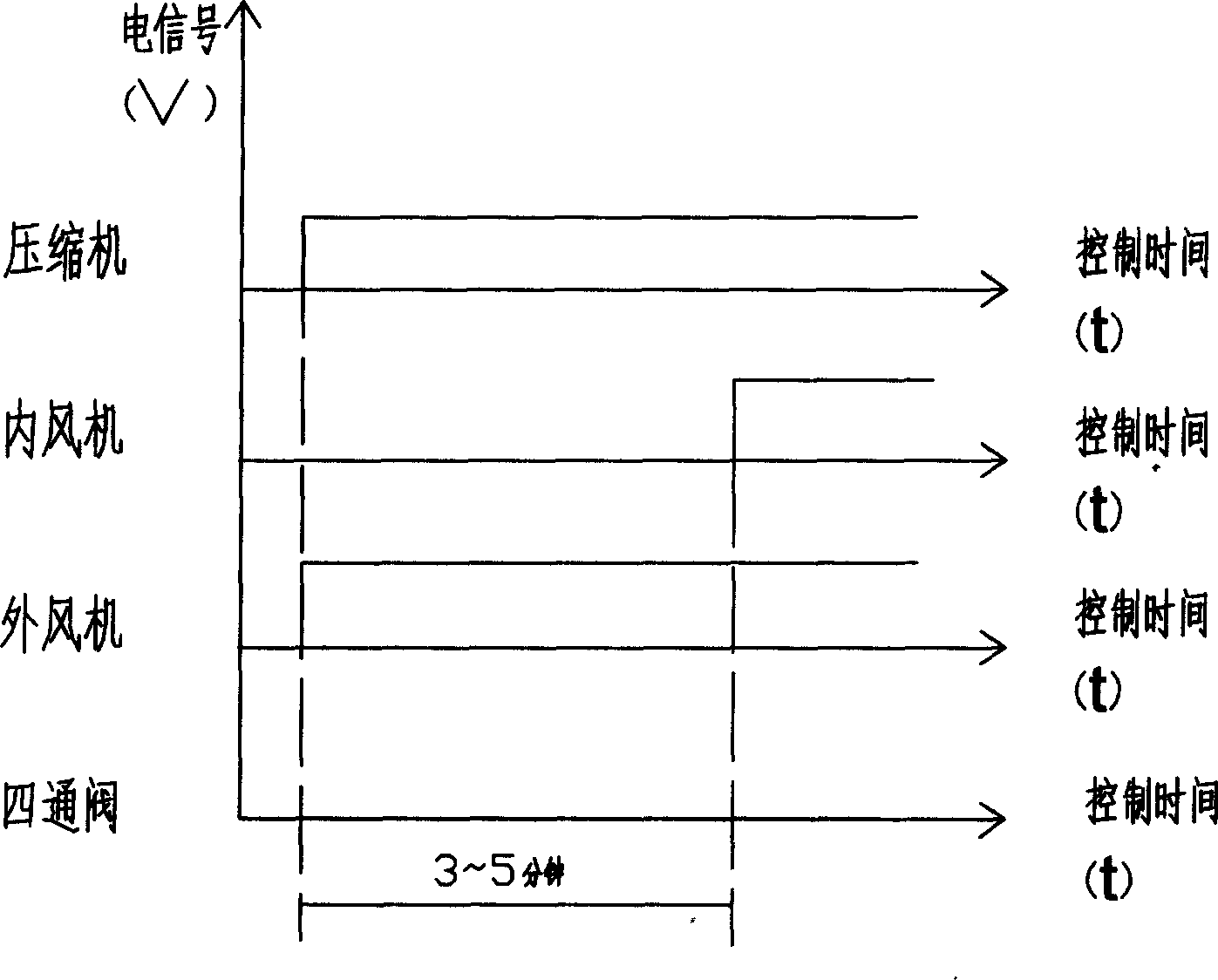

Quick self cleaning method for air conditioner heat exchanger

InactiveCN1821675AEasy to solveNo added costCleaning heat-transfer devicesSpace heating and ventilation safety systemsFour-way valveEngineering

The present invention relates to quick self cleaning method for heat exchanger in air conditioner. The self cleaning method under refrigerating mode includes the following steps: 1. starting the air conditioner, starting the compressor, immobilizing the four-way valve, setting the indoor unit temperature at T1 deg.c, turning off the blower in the indoor unit, turning on the blower in the outdoor unit and closing the wind guide strip in the indoor unit to run for t1 min; and 2. turning on the blower in the indoor unit and opening the wind guide strip in the indoor unit to run for certain period to complete the self cleaning. The self cleaning method under heating mode includes the following steps: 1. starting the air conditioner, starting the compressor, mobilizing the four-way valve, setting the indoor unit temperature at T2 deg.c, turning on the blower in the indoor unit, turning off the blower in the outdoor unit and opening the wind guide strip in the indoor unit at most to run for t2 min; and 2. turning on the blower in the outdoor unit to run for certain period to complete the self cleaning.

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

Method of monitoring heat flux and controlling corrosion of furnace wall tubes

In a method of measuring heat flux and corrosion in a furnace, pairs of thermocouples are attached to the back side of the furnace wall. One thermocouple of each pair is attached to a tube and the second thermocouple is attached to a web connected to that tube. A temperature differential is determined for each pair at selected time intervals. A decrease in the difference between temperature differentials indicates slag on the furnace wall has melted indicating corrosion can be occurring.

Owner:MISSISSIPPI LIME CO

Method for wax removal and measurement of wax thickness

ActiveUS20100300486A1Situation is differentEffective installationCleaning heat-transfer devicesHollow article cleaningEngineeringWax removal

A method for removal of wax deposited on an inner wall in contact with a fluid stream. The method includes the steps of cooling the inner wall and the fluid stream to a temperature of or below the wax appearance temperature, enabling wax to dissolve and precipitate on the inner wall, and heating of the inner wall for a short period of time to release the deposited wax from the surface of the inner wall, mainly in the form of solid parts. The thickness of wax deposits in a pipe section can be determined by computing the temperatures obtained upstream and downstream in the said pipe section, before and after applying heat pulse.

Owner:DEN NORSKE STATS OLJESELSKAP AS

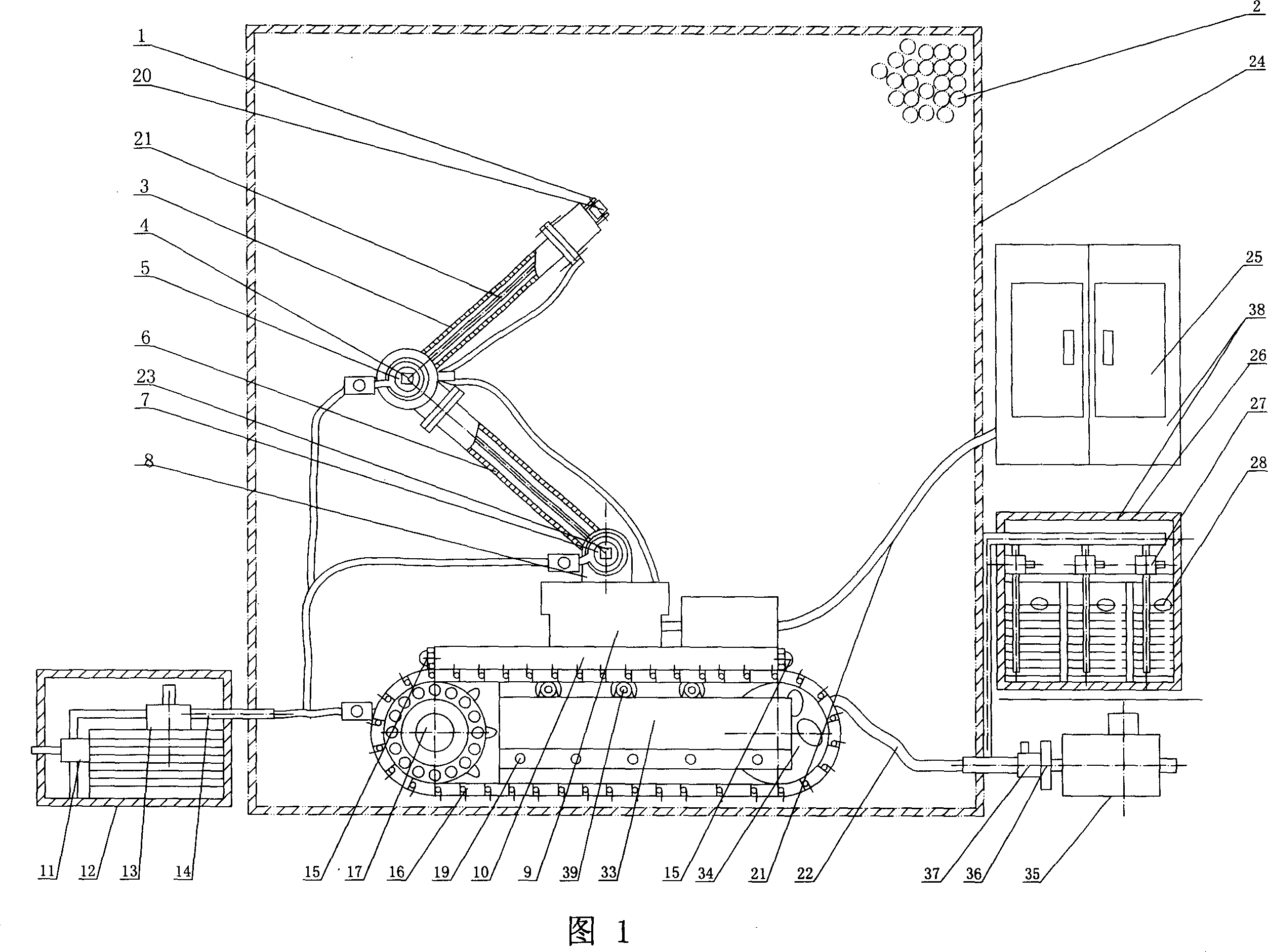

Underwater intelligent purification robot for large-scale condensing plant

InactiveCN1923467AAutonomous movementPrecise positioningProgramme-controlled manipulatorCleaning heat-transfer devicesEngineeringControl theory

The invention relates to a large condenser underwater intelligent cleaning robot. Wherein, it comprises controller and connected washer; the bottom of washer has walking device; one end of small arm of washer is mounted with small arm driving axle; another end is mounted with ejection gun and image collector; the ejection gun via connecting tube is connected to the washing medium resource; the small arm driving axle is connected to the small arm driving device; the small arm driving device via small arm photoelectric coder is connected to the controller; one end of large arm of washer is mounted with small arm driving axle; another end is mounted with large arm driving axle; the large arm driving axle and the large arm driver are connected; the large arm driving device via large arm photoelectric coder is connected to the controller; the large arm driving axle is mounted on rotator on the walking device. The invention can simplify structure and it can online wash the water room by itself.

Owner:HUNAN UNIV

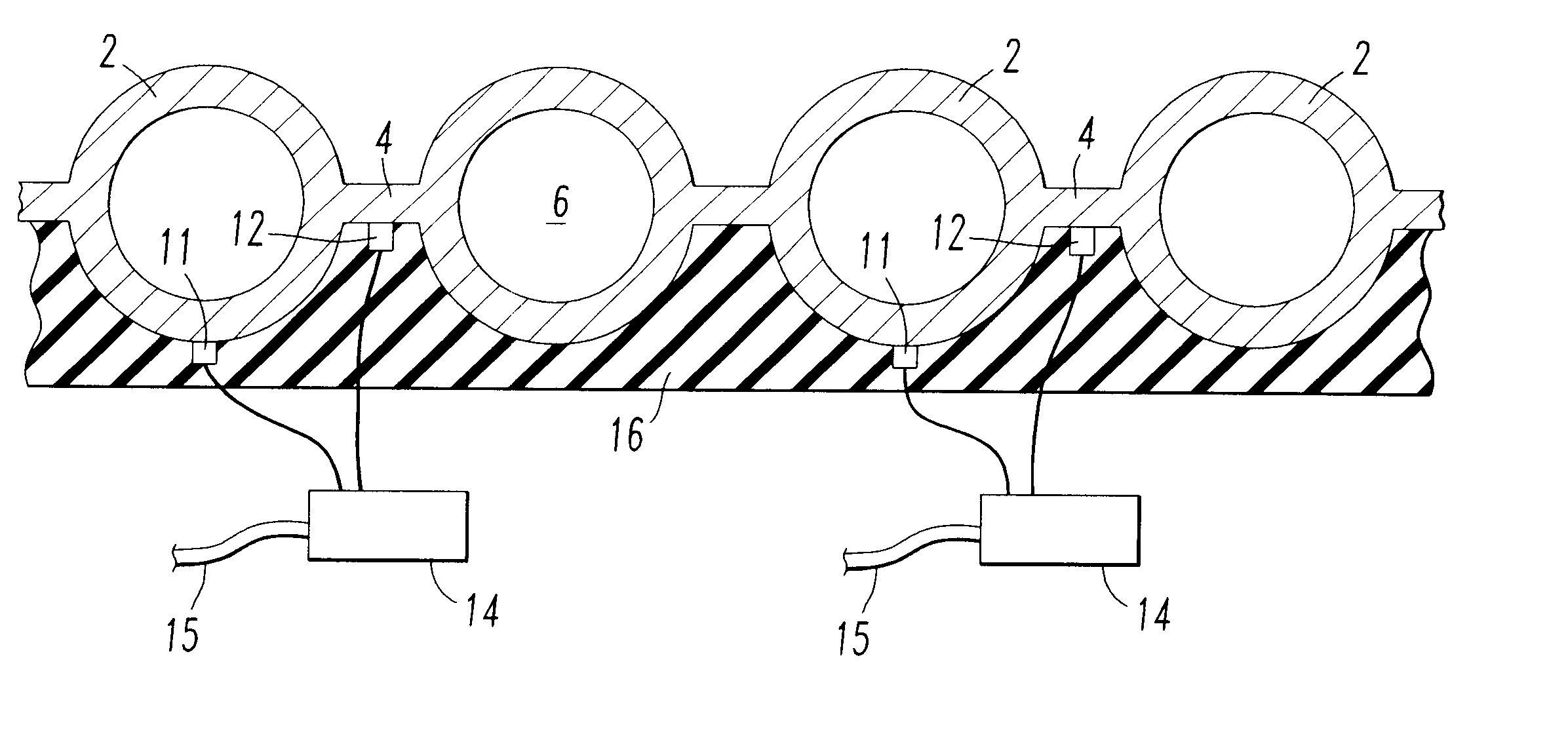

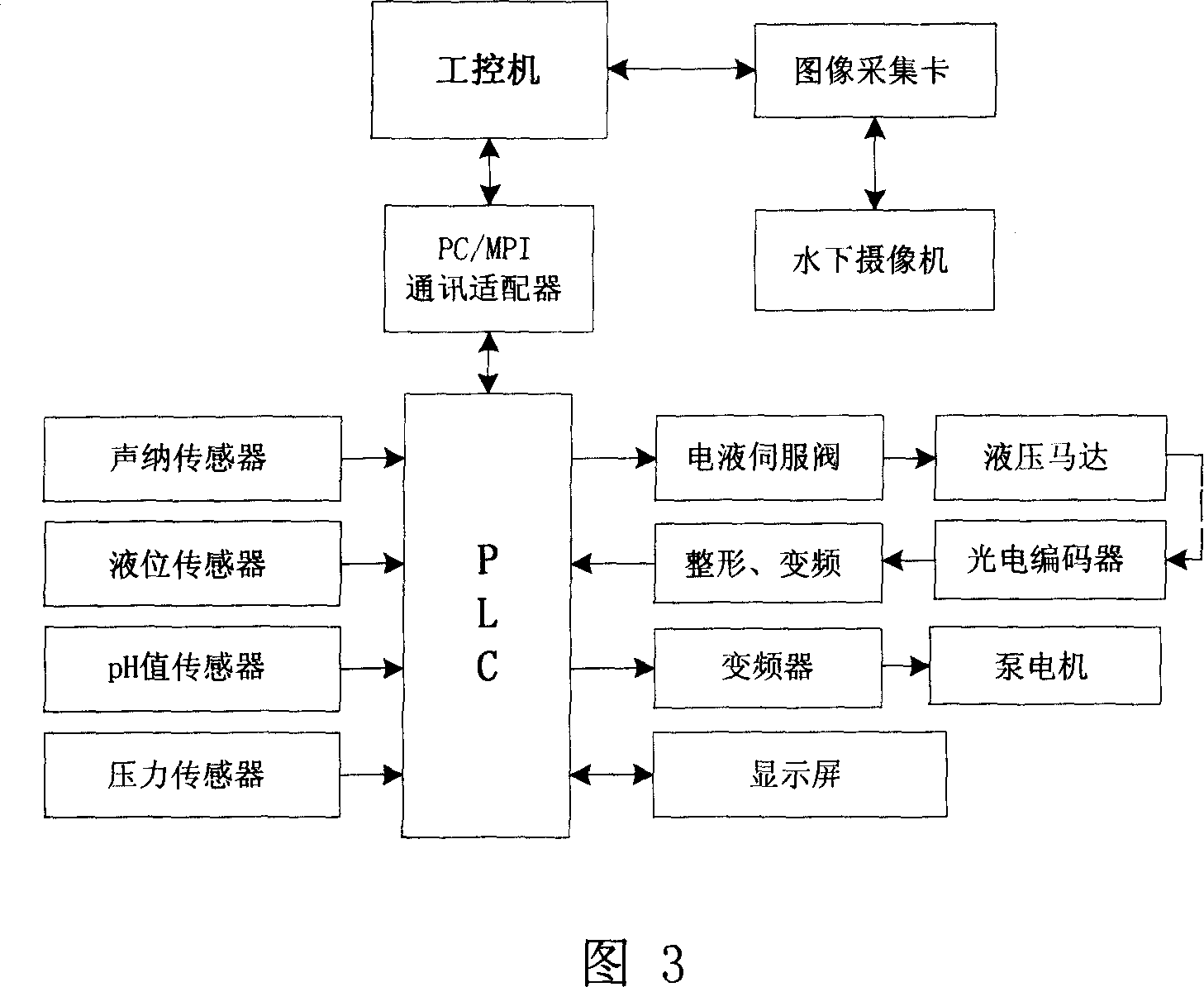

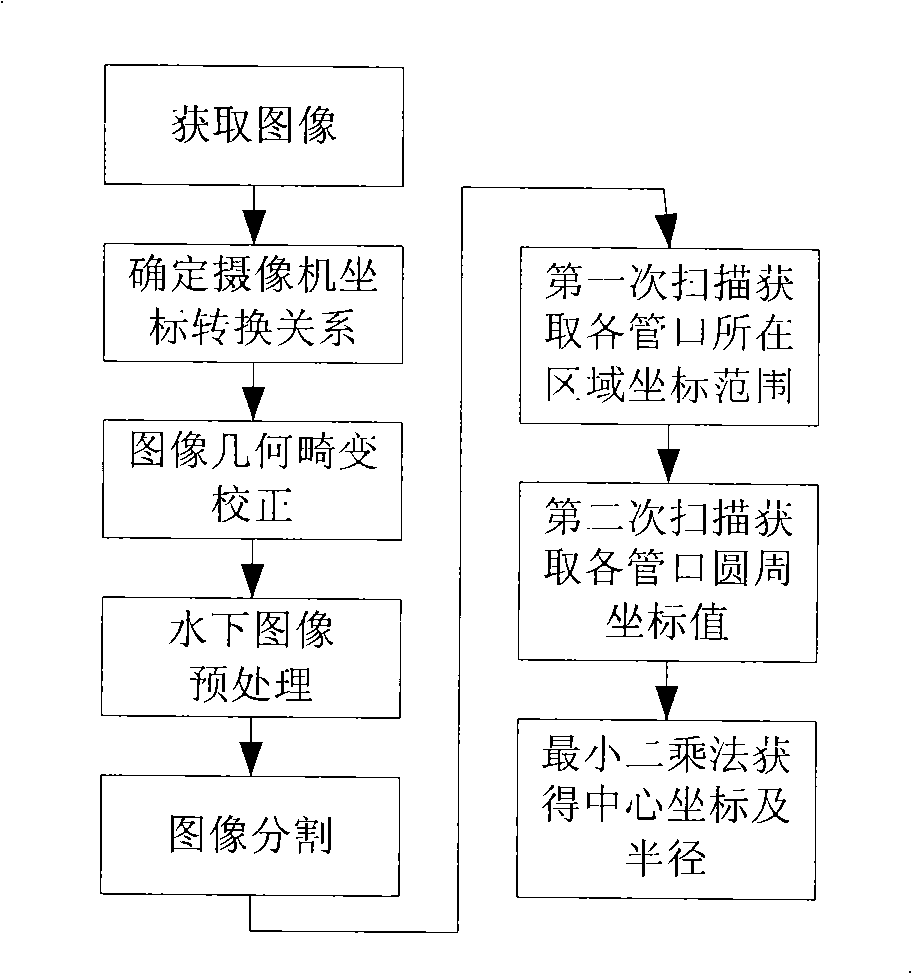

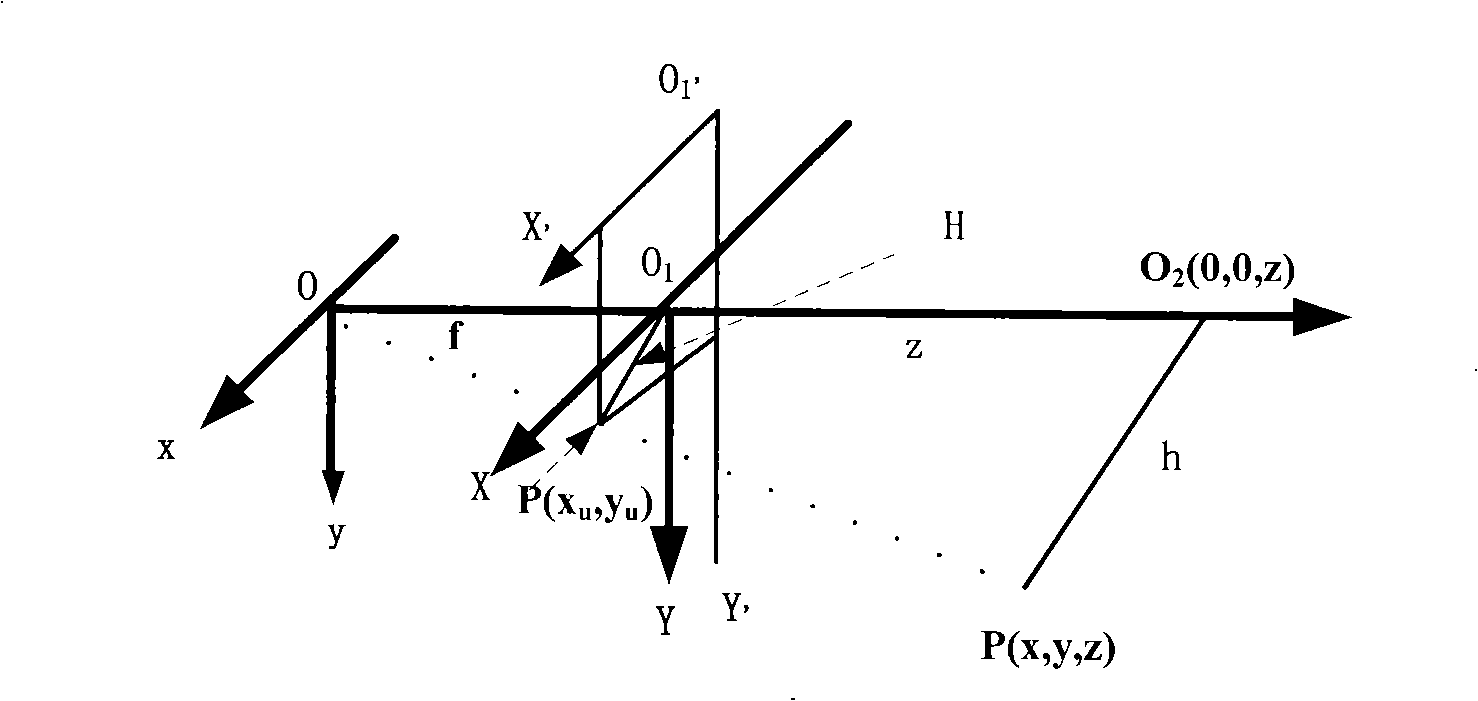

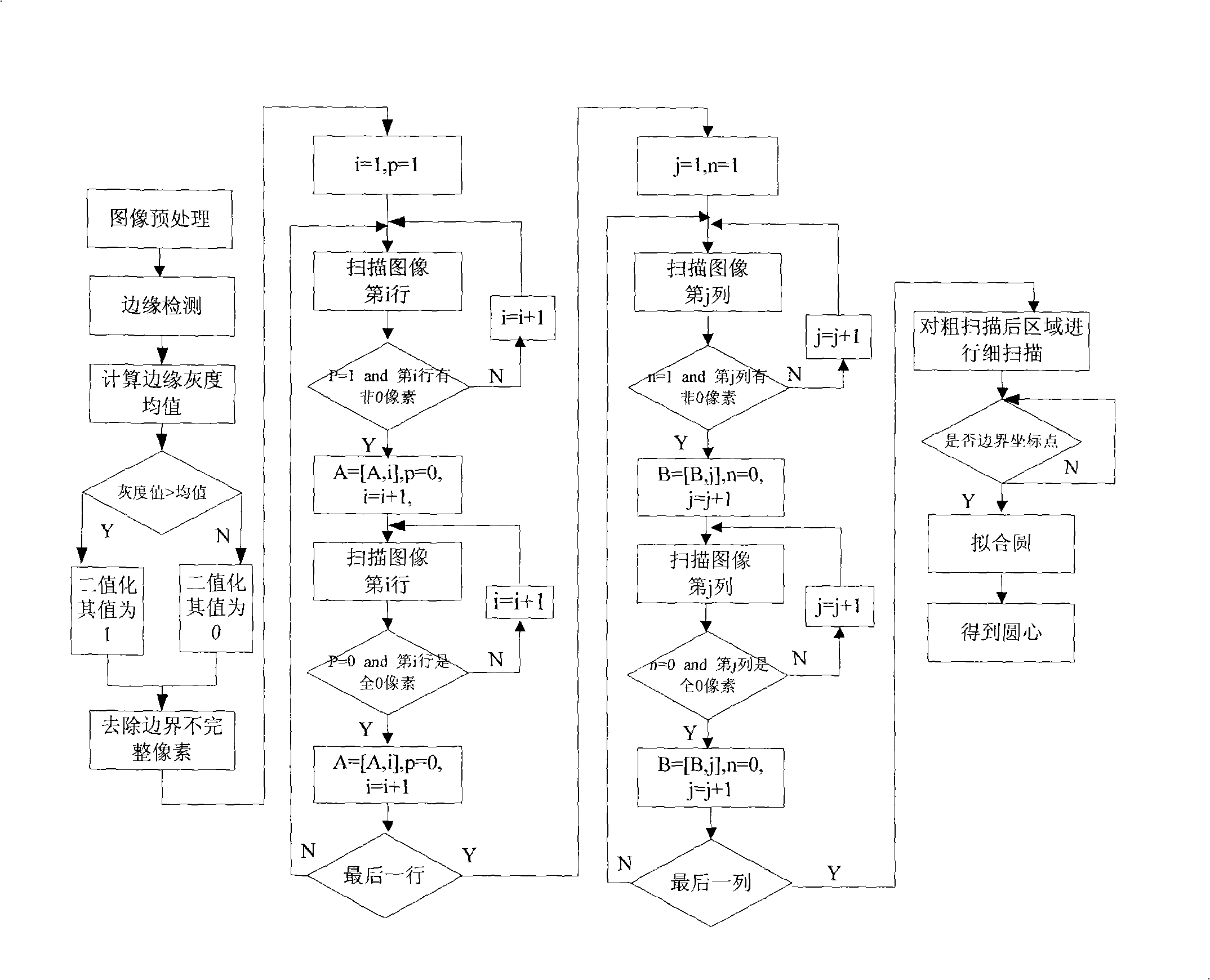

Method for accurately positioning vision in cleaning robot of condenser

ActiveCN101354785AAchieve precise calibrationEasy to cleanImage enhancementImage analysisNonlinear distortionLow-pass filter

The invention discloses an accurate vision positioning method for condenser cleaning robots. The method comprises the following steps that: the coordinate transformation relation between a camera coordinate system and an image plane, as well as the coordinate transformation relation between the image plane and a pixel coordinate system are established; nonlinear distortion is introduced on the basis of a pinhole imaging model, and a distorted image is restored; main noise of an underwater image is eliminated through an index low-pass filter and a homomorphic filter; a novel self-adaptive threshold method based on edge detection is utilized to carry out binarization segmentation to the image and eliminate incomplete tube orifices on a boundary; the edge pixel coordinate set of each tube orifice is obtained by scanning twice; and a least square method is utilized to fit the tube orifices so as to obtain a circle center coordinate of the tube orifice of a condensing tube, thereby realizing the accurate positioning of the underwater condensing tube. The invention has the advantages that the method is high in positioning precision and simple in process, needs no high-cost auxiliary adjustment equipment, and is applicable to the condenser cleaning robots in the on-site calibration for condensing tube orifices.

Owner:HUNAN UNIV

Modular plate and shell heat exchanger

ActiveUS20100276128A1Easy to disassembleCleaning heat-transfer devicesStationary tubular conduit assembliesEngineeringHeat exchanger

A modular plate and shell heat exchanger in which welded pairs of heat transfer plates are placed in the shell in order to transfer heat from a secondary fluid to a primary fluid. The heat transfer plates are removably connected using gaskets to header pipes which are connected to a primary fluid inlet and a primary fluid outlet nozzle. The header pipes are supported by a structure which rests on an internal track which is attached to the shell and facilitates removal of the heat transfer plates. The modular plate and shell heat exchanger has a removable head integral to the shell for removal of the heat transfer plates for inspection and replacement.

Owner:WESTINGHOUSE ELECTRIC CORP

Method for monitoring a heat exchanger unit

InactiveUS9970720B2Cleaning heat-transfer devicesDigital data processing detailsMicrocontrollerData acquisition

Embodiments of the disclosure pertain to a method for monitoring a heat exchanger unit that may include the steps of: associating a monitoring module with an airflow side of the heat exchanger unit; operating the monitoring module whereby a microcontroller performs tasks related to data acquisition, data comparison, and providing an indication; and taking an action based on the indication. The monitoring module includes an at least one sensor proximate to the airflow side; a logic circuit in operable communication with the at least one sensor, and further comprising the microcontroller.

Owner:FORUM US

Method for doing business

InactiveUS20170294103A1Low costCleaning heat-transfer devicesDomestic cooling apparatusProcess engineeringHeat exchanger

Embodiments of the disclosure pertain to a method of doing business that includes entering into a transaction with a first recipient; per terms of the transaction, providing a monitoring module for a heat exchanger unit; operably associating the monitoring module with the heat exchanger unit, the monitoring module being configured and operable to monitor a fouling condition of the heat exchanger unit; providing information about an indication received from the monitoring module related to the fouling condition; and performing a cleaning action of the heat exchanger unit upon based on the indication.

Owner:FORUM US

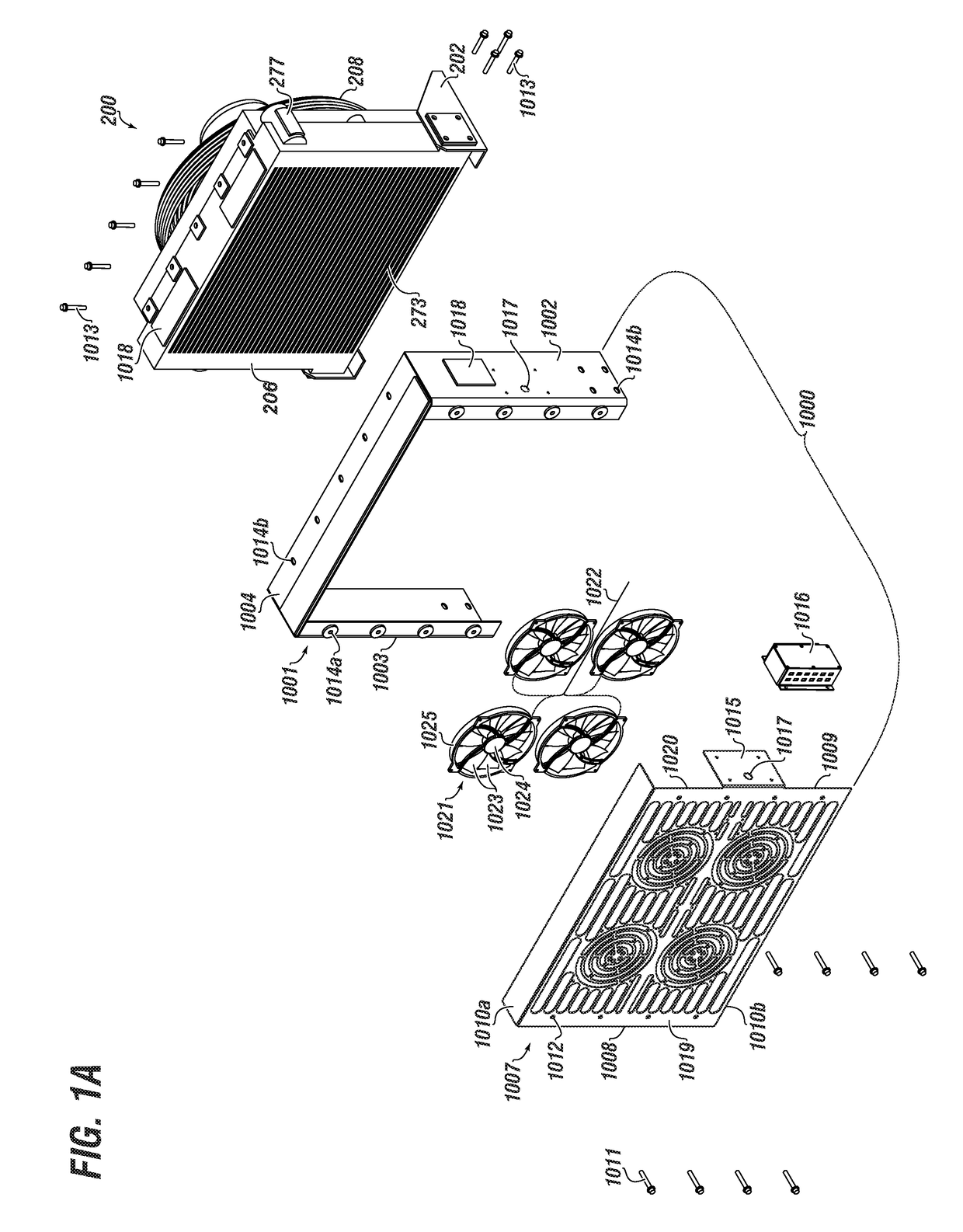

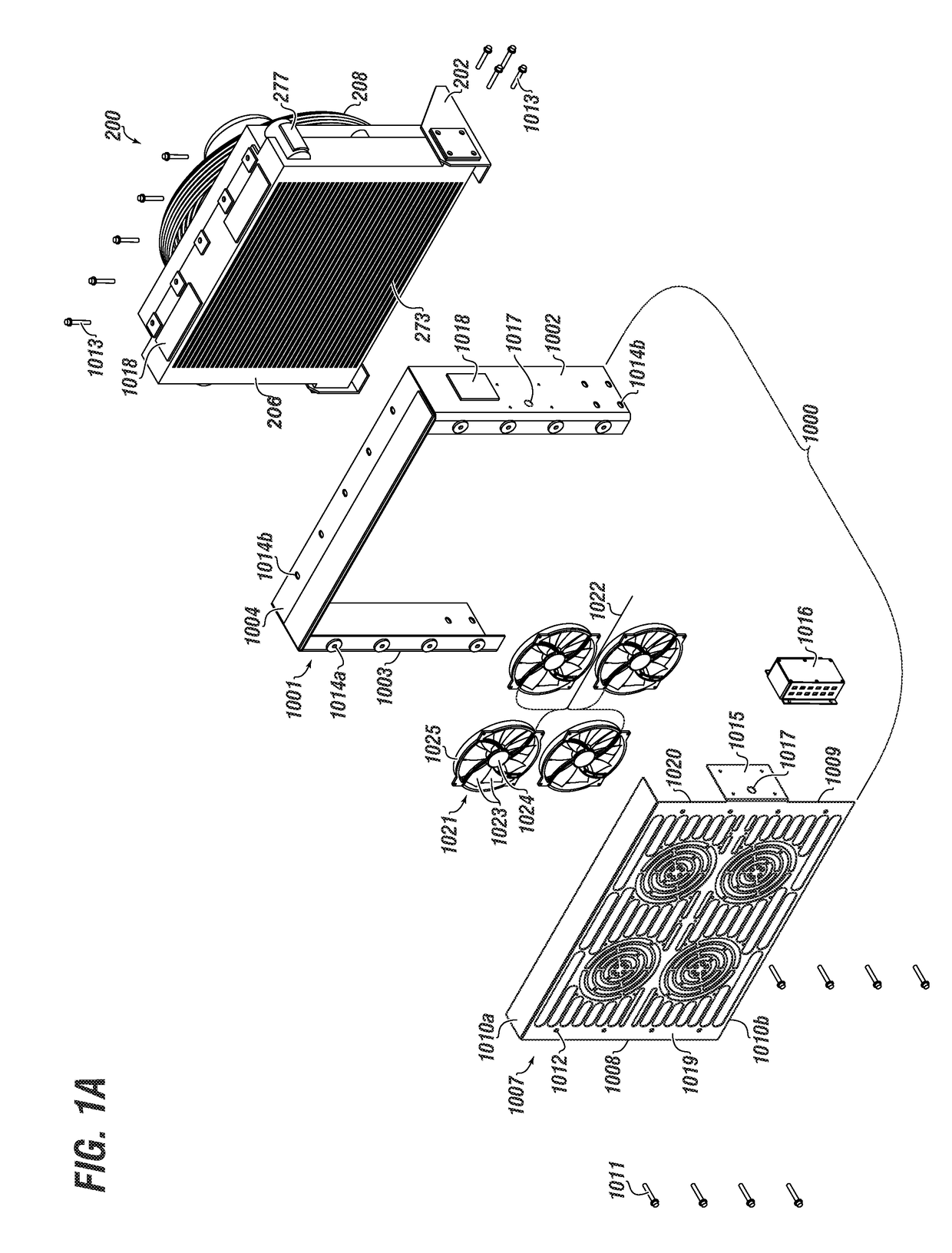

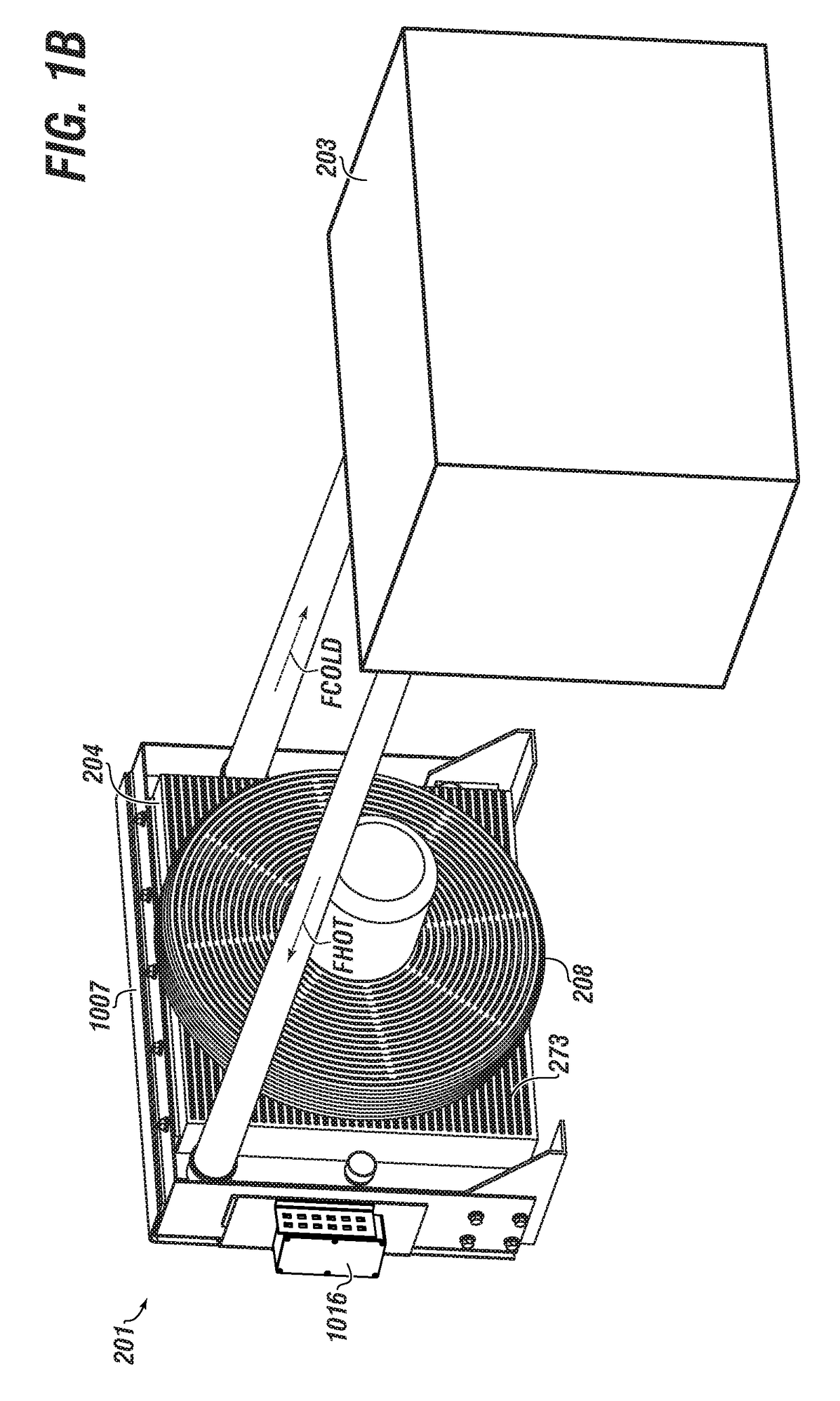

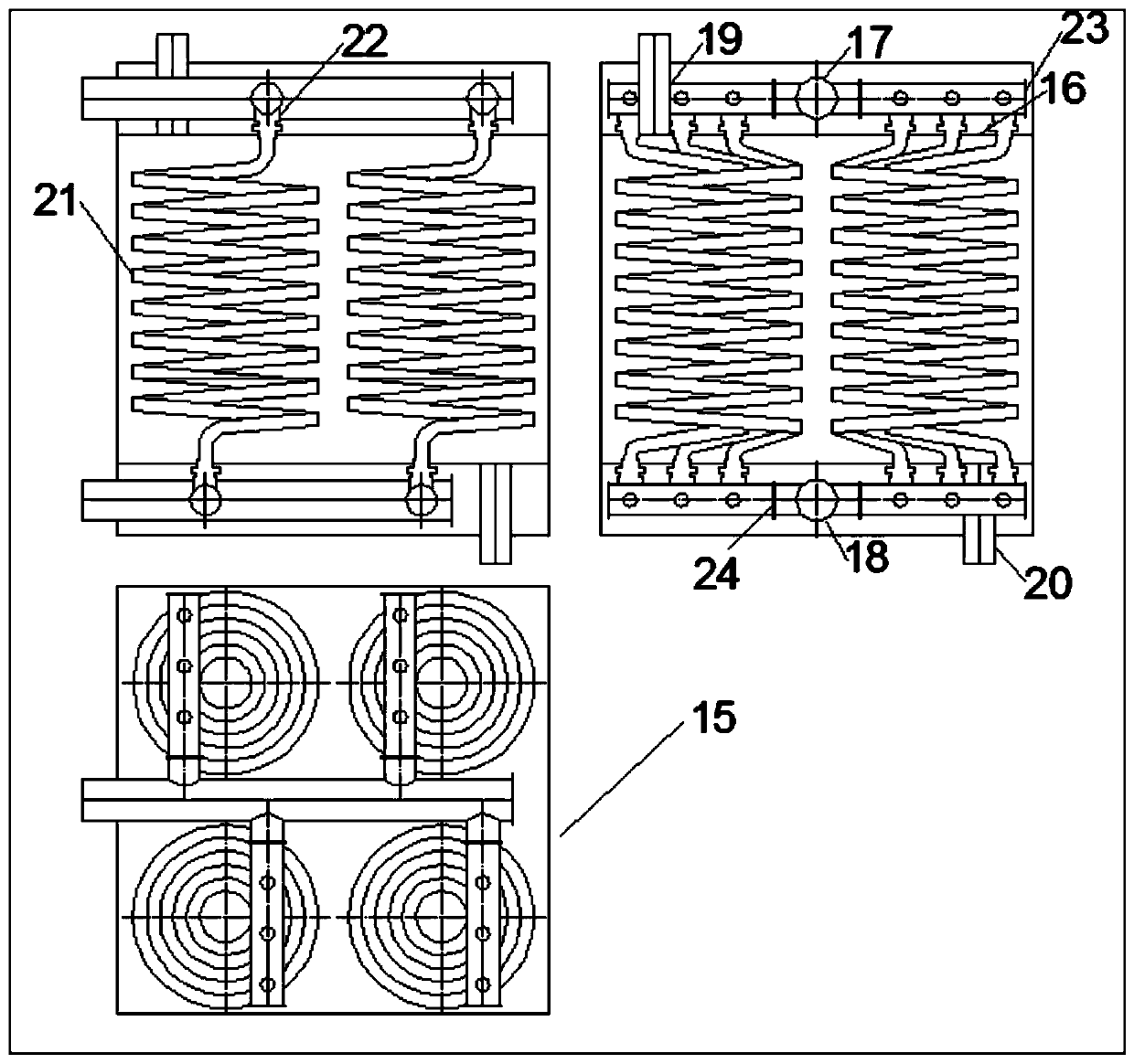

Multi-pass parallel-tube heat exchanger

ActiveUS20060278379A1Easy to manufactureEasy to cleanCleaning heat-transfer devicesTemperatue controlEngineeringHeat exchanger

A multi-pass parallel tube heat exchanger is disclosed. The multi-pass parallel tubes heat exchanger provides a compact, light and inexpensive heat exchanger that may be oriented in any direction. These features and others make the disclosed exchanger ideal for use in a restricted area such as that available when providing localized cooling systems. This design is more efficient than the prior art and allows for a versatile operation with multiple circuiting options for the flow path and enhanced performance with multiple fluid and heat transfer operations.

Owner:VERTIV CORP

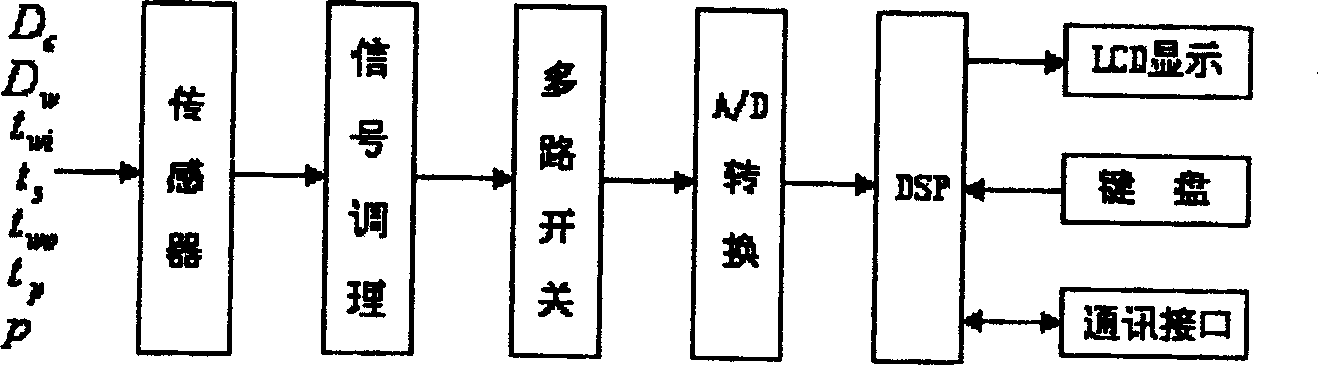

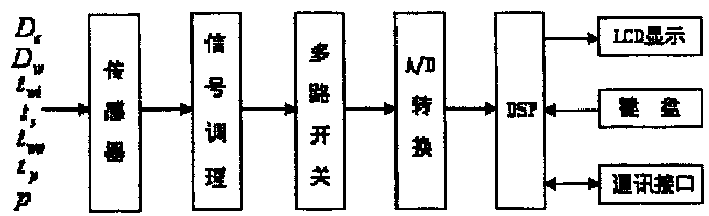

Method for on-line measuring dirty extent of condenser and its device

InactiveCN1477368AAccurate online monitoringLow costCleaning heat-transfer devicesStructural/machines measurementCommunication interfaceSignal conditioning circuits

The present invention relates to a method for on-line measuring dirty extent of the condenser and its equipment. The equipment includes several sensors, signal conditioning circuit, multiway switch, DSP, in which all the sensors are connected with signal conditioning circuit and multiway switch, at the same time connected with DSP, the LED display, keyboard and communication interface are connected with DSP. It utilizes heat transfer terminal difference as researching object, duty parameter variation and fuzzy film-forming technology to accurately implement on-line measurement of the dirty extent of condenser.

Owner:樊绍胜 +2

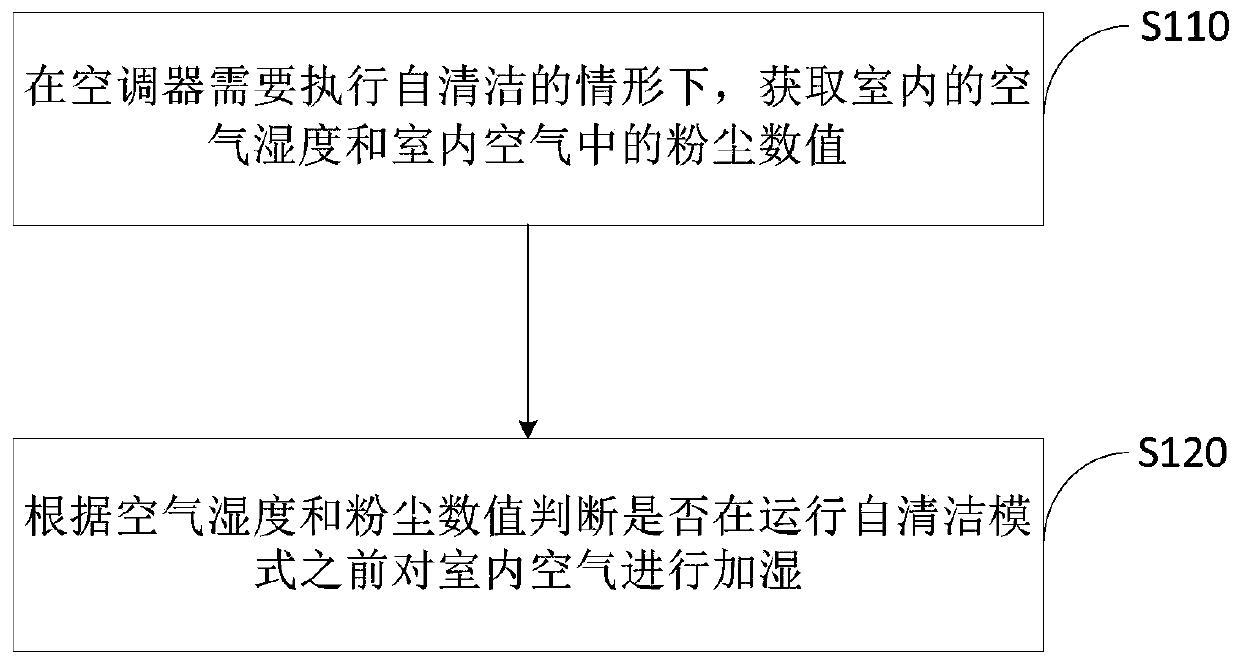

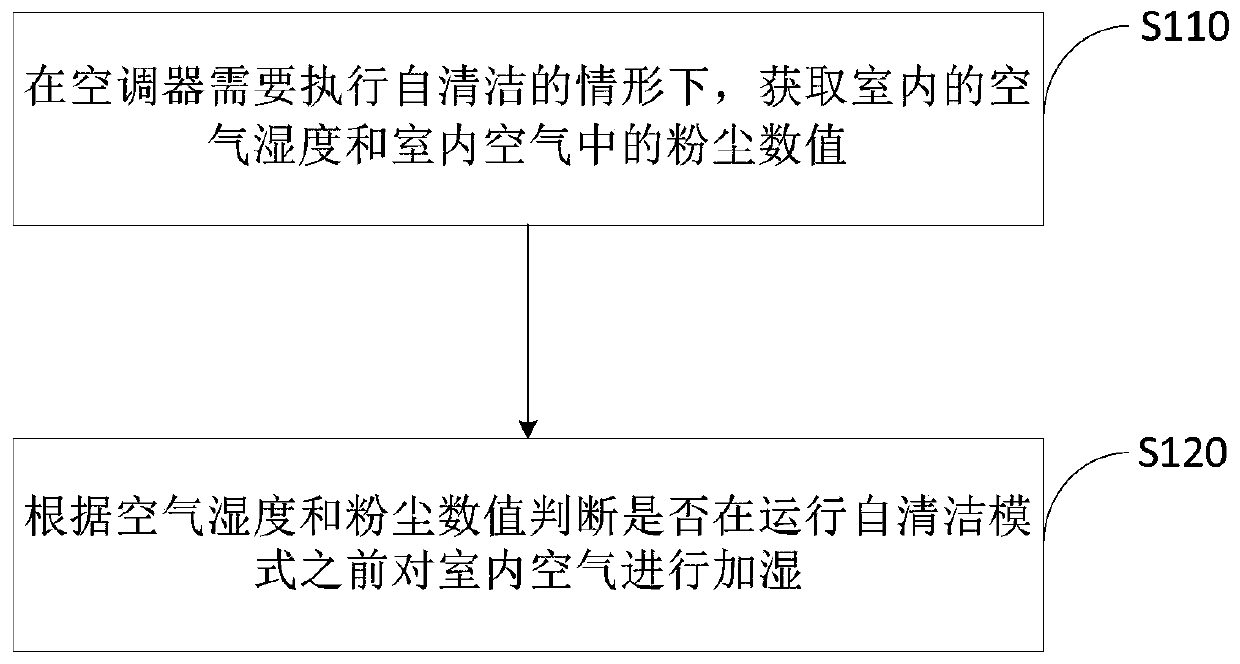

Self-cleaning and humidifying controlling method for air conditioner

InactiveCN109916001AKeep healthyImprove self-cleaning effectMechanical apparatusCleaning heat-transfer devicesIndoor air qualityEngineering

The invention belongs to the technical field of air conditioners, and particularly provides a self-cleaning humidifying controlling method for an air conditioner. In order to improve the self-cleaningeffect of an air conditioner, the self-cleaning humidifying controlling method for an air conditioner comprises the following steps of obtaining indoor air humidity and dust value in indoor air underthe condition that the air conditioner needs to perform self-cleaning, and judging whether the indoor air is humidified or not before the self-cleaning mode is operated according to the air humidityand the dust value. The self-cleaning effect of the air conditioner has a great relationship with the strength of frosting, and the strength of frosting has a great relationship with the indoor humidity, so when water in the indoor air is used for frosting, if the indoor air quality is poor, dust in the air can also be brought in during frosting, so that the self-cleaning effect is affected. Therefore, according to the method, whether the indoor air is humidified or not is judged according to the air humidity and the dust value, so that the problem that the self-cleaning effect of the air conditioner is bad due to poor air quality or indoor drying and the like is avoided.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Inspection camera

An inspection camera may be used in conjunction with a shockwave cleaning apparatus. The camera has a head held in an operative position within a vessel interior. A light source has at least a light emitting element carried by the head. At least an incident lens of the camera is carried by the head so as to capture light from the source as returned by a surface within the vessel interior.

Owner:SHOCKSYST

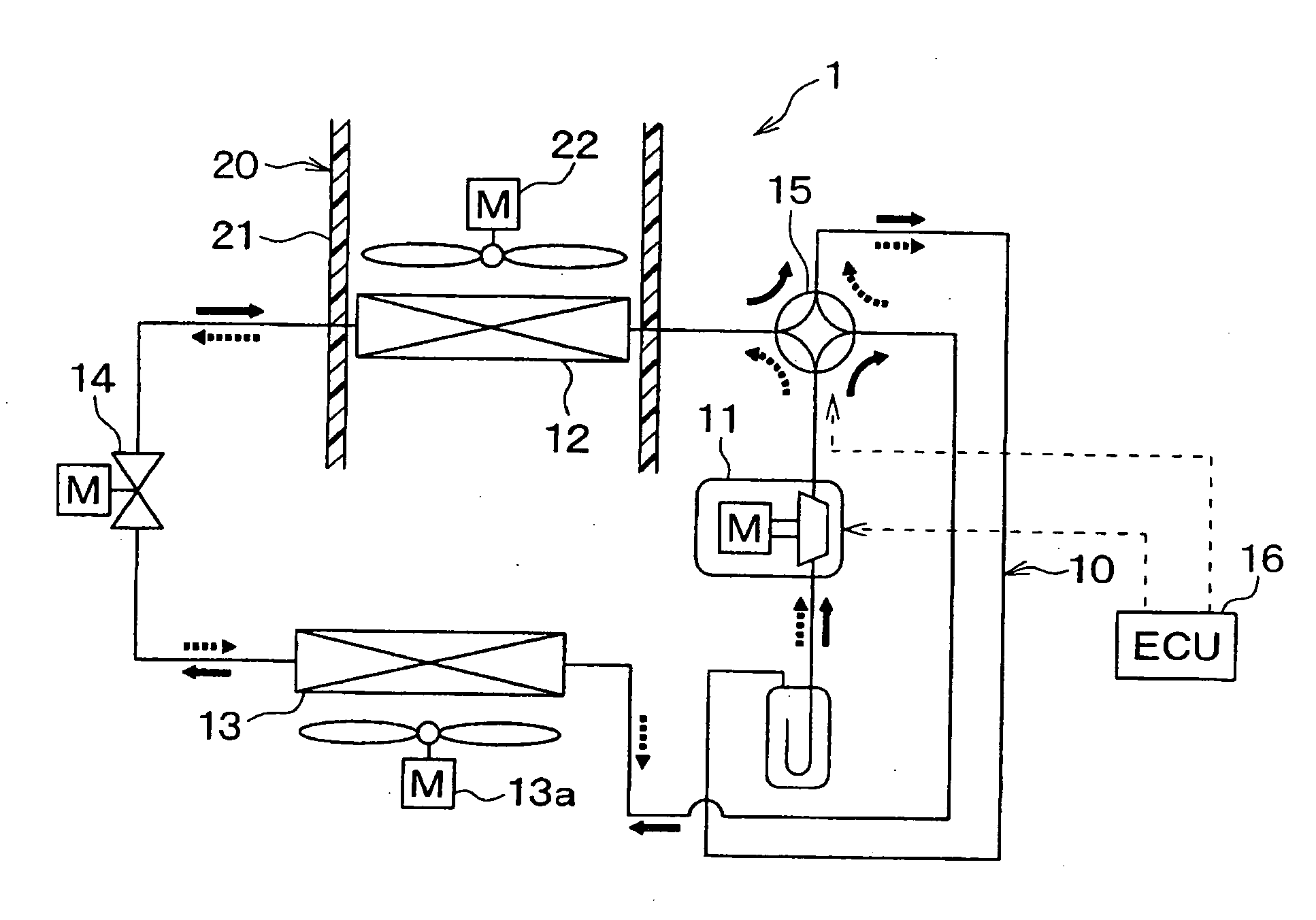

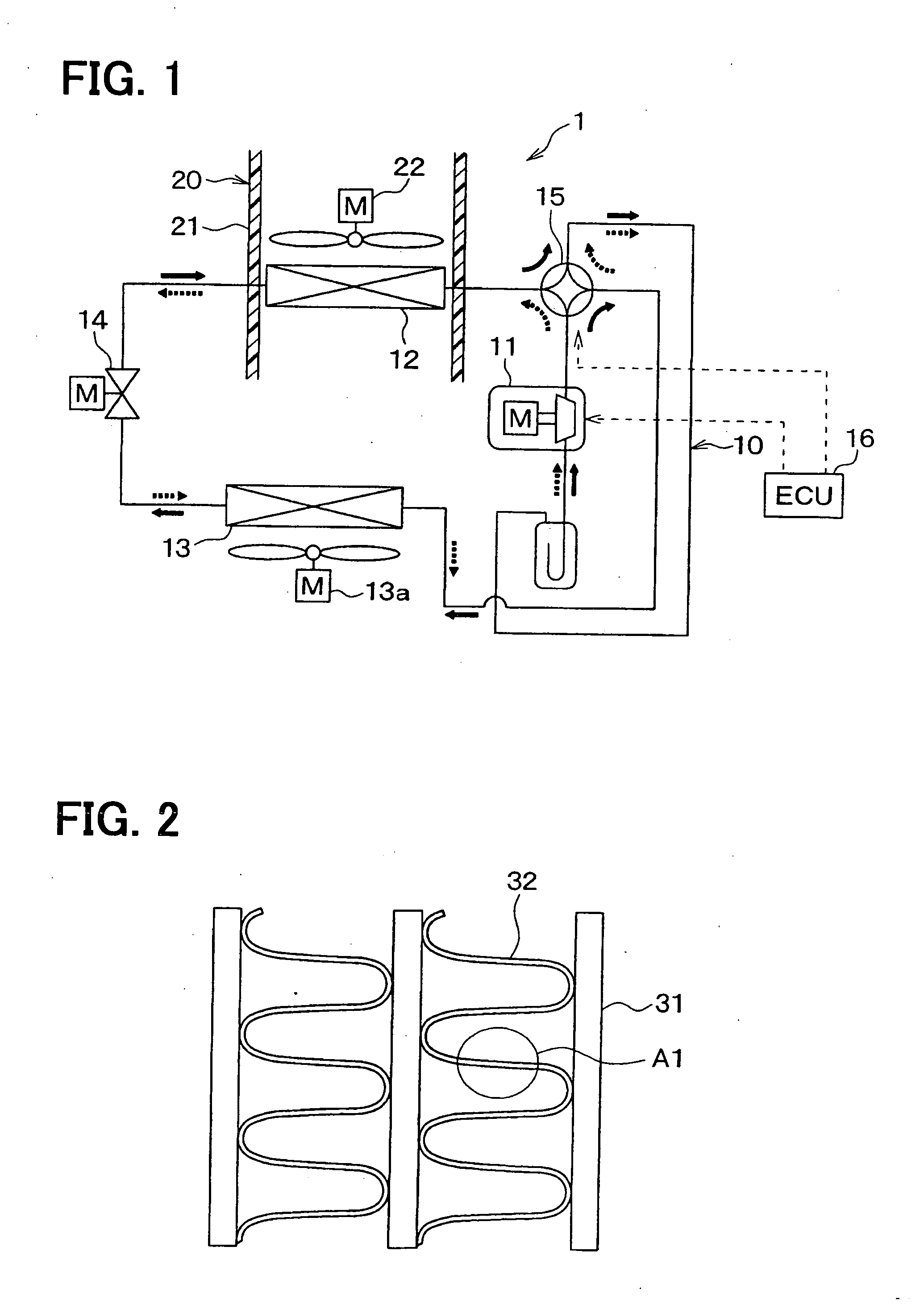

Heat exchanger and refrigerant cycle device using the same

InactiveUS20110197605A1Reduces heat energyWeaken energyCleaning heat-transfer devicesCompression machines with non-reversible cycleThermal energyThermal deformation

A heat exchanger usable as an evaporator in a refrigerant cycle device includes a heat exchanging portion configured to perform heat exchange between refrigerant and air so as to evaporate the refrigerant. A thermal deformation member is provided in en entire range on a surface of the heat exchanging portion, to be deformed bordering on a predetermined temperature when the surface of the heat exchanging portion is frosted to produce ice. The thermal deformation member is deformed by a temperature change between a first temperature lower than the predetermined temperature and a second temperature higher than the predetermined temperature, to cause distortion between the surface of the heat exchanging portion and the ice when the ice is attached to the surface of the heat exchanging portion. Thus, the ice attached to the surface of the heat exchanging portion can be effectively removed while heat energy for removing the ice can be reduced.

Owner:DENSO CORP

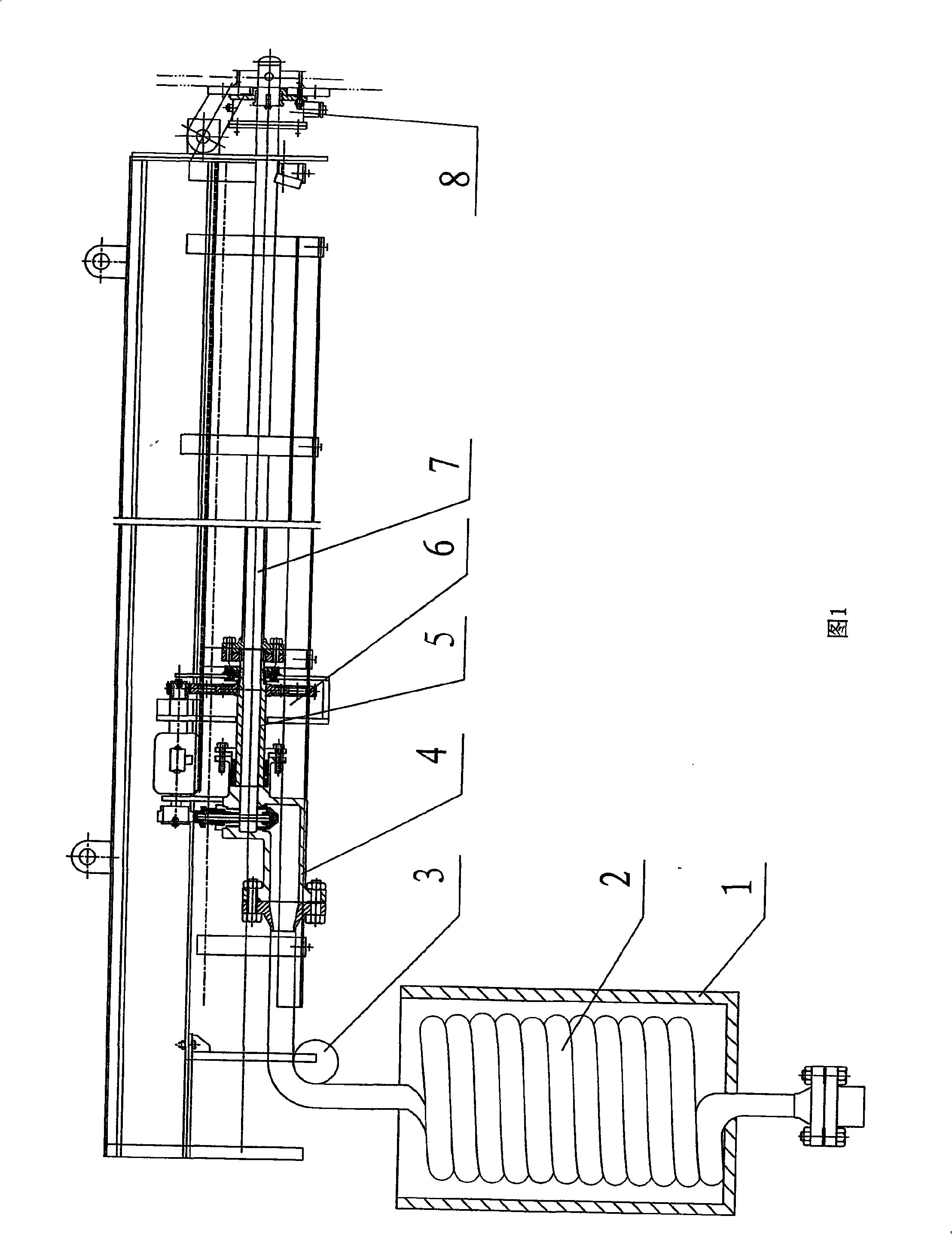

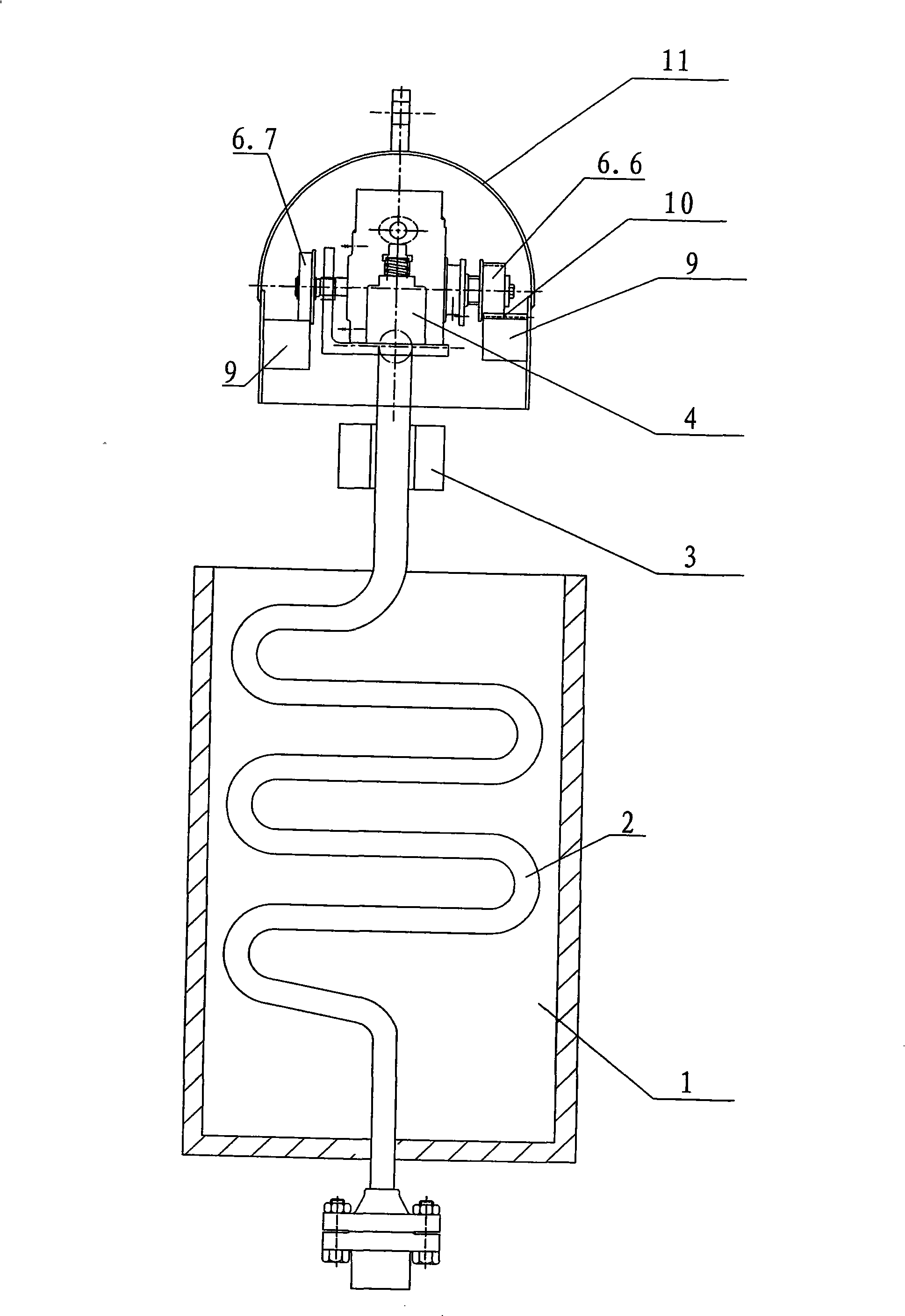

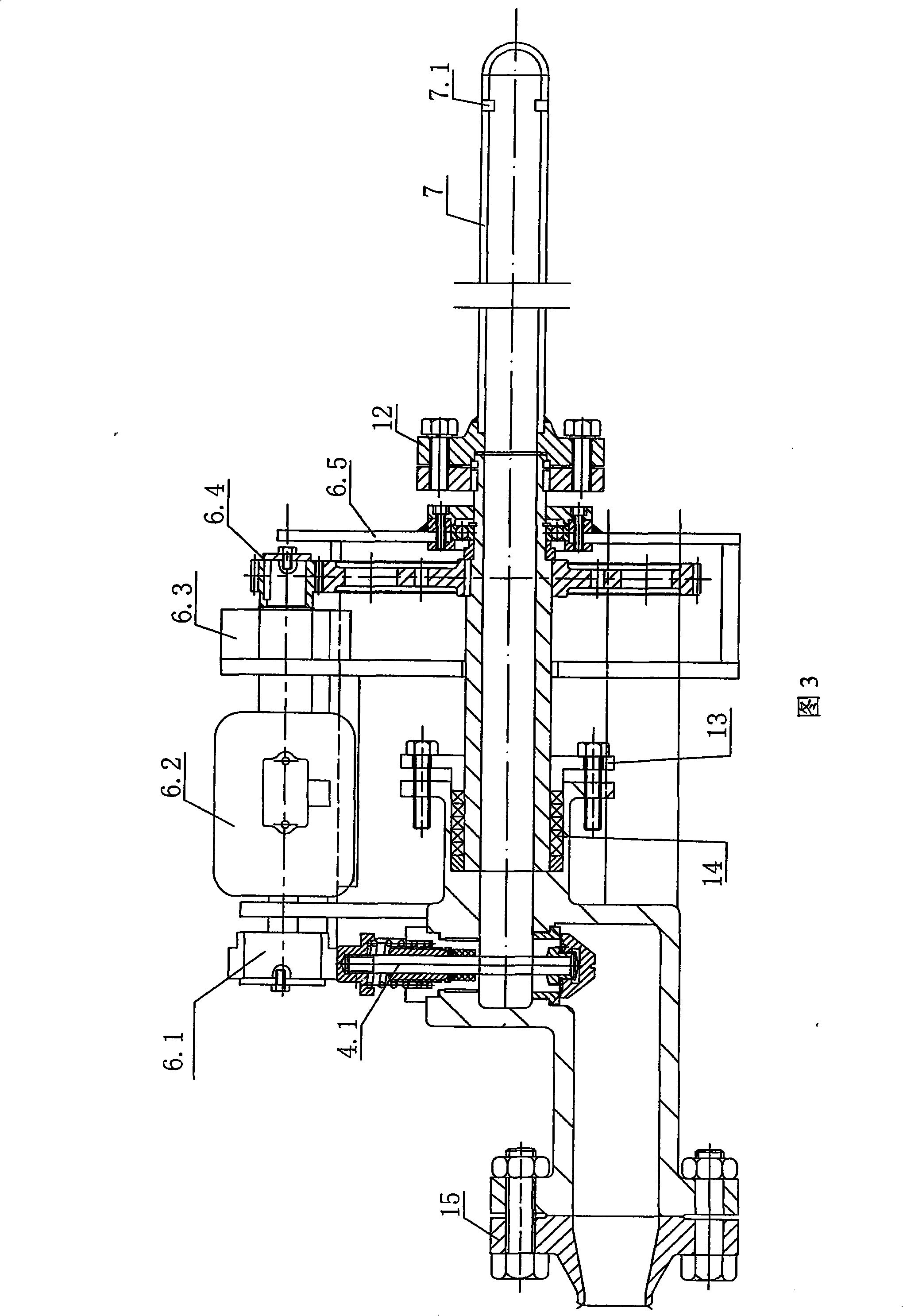

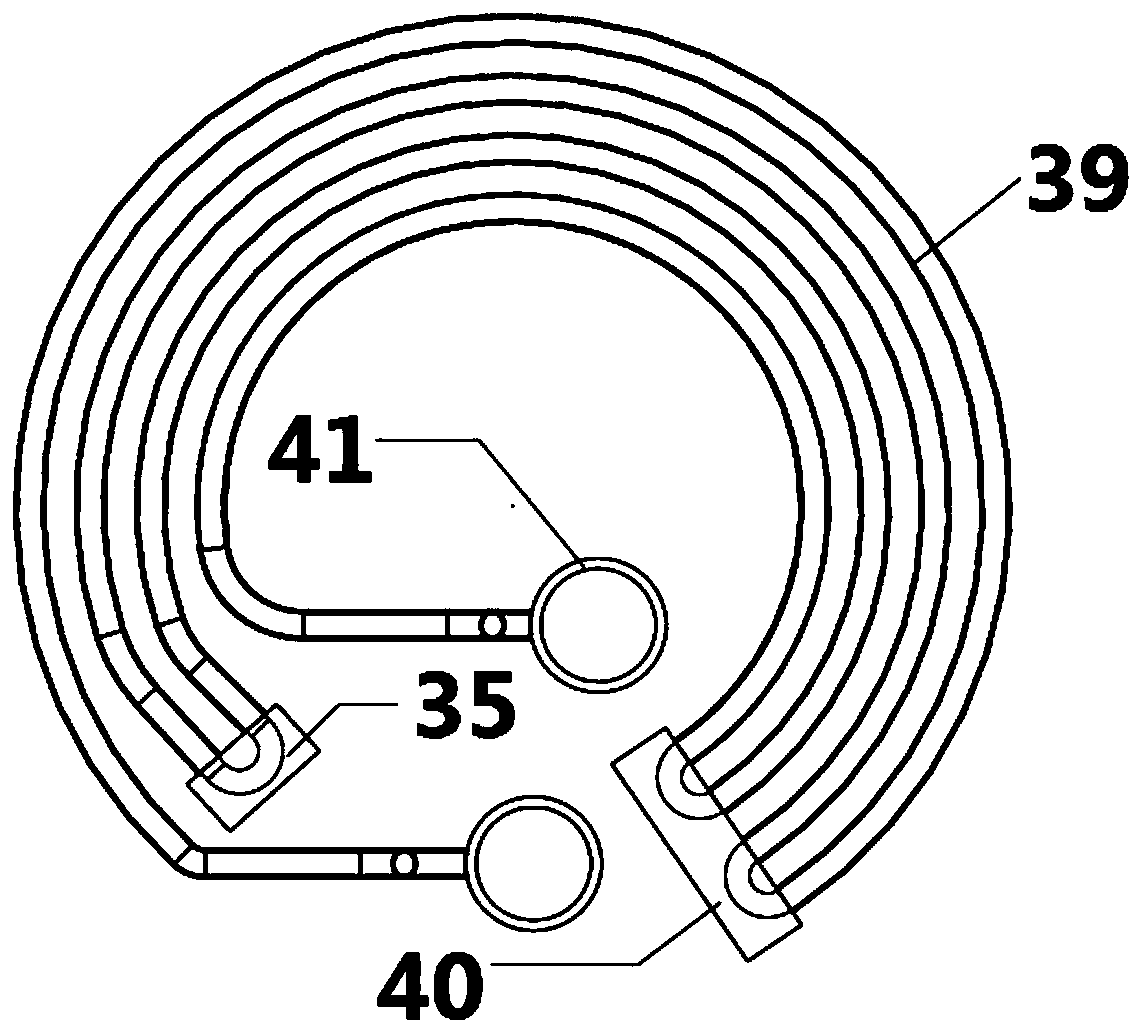

Novel non-leakage synchronous expansion steam lance

InactiveCN101319861AReduce consumptionTo achieve the purpose of energy savingCleaning heat-transfer devicesValve stemSprocket

The invention relates to a novel non-leakage same step extension steam sootblower, comprising a casing (11), a supporting guide rail (9), a guide and drive rack (10), a synchronous drive device (6), a connection pipe (5), a blowing pipe (7), a steam conduction valve (4), a guide wheel (3), a hose (2) and a hose collection pipe (1). The connection pipe is connected with the outlet of the steam conduction valve (4). The steam inlet of the steam conduction valve is connected with the hose (2). The hose is presented in a spiral shape and is collected in the hose collection pipe (1). The synchronous drive device (6) comprises a motor (6.2), a decelerator (6.3), a cam (6.1), a gear or a sprocket pair (6.4) and a drive gear (6.6). The decelerator has two output ends. One of the output shafts of the decelerator is connected with the cam (6.1) and the gear or the sprocket pair (6.4). The outer edge of the cam is matched with the moving mode of the valve stem system (4.1) of the steam conduction valve (4). The other output shaft is connected with the drive gear (6.4). The drive gear is meshed with the guide and drive rack. If blowing is needed in the process of the blowing pipe extension, the blowing pipe is conducted, and if the blowing is not needed, the blowing pipe is closed. The novel non-leakage same step extension steam sootblower has high reliability and high blowing efficiency without leakage.

Owner:江苏焱鑫科技股份有限公司

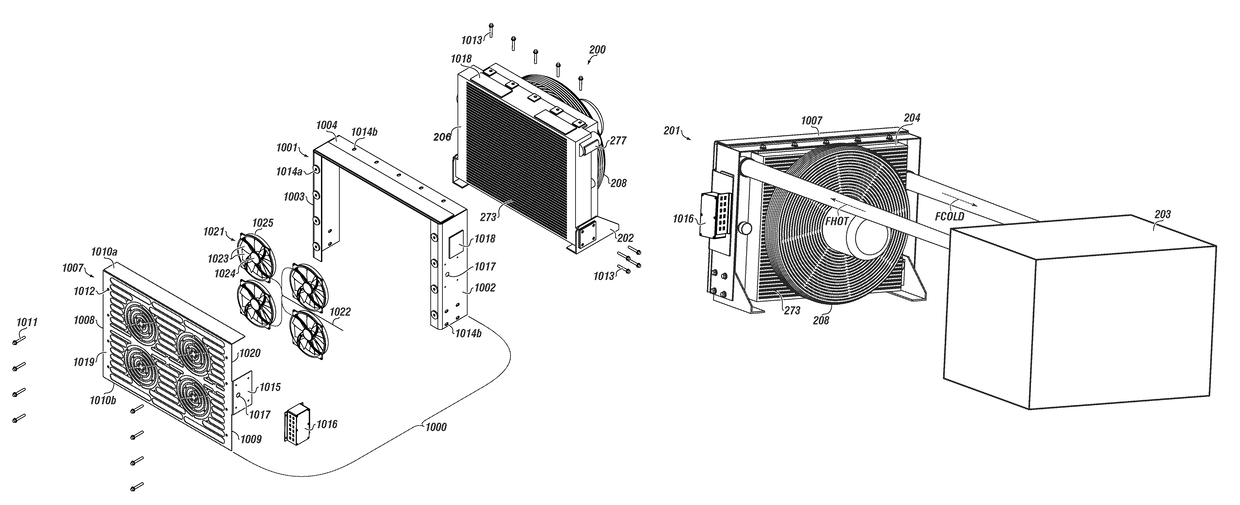

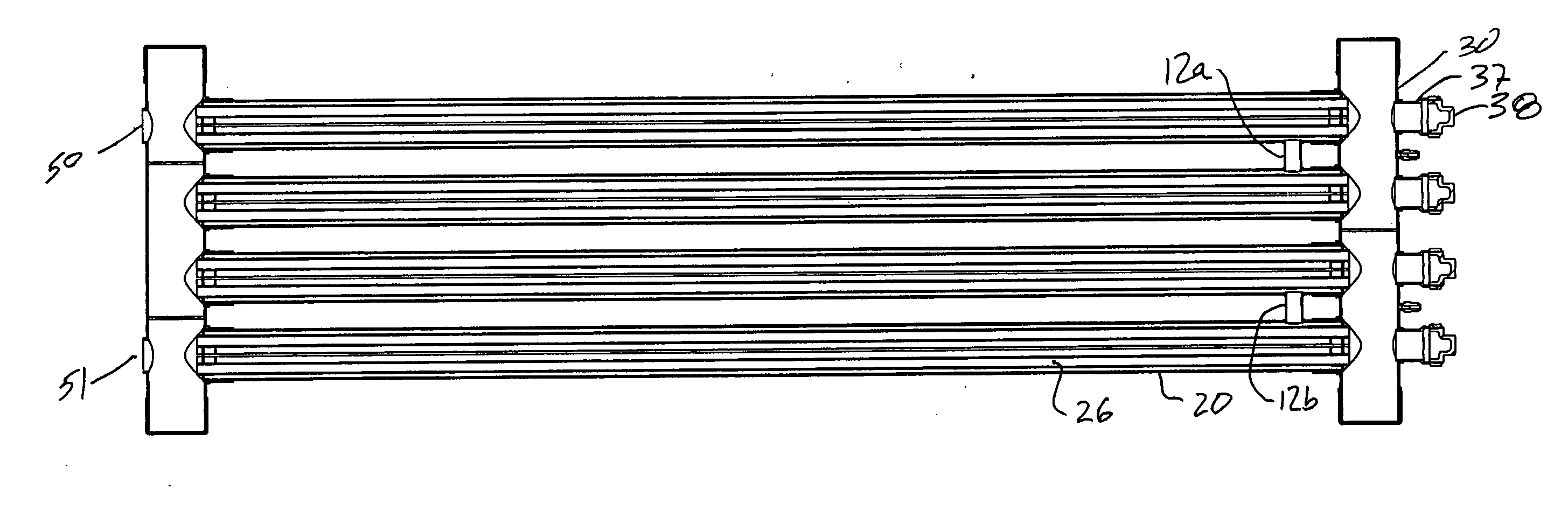

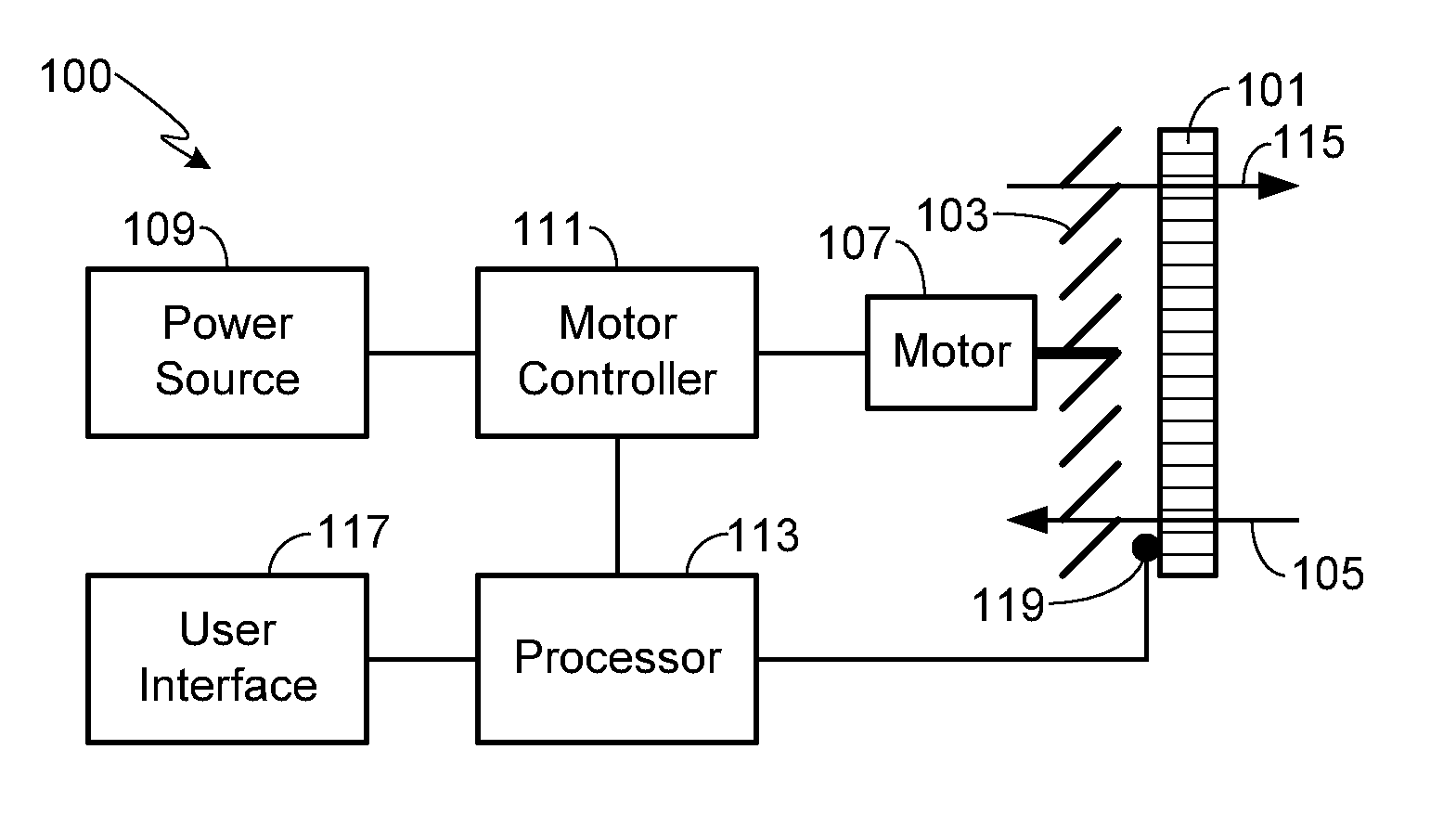

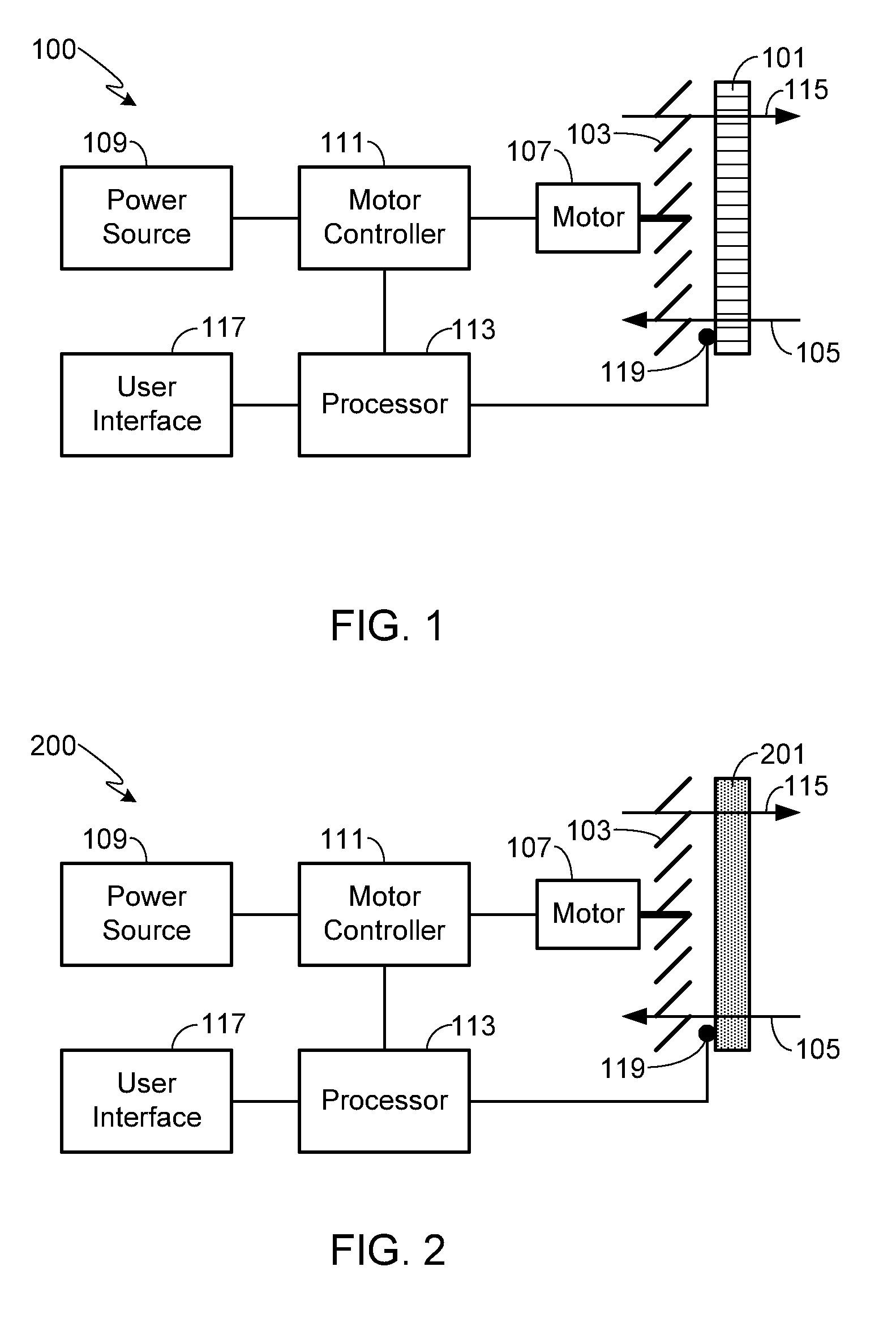

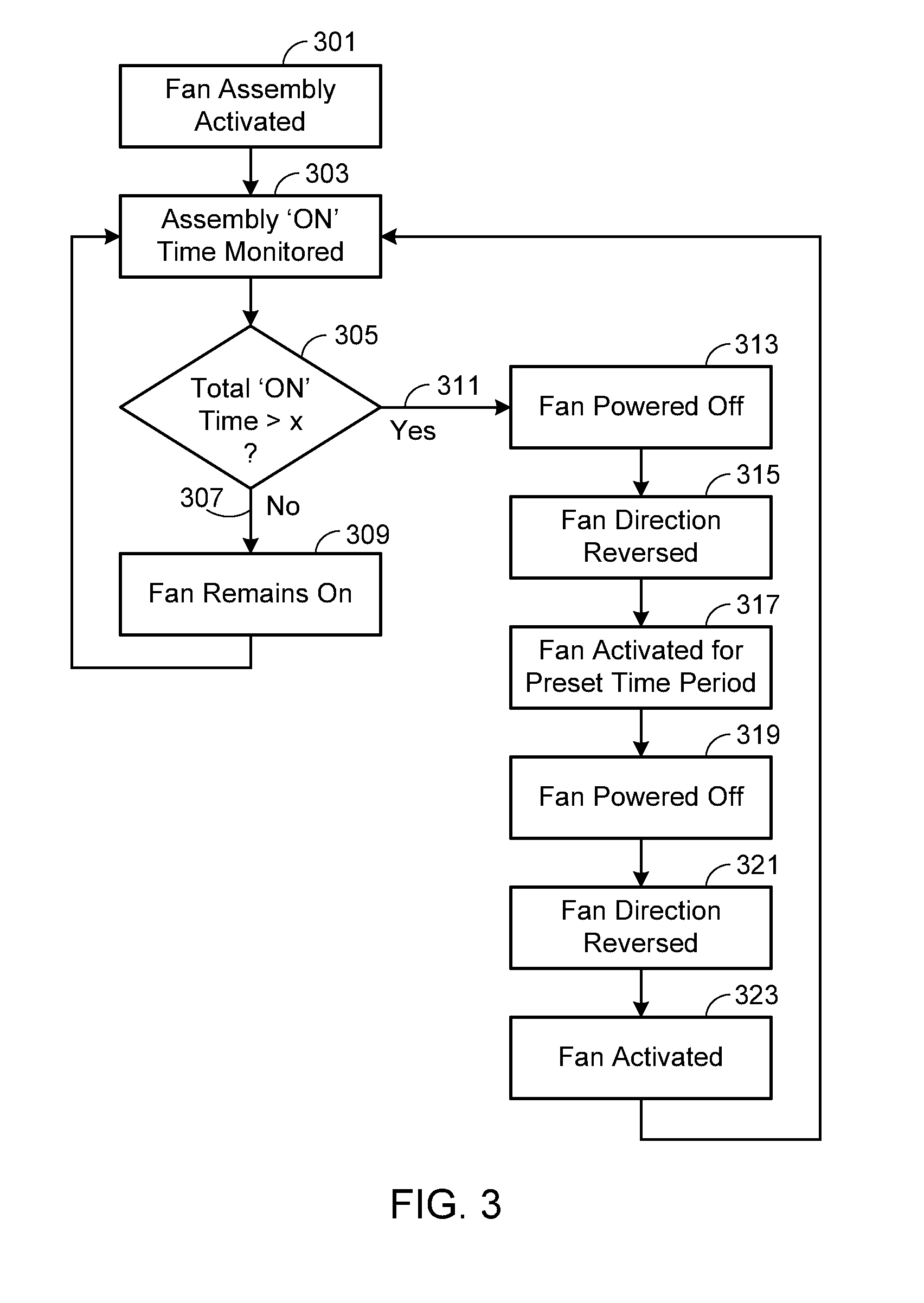

Self-Cleaning Fan Assembly

A self-cleaning fan assembly is provided that can be used to automatically clean the assembly's heat exchanger or air filter. In use, once the system determines that the heat exchanger / air filter should be cleaned, for example based on the total operational time or the number of use cycles for the system, or based on the air flow passing through the heat exchanger / air filter, the controller temporarily reverses the direction of the fan, thereby reversing the flow of air through the heat exchanger / air filter and forcing out dust, dirt and other debris.

Owner:ATIEVA USA INC

Heat exchanger and deep well heat exchange system thereof

ActiveCN109990506ASmart descaling operationSuitable for useCleaning heat-transfer devicesCompression machines with non-reversible cycleRecuperatorEngineering

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com