Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

147 results about "Heat pulse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

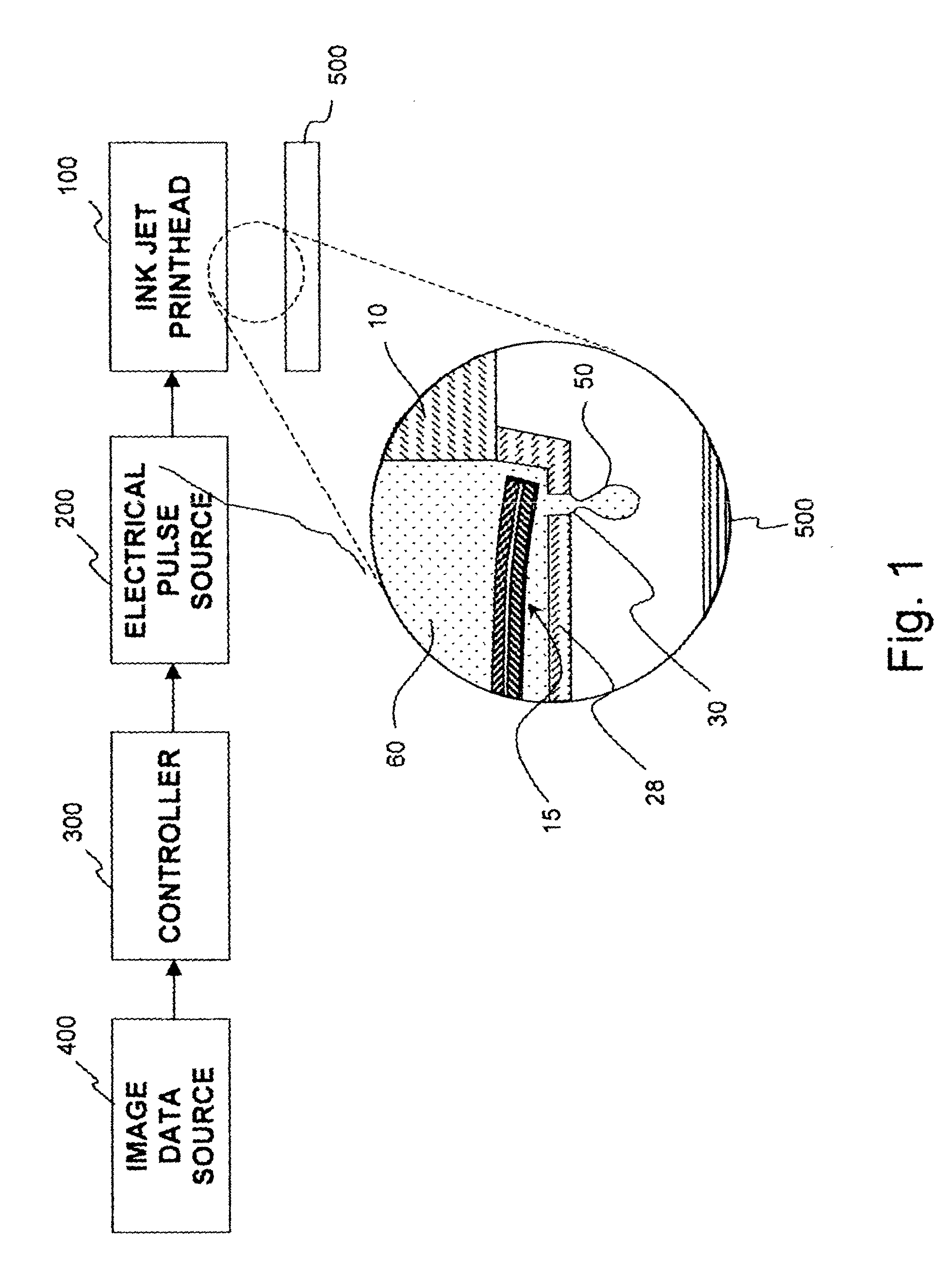

Thermally conductive thermal actuator and liquid drop emitter using same

ActiveUS7073890B2Reduce frequencyWithout excessive riseInking apparatusInfluence generatorsYoung's modulusEngineering

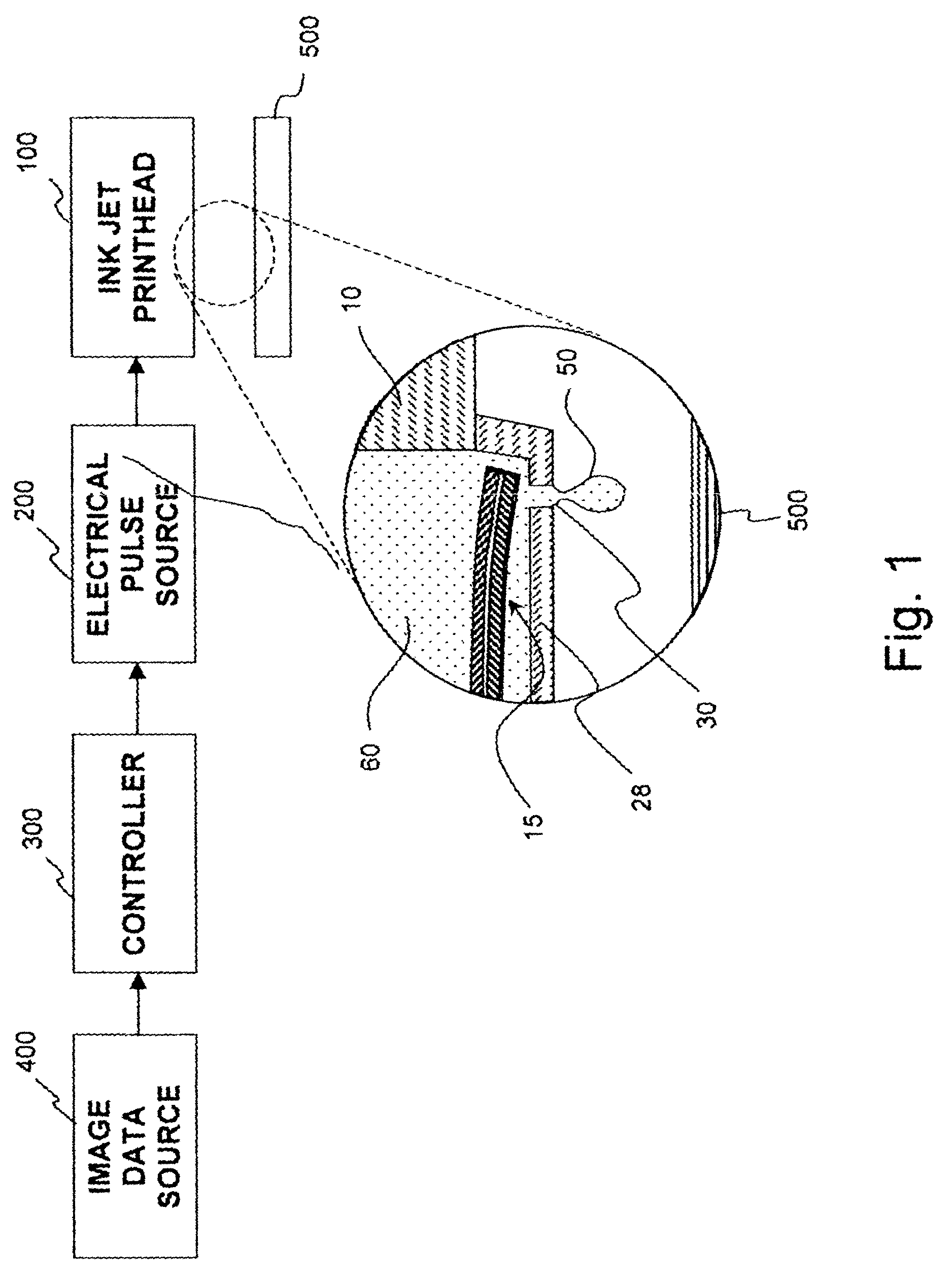

A thermal actuator for a micro-electromechanical device is disclosed. The thermal actuator includes a base element and a movable element extending from the base element and residing at a first position. The movable element includes a barrier layer constructed of a barrier material having low thermal conductivity material, bonded between a first layer and a second layer; wherein the first layer is constructed of a first material having a high coefficient of thermal expansion and the second layer is constructed of a second material having a high thermal conductivity and a high Young's modulus. An apparatus is provided adapted to apply a heat pulse directly to the first layer, causing a thermal expansion of the first layer relative to the second layer and deflection of the movable element to a second position.

Owner:EASTMAN KODAK CO

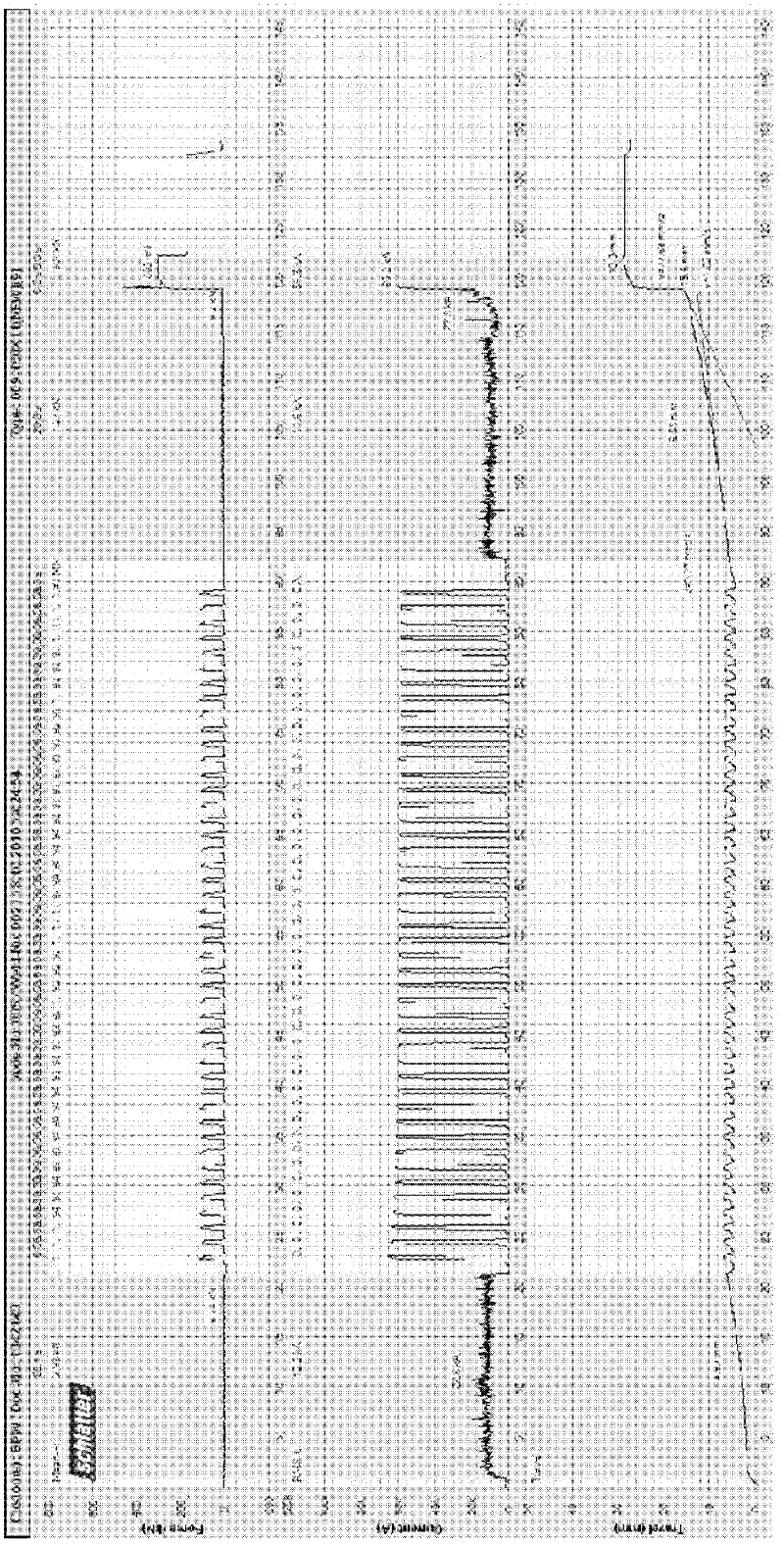

Thermo-mechanical actuator drop-on-demand apparatus and method with multiple drop volumes

InactiveUS6896346B2Data switching by path configurationOther printing apparatusEngineeringArrival time

An apparatus and method of operating a liquid drop emitter, such as an ink jet device, for emitting liquid drops of different volumes. The liquid drop emitter comprises a chamber, filled with a liquid, having a nozzle for emitting drops of the liquid, a thermo-mechanical actuator having a moveable portion within the chamber for applying pressure to the liquid at the nozzle, and apparatus adapted to apply heat pulses to the thermo-mechanical actuator. The method for operating comprises applying a first heat pulse having a first power P1, first pulse duration τp1, and first energy E1=P1×τp1, displacing the movable portion of the actuator so that a drop is emitted having a first drop volume Vd1, and traveling substantially at the target velocity v0; and applying a second heat pulse having a second power P2, second pulse duration τp2, and second energy E2=P2×τp2, displacing the movable portion of the actuator so that a drop is emitted having a second drop volume Vd2 and traveling substantially at the target velocity v0, wherein Vd2>Vd1, E2>E1, τp2>τp1, and P2<P1. An alternate method for operating causes the emission of drops having different volumes traveling at different velocities wherein all velocities are within a pre-determined drop velocity range, vd min to vd max. Further methods for operating an ink jet printhead cause the emission of drops having different volumes and velocities wherein the triggering of the drop emission is delayed so as to result in synchronized arrival times at a print plane.

Owner:EASTMAN KODAK CO

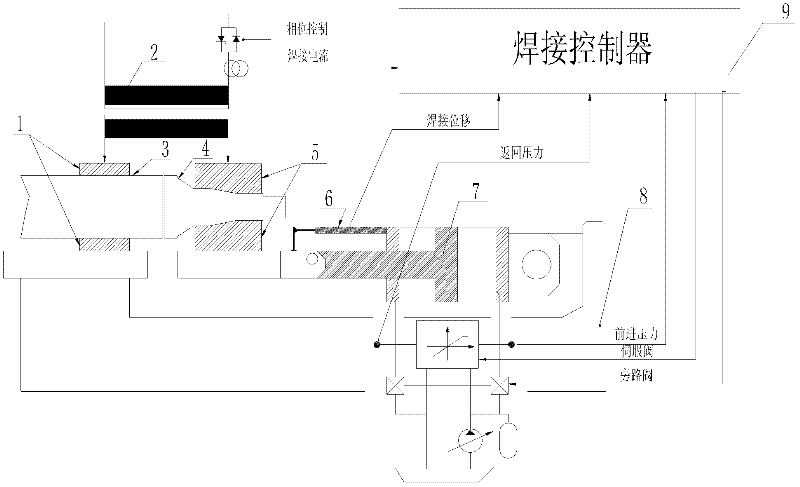

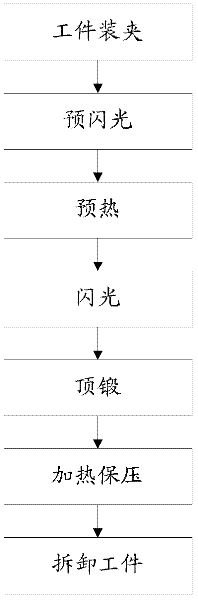

Method for producing axle beam by using preheated flash butt welding

InactiveCN102500899AImprove reliabilityHigh dimensional accuracyResistance welding apparatusButt weldingEngineering

The invention discloses a method for producing an axle beam by using preheated flash butt welding, which comprises the following steps of: a workpiece clamping step, wherein an axle head and an axle pipe which are used as workpieces are respectively arranged in a shaft beam flash butt welding machine, are clamped by a hydraulic moving clamp and a fixed clamp, and align through an adjustment mechanism; a pre flash step, wherein a power supply is powered on, so that a moving clamp is pushed at a set constant speed, and further, flash can be generated between the workpieces and gradually shortens until the flash margin reaches a preset value; a preheating step, wherein the workpieces are preheated by preset preheated pulses; a flash step, wherein flash is carried out at set speed; an upsetting step, wherein upsetting is carried out immediately after flash; a heating and pressurizing step, wherein the workpieces are applied with preset pressure and are powered on to be heated; and workpiece disassembling step, wherein after welding, the workpieces are disassembled and taken out.

Owner:BPW (MEIZHO) AXLE CO LTD

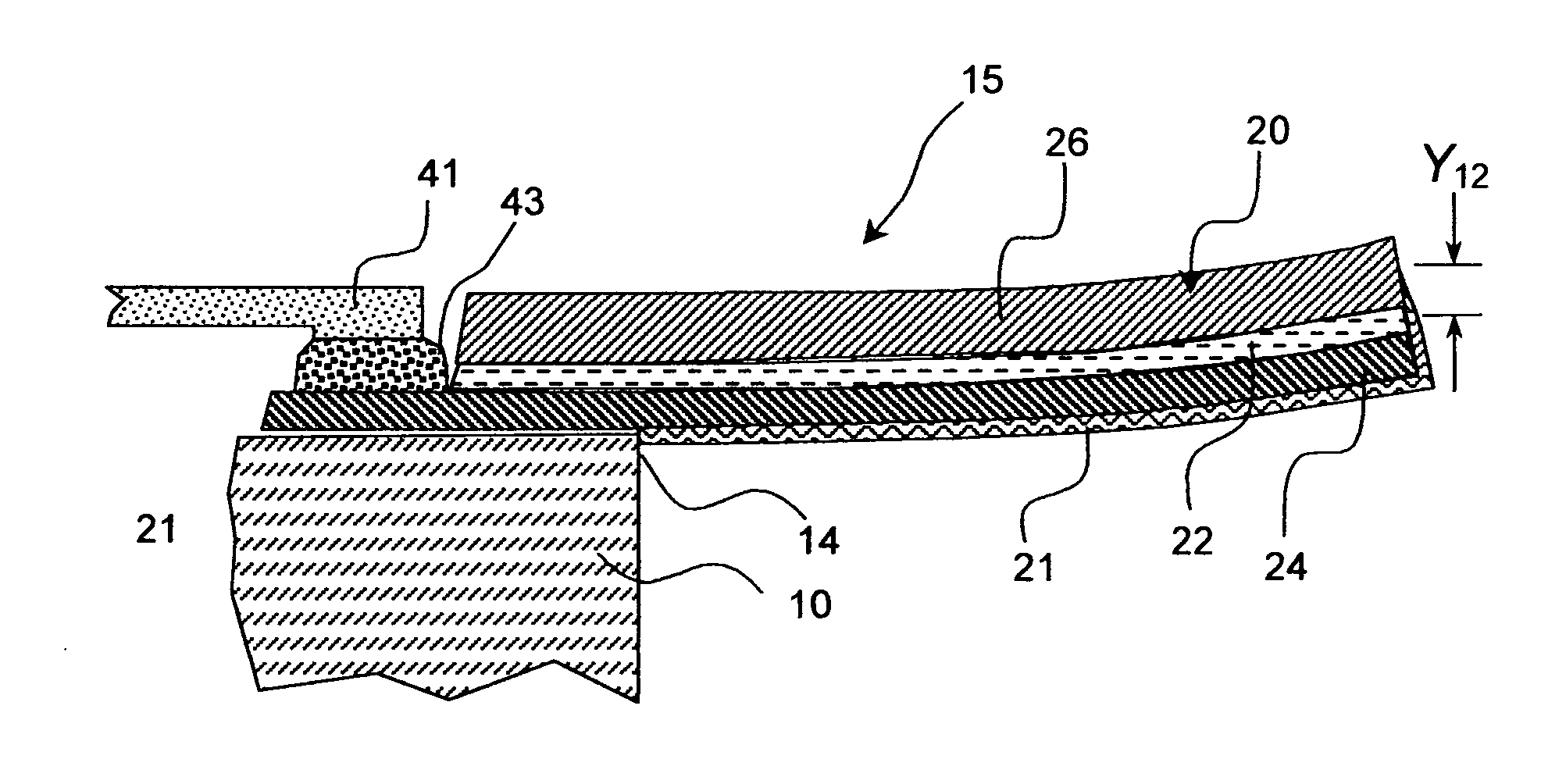

Thermally conductive thermal actuator and liquid drop emitter using same

ActiveUS20050046672A1Without excessive riseHigh repetition rateInking apparatusThermal electric motorEngineeringThermal expansion

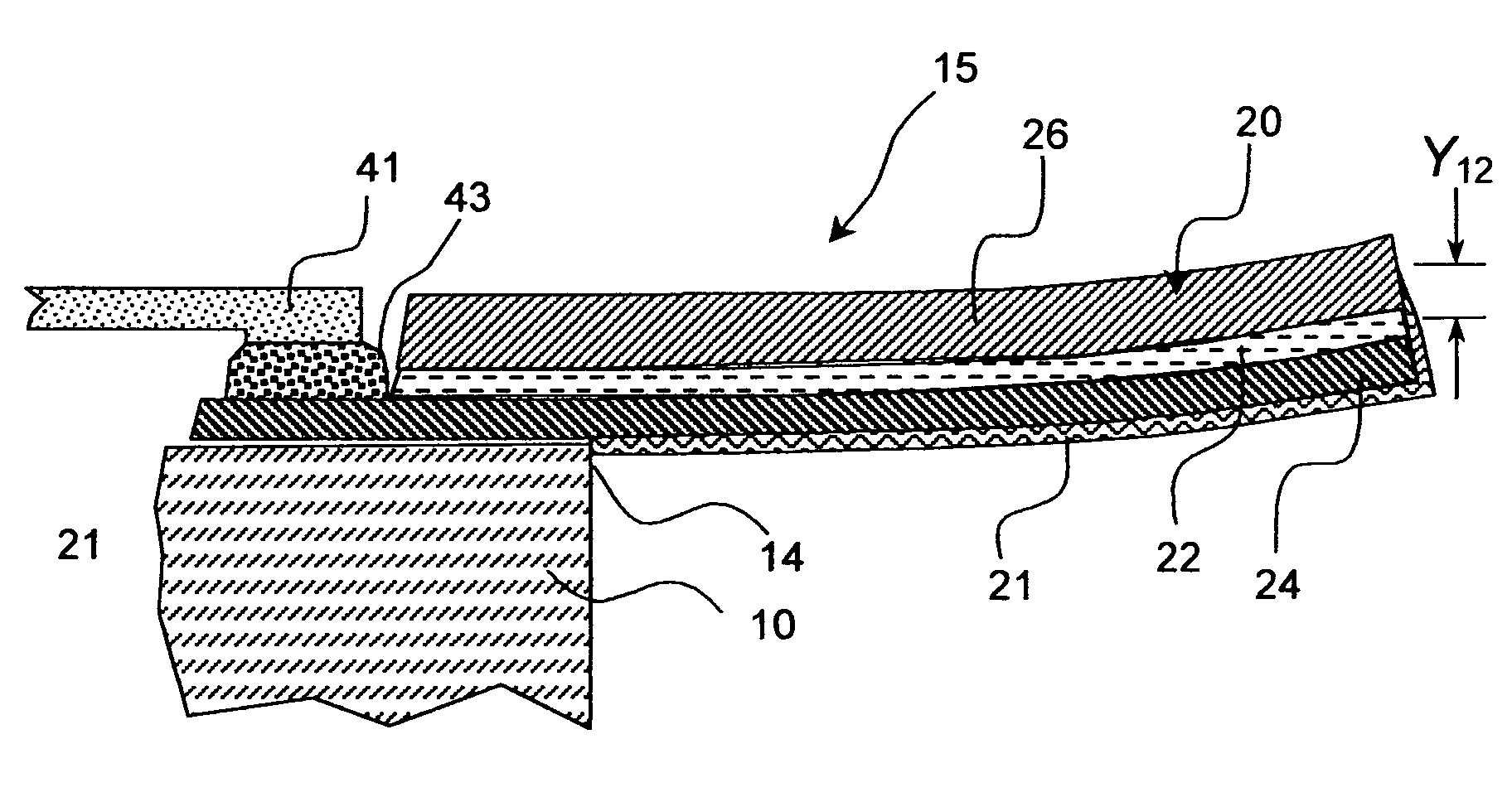

A thermal actuator for a micro-electromechanical device, especially a liquid drop emitter for ink jet printing, is disclosed. The thermal actuator comprises a base element and a movable element extending from the base element and residing at a first position. The movable element includes a barrier layer constructed of a barrier material having low thermal conductivity material, bonded between a first layer and a second layer; wherein the first layer is constructed of a first material having a high coefficient of thermal expansion and the second layer is constructed of a second material having a high thermal conductivity and a high Young's modulus. An apparatus is provided adapted to apply a heat pulse directly to the first layer, causing a thermal expansion of the first layer relative to the second layer and deflection of the movable element to a second position, followed by relaxation of the movable element towards the first position as heat diffuses through the barrier layer to the second layer. Configurations of the movable element as a cantilever, doubly-anchored beam and clamped plate are disclosed. Diamond and silicon carbide materials are well suited for use as the second material. Titanium aluminide is a preferred material for the first material.

Owner:EASTMAN KODAK CO

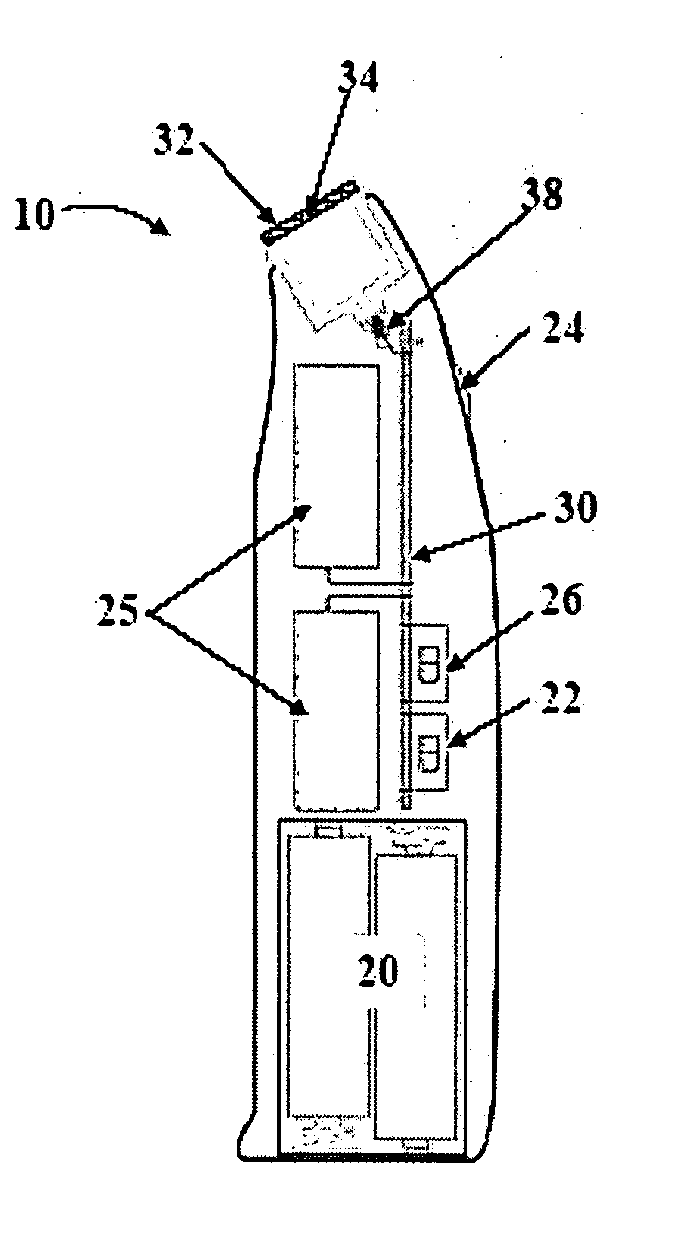

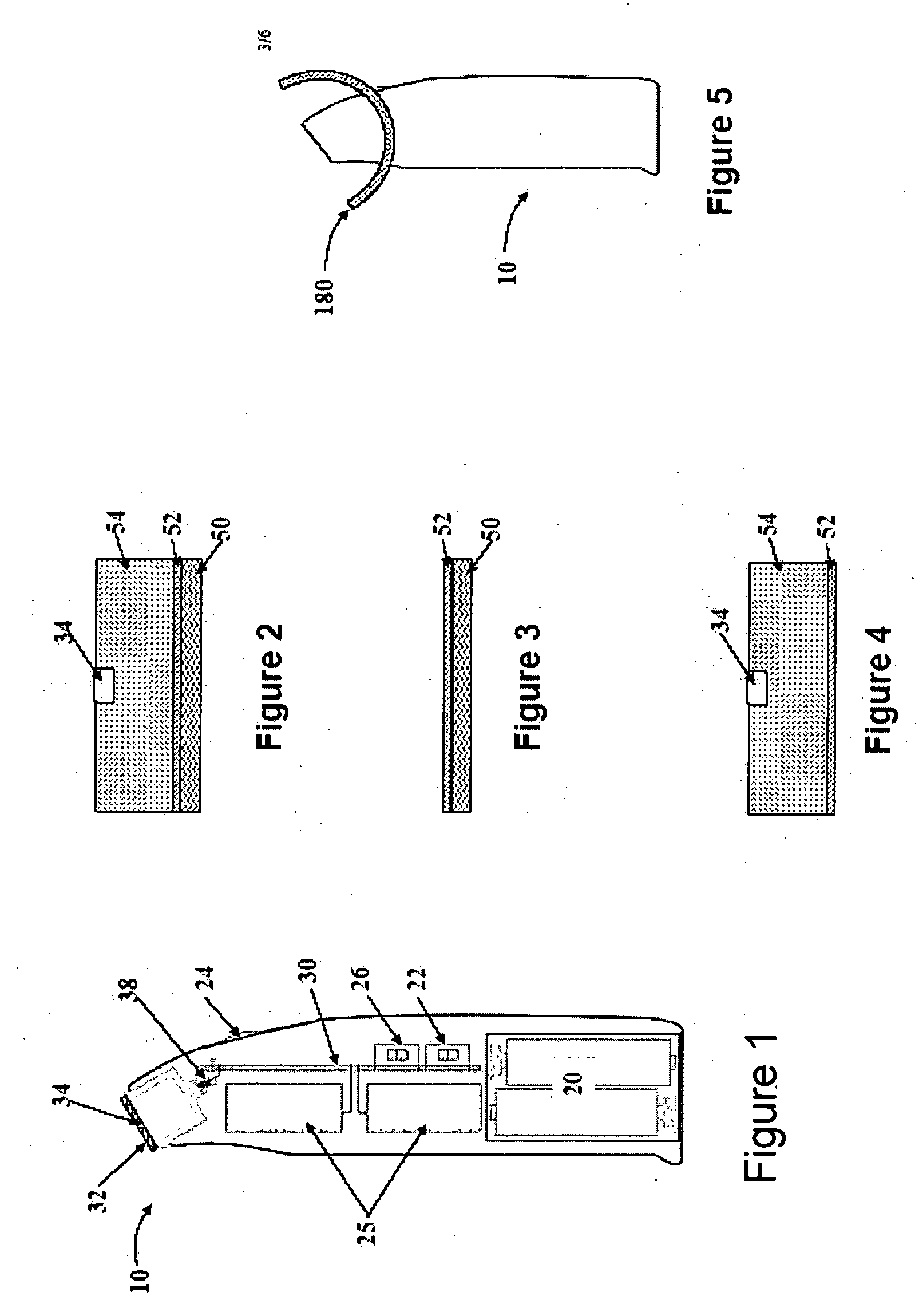

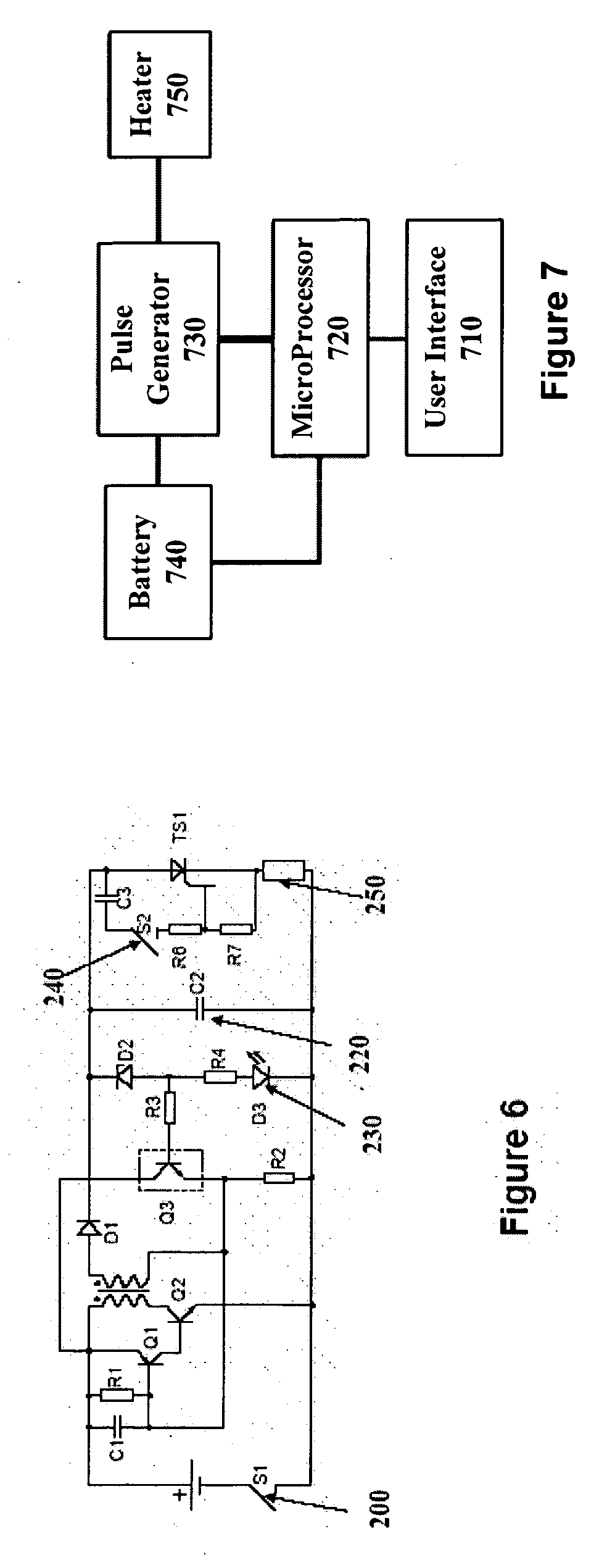

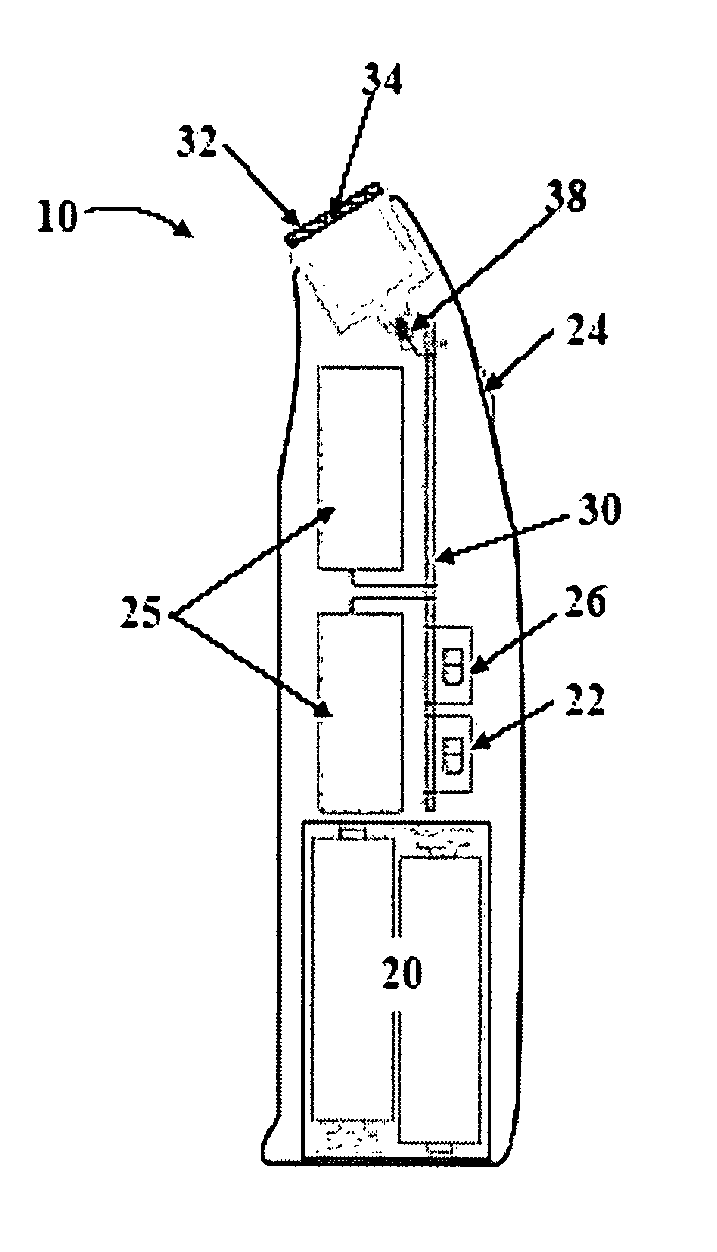

Devices and methods for treatment of skin conditions

InactiveUS20060142750A1Removing fine wrinkleClean skinSurgical instruments for heatingTherapeutic coolingWrinkle skinVirus warts

Devices and methods for the treatment of skin conditions and lesions are disclosed herein. One aspect of the invention is a compact hand held device that can be safely used by those suffering from skin conditions, such as acne, warts, cold blisters, blemished skin, or fine wrinkles. The devices described herein employ the application of heat for the treatment of skin conditions and lesions. Typically, the peak temperatures employed are about 70° C. to about 400° C. by the devices, are achieved in less than about 1 second, and maintained for less than about 1 second. In some embodiments, the skin surface is heated with heat pulses. Thermal conduction transfers heat from the device to the skin and causes a biological response that accelerates acne clearing, treats blemished skin, itching, or fine wrinkles. The total heat transferred is low enough to prevent burns.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

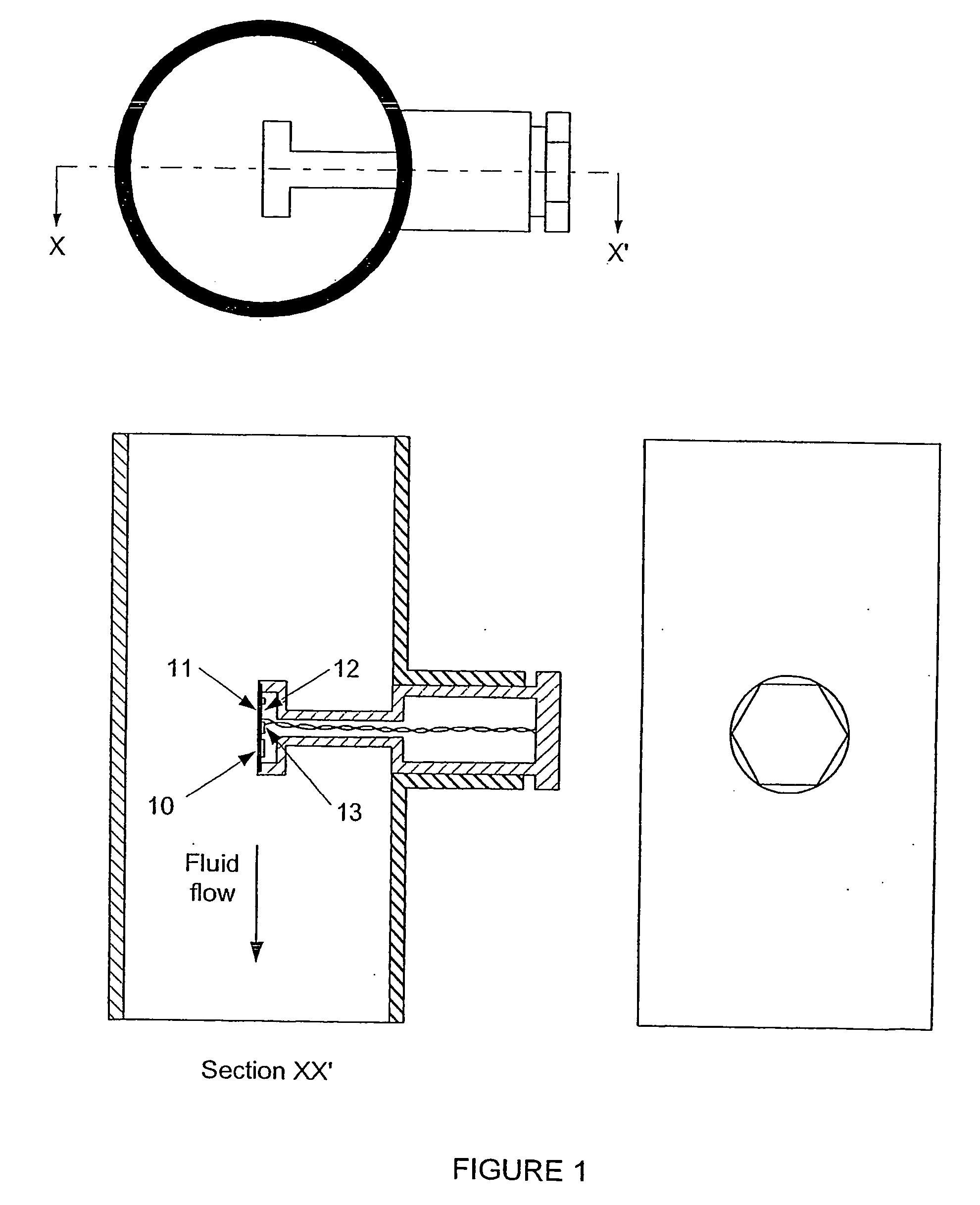

Method and system for detecting a leak in a pipeline

ActiveUS20140290343A1Detection of fluid at leakage pointMeasurement of fluid loss/gain rateSensor arrayThermal energy

System and method for detecting a leak in a pipeline with a sensing cable including an optical fiber sensor array aligned with a heating element. At least one heat pulse is propagated through the heating element along at least a portion of the sensing cable to affect an exchange of thermal energy between the heating element and fluid exposed to the sensing cable. A temperature profile of the sensing cable corresponding to the heat pulse at each of a plurality of sensor locations on the optical fiber sensor array is measured over time. A leak in a pipeline is detected by determining one or more properties of the fluid exposed to the sensing cable at each of the plurality of sensor locations based on the temperature profile corresponding thereto.

Owner:EXXON RES & ENG CO

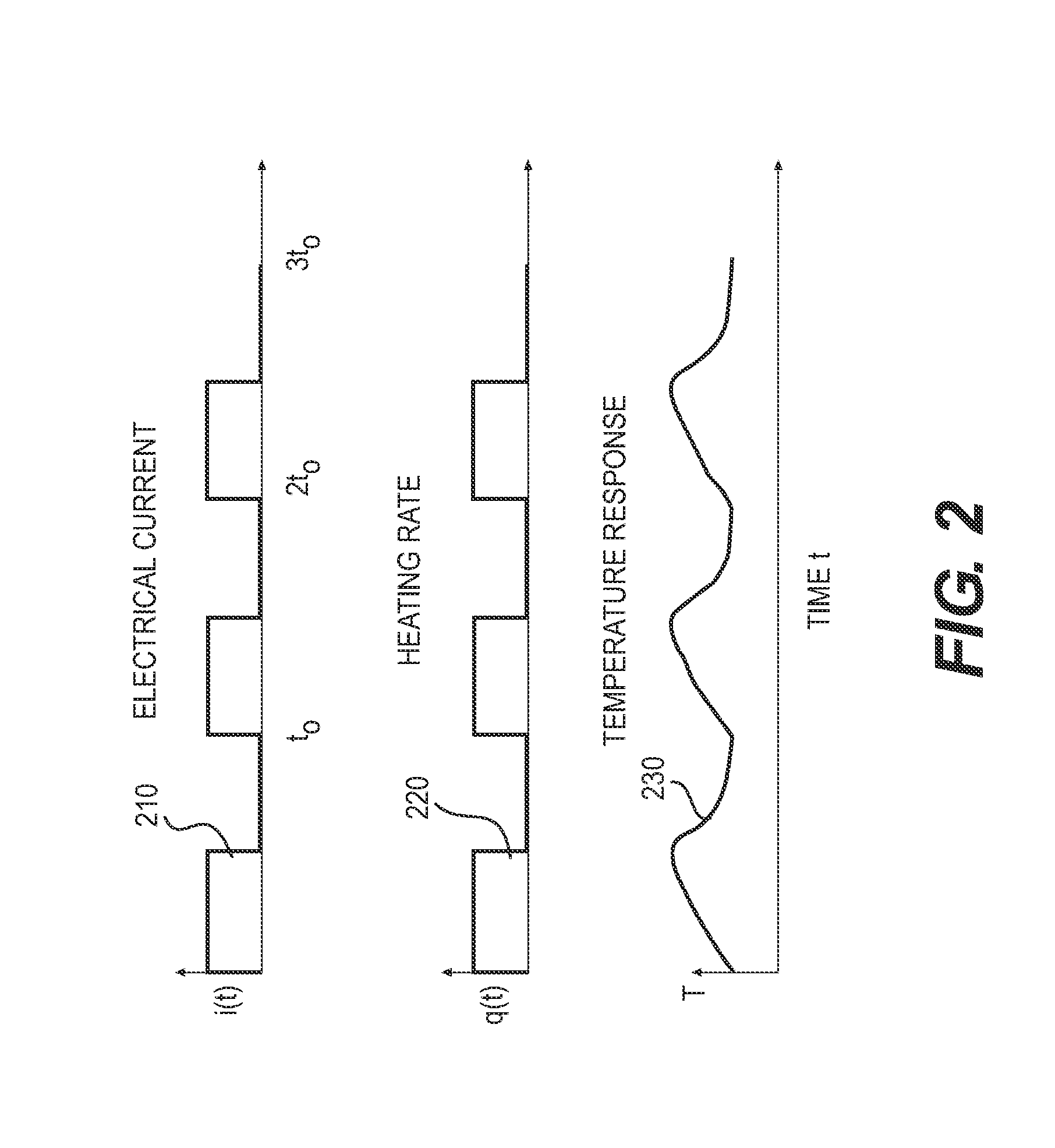

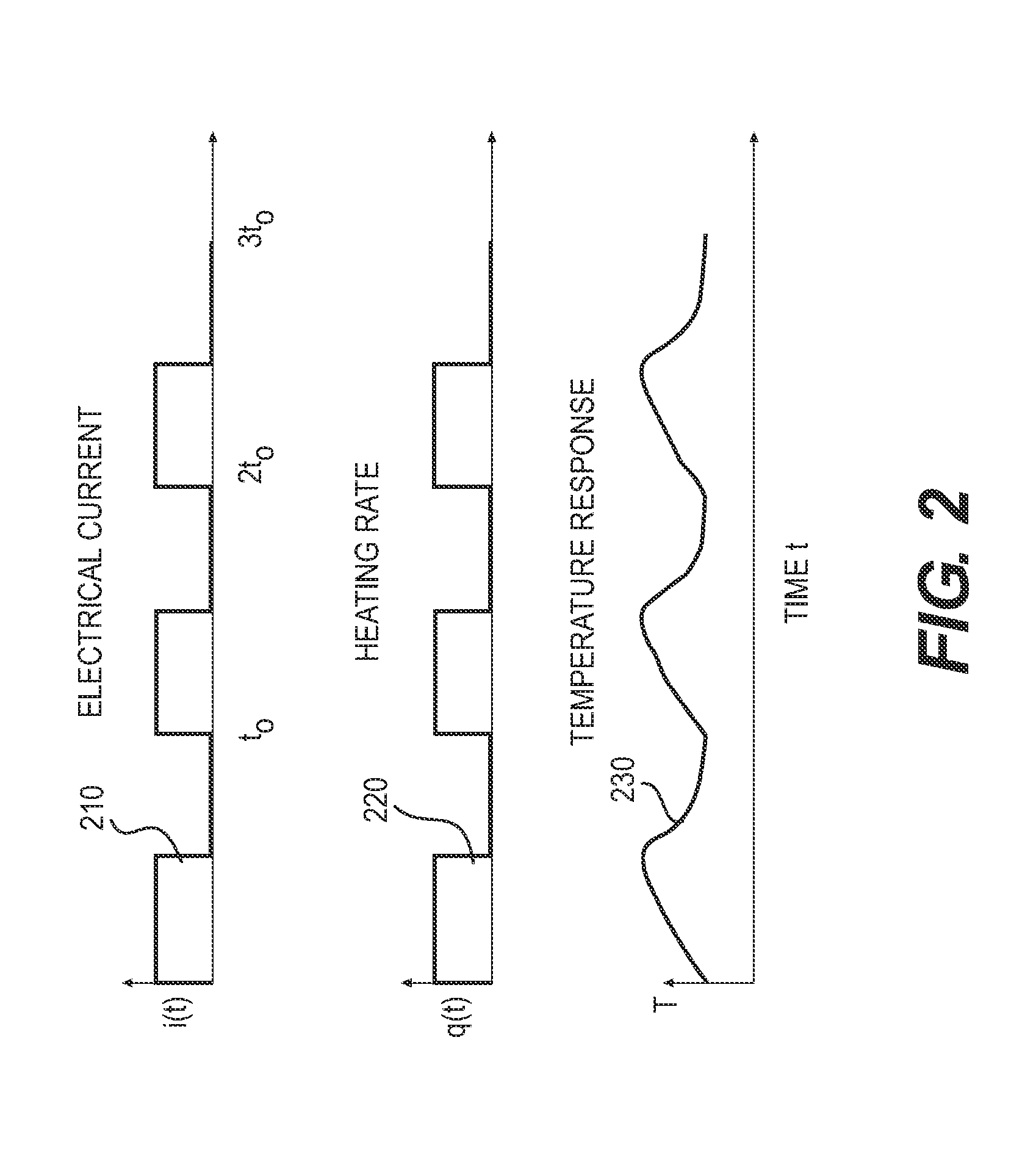

Method and system for multi-phase flow measurement

Systems and methods for detecting a condition of multi-phase flow through a component with a first sensing cable having a first sensor location and aligned with a heating element and a second sensing cable having a second sensing location a predetermined distance from the first sensing location. A heat pulse is propagated through the heating element. A first temperature profile at the first sensing location and a second temperature profile at the second sensing location, each corresponding to the heat pulse, are measured over time. A flow velocity is determined by correlating the first temperature profile with the second temperature profile. A condition of flow of the media is detected by determining a phase of at least one medium exposed to the sensing cable at the first sensing location based on the first temperature profile and the determined flow velocity.

Owner:EXXON RES & ENG CO

Doubly-anchored thermal actuator having varying flexural rigidity

Owner:EASTMAN KODAK CO

Devices and methods for treatment of skin conditions

Devices and methods for the treatment of skin conditions and lesions are disclosed herein. One aspect of the invention is a compact hand held device that can be safely used by those suffering from skin conditions, such as acne, warts, cold blisters, blemished skin, or fine wrinkles. The devices described herein employ the application of heat for the treatment of skin conditions and lesions. Typically, the peak temperatures employed are about 70° C. to about 400° C. by the devices, are achieved in less than about 1 second, and maintained for less than about 1 second. In some embodiments, the skin surface is heated with heat pulses. Thermal conduction transfers heat from the device to the skin and causes a biological response that accelerates acne clearing, treats blemished skin, itching, or fine wrinkles. The total heat transferred is low enough to prevent burns.

Owner:KONINK PHILIPS ELECTRONICS NV

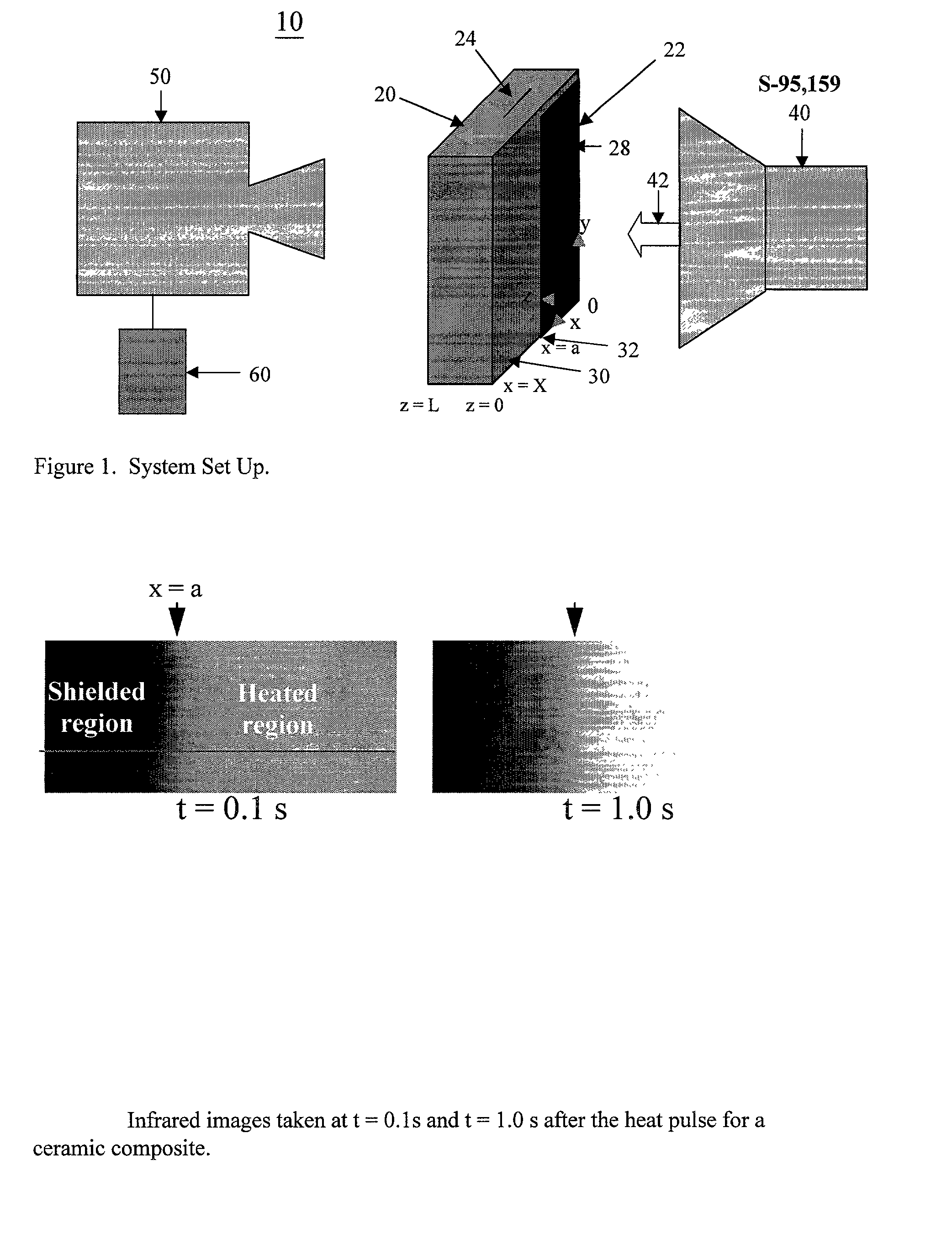

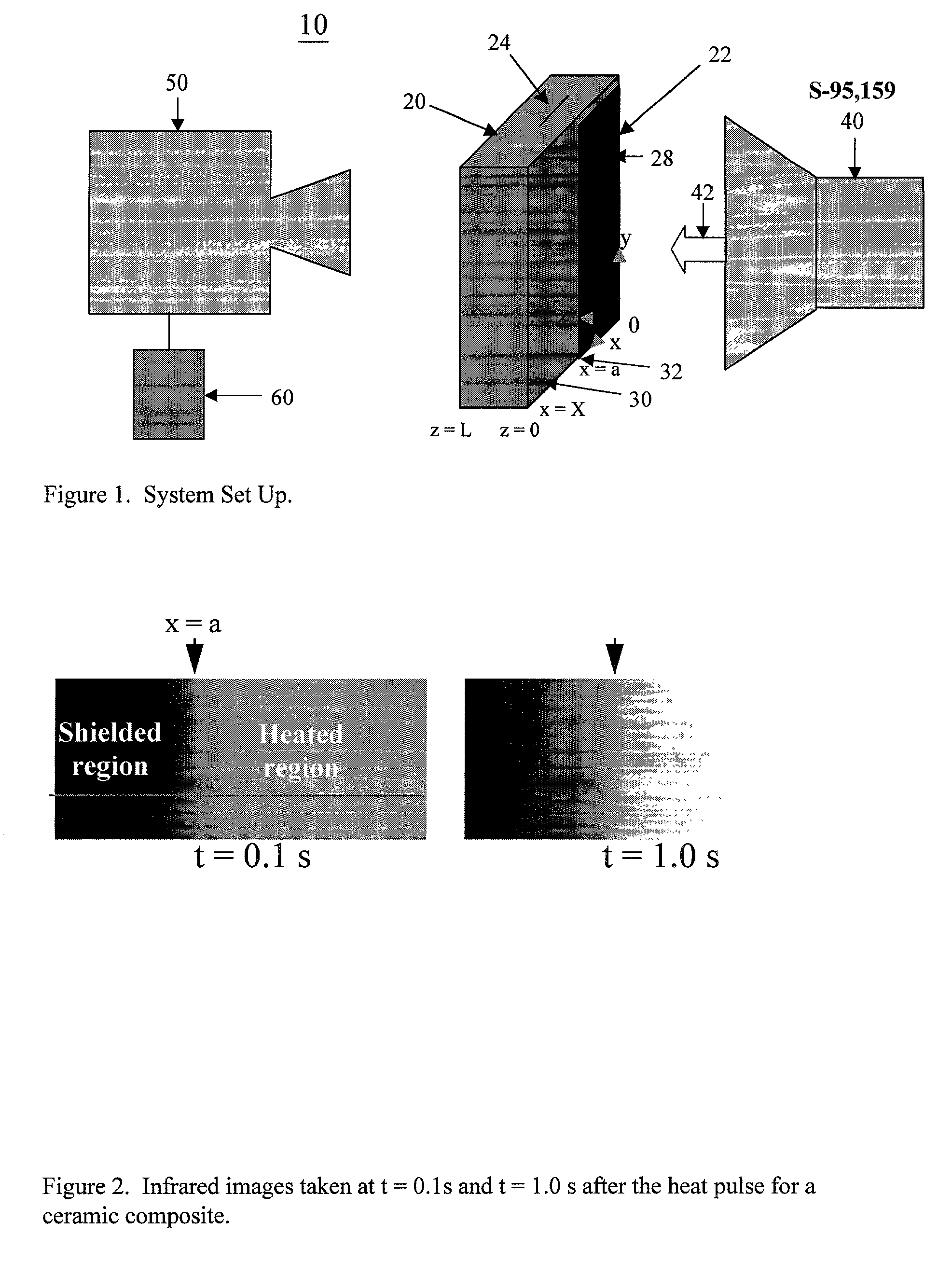

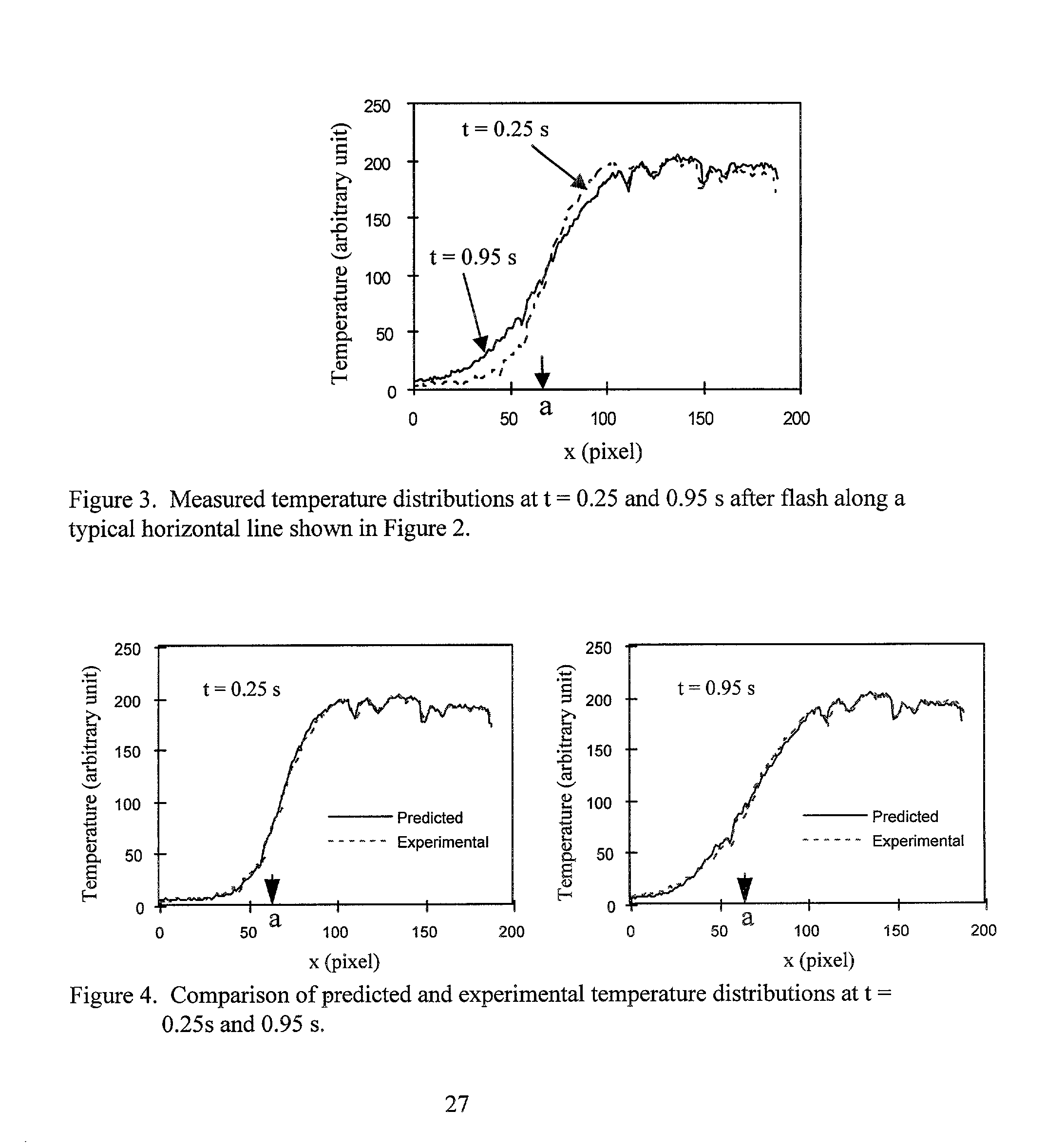

Thermal imaging measurement of lateral diffusivity and non-invasive material defect detection

InactiveUS20020126730A1Accurate methodRadiation pyrometryMaterial heat developmentMaterial defectOrthogonal coordinates

A system and method for determining lateral thermal diffusivity of a material sample using a heat pulse; a sample oriented within an orthogonal coordinate system; an infrared camera; and a computer that has a digital frame grabber, and data acquisition and processing software. The mathematical model used within the data processing software is capable of determining the lateral thermal diffusivity of a sample of finite boundaries. The system and method may also be used as a nondestructive method for detecting and locating cracks within the material sample.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Method and device for measuring deposit thickness

InactiveUS20110308548A1Improved wax thickness measurement methodWeather/light/corrosion resistanceMaterial thermal analysisEngineeringHeat pulse

The present invention concerns a method for measuring the thickness of any deposit of material on the inner wall of a structure conducting a fluid stream of hydrocarbons, the method comprising the steps of: applying a first heat pulse or continuous heating to at least one first section of the structure removing deposits on the inner wall of the first section of the structure; applying a second heat pulse to both the first section of the structure and at least one second section of the structure, the first and second sections being spaced apart, which heat pulse does not loosen any deposit of material in the second section; measuring the temperature of the wall of the structure or the fluid during the second heat pulse at both the first and second sections; and determining the thickness of any deposit of material on the inner wall of the structure at the second section based on the measured temperatures. The present invention also relates to a corresponding device and arrangement.

Owner:DEN NORSKE STATS OLJESELSKAP AS

Method for measuring thermophysical parameters of translucent material with transient photothermal signals generated by heating pulse lasers

ActiveCN103528978AHigh measurement accuracyMaterial heat developmentScattering properties measurementsPhysicsHeat pulse

The invention relates to a method for measuring thermophysical parameters of a translucent material, in particular to a method for measuring thermophysical parameters of a translucent material with transient photothermal signals generated by heating pulse lasers. The method comprises the steps that the surface of one side of the translucent material is irradiated by the lasers, a thermocouple thermodetector is used for measuring and recording the changes of the temperature of the two surfaces of the material along with time, and a laser power meter is synchronously used for respectively measuring the hemispherical reflecting radiation signals of the laser incidence side of a test-piece and the hemispherical transmission radiation signals of the laser emitting side of the test-piece. According to the laser transmission radiation signals, the reflecting radiation signals and the temperature, changed along with the time, of the two surfaces, the absorption coefficient, the scattering coefficient and the heat conduction coefficient of the translucent material are obtained on the basis of an inverse problem solving technology. A direct problem model and an inverse problem model for measuring the absorption coefficient, the scattering coefficient and the heat conduction coefficient of the translucent material are built, and the absorption coefficient, the scattering coefficient and the heat conduction coefficient of the translucent material can be simultaneously measured simply, fast and accurately through the inverse problem solving technology.

Owner:HARBIN INST OF TECH

Tapered multi-layer thermal actuator and method of operating same

InactiveUS20050052498A1Low energy inputRapid restoration of the actuatorLiquid surface applicatorsCoatingsEngineeringThermal expansion

An apparatus for and method of operating a thermal actuator for a micromechanical device, especially a liquid drop emitter such as an ink jet printhead, is disclosed. The disclosed thermal actuator comprises a base element and a cantilevered element including a thermo-mechanical bender portion extending from the base element to a free end tip. The thermo-mechanical bender portion includes a barrier layer constructed of a dielectric material having low thermal conductivity, a first deflector layer constructed of a first electrically resistive material having a large coefficient of thermal expansion, and a second deflector layer constructed of a second electrically resistive material having a large coefficient of thermal expansion wherein the barrier layer is bonded between the first and second deflector layers. The thermo-mechanical bender portion further has a base end and base end width, wb, adjacent the base element, and a free end and free end width, wf, adjacent the free end tip, wherein the base end width is substantially greater than the free end width. A first heater resistor is formed in the first deflector layer and adapted to apply heat energy having a first spatial thermal pattern which results in a first deflector layer base end temperature increase, ΔT1b, that is greater than a first deflector layer free end temperature increase, ΔT1f. A second heater resistor is formed in the second deflector layer and adapted to apply heat energy having a second spatial thermal pattern which results in a second deflector layer base end temperature increase, ΔT2b that is greater than a second deflector layer free end temperature increase, ΔT2f. Application of an electrical pulse to either the first or second heater resistors causes deflection of the cantilevered element, followed by restoration of the cantilevered element to an initial position as heat diffuses through the barrier layer and the cantilevered element reaches a uniform temperature. For liquid drop emitter embodiments, the thermal actuator resides in a liquid-filled chamber that includes a nozzle for ejecting liquid. Application of electrical pulses to the heater resistors is used to adjust the characteristics of liquid drop emission. The barrier layer exhibits a heat transfer time constant τB. The thermal actuator is activated by a heat pulses of duration τP wherein τP<½τB.

Owner:EASTMAN KODAK CO

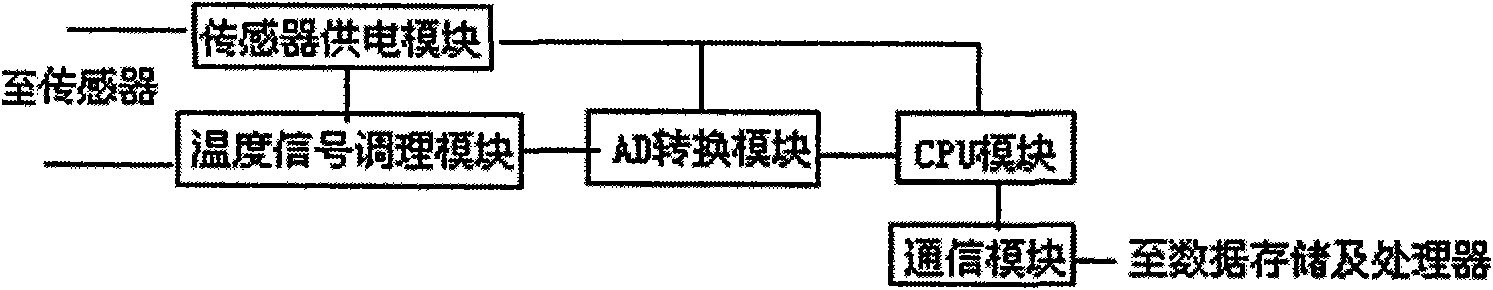

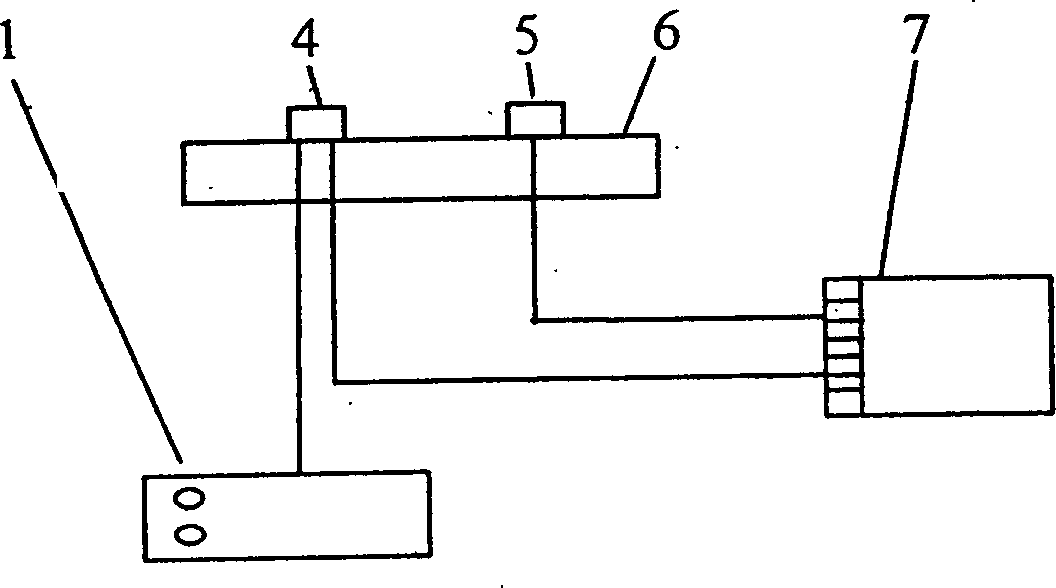

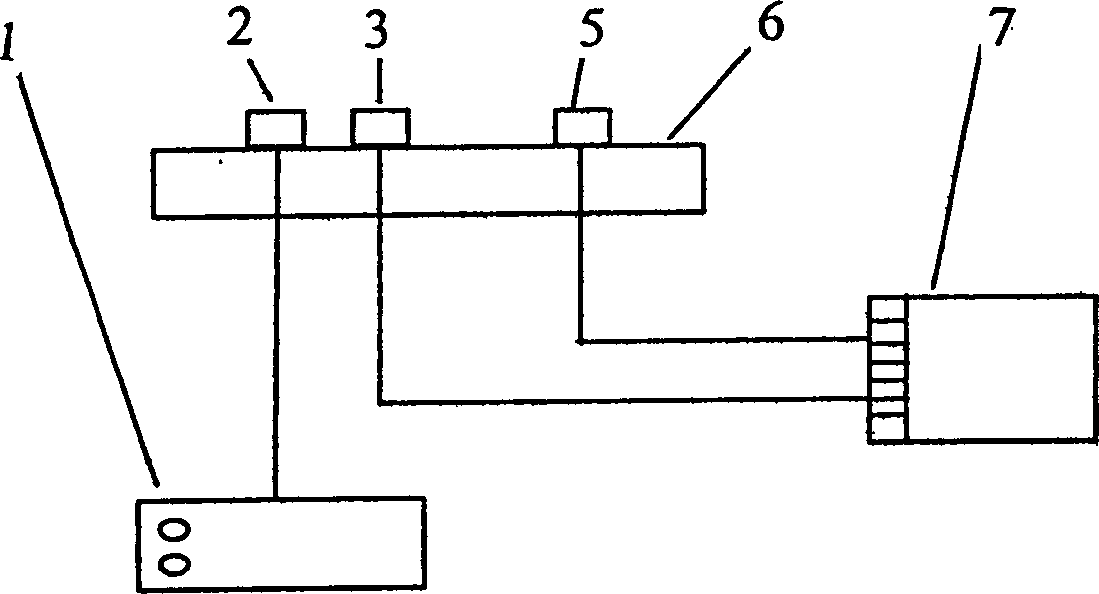

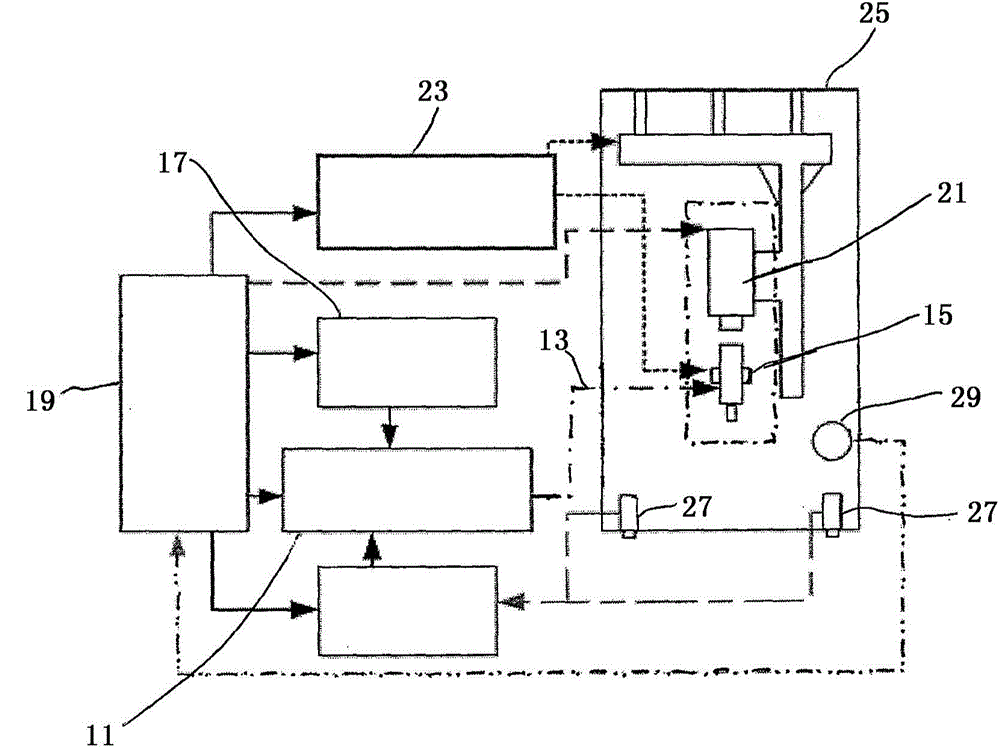

System and method for testing moisture and temperature of soil mass by heat pulse method

InactiveCN101782542AMaterial thermal conductivityMaterial moisture contentDirect effectsFeature parameter

The invention concretely relates to a system and a method for testing moisture and temperature of soil mass by heat pulse method. By utilizing the thermal physical characteristic of water-containing soil mass that the moisture content of the soil mass directly affects the thermal conductivity, thermal capacity and other thermal parameters of the soil mass, a heating element and a temperature measurement element are arranged in a testing probe. During measurement, the heating element emits a thermal pulse with controllable power; the temperature measurement element continuously measures temperature and records the change process of heating power and temperature; and through the relation between the water content of the soil mass calibrated and stored in the system in advance and the characteristic parameters of the change process of heating power and temperature, the value of the water content of the tested soil mass can be obtained. The invention has the advantages of wide testing range of soil-mass moisture, high testing precision, capability of testing the ice content of frozen soil mass, and the like, and can realize multi-channel multi-point real-time monitoring.

Owner:CHANGAN UNIV

Method for wax removal and measurement of wax thickness

ActiveUS20100300486A1Situation is differentEffective installationCleaning heat-transfer devicesHollow article cleaningEngineeringWax removal

A method for removal of wax deposited on an inner wall in contact with a fluid stream. The method includes the steps of cooling the inner wall and the fluid stream to a temperature of or below the wax appearance temperature, enabling wax to dissolve and precipitate on the inner wall, and heating of the inner wall for a short period of time to release the deposited wax from the surface of the inner wall, mainly in the form of solid parts. The thickness of wax deposits in a pipe section can be determined by computing the temperatures obtained upstream and downstream in the said pipe section, before and after applying heat pulse.

Owner:DEN NORSKE STATS OLJESELSKAP AS

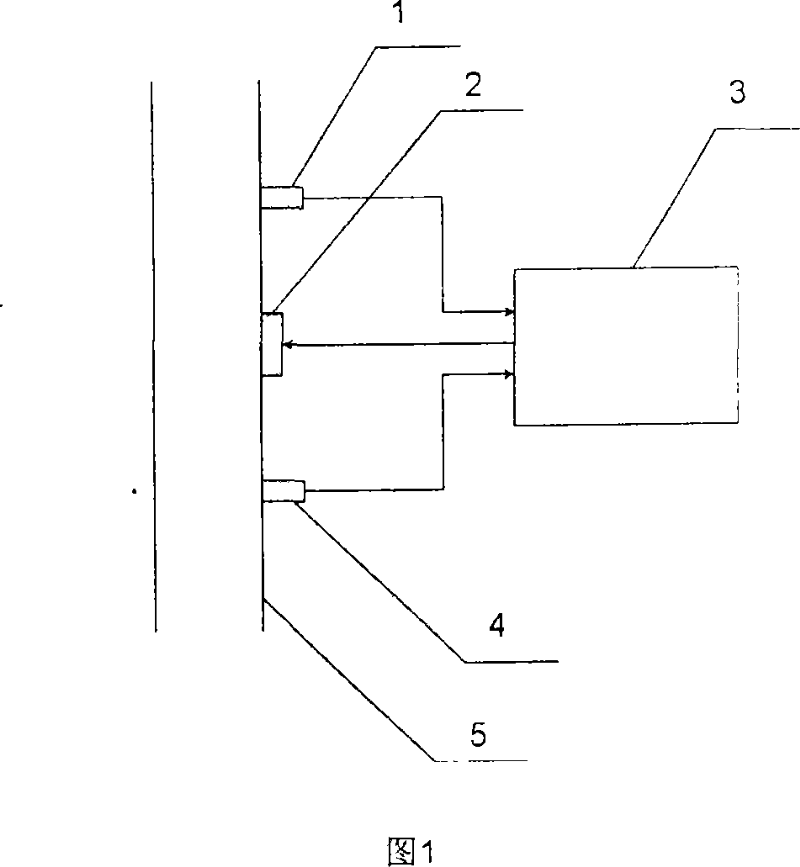

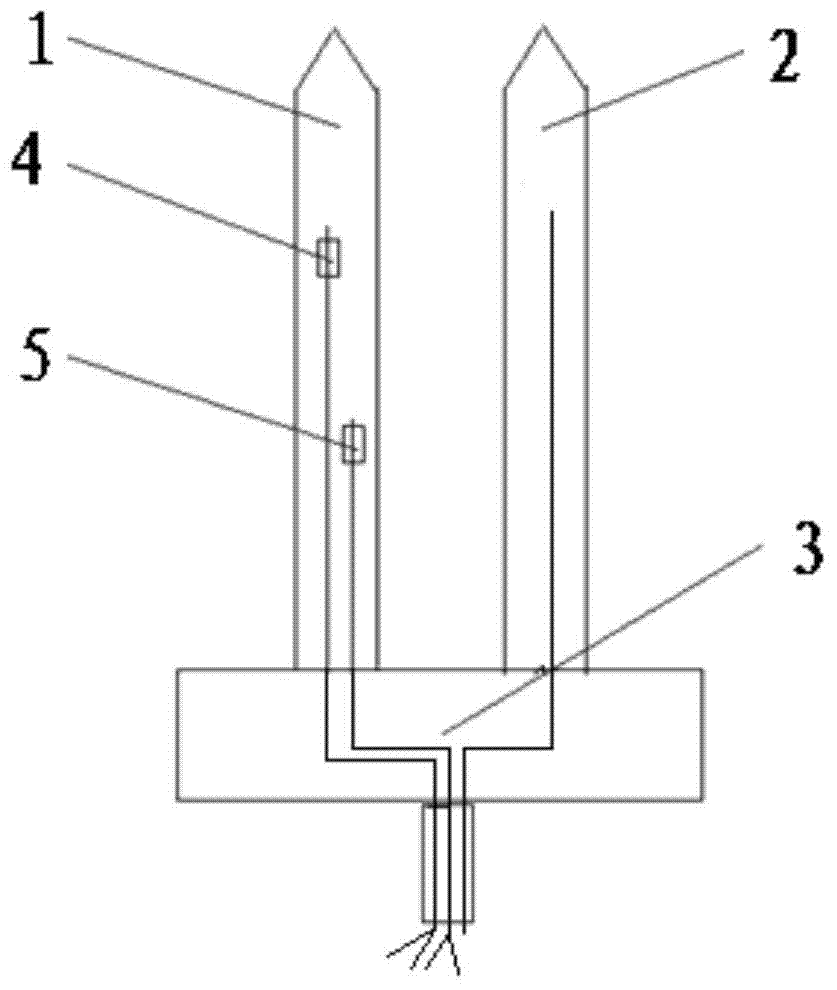

Non-invasive heat pulse stem flow gauge

The present invention provides an un-intrusive type pulse stem flow gauge including a heating element positioned on the surface of the plant, a differential amplifying circuit and a signal control processing circuit. A downriver temperature sensor is positioned down the stem flow where the heating element of the stem flow gauge is positioned; an upriver temperature sensor assortative with the downstream temperature sensor is provided on the upper of the stem flow where the heating element of the stem flow gauge is positioned. Said downriver temperature sensor and upriver temperature sensor are connected with the differential amplifying circuit and the signal control processing circuit. As a result, the stem flow measuring of the plant with a smaller diameter can be realized conveniently in the present invention by adopting an un-intrusive type heating method and a differential temperature measuring method of the temperature sensor through measuring the moving time of the heat pulse inner the plant.

Owner:ZHEJIANG UNIV

Experimental device for testing heat conductivity coefficient of building material based on quasi steady state and unsteady state methods

The invention provides an experimental device for testing a heat conductivity coefficient of a building material based on quasi steady state and unsteady state methods, relates to the field of a testing technology of thermophysical parameters of a building material, and solves the problems that an existing thermophysical parameter experimental device can not simultaneously load the measurement processes by using three methods including a quasi steady state method, a normal power method and a heat pulse method, and one-time testing time is long and a measurement maximum relative error is large. An anode and a cathode of a low-potential potentiometer are correspondingly connected with a switch control interface of an oil immersed key conversion switch; thermoelectromotive force signals output by thermocouples are respectively connected into a thermoelectromotive force signal output end of the oil immersed key conversion switch; cold ends of the thermocouples are respectively inserted into an ice bottle containing an ice-water mixture; measuring ends of the thermocouples are respectively contacted with a testing piece to be tested; a heating resistor is used for heating the testing piece to be tested. The theoretical error analysis and the actual measurement prove that the measurement maximum relative errors are as follows: the heat conductivity coefficient is less than or equal to 5.1%, the thermal diffusivity is less than or equal to 9.2% and the specific heat value is less than or equal to 7.7%; the requirement on precision by engineering is met.

Owner:HARBIN INST OF TECH

Flow transducer and method

A transducer is disclosed for sensing flow of a fluid. The transducer includes means for applying a heat pulse to the fluid and at least one temperature sensor. The temperature sensor is adapted to detect a decaying response to the heat pulse to provide an indication of the flow. The decaying response may be detected by comparing measured voltages at a set moment in time or by comparing measured times at a set voltage threshold. A method for sensing flow of a fluid is also disclosed.

Owner:HYBRID ELECTRONICS AUSTRALIA +1

Plant stemflow velocity measuring method and device thereof

InactiveCN101221193AReduce heatingStable jobThermometers using electric/magnetic elementsUsing electrical meansWoody plantPlant stem

Owner:FARMLAND IRRIGATION RES INST CHINESE ACAD OF AGRI SCI

Thermal-based diagnostic system for process transmitter

A process transmitter for measuring a process variable in an industrial process comprises a sensor module, a heating device and transmitter circuitry. The sensor module has a sensor for sensing a process variable of an industrial process and generating a sensor signal. The heating device is connected to the sensor module for generating a heat pulse to influence generation of the sensor signal. The transmitter circuitry is connected to the sensor and the heating device. The transmitter circuitry verifies operation of the sensor by measuring a change in the sensor signal due to the heat pulse. In one embodiment of the invention, the heat pulse thermally expands a volume of a fill fluid within the process transmitter. In another embodiment, the heat pulse changes a physical property, such as dielectric, of a fill fluid within the process transmitter.

Owner:ROSEMOUNT INC

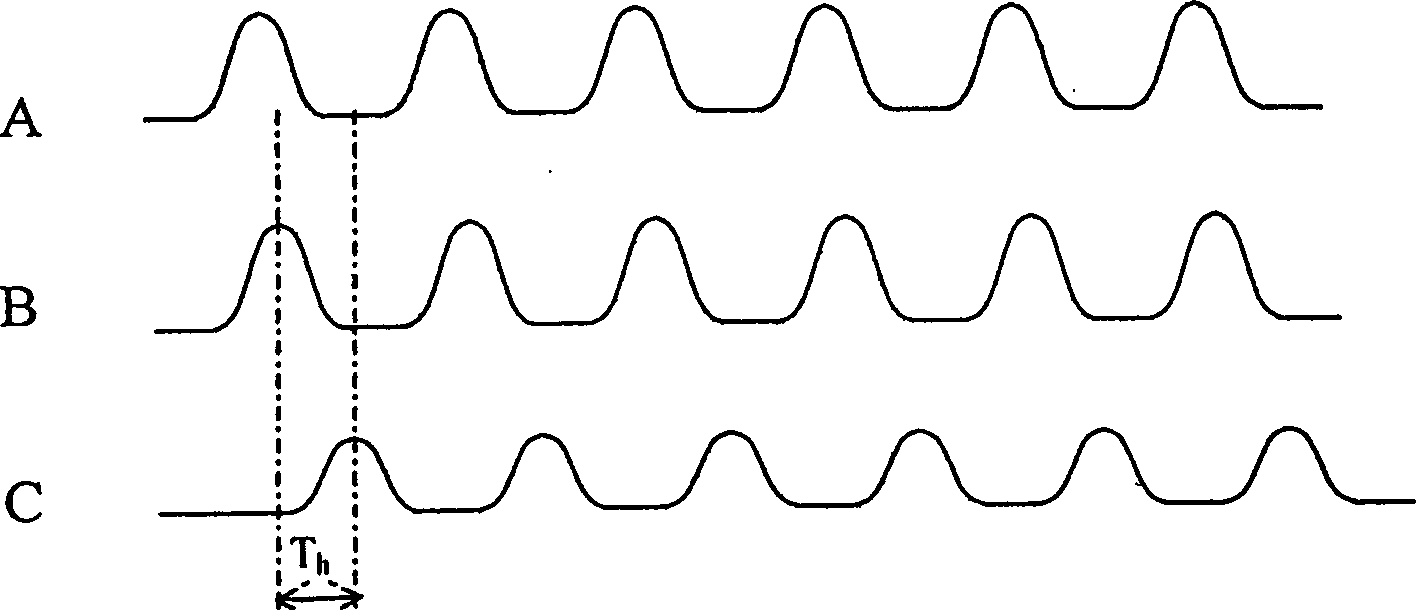

Heat pulse time difference type flow detection method

This invention discloses a heat impulse time lag flow measurement method, which puts sensor in the parallel pipe to the flow direction to get heating temperature measurement, or its denote output signal curve; then it measures the temperature change on downstream of temperature measurement element along flow direction to get output signal curve of temperature element; it compares two curves to measure the time lag value to get flow speed. This invention especially applied in the measurement of middle and low speed range of gas with constant components.

Owner:ZHEJIANG UNIV

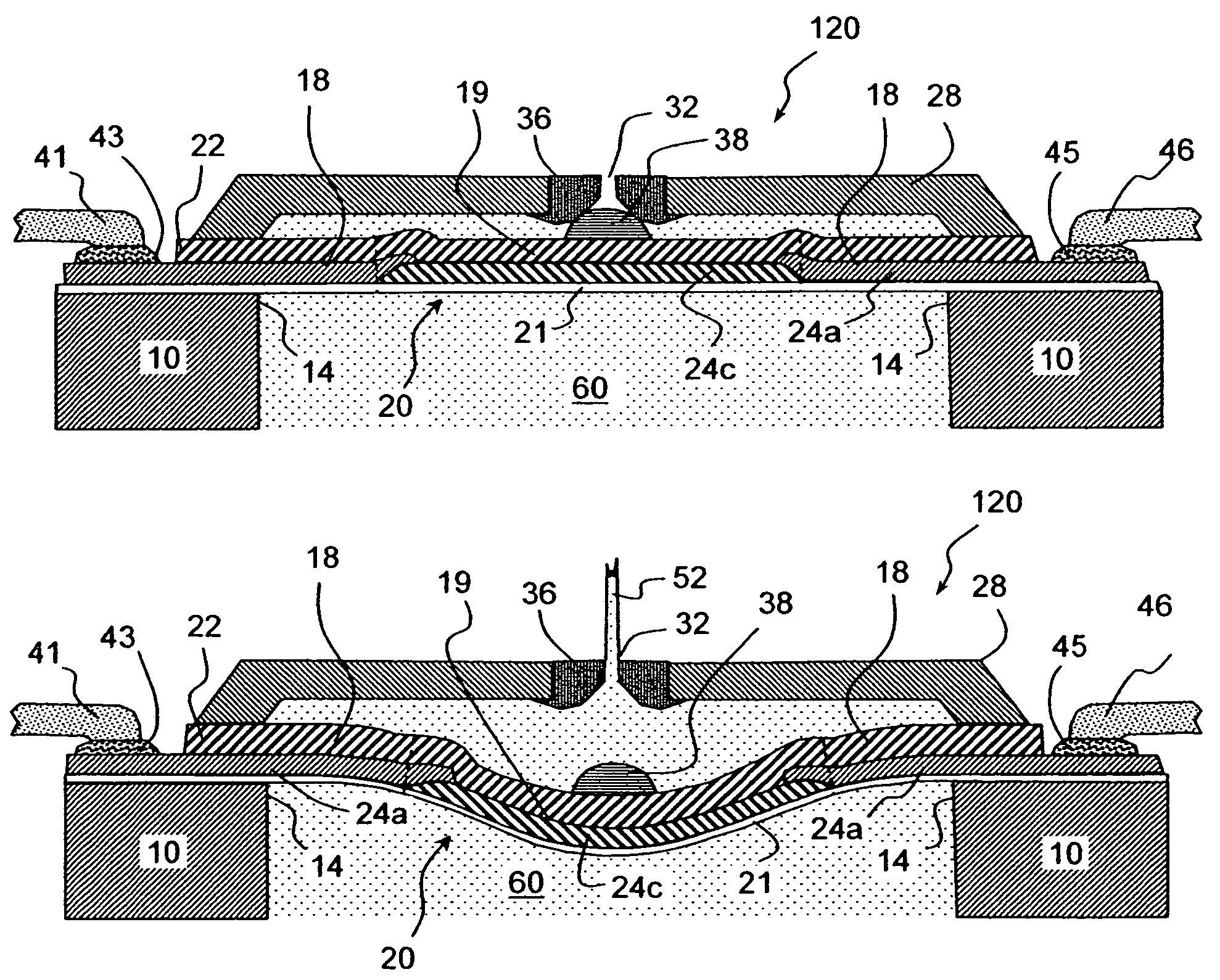

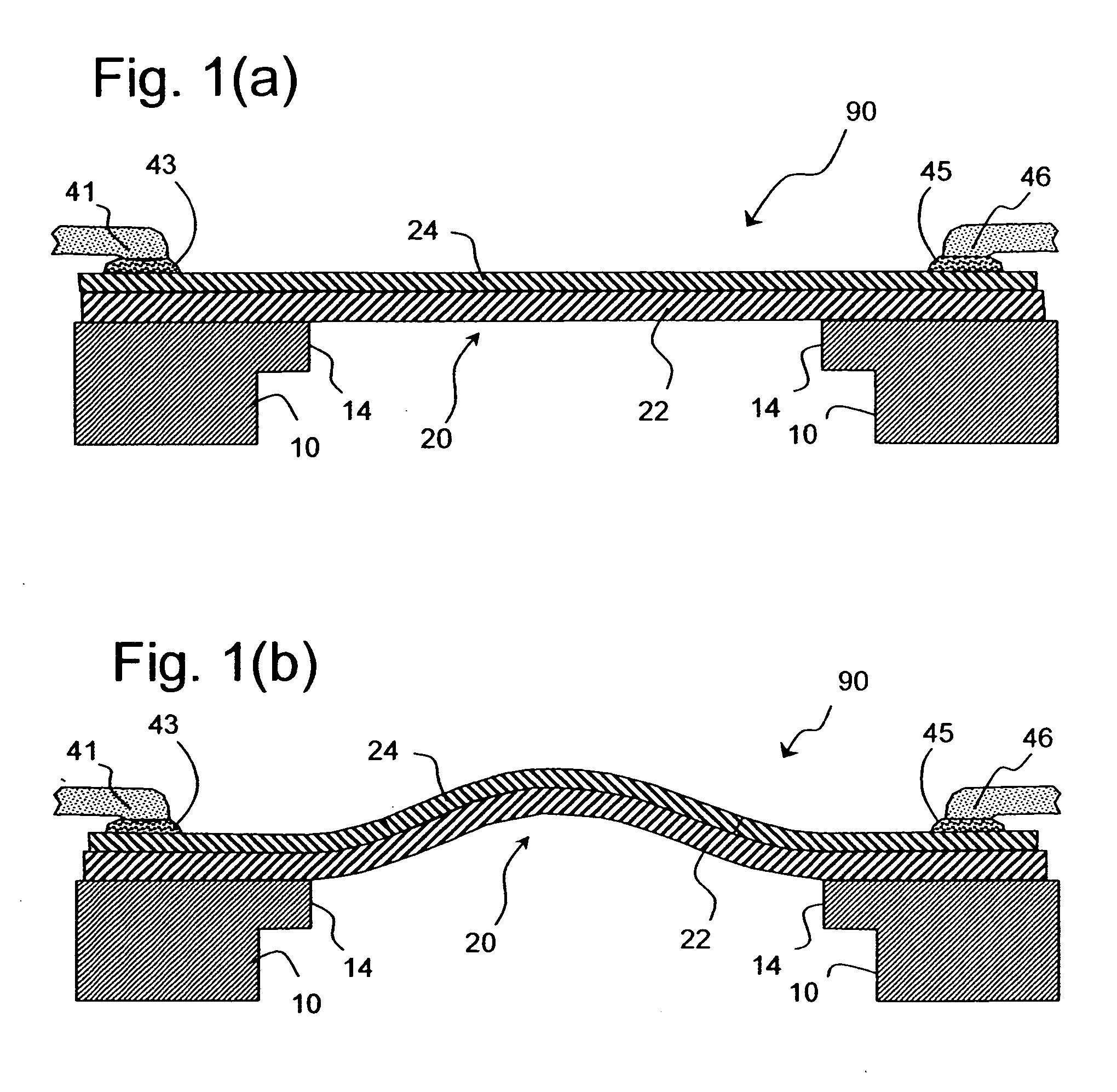

Doubly-anchored thermal actuator having varying flexural rigidity

InactiveUS20060109075A1Large force magnitudeLarge accelerationElectrothermal relaysThermal switch detailsFluid controlLight energy

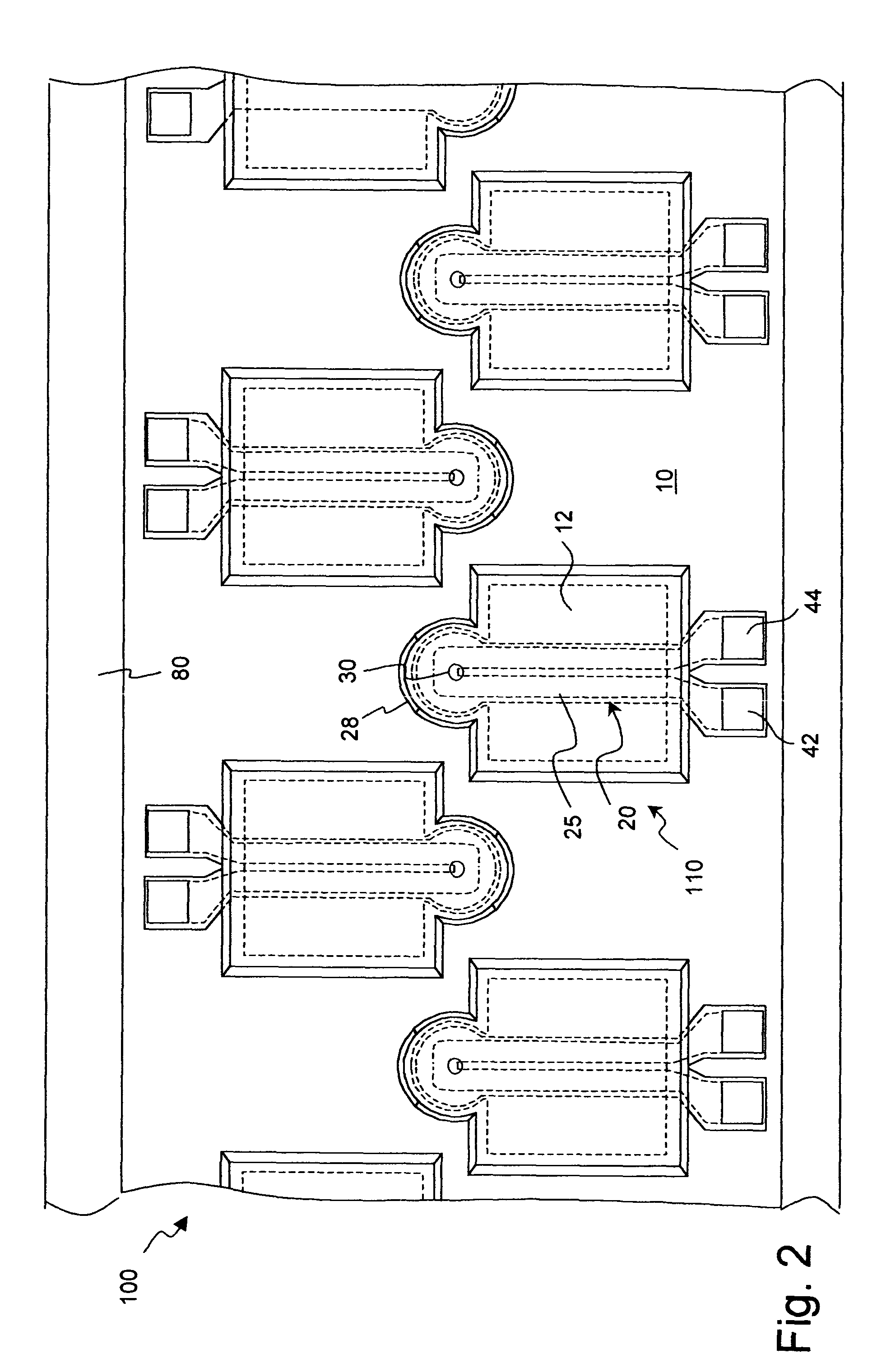

A doubly-anchored thermal actuator for a micro-electromechanical device such as a liquid drop emitter or a fluid control microvalve is disclosed. The thermal actuator is comprised of a base element formed with a depression having opposing anchor. A deformable element, attached to the base element at the opposing anchor edges, is constructed as a planar lamination including a first layer of a first material having a low coefficient of thermal expansion and a second layer of a second material having a high coefficient of thermal expansion. The deformable element has anchor portions adjacent the anchor edges and a central portion between the anchor portions wherein the flexural rigidity of the anchor portions is substantially less than the flexural rigidity of the central portion. The doubly-anchored thermal actuator further comprises apparatus adapted to apply a heat pulse to the deformable element that causes a sudden rise in the temperature of the deformable element. The deformable element bows outward in a direction toward the second layer, and then relaxes to a residual shape as the temperature decreases. The doubly-anchored thermal actuator is configured with a liquid chamber having a nozzle or a fluid flow port to form a liquid drop emitter or a fluid control microvalve, or to activate an electrical microswitch. Heat pulses are applied to the deformable element by resistive heating or by light energy pulses.

Owner:EASTMAN KODAK CO

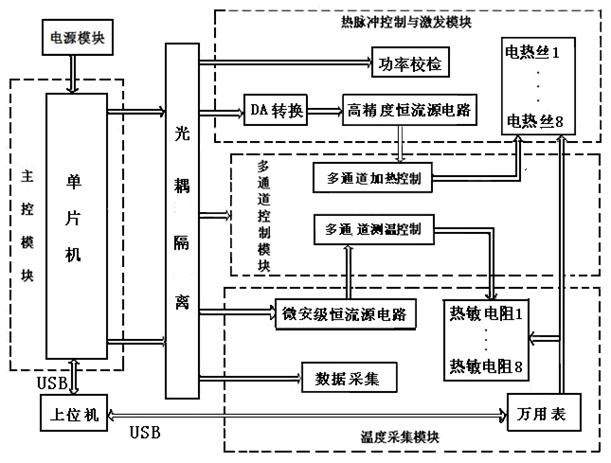

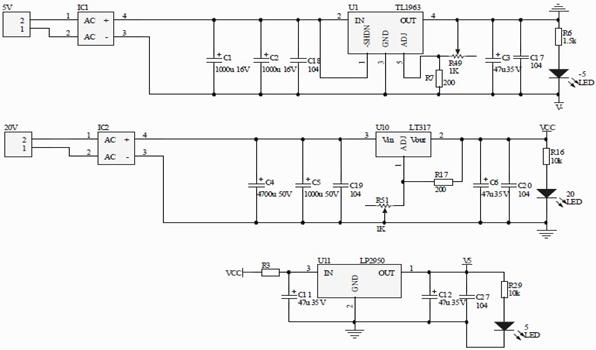

Device for measuring multi-passage heat conductivity

InactiveCN101881742AAccurate measurementOvercoming the disadvantages of low work efficiencyMaterial heat developmentThermometers using electric/magnetic elementsMicrocontrollerClosed loop feedback

The invention relates to a device for measuring the multi-passage heat conductivity, comprising two paths of independent power modules, an upper computer, a main control module, a photon coupled isolation module, a heat pulse control and excitation module, a multi-passage control module and a temperature collection module. The upper computer is respectively connected with a singlechip of the main control module and a multimeter in the temperature collection module through a USB; each I / O in the singlechip is respectively connected with the heat pulse control and excitation module, the multi-passage control module and the temperature collection module after being subjected to photo coupled isolation; the device is provided with two constant-current source circuits and adopts closed loop feedback to realize power constant value output; the multi-passage control module comprises a heating module and a measuring module which both have eight paths of passages; and the main control module selects any passage for collecting, preserving and calculating data in real time. The device has the advantages of convenient measurement, little error, high efficiency, and the like, meets the requirement of high-precision heat conductivity test, and can be further used for testing and researching the heat conductivity of solid body, powder, biological tissue, and the like.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

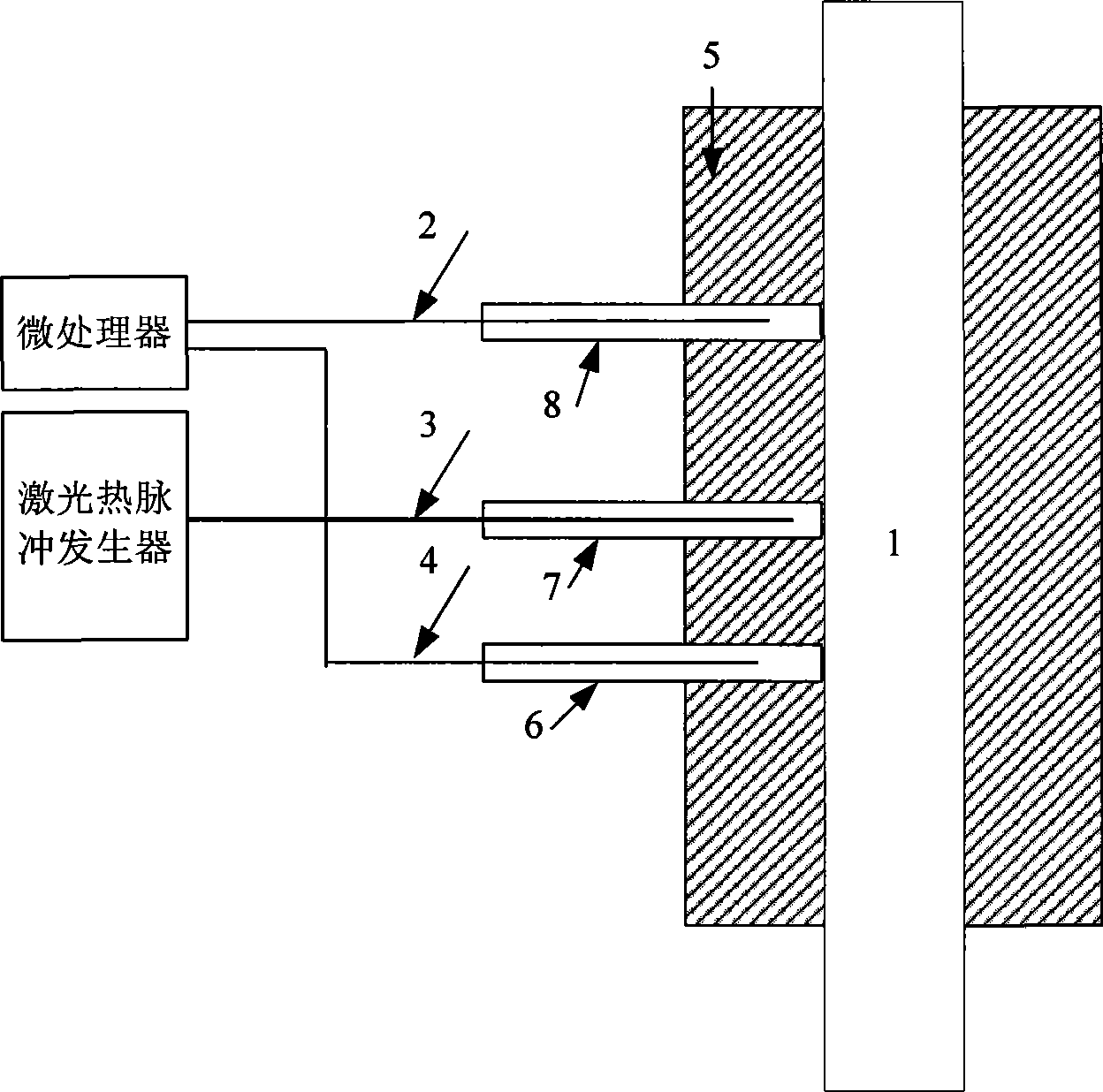

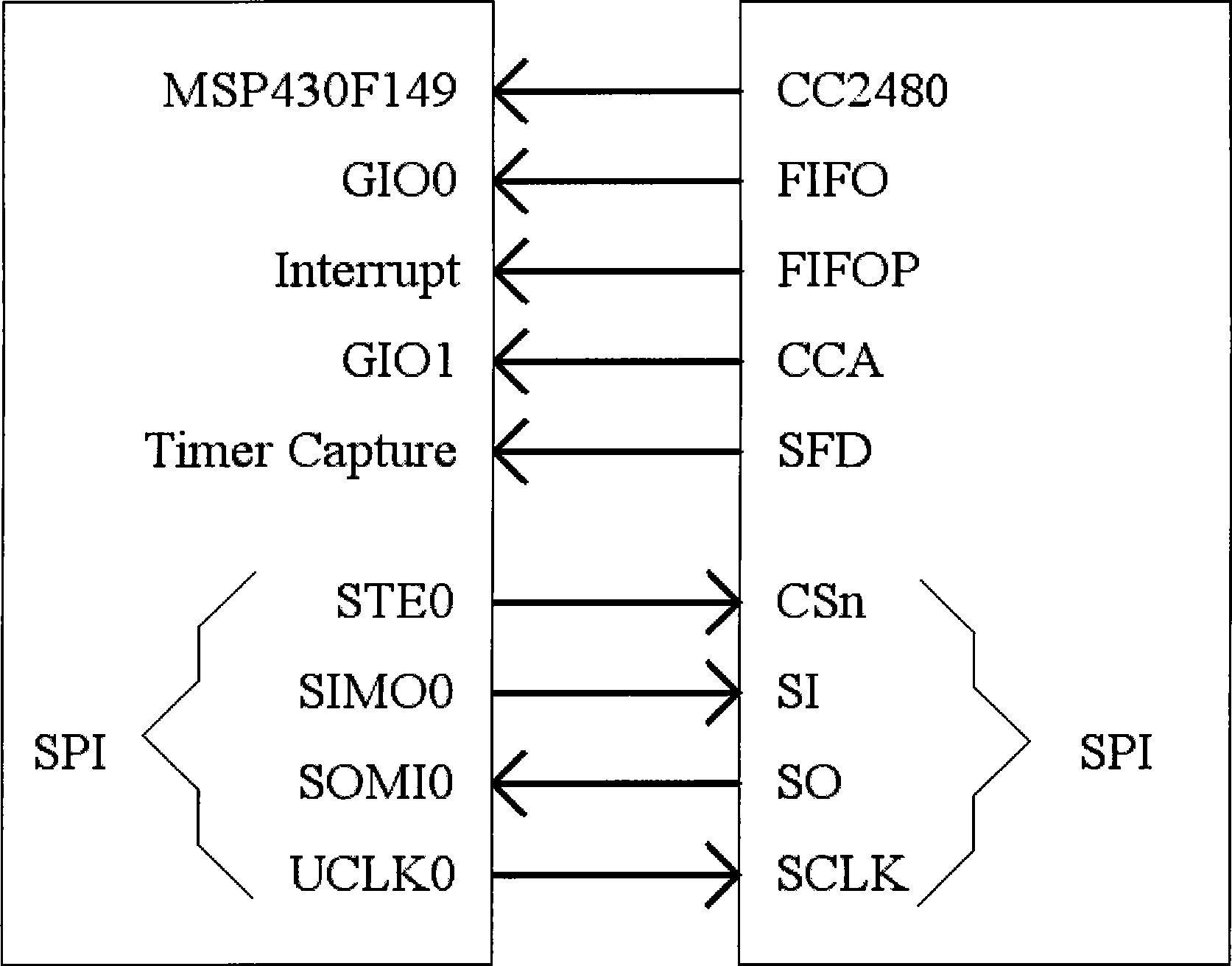

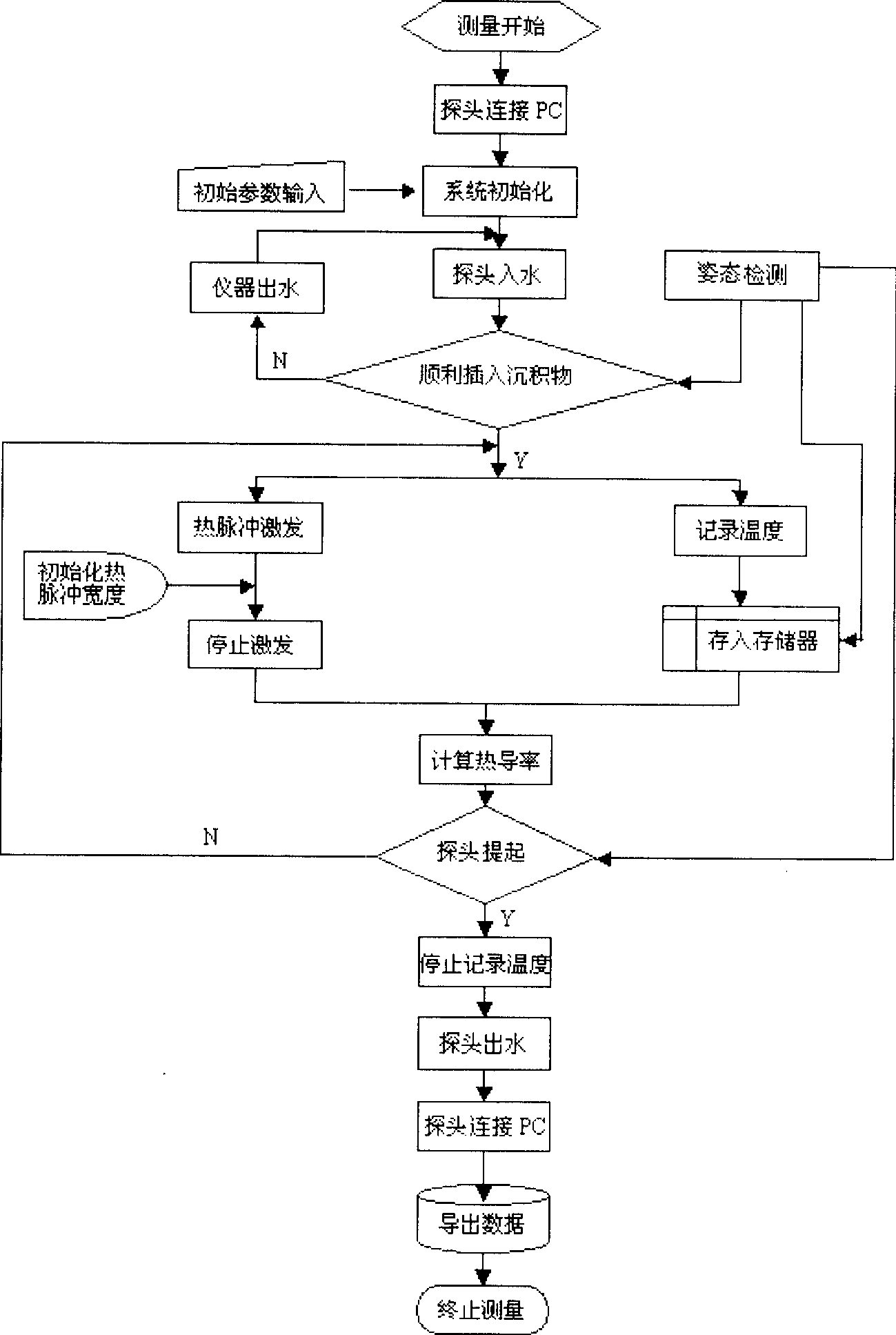

Wireless plant stem flow detection device based on laser heat pulse

InactiveCN101413815ACan respond to physiological characteristicsResponse Physiological CharacteristicsVolume/mass flow by thermal effectsVoltage converterWireless data

The invention discloses a wireless plant stem flow detection device based on a laser heat pulse. The wireless plant stem flow detection device comprises a microprocessor, a laser heat pulse generator, a stem flow sensor, a calendar chip, a voltage converter, a power supply, a wireless communication module, a keyboard, an LCD module, an RS232 interface and a USB interface module. The laser heat pulse is taken as the heat pulse of the stem flow sensor, and temperature is detected by an infrared temperature probe, the contact of the detected stem with the detection device is avoided by the heat source and the detection method, thus reducing the impact on the stem. Two infrared temperature probes are respectively arranged at the upper side and the lower side of an optical fiber, are inserted into foam enwinding the plant stem to be detected and do not contact the stem; the two infrared temperature probes are respectively connected with the microprocessor, and the optical fiber is connected with the laser heat pulse generator. A wireless data communication method of ZigBee communication protocol is employed to facilitate the device installation and the data acquisition. The wireless plant stem flow detection device can be used for measuring the stem flow of herbaceous plants or smaller stems.

Owner:ZHEJIANG UNIV

Liquid drop emitter with split thermo-mechanical actuator

InactiveUS7025443B2Low energy inputReduce resistancePrintingElectrical resistance and conductanceThermal expansion

An apparatus for a liquid drop emitter, especially for use in an ink jet printhead, is disclosed. A chamber filled with a liquid, a nozzle and a thermo-mechanical actuator, extending into the chamber from at least one wall of the chamber is disclosed. A movable element of the thermo-mechanical actuator is configured with a bending portion which bends when heated, the bending portion having at least one actuator opening for passage of the liquid. Apparatus is adapted to apply heat pulses to the bending portion resulting in rapid deflection of the movable element, ejection of a liquid drop, and passage of liquid through the at least one actuator opening. A movable element configured as a cantilever or as a beam extending from anchor walls of the chamber is disclosed. The thermo-mechanical actuator may be formed as a laminate structure including a layer constructed of a deflector material having a high coefficient of thermal expansion and that is electrically resistive, for example, titanium aluminide. Apparatus adapted to apply heat pulses comprising a resistive heater formed in the deflector material in the bending portion is also disclosed.

Owner:EASTMAN KODAK CO

Measurer for oceanic sediment thermal conductivity in-situ measuring system

InactiveCN1837798AHigh measurement accuracyShorten the timeMaterial thermal conductivityMaterial heat developmentOcean bottomMeasurement device

This invention relates to a measurer for oceanic sediment thermal conductivity in-situ measuring system, which comprises: a measuring probe, an attitude detection circuit, a thermal impulse excitation circuit, a temperature collection circuit, a CPU, I / O, and a memory. Wherein, the measuring device comprises: a. a memory; b. an input device; c. a detection device; d. a calculation device to calculate the thermal conductivity by formula k=0.029275*Q / (Tmtm) and store the data in an EFPROM; e. an output device. This device improves measurement precision by filter, high-bit A / D conversion and complex algorithm, cuts time to 1~2min, and has simple structure with light weight for convenient communication.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

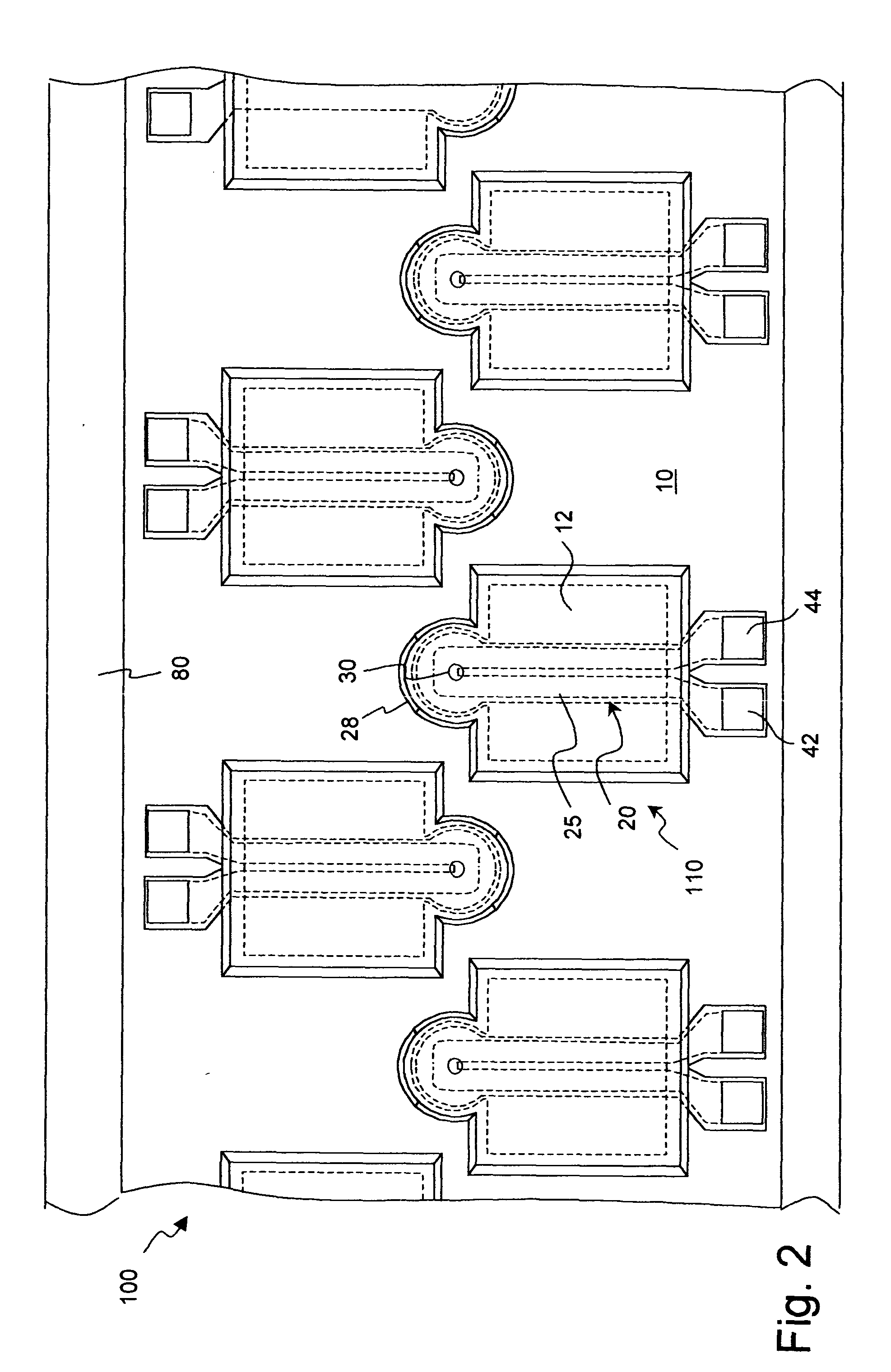

Doubly-anchored thermal actuator having varying flexural rigidity

InactiveUS7175258B2Large force magnitude and accelerationPrintingElectricityElectrical resistance and conductance

A doubly-anchored thermal actuator for a micro-electromechanical device such as a liquid drop emitter or a fluid control microvalve is disclosed. The thermal actuator is comprised of a base element formed with a depression having opposing anchor. A deformable element, attached to the base element at the opposing anchor edges, is constructed as a planar lamination including a first layer of a first material having a low coefficient of thermal expansion and a second layer of a second material having a high coefficient of thermal expansion. The deformable element has anchor portions adjacent the anchor edges and a central portion between the anchor portions wherein the flexural rigidity of the anchor portions is substantially less than the flexural rigidity of the central portion. The doubly-anchored thermal actuator further comprises apparatus adapted to apply a heat pulse to the deformable element that causes a sudden rise in the temperature of the deformable element. The deformable element bows outward in a direction toward the second layer, and then relaxes to a residual shape as the temperature decreases. The doubly-anchored thermal actuator is configured with a liquid chamber having a nozzle or a fluid flow port to form a liquid drop emitter or a fluid control microvalve, or to activate an electrical microswitch. Heat pulses are applied to the deformable element by resistive heating or by light energy pulses.

Owner:ABLECO FINANCE LLC AS AGENT +1

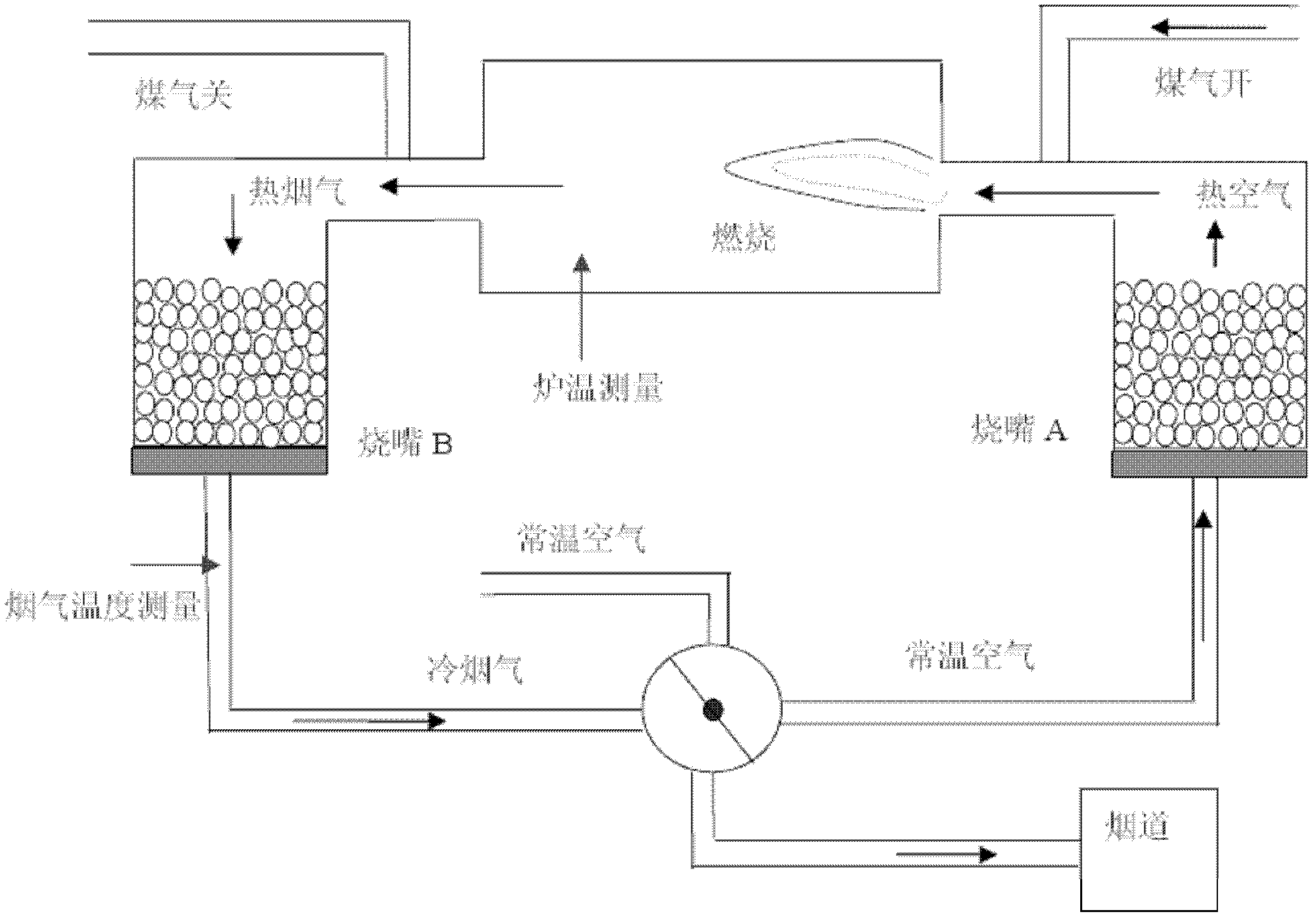

Combustion control method for regenerative pulse heating furnace

ActiveCN103256625AImprove combustion efficiencyImprove product qualityCombustion regulationCombustionFlue gas

The invention discloses a combustion control method for a regenerative pulse heating furnace. The combustion control method includes acquiring a set flow value of a current section and a flow grading threshold table specified by a technology, dividing the set flow value by the maximum flow value of the current section to acquire a set flow percentage, comparing the set flow percentage to the flow grading threshold table and determining a current new flow grade and the number of pairs of operating burners; computing a flue gas temperature curve corresponding to a given regenerative reversal cycle by the aid of a regenerative box model according to standard flue gas flow and the furnace gas temperature which correspond to the new flow grade; performing interpolation according to the regenerative box flue gas temperature specified by the technology and the flue gas temperature curve to determine a regenerative reversal cycle corresponding to the flue gas temperature; determining the number of operating burners, the total number of available burners in the section and a regenerative reversal cycle in the section according to the new flow grade and determining a regenerative pulse cycle and a grouping rolling process; and performing regenerative combustion control and regenerative pulse logic control according to the regenerative reversal cycle, the regenerative pulse cycle and the grouping rolling process.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for measuring thermal conductivity

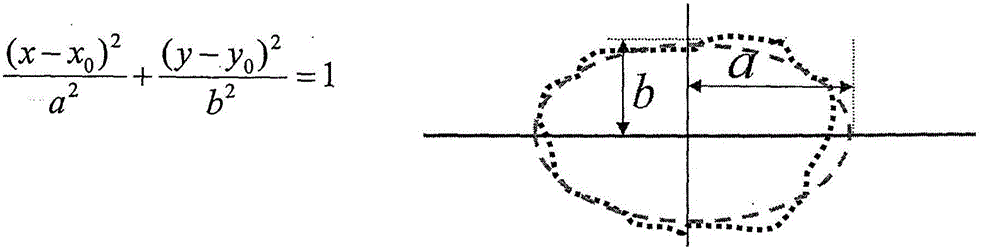

InactiveCN104040327AReduced measurement timeHigh precisionMaterial thermal conductivityMaterial heat developmentHeat pulseThermal conductivity

A method for measuring thermal conductivity of a material contains the now described steps. A heat pulse is applied to a front side of the material. The resulting time-dependent two-dimensional temperature field of the front side of the material is detected using an infrared detector. An isotherm is identified in the temperature field. First and second thermal conductivities of the material in first and second directions of the material are calculated on the basis of the shape of the isotherm and on the basis of first and second temperatures detected at one point of the front side of the material at two points in time.

Owner:SGL CARBON SE

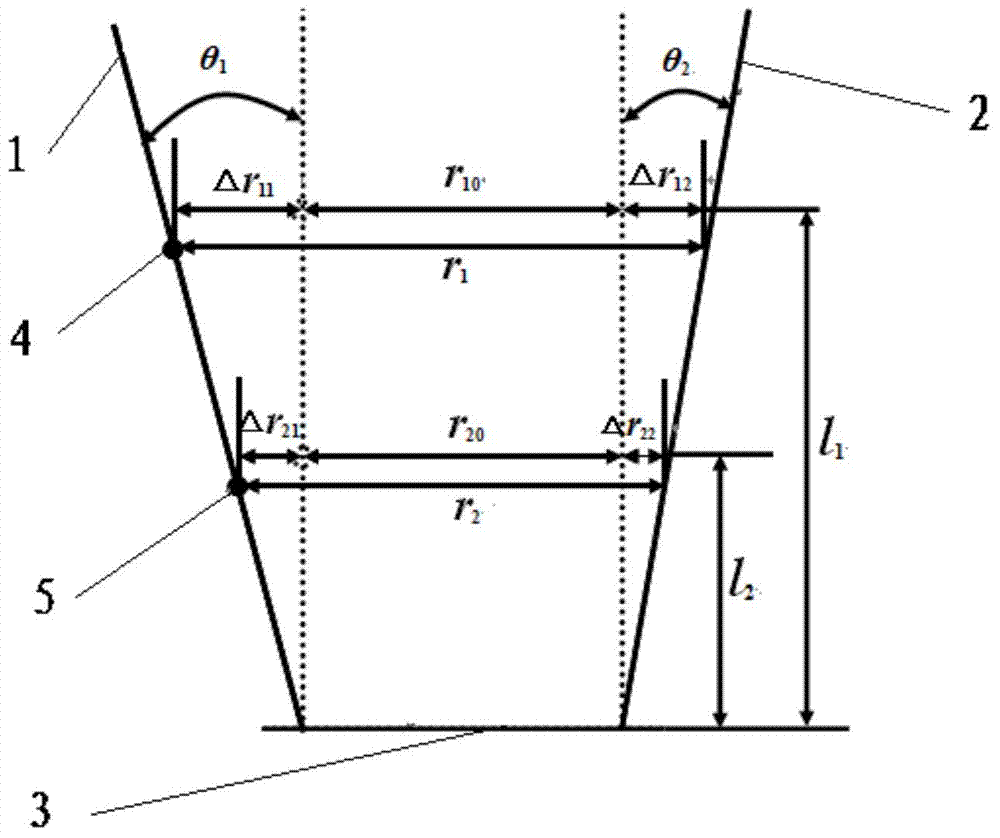

Double-probe heat-pulse thermal-property measure apparatus capable of realizing spacing in-field self correcting and method

InactiveCN103713011AHigh precisionReduce measurement errorMaterial heat developmentMeasurement deviceTwo temperature

The invention belongs to the technical field of measure, and especially relates to a double-probe heat-pulse thermal-property measure apparatus capable of realizing spacing in-field self correcting and a method. The double-probe heat-pulse thermal-property measure device capable of realizing spacing in-field self correcting comprises a pedestal, and a temperature probe and a heating probe both fixedly disposed on the pedestal, and is characterized in that the length / internal diameter of the temperature probe and the heating probe is larger than 25, two temperature-measuring elements are arranged in the temperature probe along the axial direction of the temperature probe, and the two temperature-measuring elements and the heating probe are all connected with an external-connection device. By employing the two temperature-measuring elements, the provided measure apparatus and the measure method help to reduce the specific heat measurement error caused by bending deformation of the probes in practical application. Additionally, the apparatus is simple in structure, low in cost, convenient to use and rapid and accurate for measurement.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com