Non-invasive heat pulse stem flow gauge

A non-invasive, thermal pulse technology, used in the application of thermal effects to detect fluid flow, calorimeters, measure heat, etc., can solve the problem of high requirements for the use environment of temperature sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

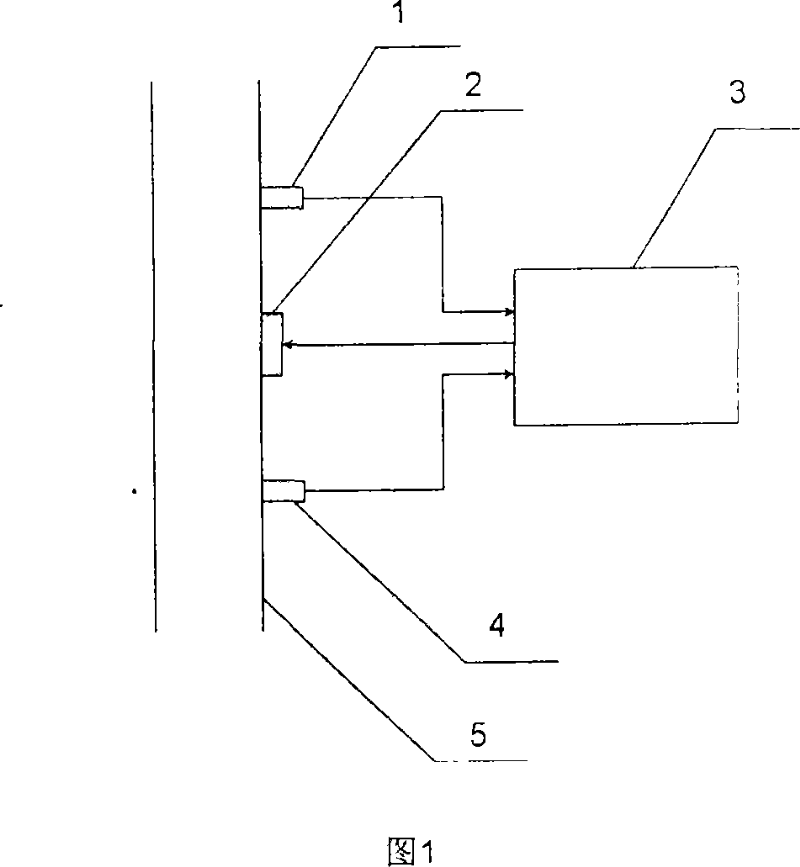

[0014] Refer to accompanying drawing 1. The principle of the non-invasive thermal pulse sap flow meter of the present invention is shown in Figure 1. It includes a heating element 2 and a differential amplification and signal control processing circuit 3 arranged on the surface of the plant 5. The sap flow meter is placed on the heating element. Downstream of the sap flow at the location, a downstream temperature sensor 1 is provided, and the sap flow meter is provided with an upstream temperature sensor 4 paired with the downstream temperature sensor at the upstream of the sap flow at the location of the heating element, and the paired upstream temperature sensor It is connected with the downstream temperature sensor and the differential amplification and signal control processing circuit.

[0015] In the present invention, since the sap flow moves from the root to the top of the plant, we define the root of the plant as upstream and the top of the plant as downstream.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com