Microfabricated structures and processes for manufacturing same

a microfabricated structure and mold technology, applied in microstructural technology, microelectromechanical systems, microelectroforming processes, etc., can solve the problems of serial processing, high cost of devices, and many limitations of the surface exposed to fluids and/or biological samples, so as to minimize the roughness of the surface of the microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

”.

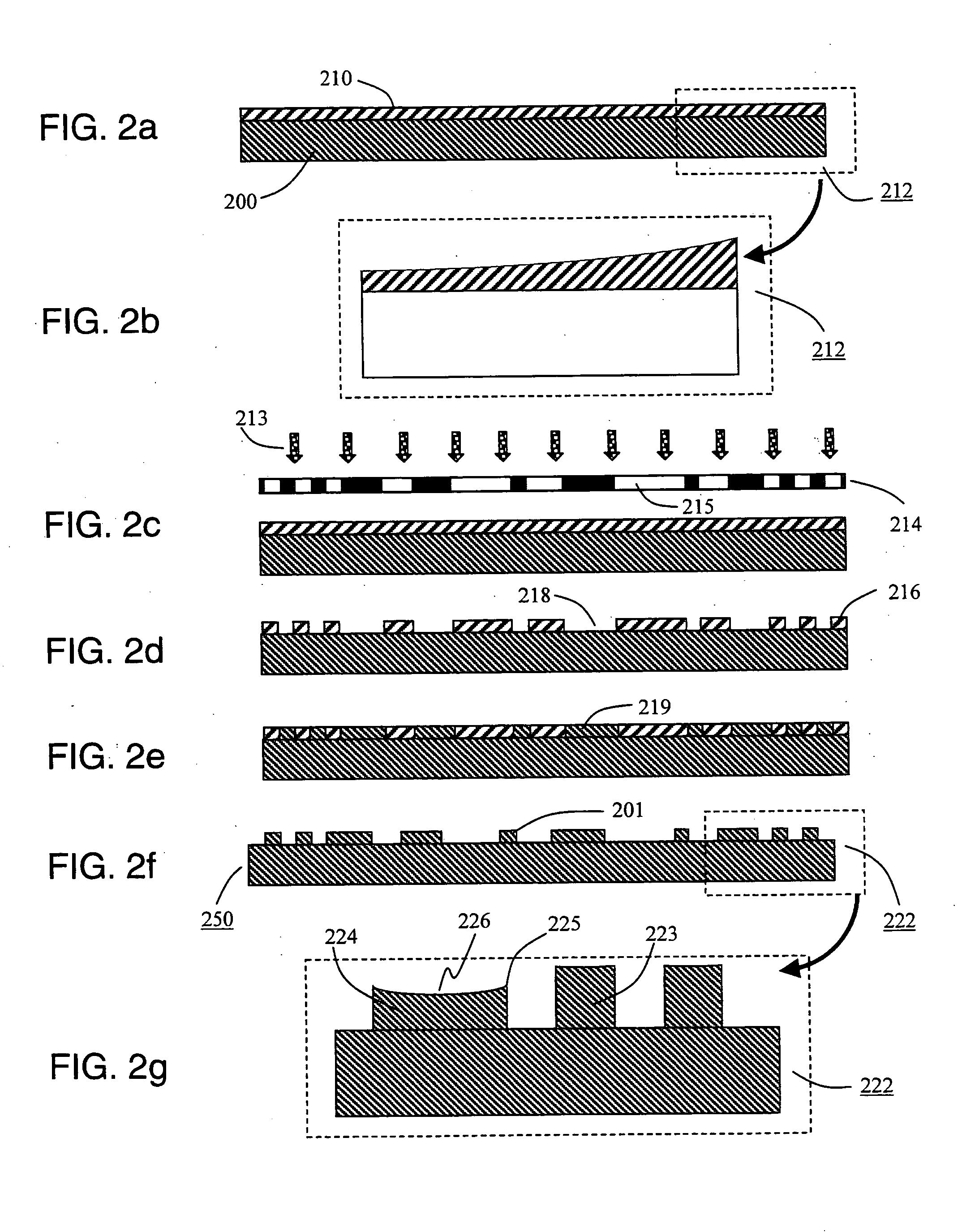

[0020] Certain embodiments of the present invention provide an elegant solution to creating a negative image of an array of Piano-Convex microlenses on a master mold and subsequently replicating the Plano-Convex lens array structure on the plastic substrate.

[0021] Embodiments of the present invention overcome the deficiencies and inadequacies in the prior art as described in the previous section and as generally known in the industry.

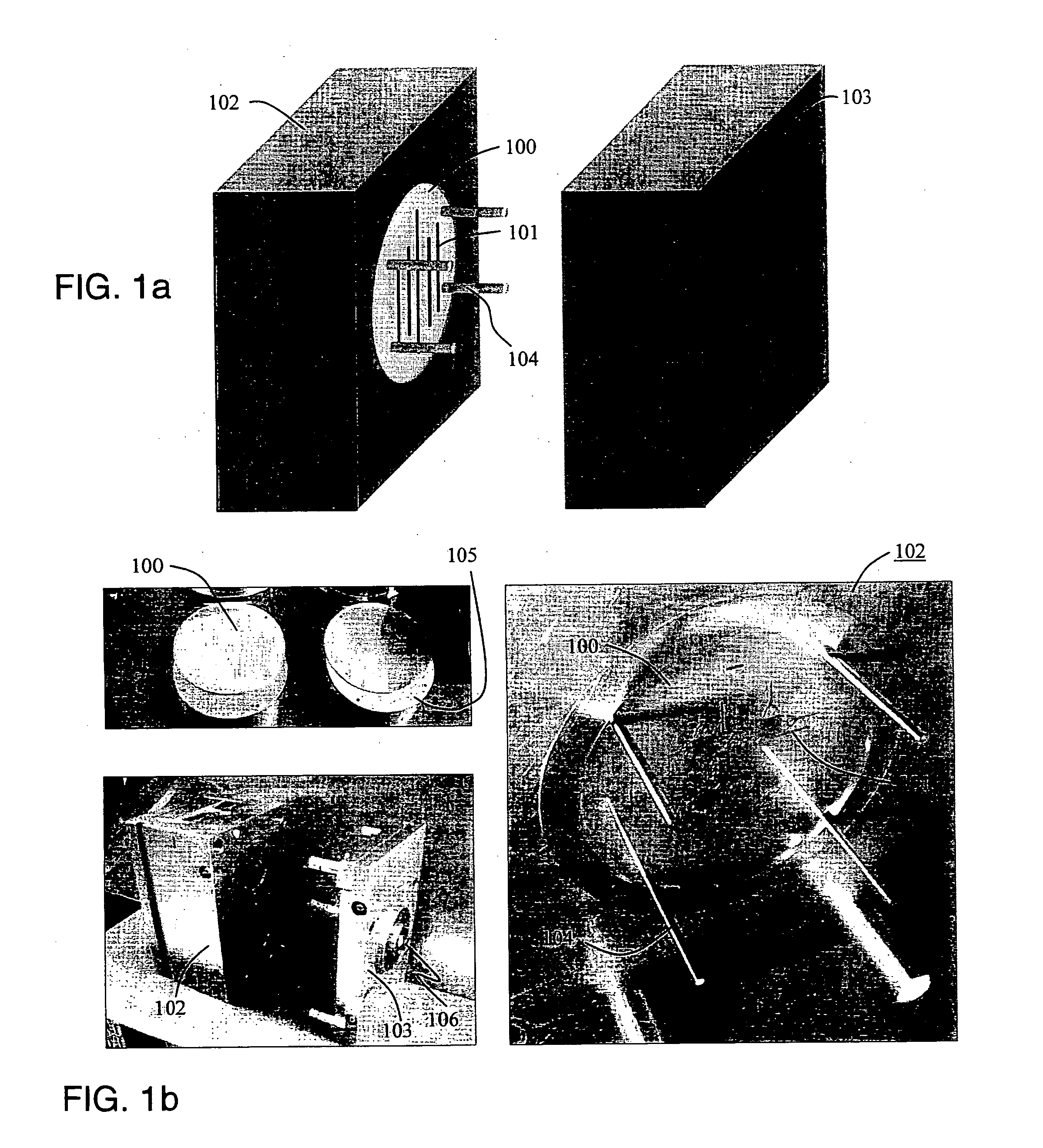

[0022] Certain embodiments of the present invention are concerned with developing a master mold for plastic replication, wherein the master mold is a discrete component, which can be easily assembled into the injection mold block for plastic replication.

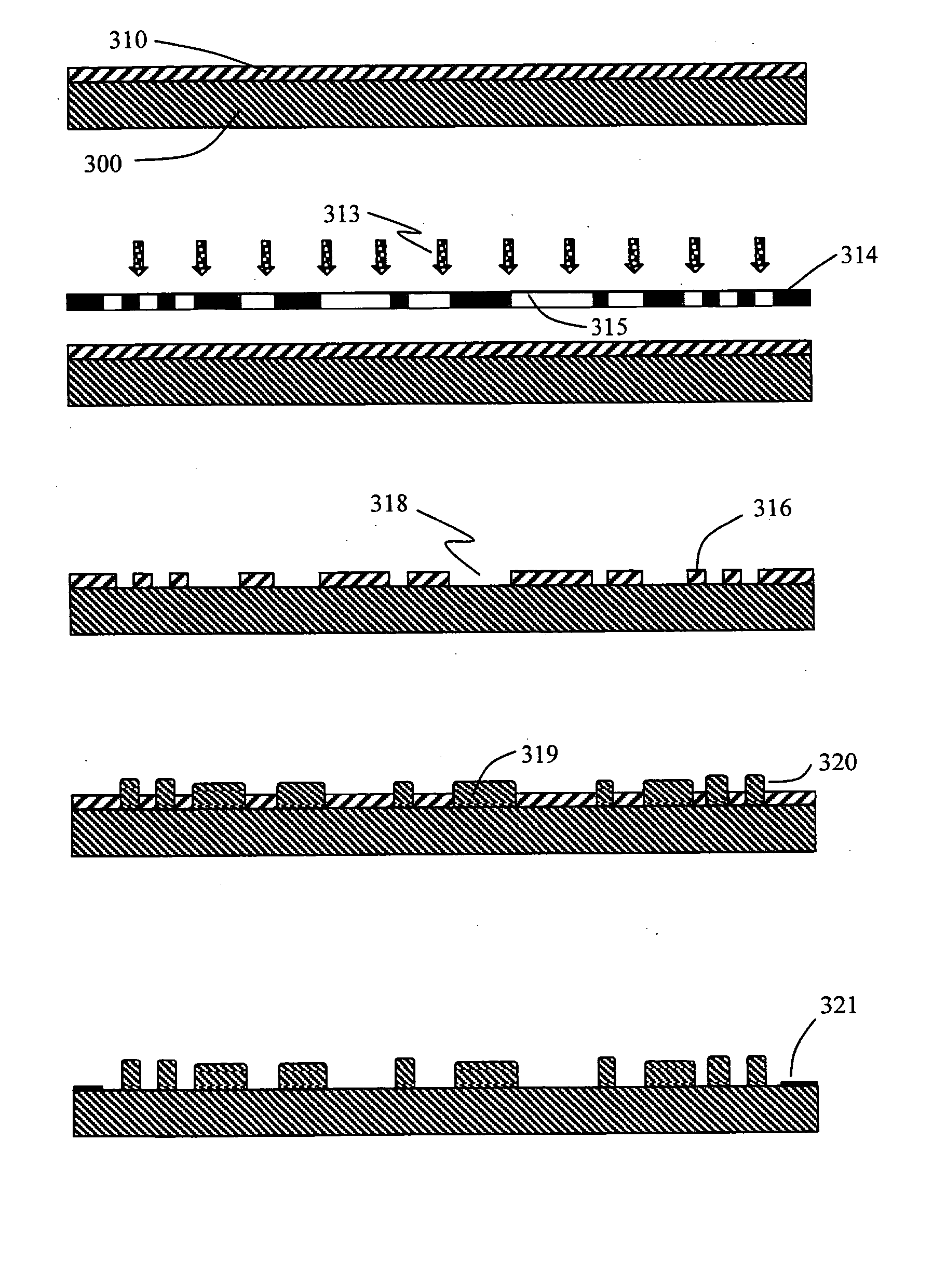

[0023] Certain embodiments of the present invention are concerned with developing a master mold using a modified UV-LIGA fabrication process, specifically the two-step electroplating process with one of the electroplating used for sacrificial metal deposition, to create master molds with microstruct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

| Microstructure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com