Minitype metal nickel mould producing method

A production method and technology of metal nickel, applied in the direction of metal material coating process, microstructure technology, microstructure device, etc., can solve the problems of low production efficiency, high production cost, complicated micro-mold production process, etc., and achieve low production cost , high productivity and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

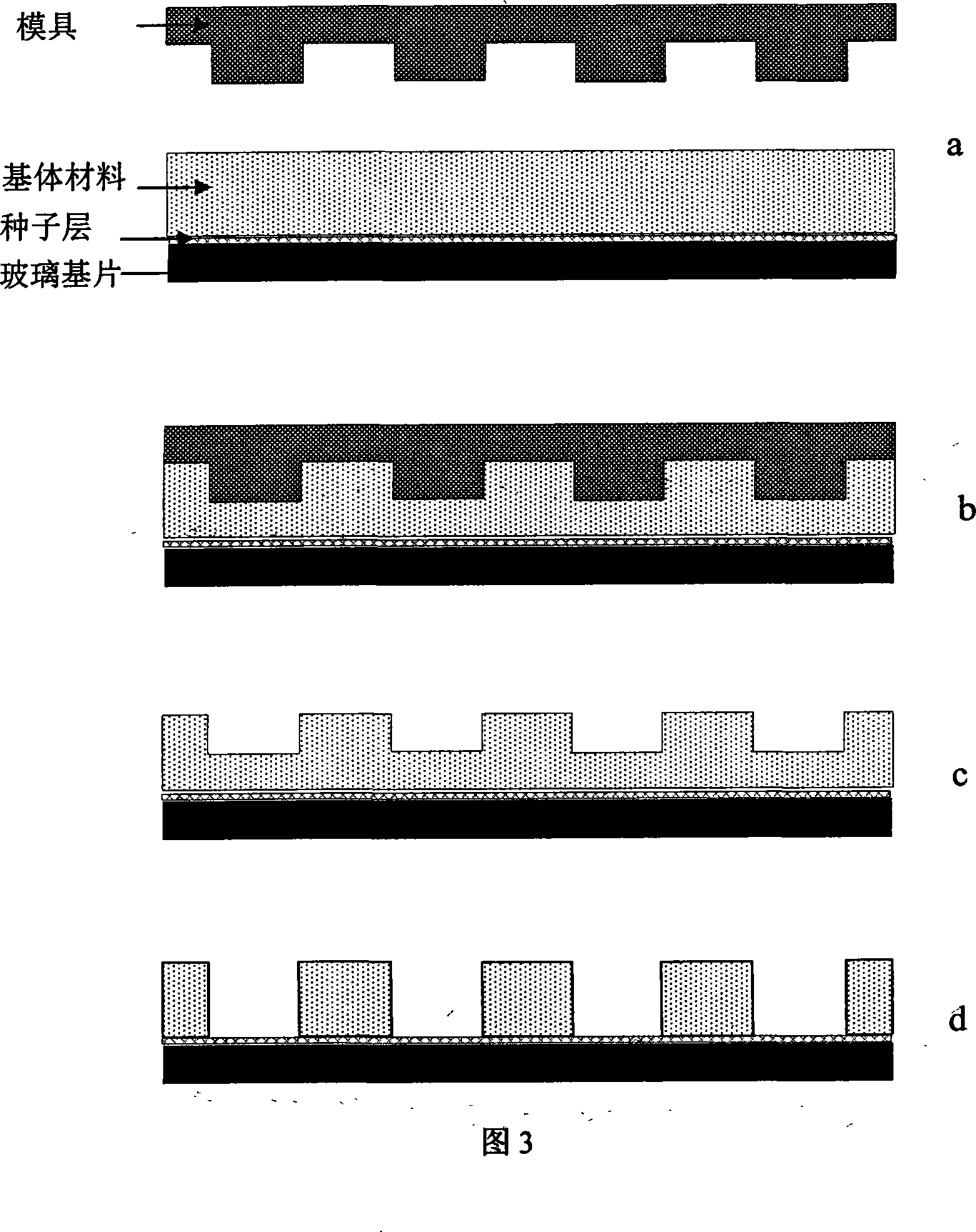

[0041] Refer to Figure 1 for the technical route of preparing micro-nickel metal molds based on the composite process of ultraviolet nanoimprinting and micro-electroforming, including: ①mastering; ②substrate pretreatment; ③sputtering seed layer; ④UV nanoimprinting; ⑤ Deposition of the seed layer; ⑥ electroplating nickel deposition; ⑦ additional metal backing; ⑧ demoulding.

[0042] 1) Mastering

[0043] Using the electron beam direct writing lithography system, due to its ability to continuously change its exposure dose along with the point exposure scanning path, it is possible to obtain continuously varying exposure depths on the electron photoresist. Utilizing this characteristic, three-dimensional micro-nano structures can be formed on electronic photoresists. Therefore, the master plate containing the mold cavity microstructure was prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com