Method for on-line measuring dirty extent of condenser and its device

A condenser and degree technology, which is applied to measuring devices, cleaning heat transfer devices, instruments, etc., can solve the problems of difficult realization of engineering, errors, and no reflection of the thermal conductivity of dirt, and achieves easy installation, low cost, and good application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

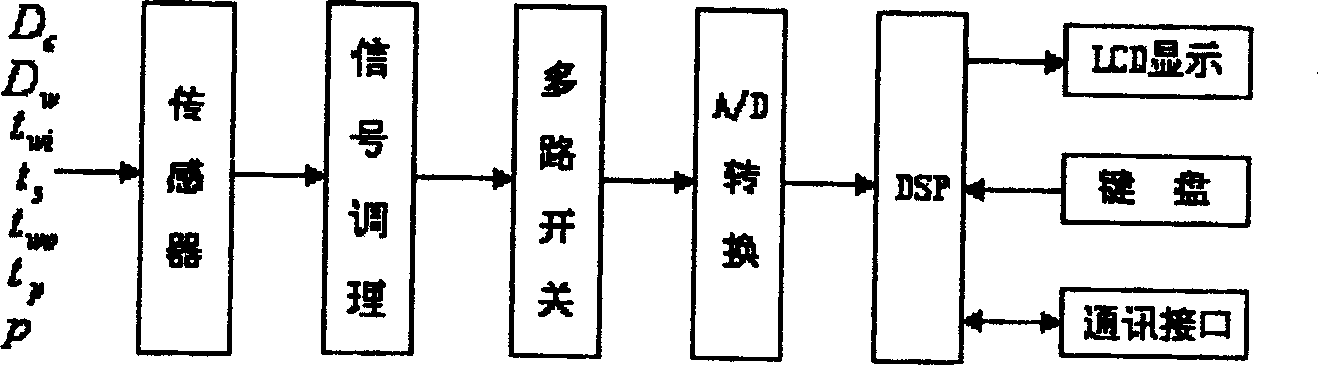

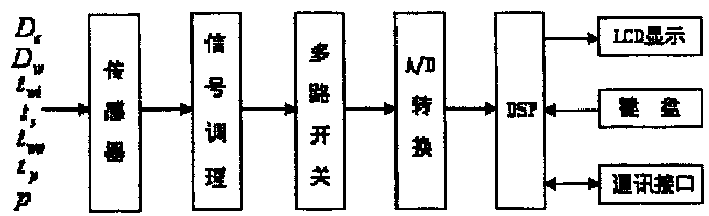

[0012] The present invention proposes a new method aiming at the deficiencies of the three detection methods in the current prior art. In this method, the heat transfer end difference is used as an important performance index reflecting the heat exchange condition of the condenser, and the effect of each factor on the end difference is considered comprehensively. The fuzzy modeling method is used to realize the separation of condenser fouling and the effect of working condition parameter changes on the end difference, so as to accurately monitor the condenser fouling online. It is characterized in that after thoroughly cleaning the condenser, first measure the heat transfer end difference of a given working condition, and this end difference is the end difference corresponding to the working condition in the clean state, and then change the working condition to run , and then measure the above-mentioned heat transfer end difference to obtain the change end difference between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com