Heat pulse time difference type flow detection method

A technology of flow detection and thermal pulse, which is applied in mass flow measurement devices, indirect mass flow meters, etc., can solve the problems of high energy consumption and sensor loss, increase the measurement range, and move the saturation point of the curve backward, so as to reduce loss, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

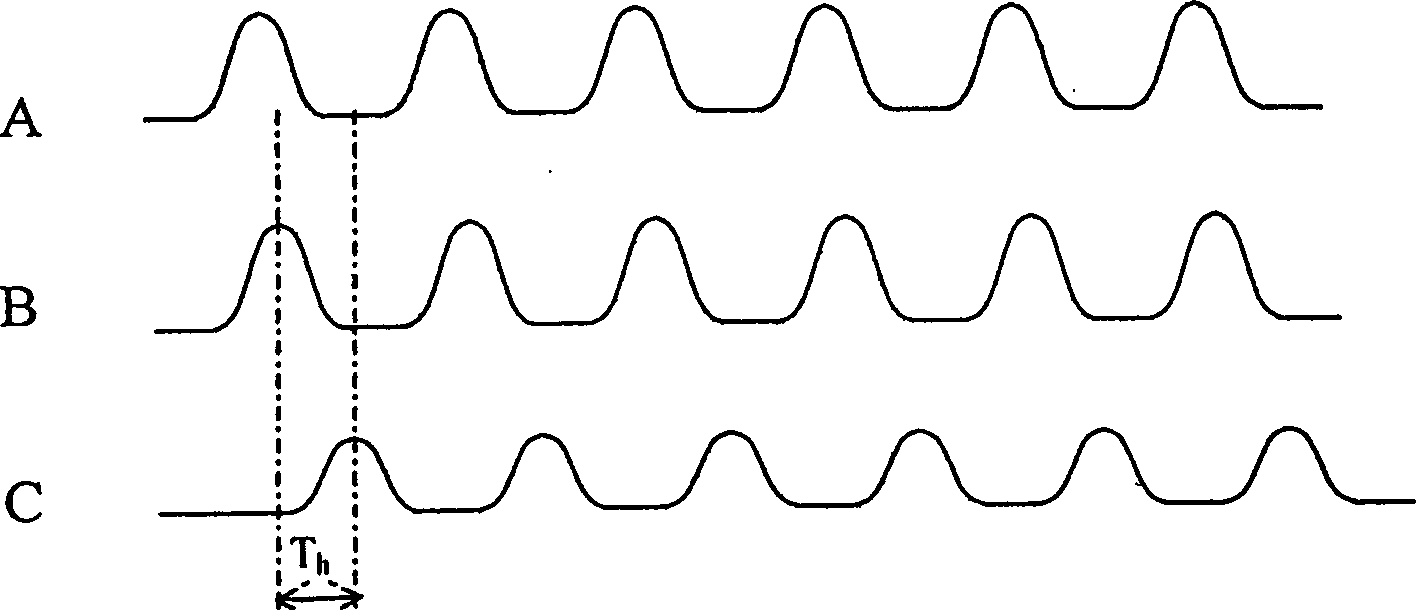

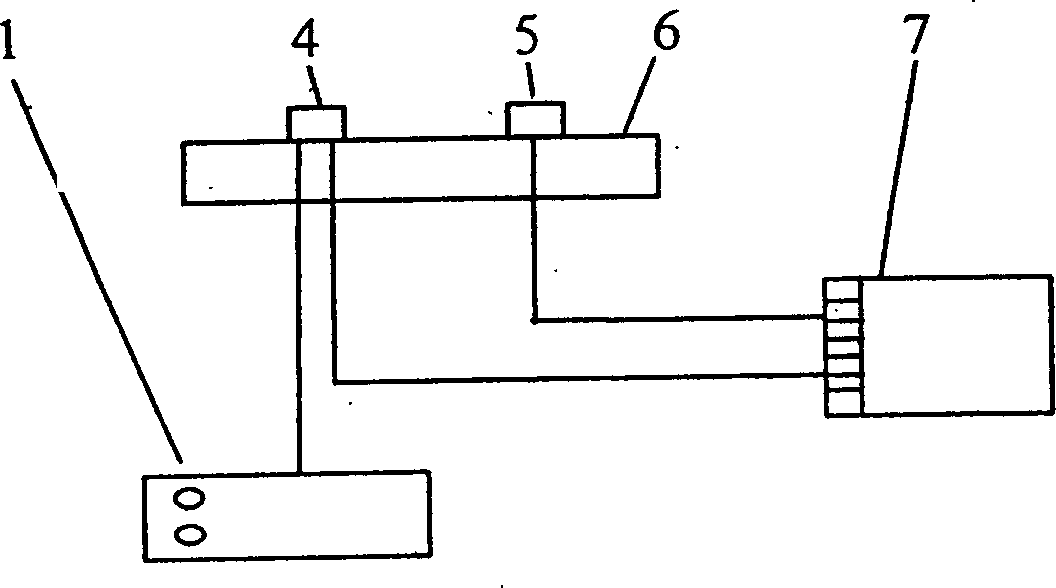

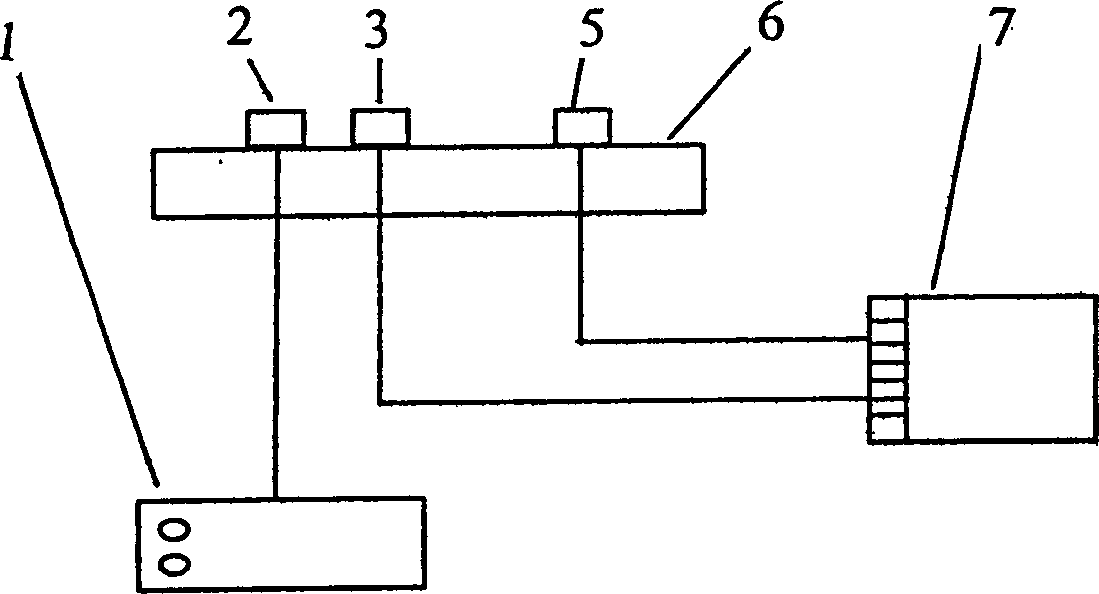

[0022] 1. Thermal pulse time-difference flow detection method, such as figure 1 Shown:

[0023] 1) Put the sensor into the pipeline parallel to the direction of flow velocity, and use the pulse power supply to provide pulse power supply to the heating temperature measuring element or heating element, and the heating signal is the heating pulse input signal A; generated in the heating temperature measuring element or heating element The pulse current is measured, and the temperature change of the heating temperature measuring element or the temperature measuring element representing the temperature of the heating element is measured to obtain a pulse curve, that is, the output signal curve B of the heating temperature measuring element or the temperature measuring element representing the temperature of the heating element;

[0024] 2) Measure the temperature change of the temperature measuring element downstream of the heating temperature measuring element or the temperature m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com