Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

190 results about "Batch fabrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods of forming oxide masks with submicron openings and microstructures formed thereby

ActiveUS20050124135A1High process yieldHigh quality factorSemiconductor/solid-state device manufacturingMicrostructural device manufactureSingle crystalPhotolithography

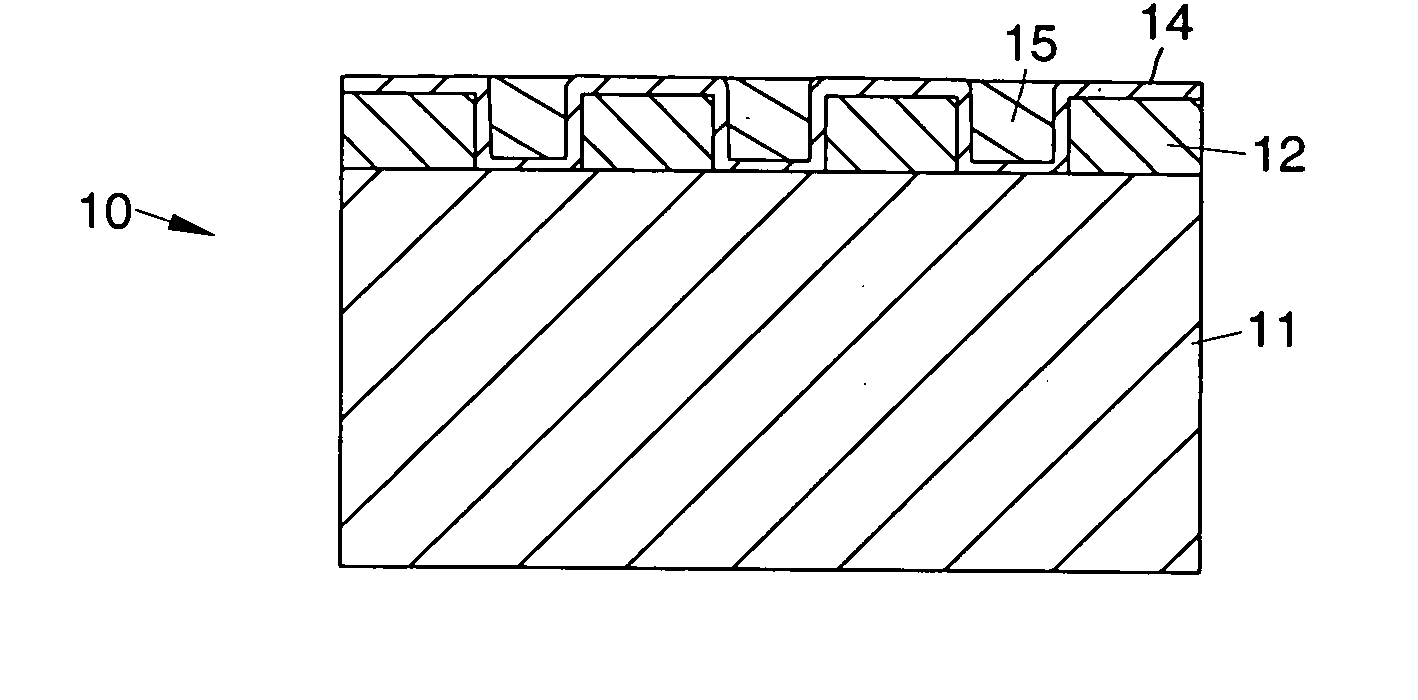

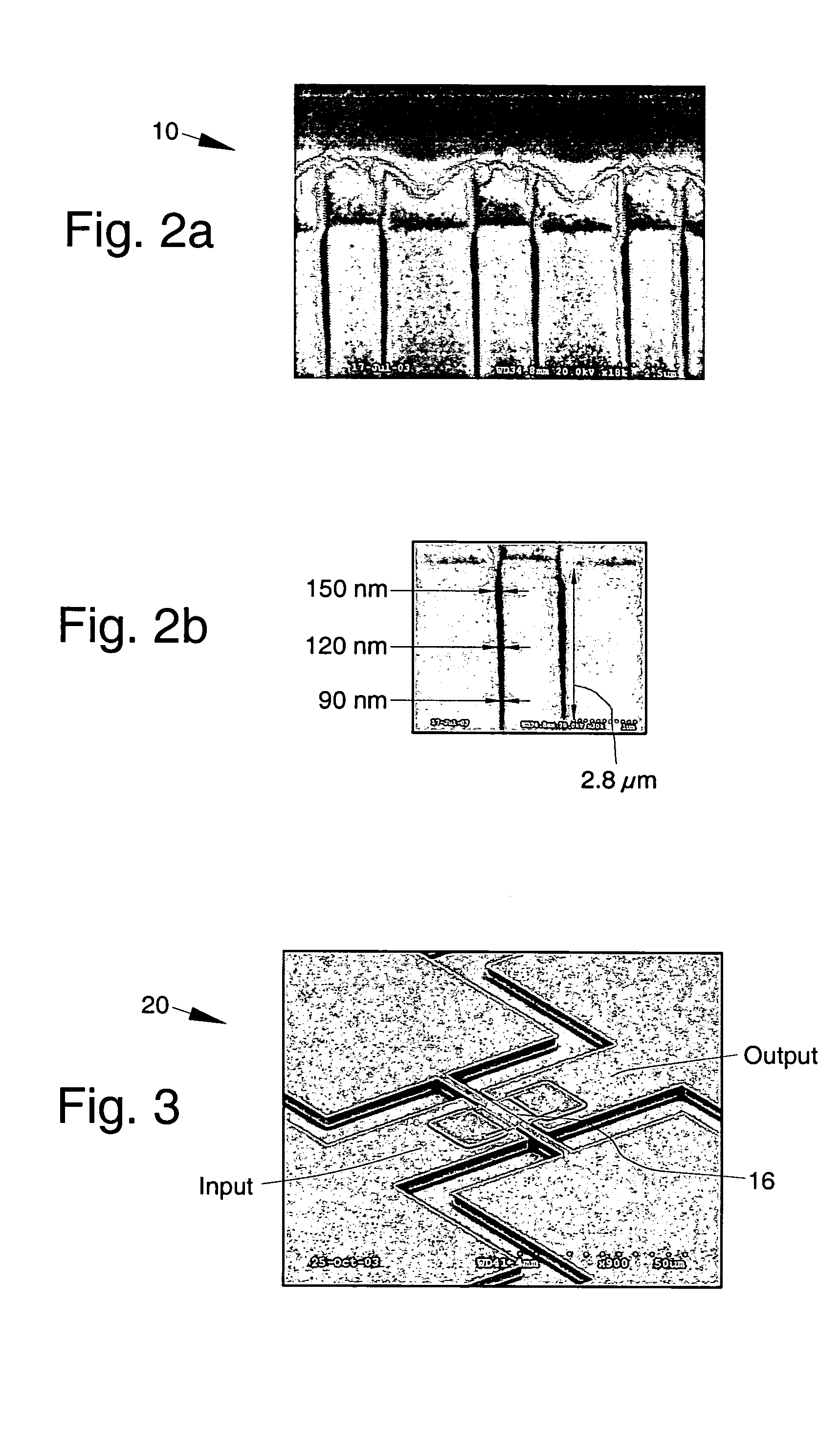

Processing techniques are disclosed for batch fabrication of microstructures comprising an oxide mask on a substrate with submicron openings formed therein, and microstructures having deep-submicron, high aspect-ratio etched trenches, using conventional optical photolithography. Exemplary high aspect-ratio etched-trench microstructures that may be produced include single crystal resonators and sensors.

Owner:GEORGIA TECH RES CORP

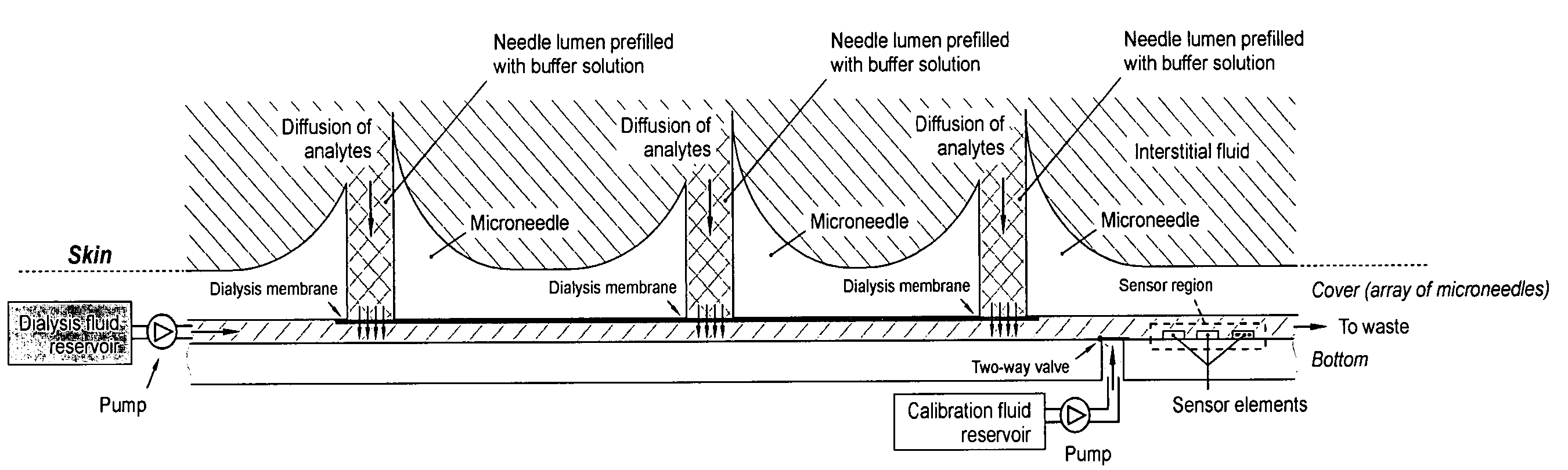

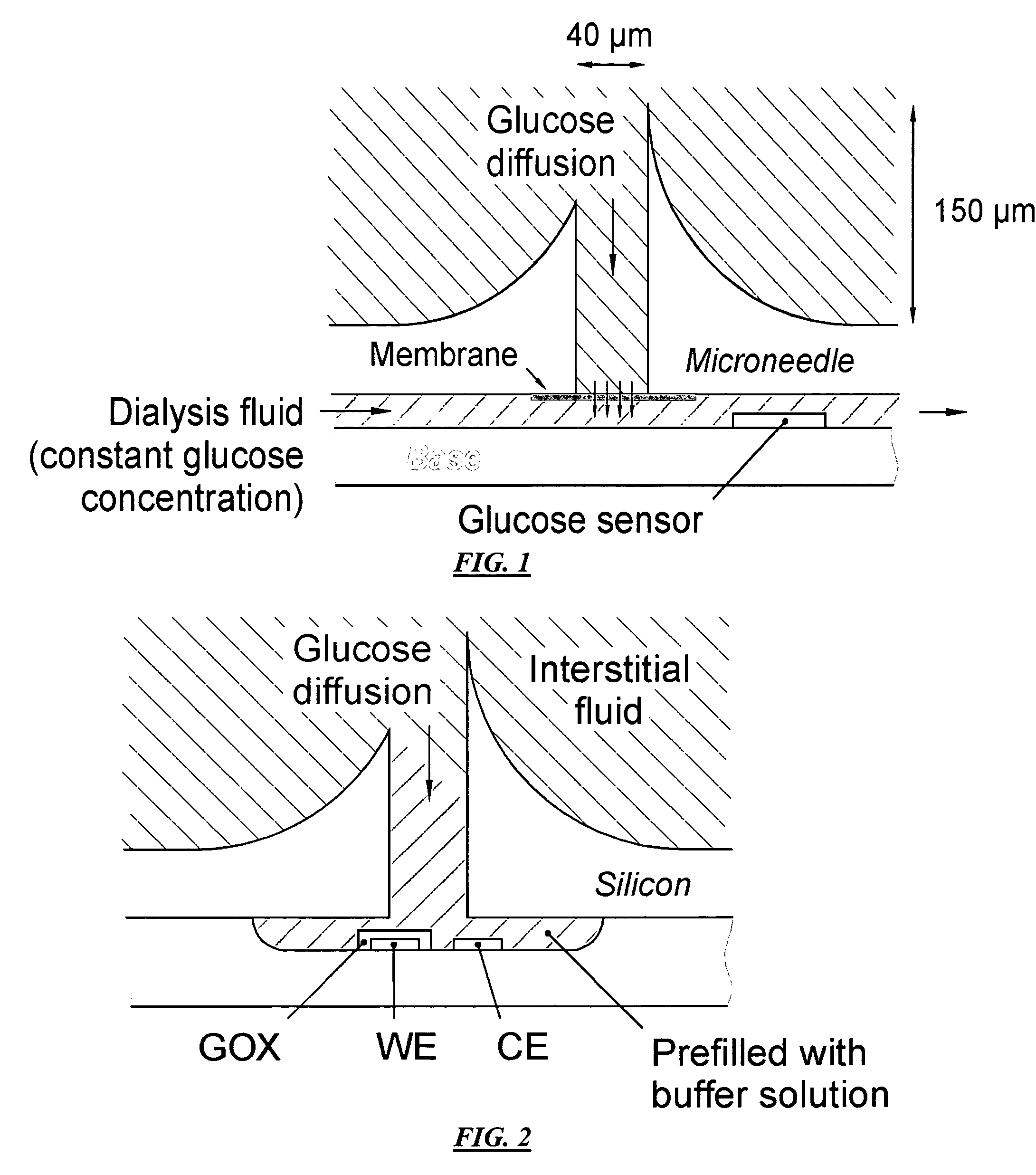

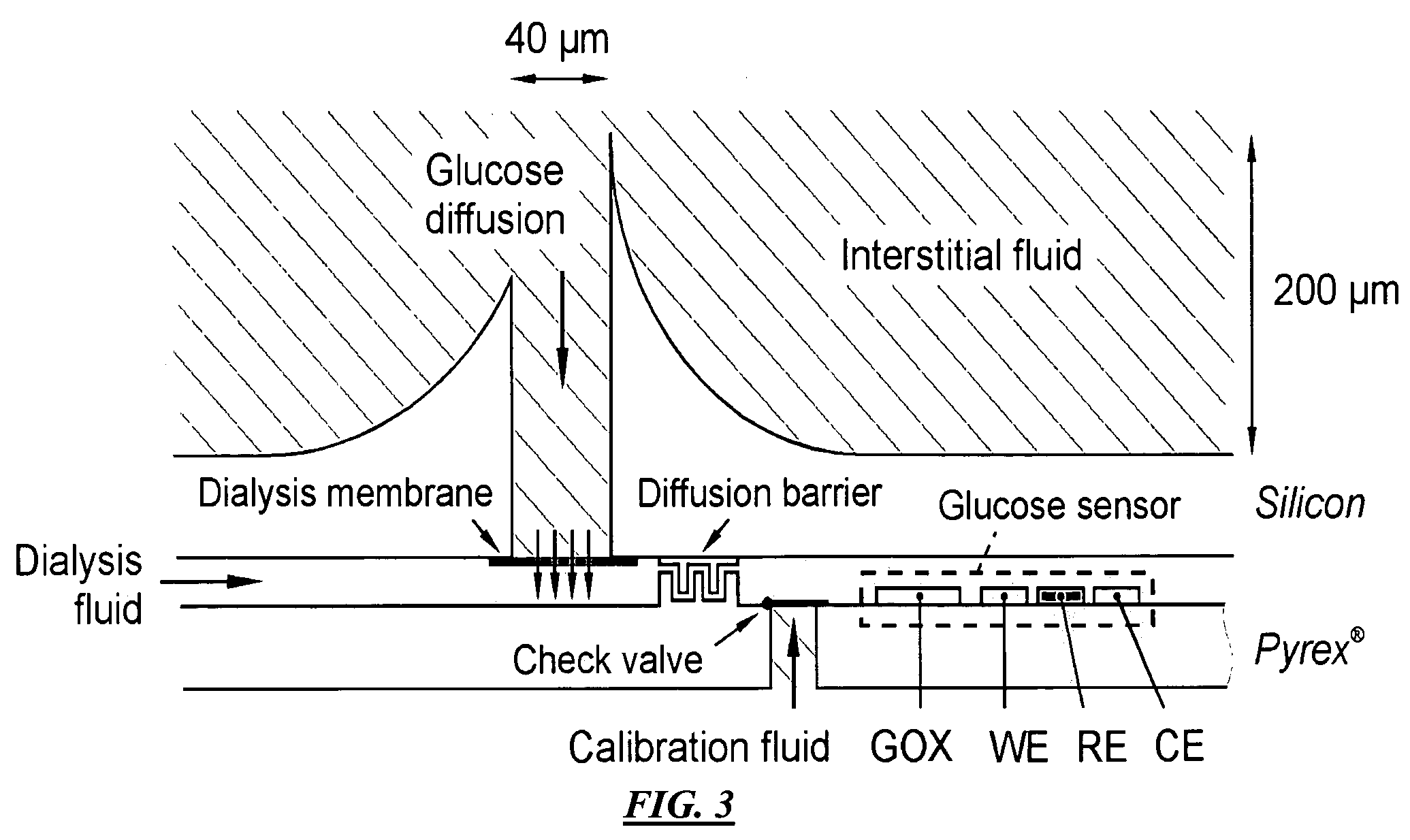

Monitoring method and/or apparatus

ActiveUS20060211933A1Easy recalibrationMinimally invasiveSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisDialysis membranesContinuous glucose monitoring

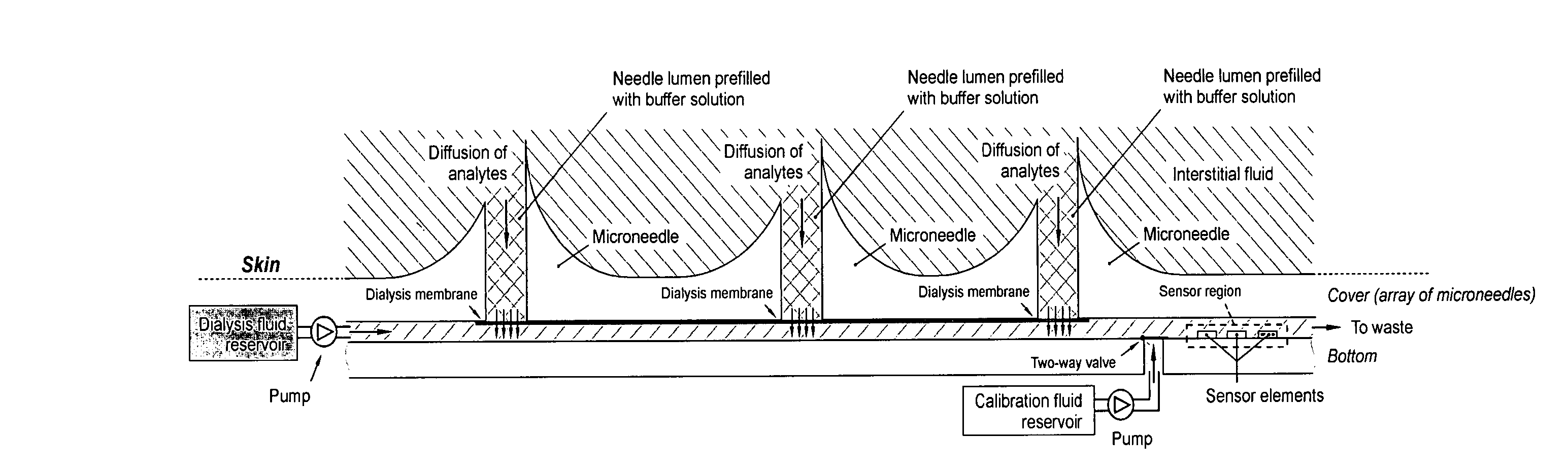

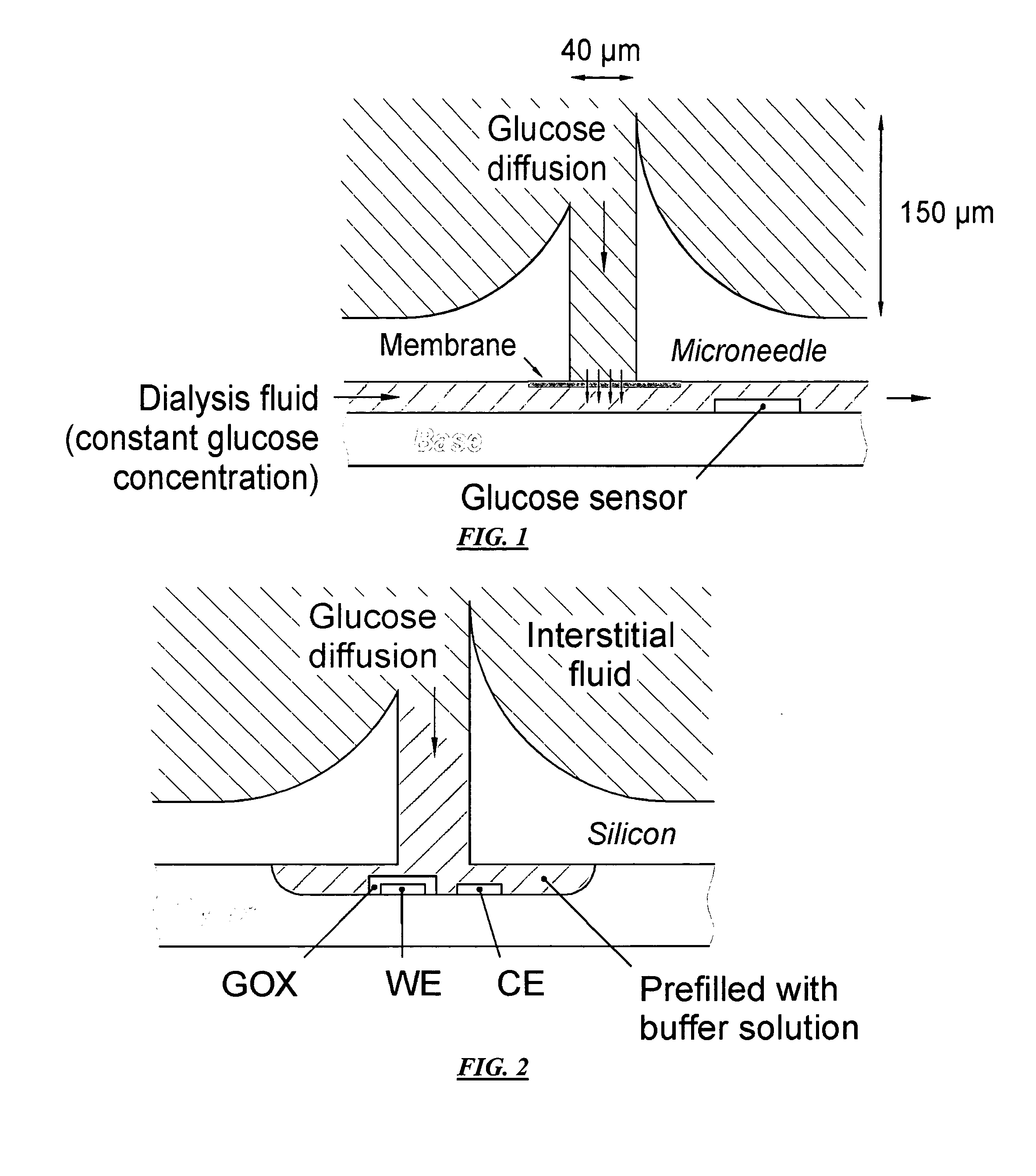

A method and apparatus for substance monitoring. One application is an easy to handle continuous glucose monitor using a group of hollow out-of-plane silicon microneedles to sample substances in interstitial fluid from the epidermal skin layer. The glucose of the interstitial fluid permeates a dialysis membrane and reaches a sensor. Using MEMS technology, for example, allows well-established batch fabrication at low cost.

Owner:RGT UNIV OF CALIFORNIA

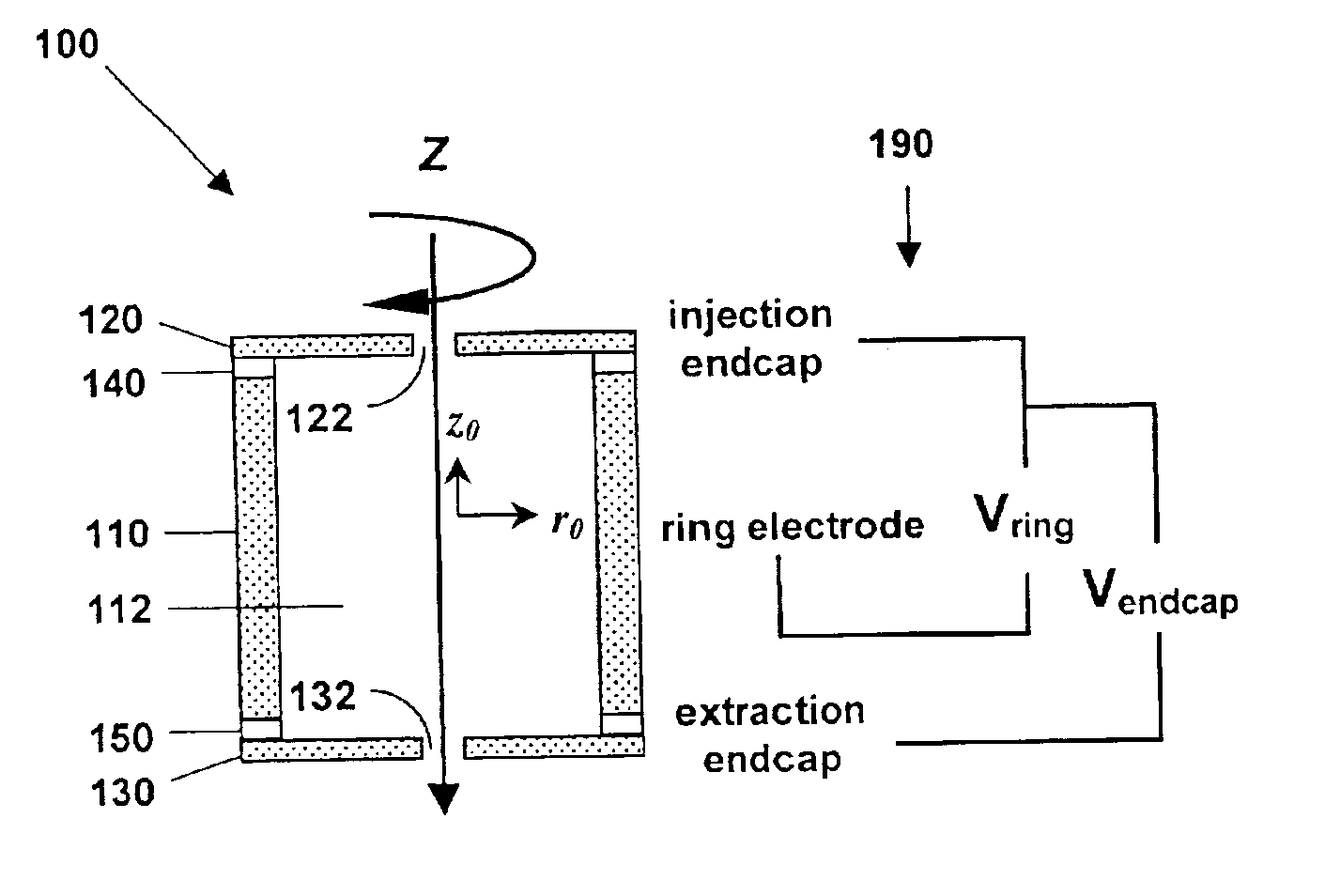

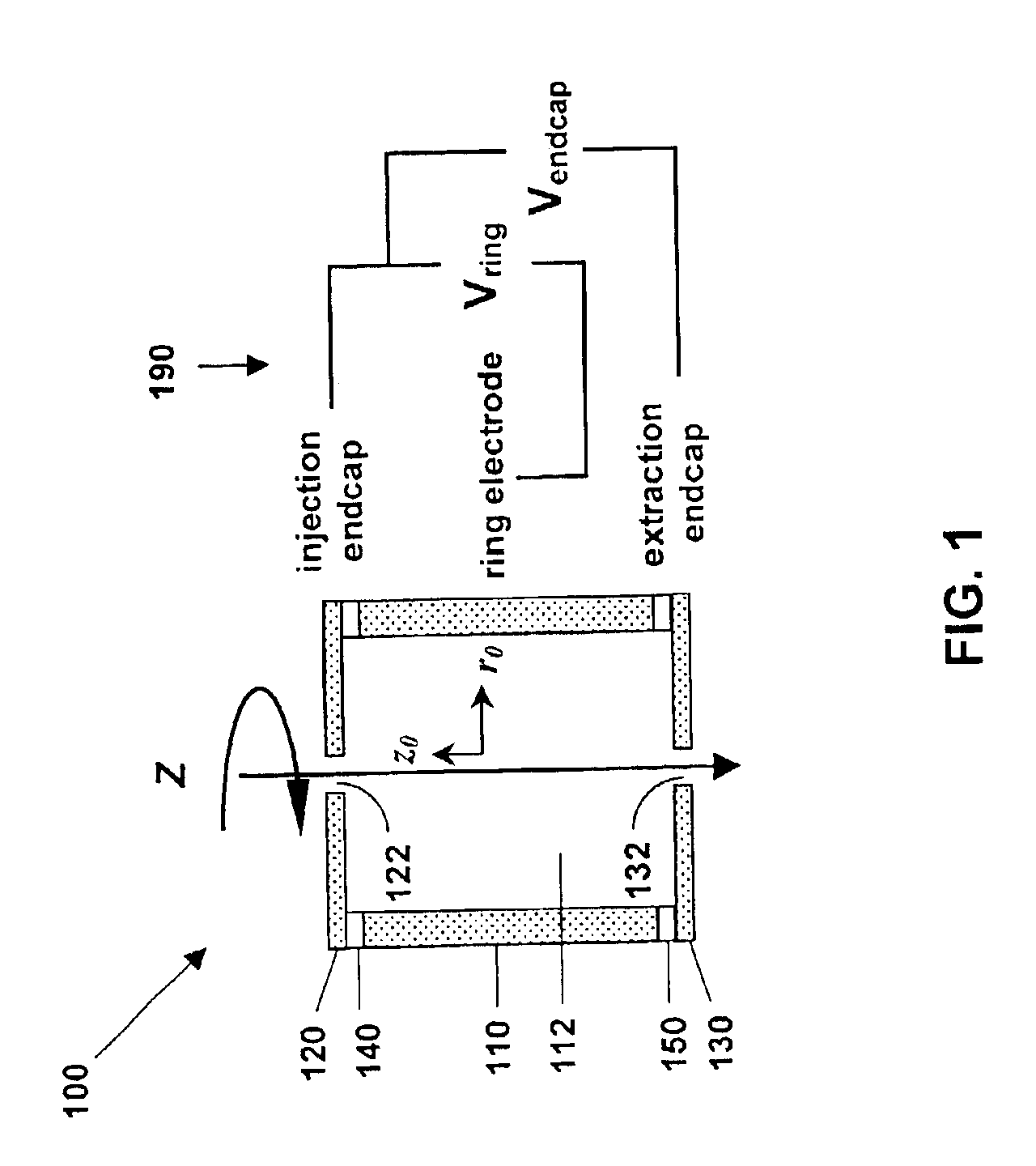

Microfabricated cylindrical ion trap

InactiveUS6870158B1Stability-of-path spectrometersIsotope separationManufacturing cost reductionHigh pressure

A microscale cylindrical ion trap, having an inner radius of order one micron, can be fabricated using surface micromachining techniques and materials known to the integrated circuits manufacturing and microelectromechanical systems industries. Micromachining methods enable batch fabrication, reduced manufacturing costs, dimensional and positional precision, and monolithic integration of massive arrays of ion traps with microscale ion generation and detection devices. Massive arraying enables the microscale cylindrical ion trap to retain the resolution, sensitivity, and mass range advantages necessary for high chemical selectivity. The microscale CIT has a reduced ion mean free path, allowing operation at higher pressures with less expensive and less bulky vacuum pumping system, and with lower battery power than conventional- and miniature-sized ion traps. The reduced electrode voltage enables integration of the microscale cylindrical ion trap with on-chip integrated circuit-based rf operation and detection electronics (i.e., cell phone electronics). Therefore, the full performance advantages of microscale cylindrical ion traps can be realized in truly field portable, handheld microanalysis systems.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

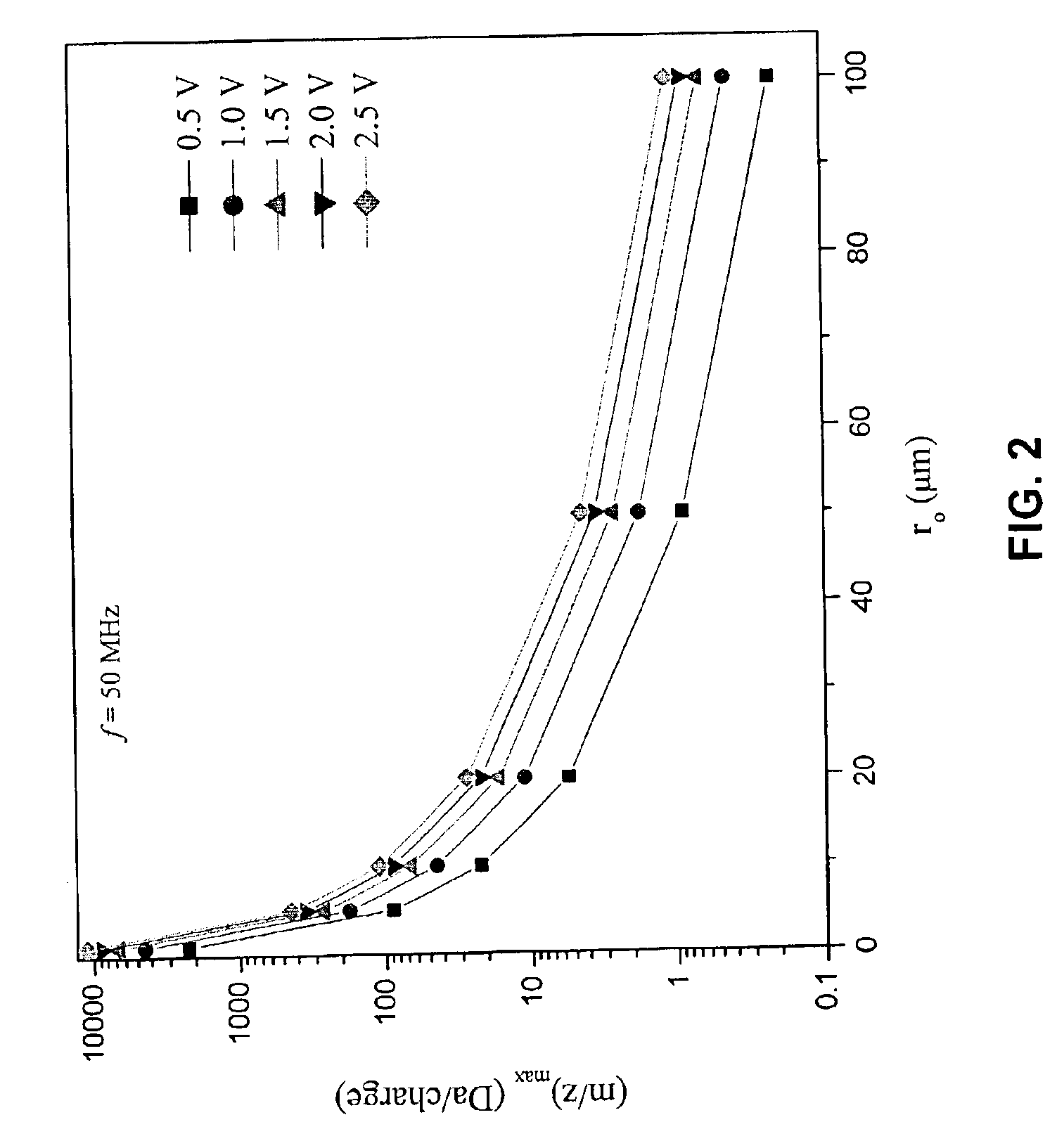

Minitype metal nickel mould producing method

InactiveCN101205054ASimple preparation processReduce manufacturing costDecorative surface effectsChemical vapor deposition coatingUltravioletElectron

The invention discloses a method for making a micro metal nickel mold. By adopting ultraviolet nano-imprint lithography and micro electroforming composite technology, the invention comprises the following basic technique flow: (1) a mother blank is lithographed by electron direct lithographing and dry etching; (2) a piece of glass taken as a substrate is cleaned and baked, with surface pretreated; (3) a Cr / Cu electroforming seed layer with a thickness of 90-110nm is sputtered on the glass substrate; (4) by taking the mother blank made by the step (1) as an imprint plate, a mold cavity microstructure is copied on ultraviolet organic light-cured substrate material by using a UV nano-imprint lithography technique; (5) a Cr / Cu or Au / Ti electroforming seed layer with a thickness of 8-12nm is deposited on the substrate material; (6) nickel with a depositional thickness of 300-500Mum is electroformed on the seed layer of the substrate material; (7) a metal backing is added; (8) after knockout, the metal nickel mold is obtained. The method has the advantages of low producing cost, simple technique and high producing effect, and can realize batch fabrication of submicron and nano-micro metal nickel mold with low cost.

Owner:SHANDONG UNIV

Monitoring method and/or apparatus

ActiveUS7415299B2Easy recalibrationMinimally invasiveSemi-permeable membranesMedical devicesDialysis membranesContinuous glucose monitoring

A method and apparatus for substance monitoring. One application is an easy to handle continuous glucose monitor using a group of hollow out-of-plane silicon microneedles to sample substances in interstitial fluid from the epidermal skin layer. The glucose of the interstitial fluid permeates a dialysis membrane and reaches a sensor. Using MEMS technology, for example, allows well-established batch fabrication at low cost.

Owner:RGT UNIV OF CALIFORNIA

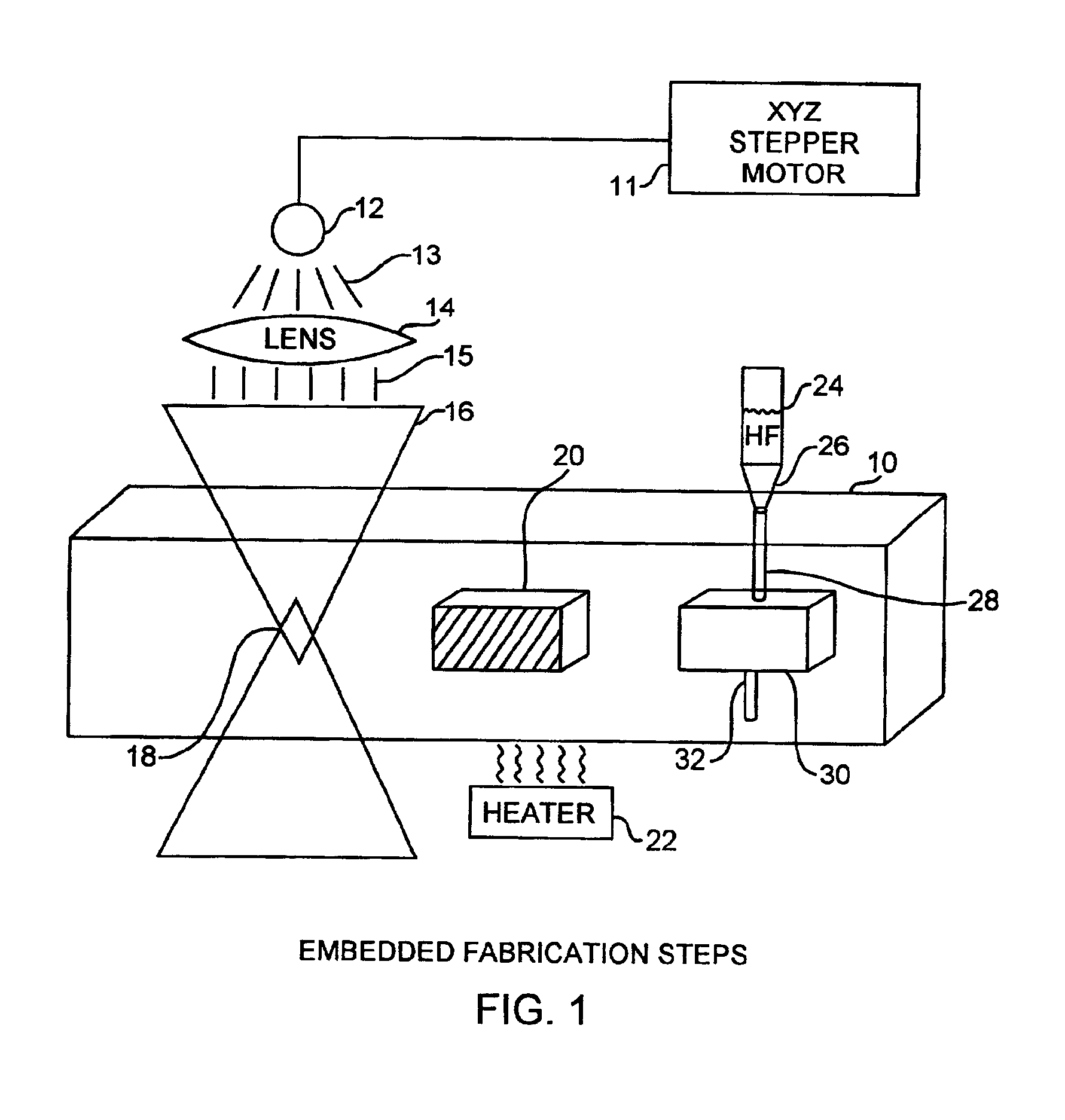

Ultraviolet method of embedding structures in photocerams

InactiveUS6932933B2Fast batch processingEasy to controlDecorative surface effectsPhotomechanical apparatusUltravioletVolumetric Mass Density

A laser direct write method creates true three dimensional structures within photocerams using an focused pulsed ultraviolet laser with a wavelength in a weakly absorbing region of the photoceram material. A critical dose of focused laser UV light selectively exposes embedded volumes of the material for subsequent selective etching. The photoceram material exposure is nonlinear with the laser fluence and the critical dose depends on the square of the per shot fluence and the number of pulses. The laser light is focused to a focal depth for selective volumetric exposure of the material within a focal volume within the remaining collateral volumes that is critically dosed for selecting etching and batch fabrication of highly defined embedded structures.

Owner:THE AEROSPACE CORPORATION

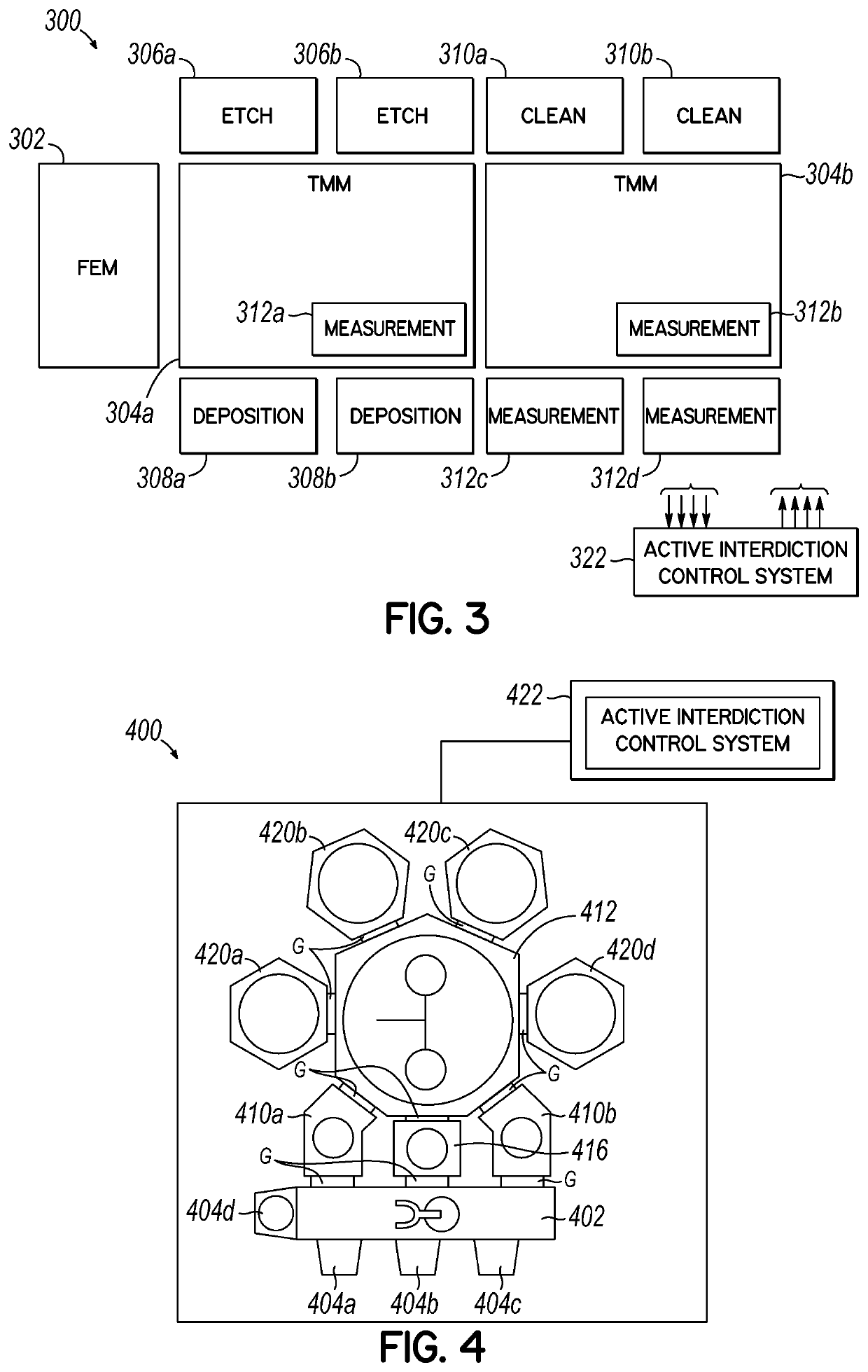

Self-aware and correcting heterogenous platform incorporating integrated semiconductor processing modules and method for using same

PendingUS20200083080A1Lower potentialReduce exerciseProgramme controlSemiconductor/solid-state device testing/measurementThermodynamicsHigh volume manufacturing

This disclosure relates to a high volume manufacturing system for processing and measuring workpieces in a semiconductor processing sequence without leaving the system's controlled environment (e.g., sub-atmospheric pressure). The systems process chambers are connected to each other via transfer chambers used to move the workpieces, in the controlled environment, between the process chambers. The transfer chambers include a measurement module capable of measuring workpiece attributes before and / or after process treatments. The measurement module may include an inspection system mounted above, below, or inside the transfer chamber.

Owner:TOKYO ELECTRON LTD

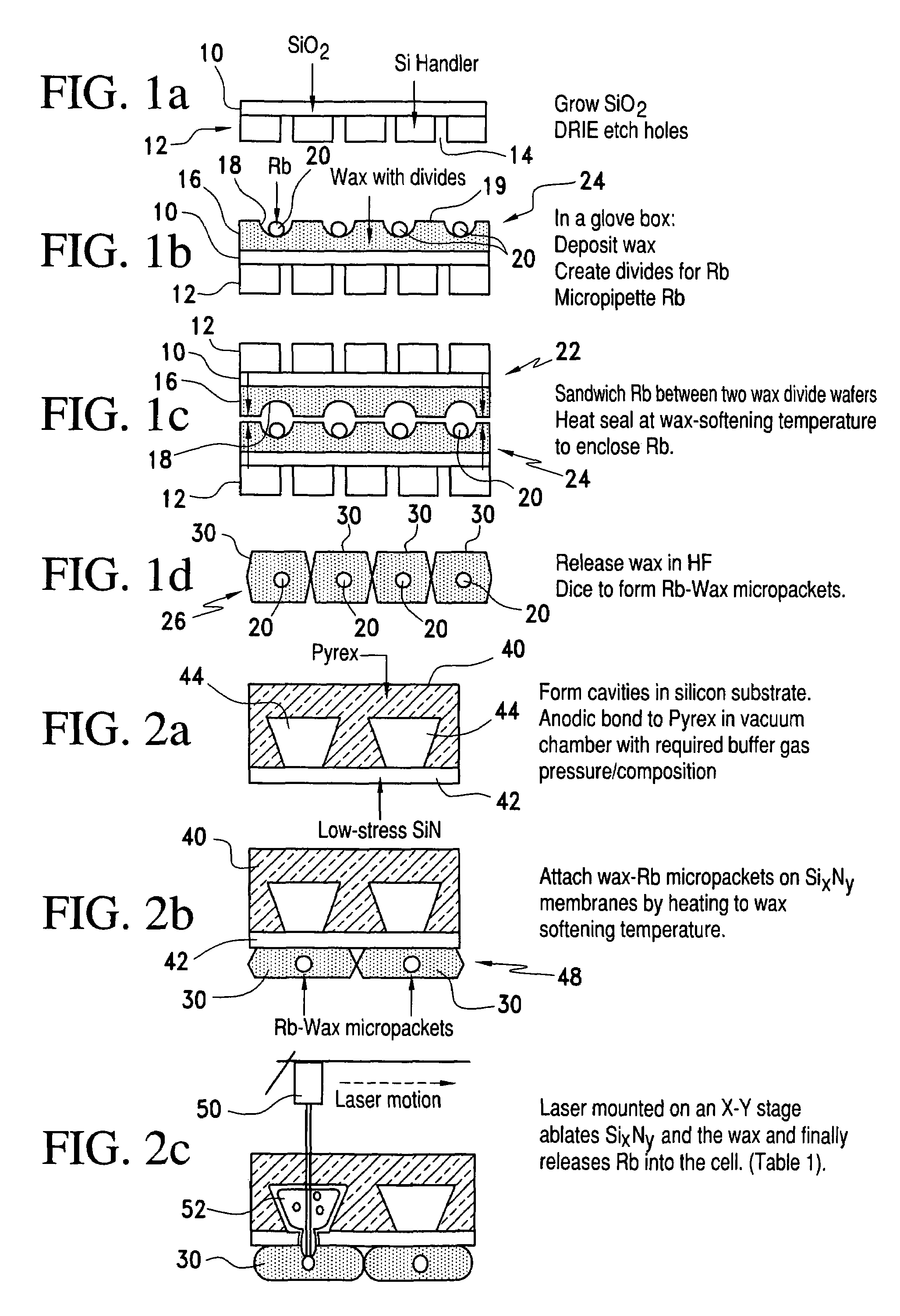

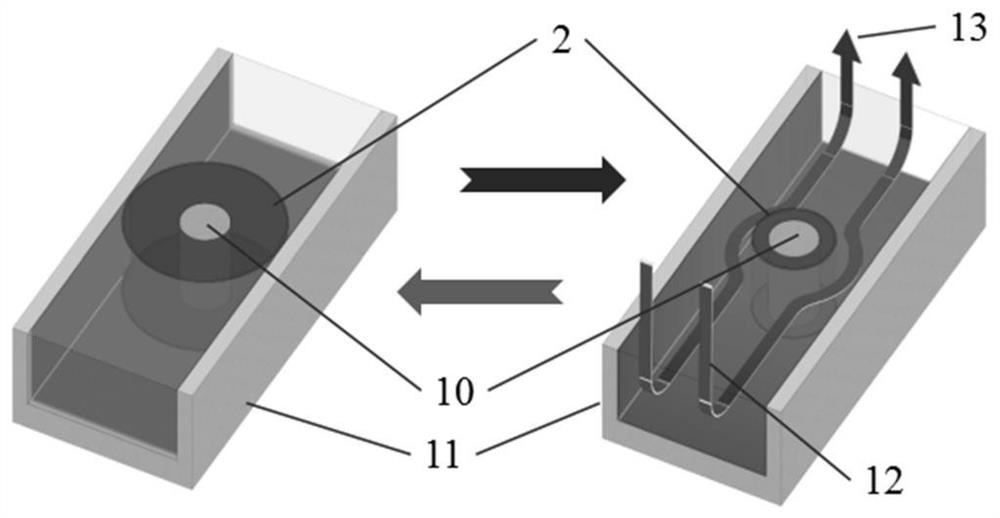

Alkali metal-wax micropackets for alkali metal handling

ActiveUS7666485B2Inexpensive and flexible manufacturingEasy to operateEnvelopes/bags making machineryApparatus using atomic clocksWaxPhysical chemistry

A method of making alkali-metal vapor cells by first forming microscale-wax micropackets with alkali metals inside allows fabrication of vapor cells at low cost and in a batch fabricated manner. Alkali metals are enclosed in a chemically inert wax to preform alkali metal-wax micropackets, keeping the alkali metals from reacting with the ambient surroundings during the vapor cell fabrication. This enables the deposition of precise amounts of pure alkali metal inside the vapor cells. Laser ablation of the alkali metal-wax micropackets provides a simple and effective way of releasing the enclosed metal. The method reduces the cost of making chip-scale atomic clocks and allows shipping of alkali vapor packets without contamination issues, thereby creating a technology for alkali-metal vendors to provide small packets of alkali metals.

Owner:CORNELL UNIVERSITY

Methods of forming oxide masks with submicron openings and microstructures formed thereby

ActiveUS7056757B2High quality factorHigh process yieldSemiconductor/solid-state device manufacturingMicrostructural device manufactureSingle crystalPhotolithography

Processing techniques are disclosed for batch fabrication of microstructures comprising an oxide mask on a substrate with submicron openings formed therein, and microstructures having deep-submicron, high aspect-ratio etched trenches, using conventional optical photolithography. Exemplary high aspect-ratio etched-trench microstructures that may be produced include single crystal resonators and sensors.

Owner:GEORGIA TECH RES CORP

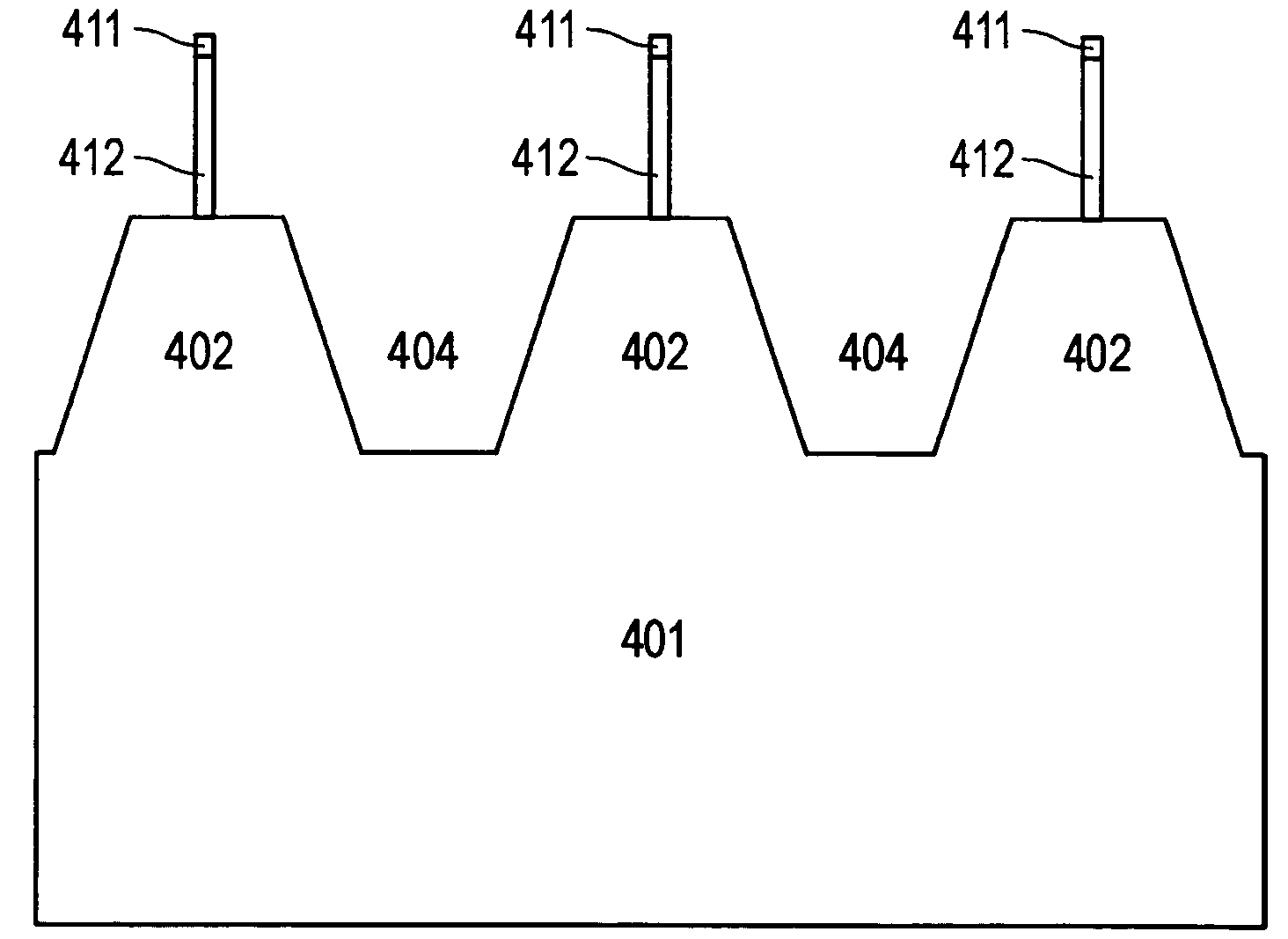

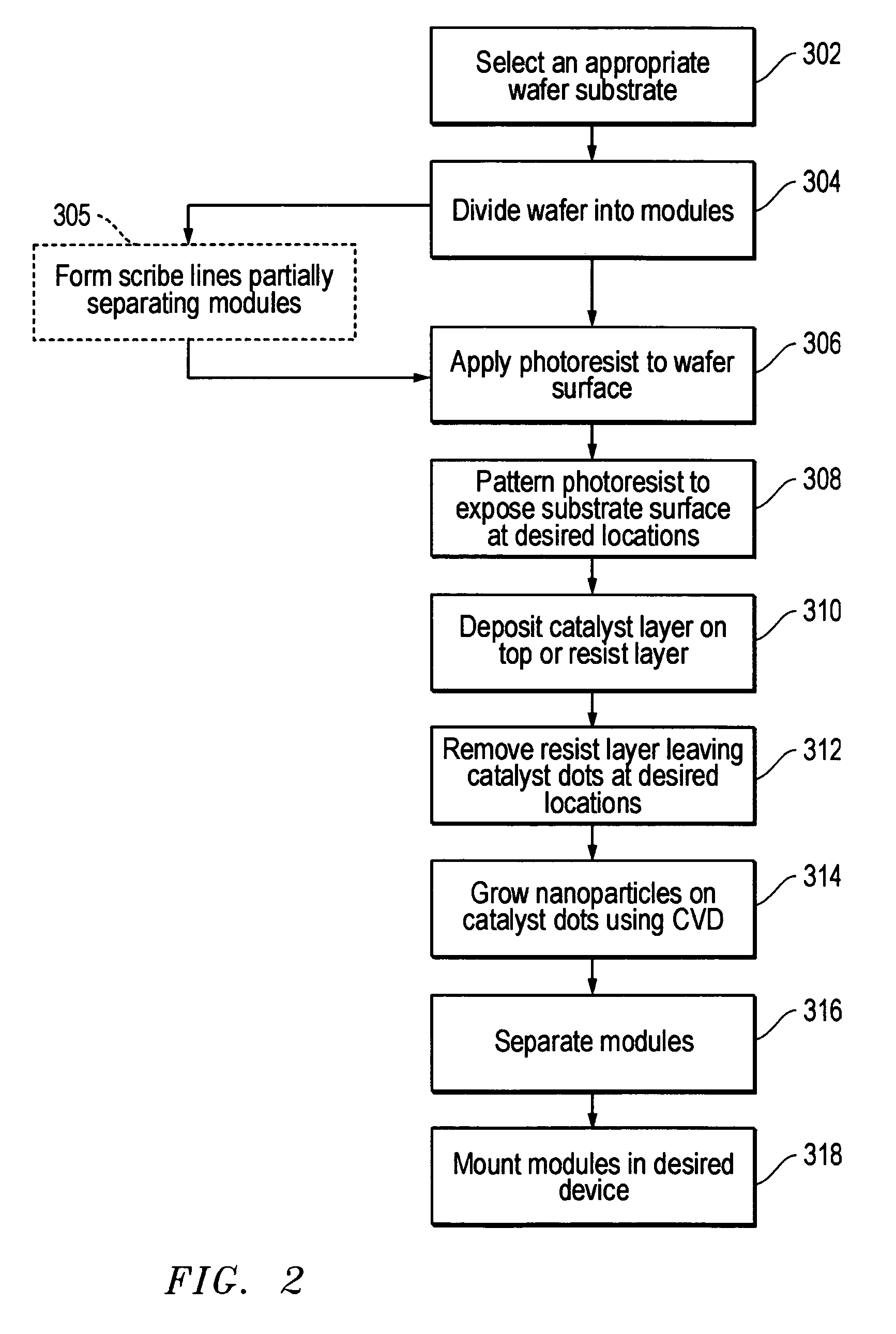

Method of fabricating nanodevices

ActiveUS7544523B2Repeatable and reliable mannerLarge-scale mass productionMaterial nanotechnologyThermionic cathodesNanoparticleNanodevice

A method of batch fabrication using established photolithographic techniques allowing nanoparticles or nanodevices to be fabricated and mounted into a macroscopic device in a repeatable, reliable manner suitable for large-scale mass production. Nanoparticles can be grown on macroscopic “modules” which can be easily manipulated and shaped to fit standard mounts in various devices.

Owner:FEI CO

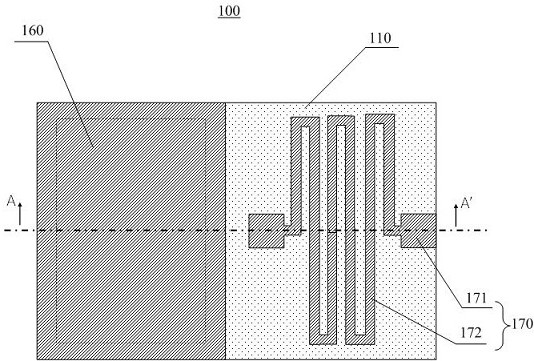

Micro super capacitor applied for micro system and production process thereof

InactiveCN101504889AReduce gapImprove power storage performanceHybrid capacitor electrolytesHybrid capacitor electrodesCurrent collectorOxide

The invention discloses a micro supercapacitor applied to a micro system and a preparation method thereof, which belong to the manufacturing technology range of miniature supercapacitors. The preparation method comprises the following steps: drawing graphs of a micro capacitor and an array thereof on a silicon substrate through a mask and a photoetching method; preparing a layer of a metal film current collector and a layer of a ruthenium-oxide film cathode layer on the silicon substrate; spin-coating a layer of a polyimide sacrifice layer on the layers to obtain a required support body structure and a peripheral liquid storage cavity enclosure structure; spin-coating the sacrifice layer on the layers again and depositing an anode ruthenium-oxide active substance layer and a nickel film current collector layers in turn on the layers; perforating filling holes on the upper nickel layer and an oxide layer to fill an electrolyte in a cavity; and finally, covering a polymer film layer on the whole micro supercapacitor array again to finish an encapsulation process. The micro supercapacitor is provided with the unique support body structure and the liquid storage cavity structure, has the characteristics of small volume, large energy storage density, high discharge power, monolithic and the like, can be manufactured in batches, and has wide application prospect.

Owner:TSINGHUA UNIV

Metal needle tube array component and disposable array type injection needle head formed by metal needle tube array component

The invention discloses a metal needle tube array component which comprises a metal needle tube array, a structural adhesive substrate and a locating piece. The metal needle tube array comprises at least two metal tubes. The two metal tubes are used for transmitting liquid, are arrayed at a preset interval and are fixed on the structural adhesive substrate. One end of each metal tube is used as a needle tip for puncture, and the other end of each metal tube penetrates through the structural adhesive substrate and is inserted in a locating through hole of the locating piece connected with the structural adhesive substrate. The metal needle tubes and the locating piece are sealed and combined into a whole in an adhesive mode by the structural adhesive substrate so that liquid can only pass through the inside of the metal needle tubes. The invention further discloses an injection needle head based on the metal needle tube array component. Lot manufacturing, with low cost and a high finished product rate, of the he metal needle tube array component and the injection needle head can be realized by utilization of existing mature processing technology and specified conventional medical materials. Blanks in relevant application fields are expected to be filled. Consequently, enormous economic benefit and social benefit can be created, and contribution is conducted to health and beautiful life of human beings.

Owner:TSINGHUA UNIV

Probe for a scanning probe microscope and method of manufacture

InactiveUS20060213289A1Overcomes drawbackDrawback can be obviatedNanotechnologyMechanical roughness/irregularity measurementsEngineeringScanning probe microscopy

A probe assembly for an instrument and a method of manufacture includes a substrate and a cantilever having a length independent of typical alignment error during fabrication. In one embodiment, the probe assembly includes a buffer section interposed between the substrate and the cantilever. The cantilever extends from the buffer section and a portion of the buffer section extends beyond an edge of the substrate. The portion of the buffer section is more stiff than the cantilever. The corresponding method of producing the probe assembly facilitates batch fabrication without compromising probe performance.

Owner:VEECO INSTR

Microelectro mechanical system for magneto-optic data storage apparatus

InactiveUS7002226B2High dataImprove efficiencyCombination recordingPhotometry using reference valueResistAir bearing

Owner:NAT CHIAO TUNG UNIV

Method of fabricating nanodevices

ActiveUS20070148991A1Simple methodSuitable for mass productionMaterial nanotechnologySemiconductor/solid-state device manufacturingNanoparticleNanodevice

A method of batch fabrication using established photolithographic techniques allowing nanoparticles or nanodevices to be fabricated and mounted into a macroscopic device in a repeatable, reliable manner suitable for large-scale mass production. Nanoparticles can be grown on macroscopic “modules” which can be easily manipulated and shaped to fit standard mounts in various devices.

Owner:FEI CO

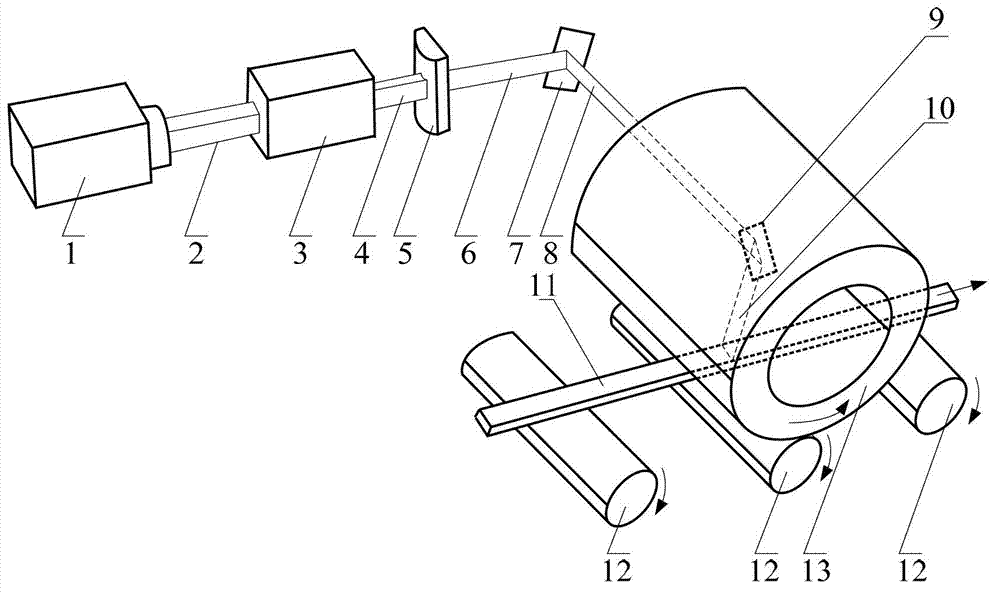

Reflection-type long grating process method for laser-assisted roll pressing manufacturing machine tool

InactiveCN102759856ALiquidityImprove fill ratePhotomechanical apparatusOptical elementsGratingLight beam

The invention discloses a reflection-type long grating process method for a laser-assisted roll pressing manufacturing machine tool. The method comprises the following steps that: outgoing beams of excimer laser are modulated into linear beams with uniform light intensity distribution; the linear beams directionally irradiate a pressing region from beginning to end; a metal material on the surface of a grating ruler blank in the pressing region is instantly heated to be at a temperature close to a melting point of the metal material in the instant of pressing, so that the metal material in the region has certain flowability and fills a groove-shaped concave cavity with a grating microstructure on a quartz roll pressing mold under small pressing force; and after a heated region is separated from a laser irradiating region, the metal material is cooled and cured instantly, so that the form of the grating line grain microstructure is maintained, and the high-precision replication of grating line grains from a roll pressing mold to the grating ruler blank is completed. The method disclosed by the invention is suitable for the high-precision and low-cost batch manufacturing of reflection-type long grating (more than one meter) and ultra-long grating (made from a couple of meters of, dozens of meters of and even hundreds of meters of metal belt materials), and has a good promotion value and good application prospect.

Owner:XI AN JIAOTONG UNIV +1

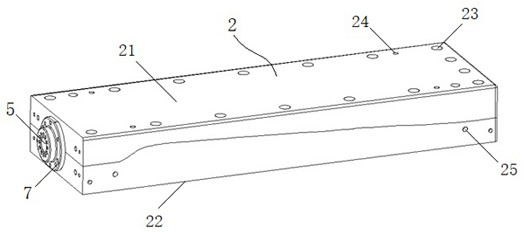

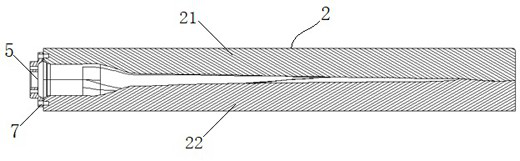

Tubular circulating bioreactor and tubular circulating biological reaction system device

InactiveCN103255051AChange volumeEasy to assemble and disassembleBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringNutrient solution

The invention relates to a tubular circulating bioreactor which comprises a pipeline, and the pipeline is bended, is connected end to end and has an up and down reciprocating cycle structure; the invention also relates to a tubular circulating biological reaction system device which comprises a nutrient solution gas-liquid separation device, a nutrient solution circulating pump, a gas-liquid mixing device, the tubular circulating bioreactor and a temperature control purification device, wherein the nutrient solution gas-liquid separation device, the nutrient solution circulating pump, the gas-liquid mixing device and the tubular circulating bioreactor are connected by a pipeline; and the temperature control purification device is connected with the tubular circulating bioreactor. Due to the adoption of the tubular circulating bioreactor and the tubular circulating biological reaction system device are adopted, the equipment utilization rate is improved, the energy is saved, and the consumption is reduced; and the tubular circulating bioreactor is simple in structure and convenient in batch manufacturing.

Owner:ZHENJIANG FENGZE BIOTECH EQUIP MFG +1

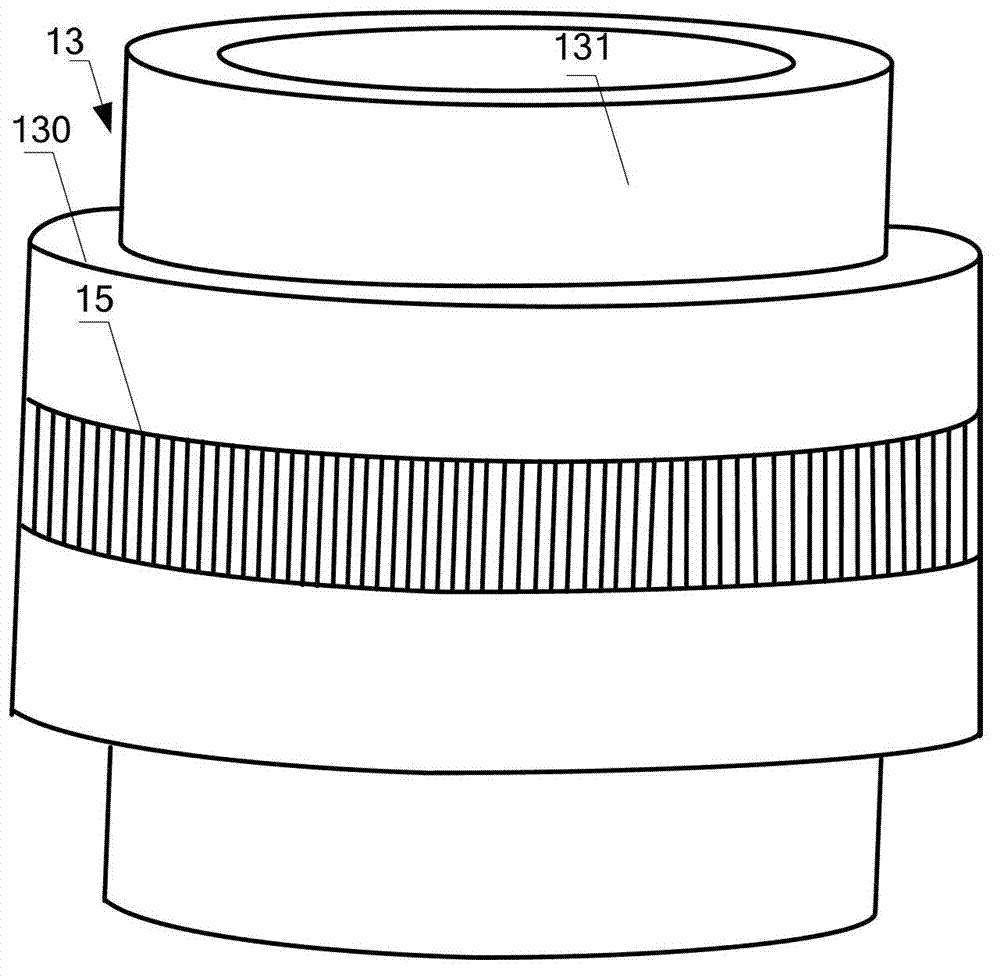

Annular micro-fold optical lens and preparation method thereof

The invention provides an annular micro-fold optical lens and a preparation method thereof, and belongs to the field of optics and micromachining. The preparation method is completed by the following steps of: firstly preparing a soft material film; fixing the soft material film on a substrate with a hole, and then pulling or pushing the film through the preset position of the hole to form a conical structure; and depositing a hard material film on the surface of the conical structure or hardening the surface of the conical structure and then stopping pulling or pushing, to form periodical annular micro-folds on the surface of the soft-hard two-layer film. The annular micro-fold optical lens provided by the invention has similar optical performance to the conventional pyramidal lens; the optical parameters (such as convergence angle, divergence angle and focal length) of the lens can be conveniently adjusted by controlling the process parameters of the preparation method; and compared with the conventional pyramidal lens, the annular micro-fold optical lens has huge advantages due to the characteristics of extremely-thin thickness, extremely-light weight, flexibility and low processing cost as well. The process for preparing the annular folds can also be applied to prepare optical lenses of large size and is suitable for batch fabrication.

Owner:SHANGHAI JIAO TONG UNIV

Self-aware and correcting heterogenous platform incorporating integrated semiconductor processing modules and method for using same

ActiveUS20200083074A1Semiconductor/solid-state device testing/measurementElectric discharge tubesHigh volume manufacturingControl system

This disclosure relates to a method for using a high volume manufacturing system for processing and measuring workpieces in a semiconductor processing sequence without leaving the system's controlled environment (e.g., sub-atmospheric pressure). The system includes an active interdiction control system to implement corrective processing within the system when a non-conformity is detected. The corrective processing method can include a remedial process sequence to correct the non-conformity or compensate for the non-conformity during subsequent process. The non-conformity may be associated with fabrication measurement data, process parameter data, and / or platform performance data.

Owner:TOKYO ELECTRON LTD

Mold core with copied natural biological super-hydrophobic surface as well as preparation method and application of mold core

ActiveCN104313654AImitation biology good hydrophobicityMicro-Nano Structure RulesElectroforming processesMicro nanoHydrophobic polymer

The invention discloses a mold core with a copied natural biological super-hydrophobic surface as well as a preparation method and application of the mold core, and belongs to the technical field of preparation of hydrophobic surfaces. The method comprises the steps of putting a natural biological super-hydrophobic surface serving as a mother board into electroforming liquid using nickel sulfamate as a main salt to serve as a cathode, connecting a nickel plate serving as an anode to a pulse power supply and performing electroforming to obtain a cast layer copied with a super-hydrophobic surface structure; and then manufacturing an injection mold core by using the cast layer, installing the injection mold core on an injection mold and performing injection molding to obtain a super-hydrophobic polymer piece consistent with the natural biological surface structure. The super-hydrophobic surface matrix is selected from a natural biology and has a regular micro-nano structure and good hydrophobic performance, and the prepared super-hydrophobic polymer piece has relatively good bionic hydrophobic property. The mold core with the natural biological super-hydrophobic surface, which is prepared by using an electroforming process, can realize large-batch manufacturing of the super-hydrophobic polymer piece consistent with the natural biological super-hydrophobic surface mother board structure.

Owner:CENT SOUTH UNIV

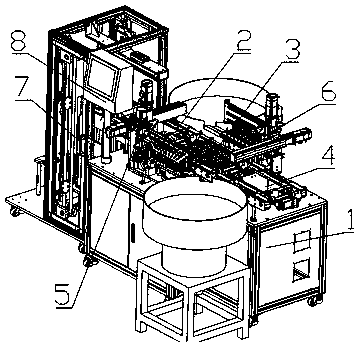

Whole-row transplantation device for glass slides

InactiveCN110053971ARealize automatic feeding processQuick placementConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses a whole-row transplantation device for glass slides. The device comprises a rack, a left arrangement mechanism, a right arrangement mechanism, a carrying disk feeding mechanism, a material waiting station, a slide arrangement station and a discharge station, wherein inlet ends and outlet ends of the material waiting station, the slide arrangement station and the discharge station along the rack are horizontally disposed on a platform of the rack in a head-tail adjacent manner; the carrying disk feeding mechanism is located on the left side of the inlet end of the rack and is adjacent to the material waiting station; and the left arrangement mechanism and the right arrangement mechanism are disposed on the platform of the rack and located on the left side and the right side of the slide arrangement station. The device disclosed by the invention has the beneficial effects that a plurality of glass slides with different specifications and sizes can be placed quickly without replacement of a fixture, so manpower is saved and working efficiency is increased; reliable guarantee is provided for rapid placement of the glass slides during batched fabrication of detection specimens; and the market application value is high.

Owner:孙峰 +3

Cantilever beam acceleration transducer manufactured by micro-machining on single side of single silicon chip and method

ActiveCN101968495BHigh sensitivityImprove stabilityAcceleration measurement using interia forcesDecorative surface effectsEtchingAccelerometer

The invention relates to a cantilever beam acceleration transducer manufactured by micro-machining on a single side of a single silicon chip and a manufacturing method. The acceleration transducer is characterized in that: an accelerometer is manufactured by micro-mechanical single side machining through the single silicon chip, so that stress caused by the bonding process of a plurality of chips and different materials is avoided. In order to realize a single side-machined cantilever beam sensitive structure, the cantilever beam structure is released by transversely etching the bottom of the cantilever beam by an anisotropic corrosion method after deep structural etching. The structure provides air squeeze-film damping and mechanical overload protection in a sensitive direction, solves the problem of the absence of air squeeze-film damping in the vertical sensitive direction of the conventional structure and prevents parasitic signal interference caused by structural resonance in the vertical direction. The acceleration transducer has the characteristics of particular suitability for measuring a high g value, simple structure, small size of the chip and the like. Simultaneously, a single side process can use low-cost single throwing silicon chips, is suitable for low-cost mass manufacturing and has higher performance and wide application prospects.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Apparatus for manufacturing components using electrophoretic deposition

InactiveUS20070131555A1High yieldLow costCellsElectrophoretic coatingsElectrophoresisElectrolytic capacitor

The invention is an apparatus, methods and systems for the production of coatings or small components having defined pre-set dimensions and properties by electrophoretic deposition (EPD) on electrically conducting or semi-conducting substrates. The invention provides efficient and precise mass manufacturing of components by EPD, such as anodes of electrolytic capacitors, by achieving high utilization of expensive raw materials and by consistently achieving tight dimensional tolerances of defined component shapes in repeated depositions. This includes production sequences of discrete components, batches of components, and production by semi-continuous operation.

Owner:CEREL CERAMIC TECH

Lower stator of guiding motion valve core of automobile exhaust backflow controlling valve

InactiveCN102305121AReduce lossReduce processing difficultyExhaust apparatusSilencing apparatusEngineeringControl valves

The invention discloses a lower stator of a guiding motion valve core of an automobile exhaust backflow controlling valve, comprising a housing, a gasket and a stator, wherein a step is arranged at the upper part of the stator; holes are arranged at the bottom surface of the housing and in the middle of the gasket; and the gasket and the housing are successively sleeved on the step and are fixed through being riveted on the top of the step. The lower stator provided by the invention has the advantages that: the lower stator of the guiding motion valve core of the automobile exhaust backflow controlling valve is disassembled to split type parts and then assembled to a whole; each part are independently processed; and therefore, the processing difficulty is reduced, the raw material loss is decreased, the batch fabrication can be formed and the production efficiency is increased.

Owner:镇江先锋汽车零部件有限公司

MEMS vacuum gauge and preparation method thereof

ActiveCN113979405ALarge rangeGuaranteed SensitivityTelevision system detailsSemiconductor/solid-state device detailsElectrical resistance and conductanceOhmic contact

The invention provides an MEMS vacuum gauge and a preparation method thereof. The method comprises the following steps of providing a first substrate and a second substrate, forming an ohmic contact layer on the first surface of the first substrate, forming a bonding layer on the first surface of the first substrate, forming a first electrode layer and a suspension resistance layer on the first surface of the second substrate, performing anodic bonding on the bonding layer on the first surface of the first substrate and the first surface of the second substrate to form a first cavity located among the first substrate, the bonding layer and the first electrode layer and a second cavity located among the first substrate, the bonding layer and the suspension resistance layer, corroding the second surface of the second substrate until the first electrode layer and the suspension resistance layer are reached, and forming a lead layer on the first electrode layer and the ohmic contact layer, and forming a second electrode layer on the suspension resistance layer. According to the method, the measuring range of the MEMS vacuum gauge is effectively improved, and the vacuum gauge has the advantages of being small in size, high in precision, good in consistency, easy to manufacture in batches and low in cost.

Owner:南京元感微电子有限公司

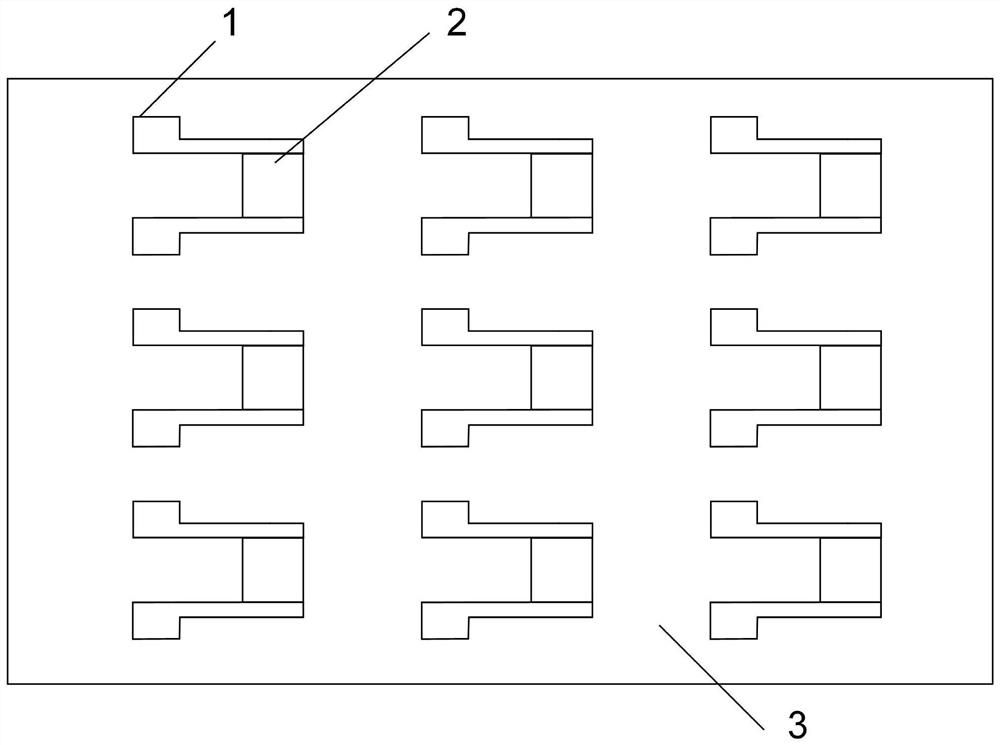

Crack flexible strain sensor based on graphene-gold composite film and preparation method

ActiveCN113074622AMaintain linear strain awarenessPrevent penetrationElectrical/magnetic solid deformation measurementBatch fabricationThin membrane

The invention discloses a crack flexible strain sensor based on a graphene-gold composite film and a preparation method thereof. The preparation method comprises the following steps of preparing a metal electrode on a PDMS flexible substrate through a mask method, forming a quasi-continuous graphene film by using a liquid level self-assembly method, transferring the graphene film to a flexible substrate covering the sensing unit mask through a pulling method, performing magnetron sputtering of nanogold on the surface of the graphene to prepare a graphene-gold composite film, and pre-stretching the PDMS flexible substrate to enable the graphene-gold composite film to generate an initial crack, thereby obtaining the flexible strain sensor based on the graphene-gold composite film crack. The process conditions are mild, array batch manufacturing is easy, the prepared sensor has high sensitivity and a large linear range, the sensitivity can be improved through a mask patterning method, and the sensor is suitable for being integrated in a sensing system to complete strain measurement in a wide range.

Owner:BEIHANG UNIV

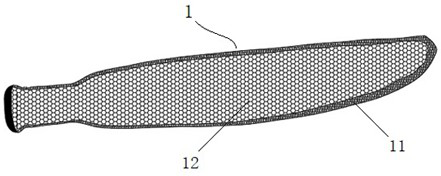

Method for assisting in forming composite material propeller blade by using air bag inflation

ActiveCN112406135AWith excellent performanceUniform deliveryDomestic articlesSkin structureIndustrial engineering

The invention discloses a method for assisting in forming a composite material propeller blade by using air bag inflation. A flexible air bag is adopted to perform inflation manufacturing on a skin shell of the propeller blade, and then a foaming process is adopted to manufacture an internal core material. The method specifically comprises the steps of carrying out forming tool design, carrying out skin prepreg laying, placing flexible air bag, carrying out die assembly installation, carrying out inflation curing, carrying out inner core filling and the like. According to the method, the pressure applied by compressed air can be uniformly and accurately transmitted, the thickness uniformity of a skin structure is guaranteed, meanwhile, the internal quality of the skin is guaranteed, and the problem of sandwich pressure loss or insufficient filling in a die pressing process is avoided; and compared with a die pressing and autoclave process, the method has the advantages that the operation is simple, the equipment cost is relatively low, and the method can be used for large-batch manufacturing. In addition, the flexible air bag used in the method can be repeatedly used, the materialsare easy to purchase, the manufacturing process is simple, the production cost is effectively reduced, and the manufacturing period is effectively shortened.

Owner:航天海鹰(镇江)特种材料有限公司

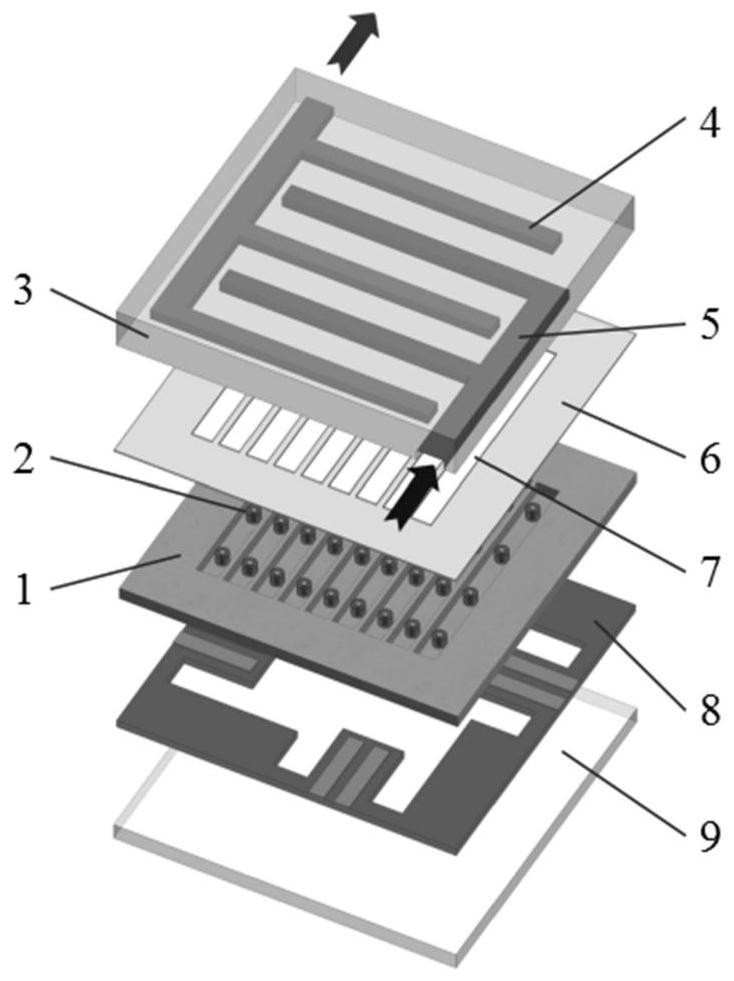

Electronic chip self-adaptive micro-channel cooling device and manufacturing method thereof

ActiveCN112185914ASimple structureSimple waySemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic chip

The invention discloses an electronic chip self-adaptive micro-channel cooling device and a manufacturing method thereof.The electronic chip self-adaptive micro-channel cooling device comprises an analog chip with one face provided with a micro-channel structure, a hydrogel micro-valve, a manifold distributor / collector, a sealing film layer, a PCB and a substrate. The hydrogel micro-valve realizesintelligent regulation and control on the flow of the micro-channel through the change of the volume of the hydrogel micro-valve along with the thermal load. When the self-adaptive micro-channel cooling device is manufactured, firstly, the micro-channel structure and the metal coating are machined, molten paraffin is filled, the periphery of the micro-column structure is embossed with the hydrogel micro-valve outline, then the embossed outline is filled with the hydrogel solution, paraffin is cleaned after polymerization is completed, and the hydrogel micro-valve integrated in the channel isobtained. Finally, the components are pressed and compacted. The micro-channel cooling device is simple in structure and easy to manufacture in batches, has a good flow adjusting effect, and can solvethe problems of pump power waste and cooling economy of traditional micro-channel cooling.

Owner:NANJING UNIV OF SCI & TECH

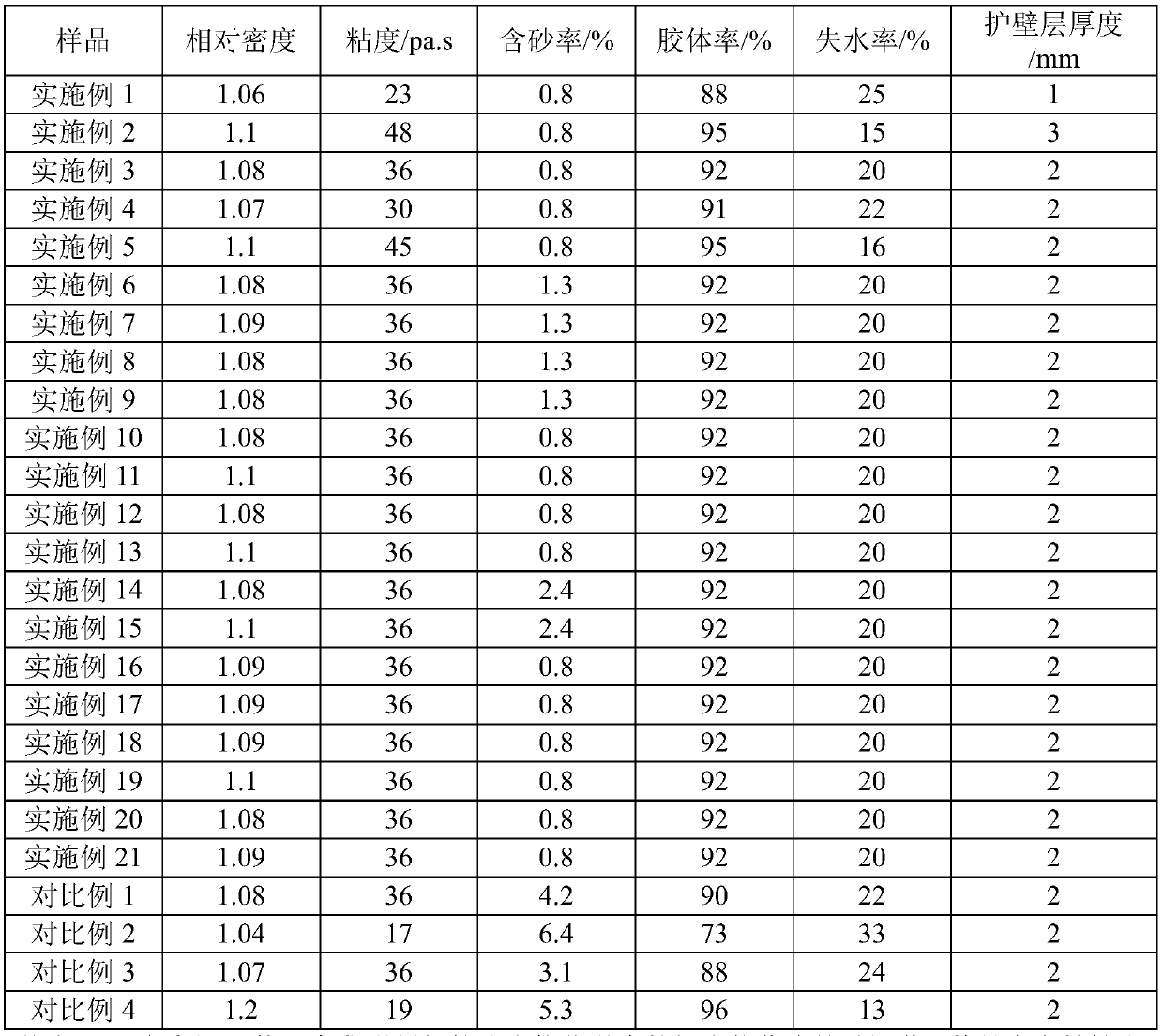

Composition for drilling and pouring, preparation method thereof and wall protection mud

InactiveCN111574971AIncrease stickinessImprove permeabilityDrilling compositionAluminium chlorideTackifier

The invention discloses a composition for drilling and pouring, a preparation method thereof and wall protection mud, and relates to the technical field of wall protection materials. The composition for drilling and pouring comprises a wall protecting agent potassium polyacrylate, a tackifier polyacrylamide, an instant solvent sodium chloride, a precipitator polyaluminum chloride and a stabilizersodium hydroxide; after being dissolved in water, the composition has the advantages of being good in wall protection effect and capable of improving the pile forming quality. The preparation method of the composition for drilling and filling comprises the following steps: uniformly stirring the raw materials in the composition in a closed space to obtain the composition; the preparation method has the advantages of simple preparation steps, easiness in implementation and convenience in batch manufacturing and production. The wall protection mud comprises the composition and water mixed with the composition in use. The wall protection mud has the advantages of being good in wall protection effect and capable of improving the pile forming quality.

Owner:中科兴创(北京)科技有限公司

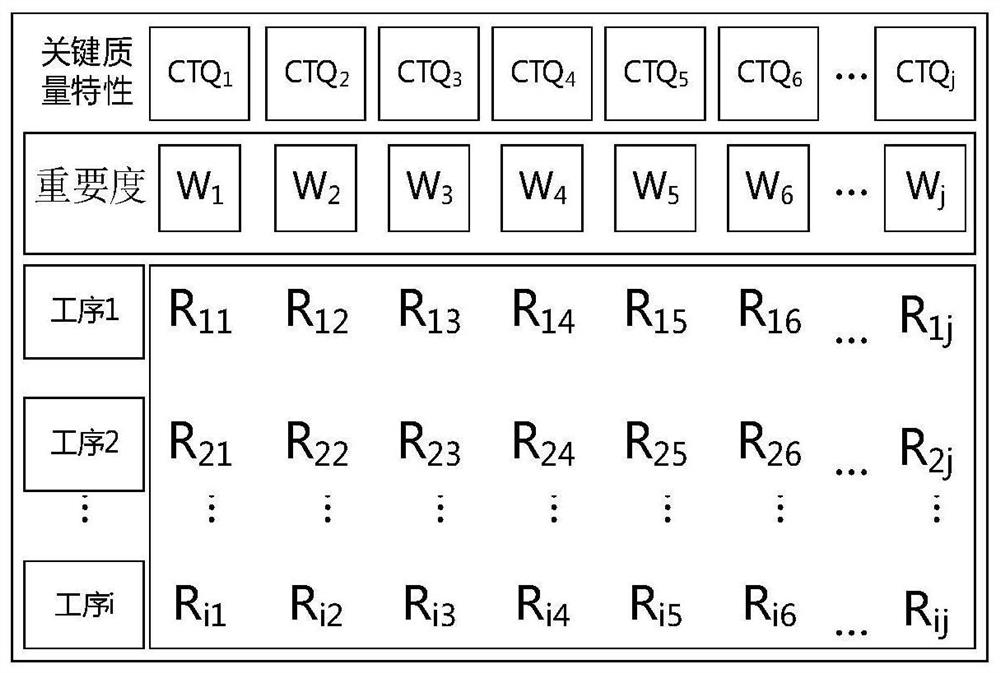

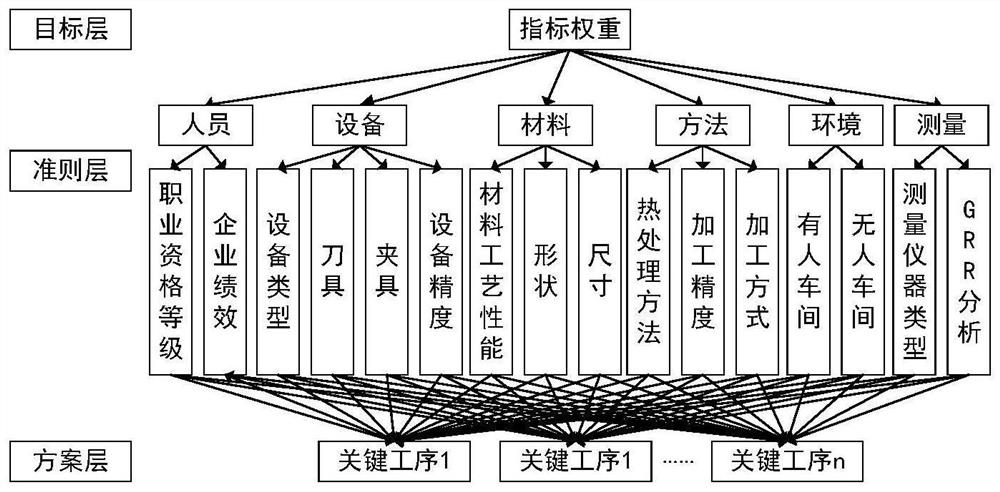

Key process identification and clustering analysis method for multi-variety small-batch manufacturing process

PendingCN112465377AIncrease sample sizeAddressing Insufficient Quality Characteristic DataCharacter and pattern recognitionResourcesManufacturing technologyManufacturing enterprises

The invention relates to a key process identification and clustering analysis method for a multi-variety small-batch manufacturing process. The method comprises the following steps: S1, constructing amulti-variety small-batch quality key process identification model; s2, performing clustering analysis on the key processes of each variety based on a hierarchical clustering analysis method, furtherdetermining a selection scheme of resolution, expanding the sample size of the quality characteristic data, and solving the problem of insufficient quality characteristic data of the key processes; and S3, taking the manufacturing process flow of each variety of products of a certain aerospace complex component manufacturing enterprise as an example, and verifying the effectiveness and feasibility of the proposed model and method. According to the invention, key quality characteristics and influence factors involved in the key process are considered, quantitative analysis and calculation areperformed on the process criticality of the manufacturing process, identification of the key process is realized, and the key process is clustered and grouped. Accuracy, effectiveness and feasibilityare verified through program simulation and instance analysis, reference is provided for key process research, and support is provided for quality control.

Owner:SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com