Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "High data" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Application of virtual servers to high availability and disaster recovery soultions

InactiveUS20070078982A1Improve availabilityHigh dataError detection/correctionMultiple digital computer combinationsVirtualizationStorage area network

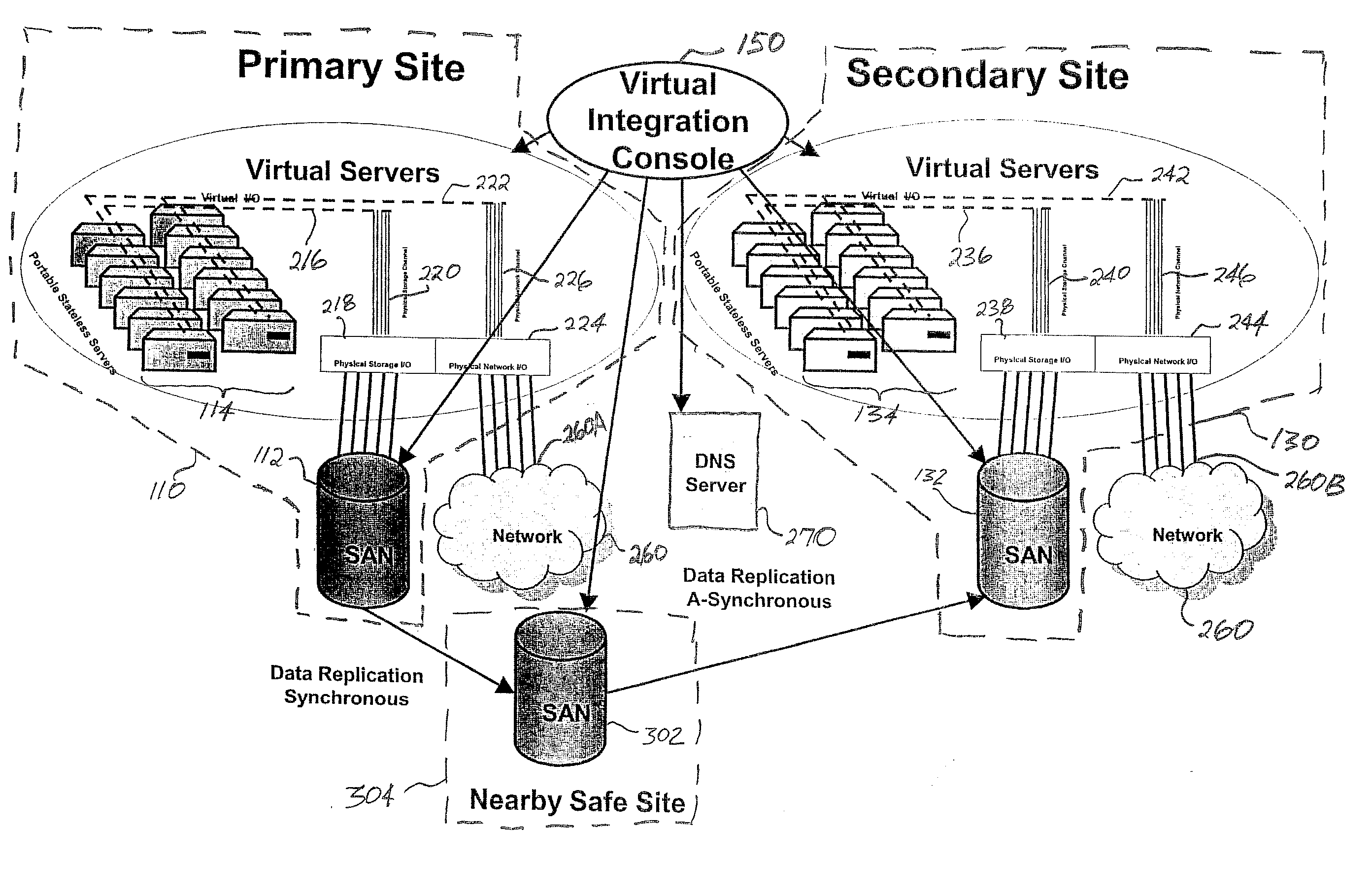

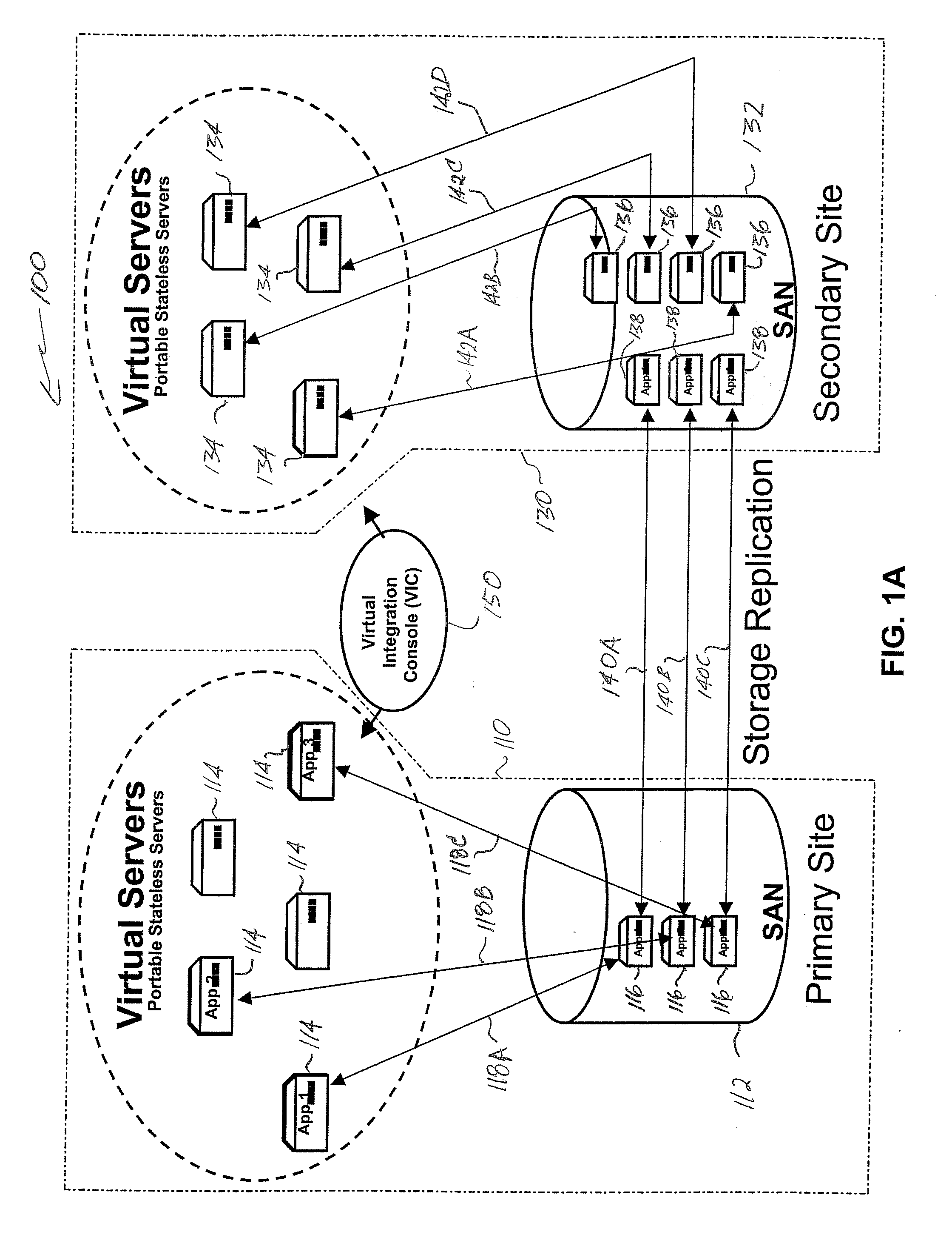

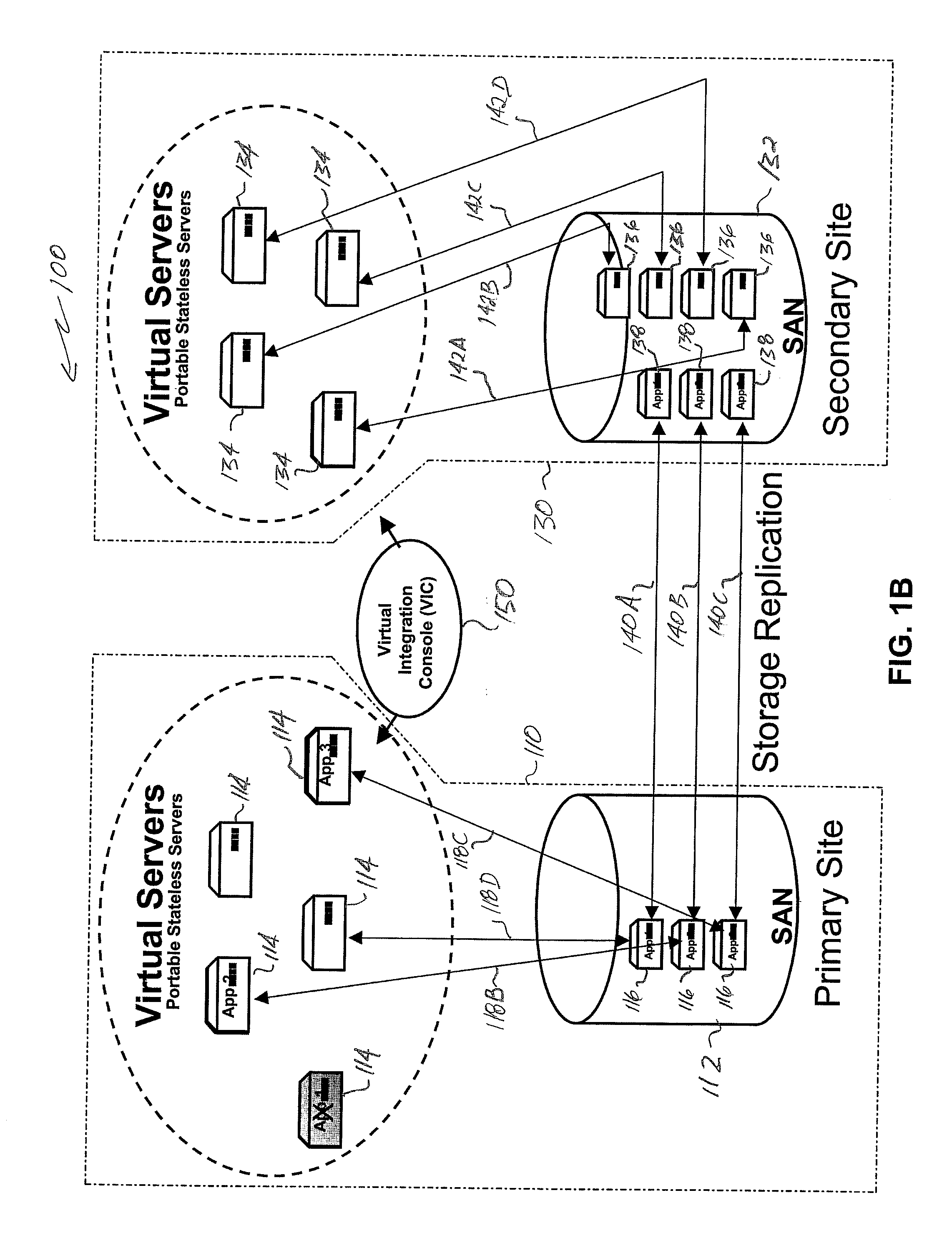

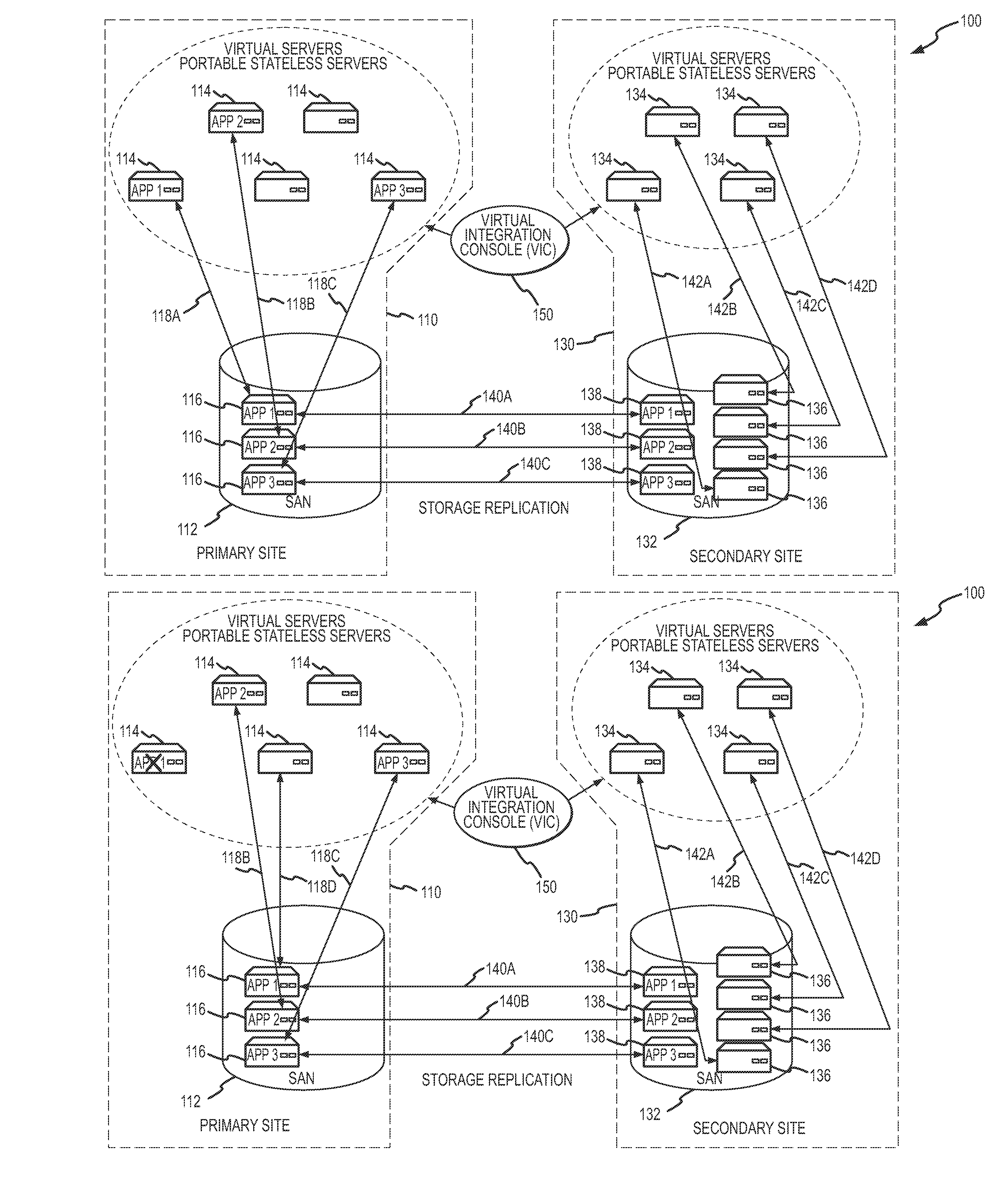

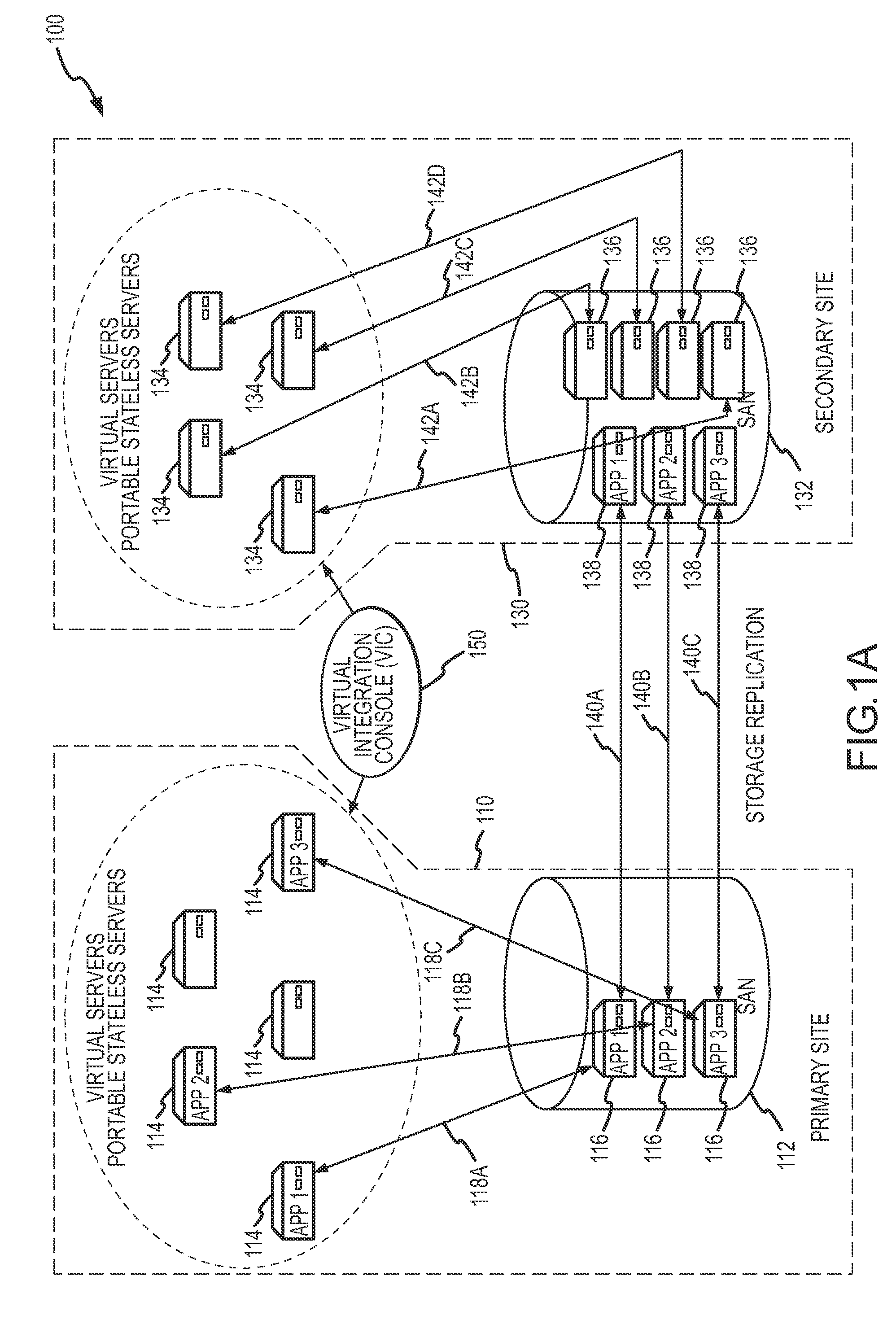

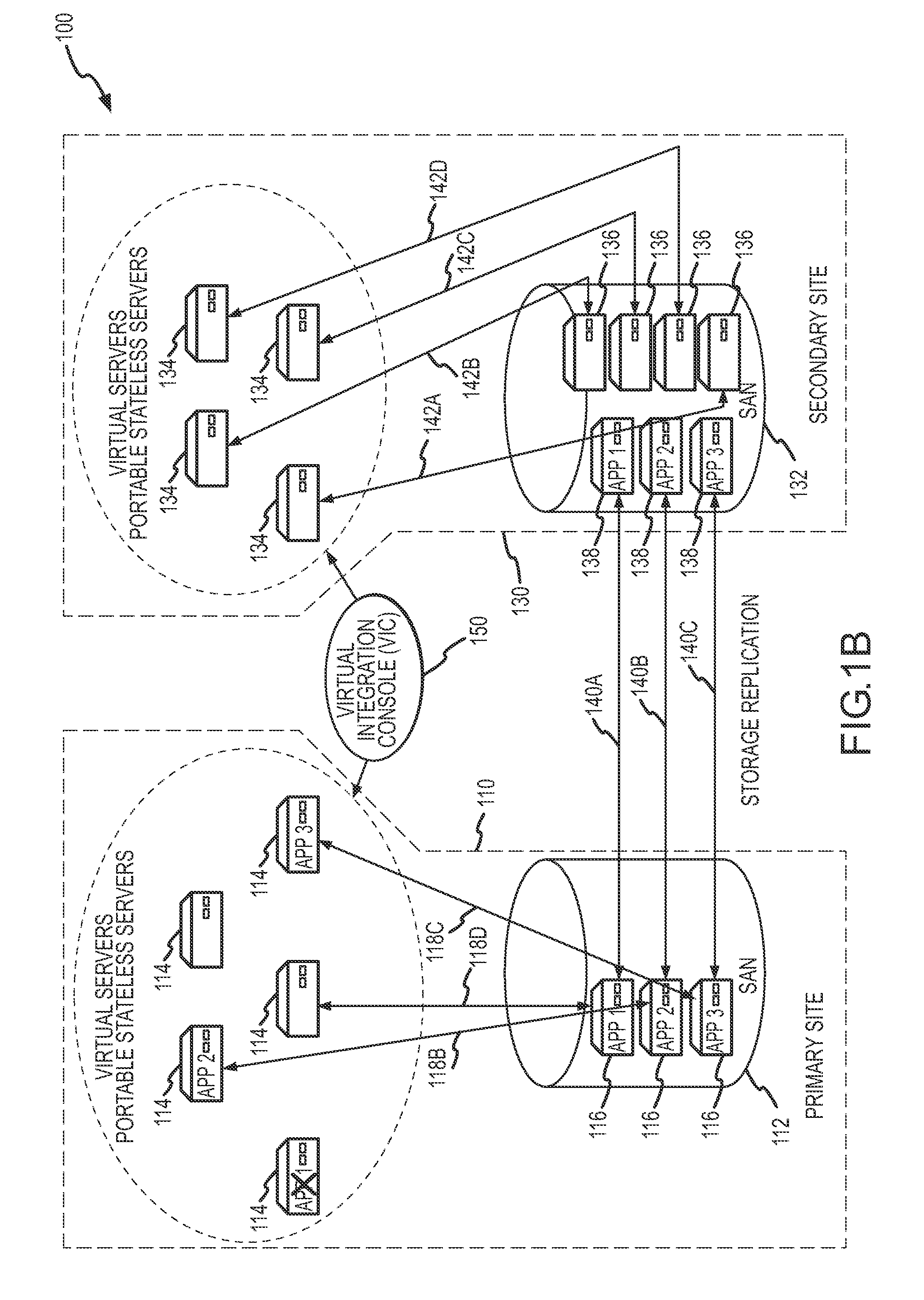

Server virtualization technology is applied to virtualize and encapsulate all unique information of a server as an image that is stored on a storage area network at one site and replicated on a storage area network at another site to provide high availability of system resources and data recovery capabilities. In one embodiment, a virtualized server system (100) includes a primary site (110), a secondary site (130), and a computer executable control application (150). The primary site (110) includes a storage area network (112), at least one primary virtual server platform (114), and at least one primary virtual server stored as at least one image (116) on the storage area network (112). The control application (150) directs replication of the primary virtual server image (116) onto a storage area network (132) at the secondary site (130) to create a corresponding replicated virtual server image (138). The control application (150) also monitors operation of the primary virtual server platform (114) and associates the replicated virtual server image (138) with a secondary virtual server (134) at the secondary site (130) in the event that a problem is detected with the primary site virtual server (114).

Owner:LEIDOS INNOVATIONS TECH INC

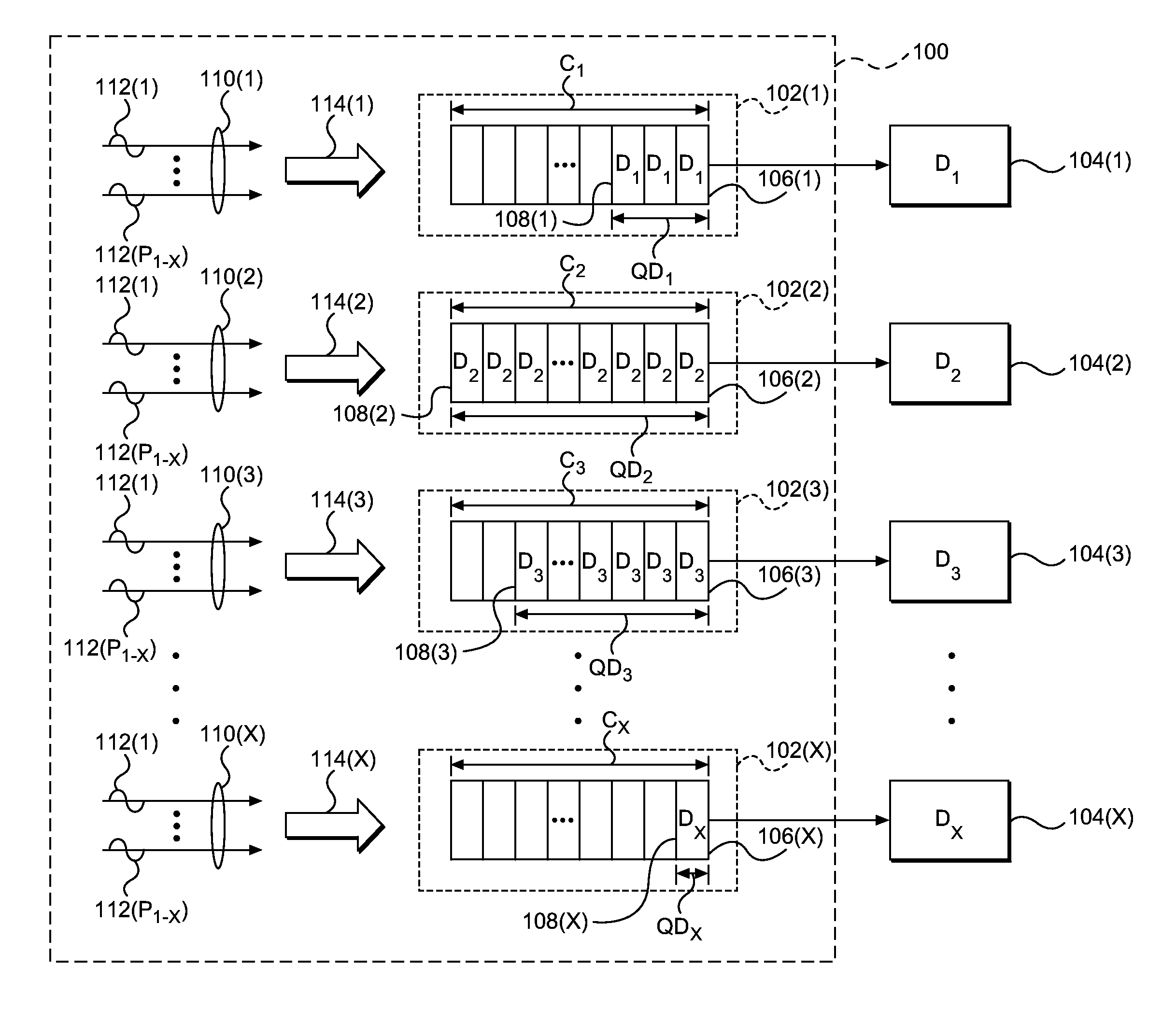

High bandwidth memory management using multi-bank DRAM devices

InactiveUS7296112B1Performance maximizationHigh bandwidthMemory adressing/allocation/relocationHidden dataData segment

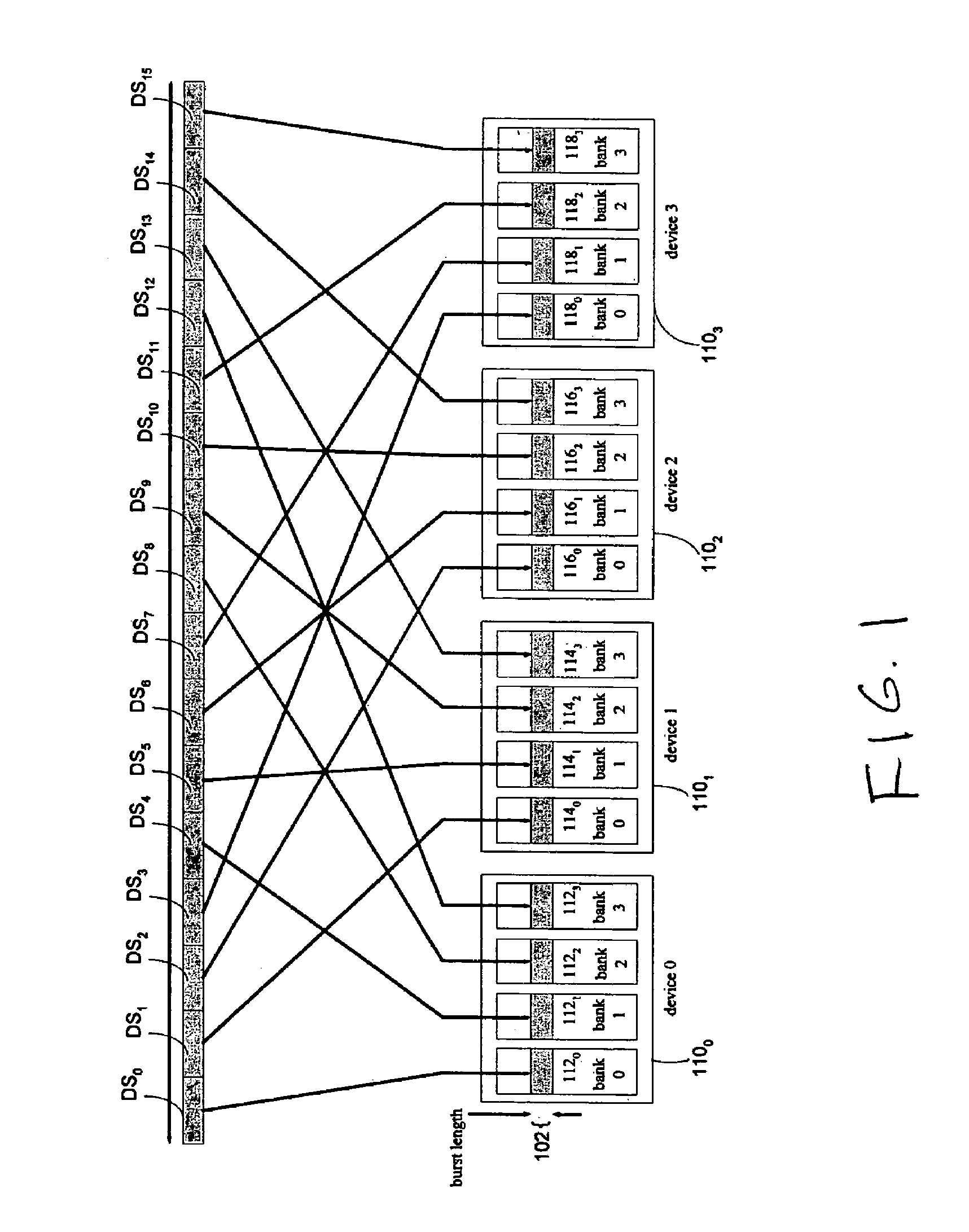

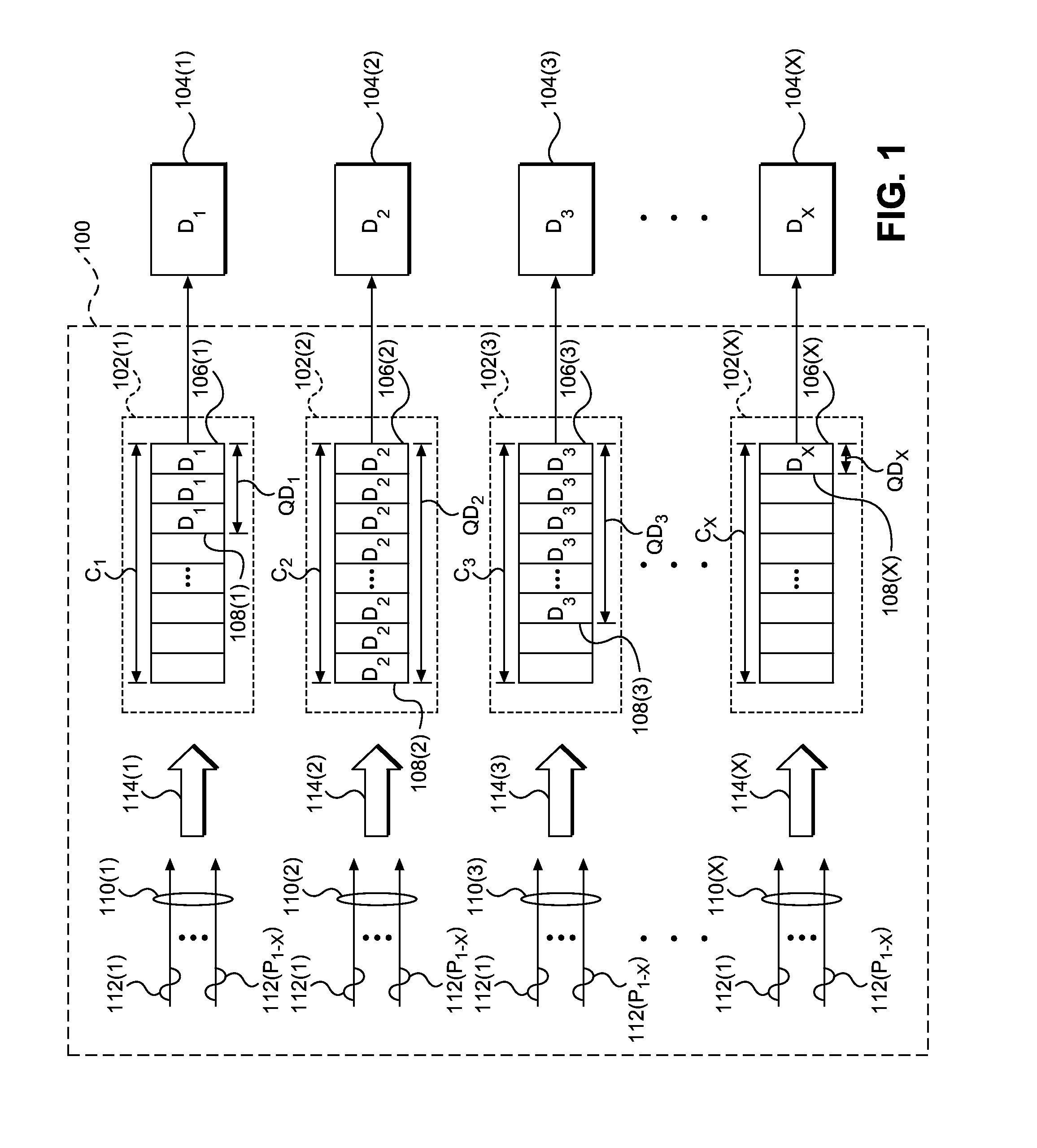

The disclosure describes implementations for accessing in parallel a plurality of banks across a plurality of DRAM devices. These implementations are suited for operation within a parallel packet processor. A data word in partitioned into data segments which are stored in the plurality of banks in accordance with an access scheme that hides pre-charging of rows behind data transfers. A storage distribution control module is communicatively coupled to a memory comprising a plurality of storage request queues, and a retrieval control module is communicatively coupled to a memory comprising a plurality of retrieval request queues. In one example, each request queue may be implemented as a first-in-first-out (FIFO) memory buffer. The plurality of storage request queues are subdivided into sets as are the plurality of retrieval queues. Each is set is associated with a respective DRAM device. A scheduler for each respective DRAM device schedules data transfer between its respective storage queue set and the DRAM device and between its retrieval queue set and the DRAM device independently of the scheduling of the other devices, but based on a shared criteria for queue service.

Owner:CISCO TECH INC

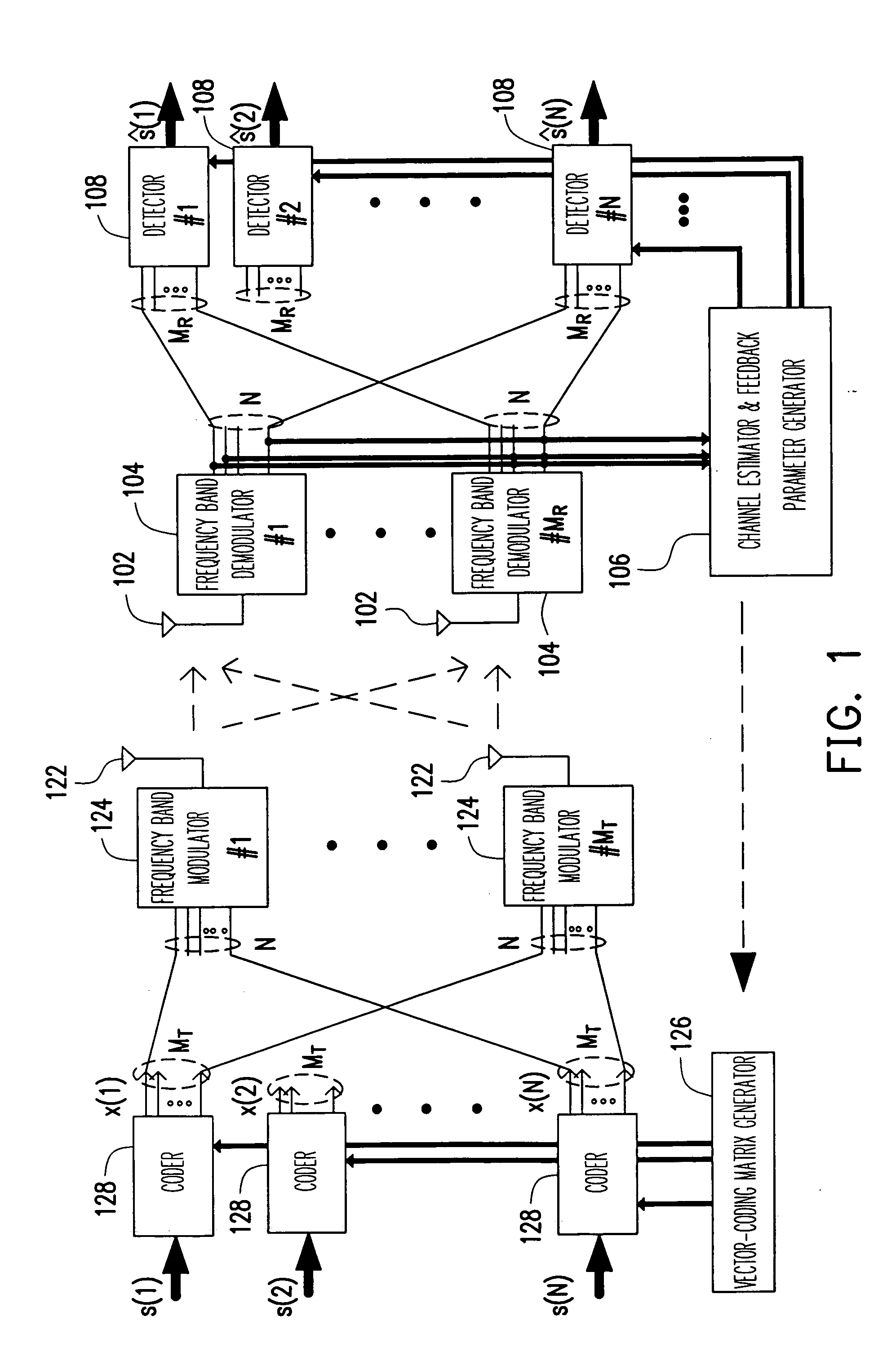

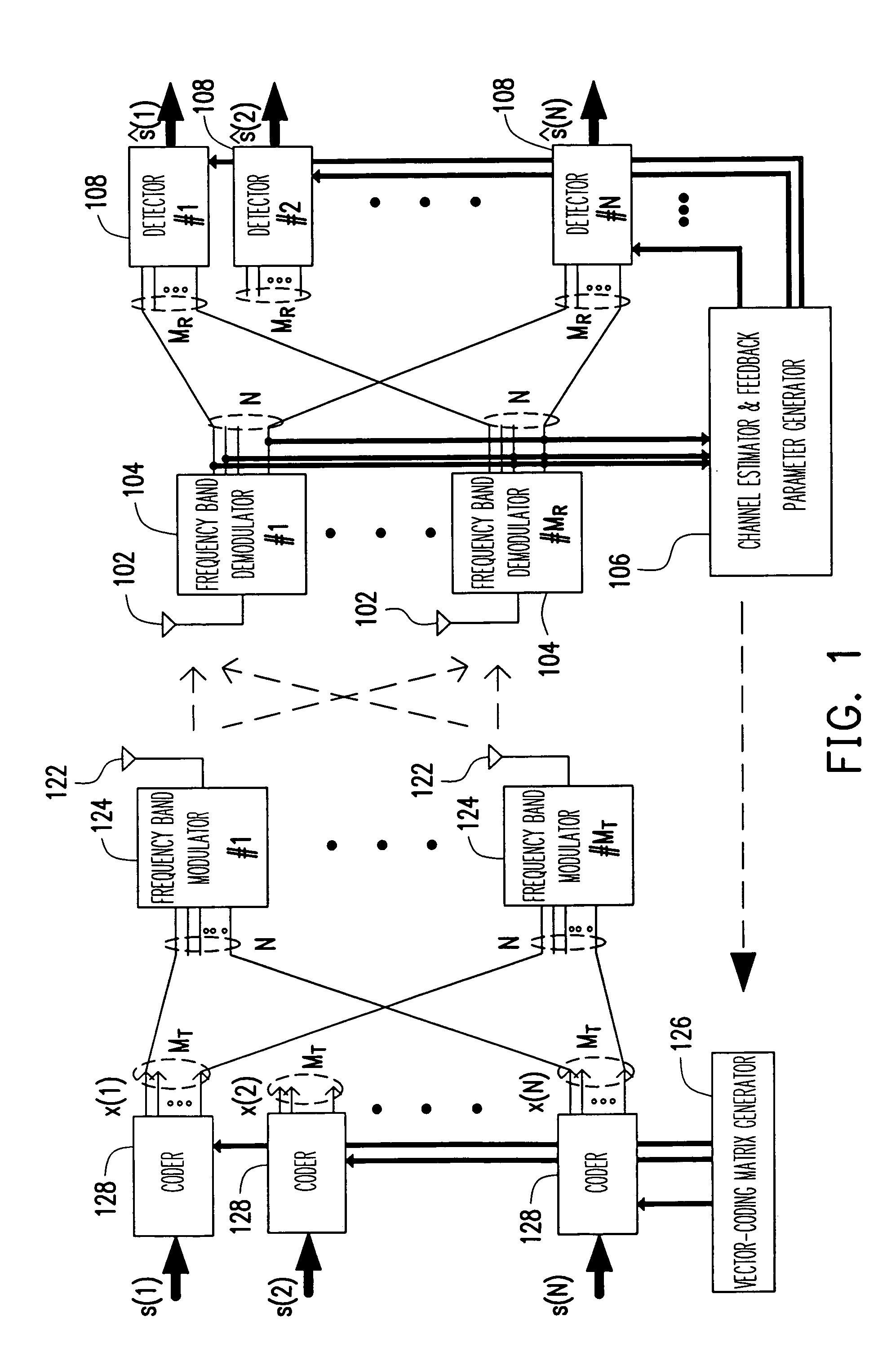

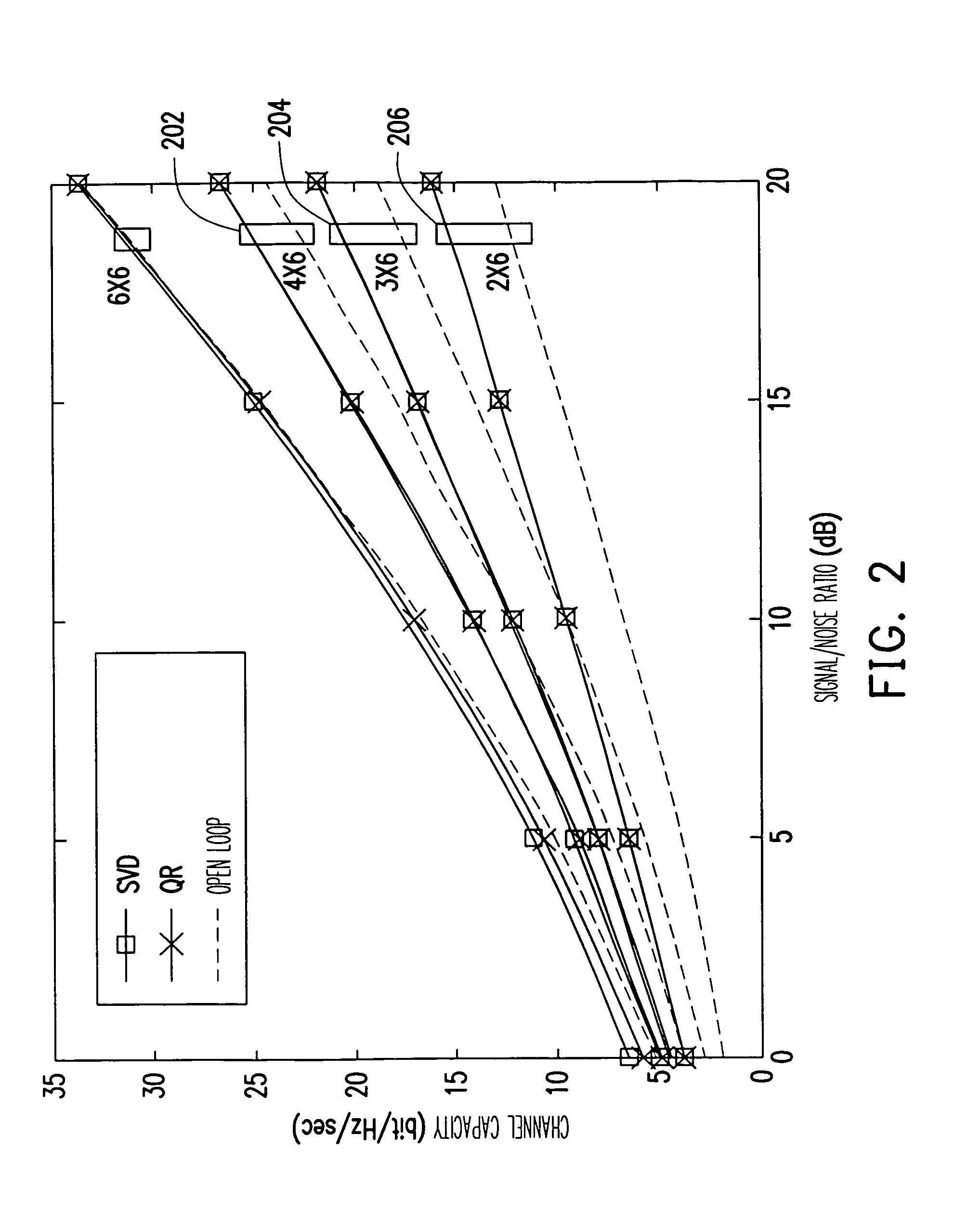

MIMO-OFDM system and pre-coding and feedback method therein

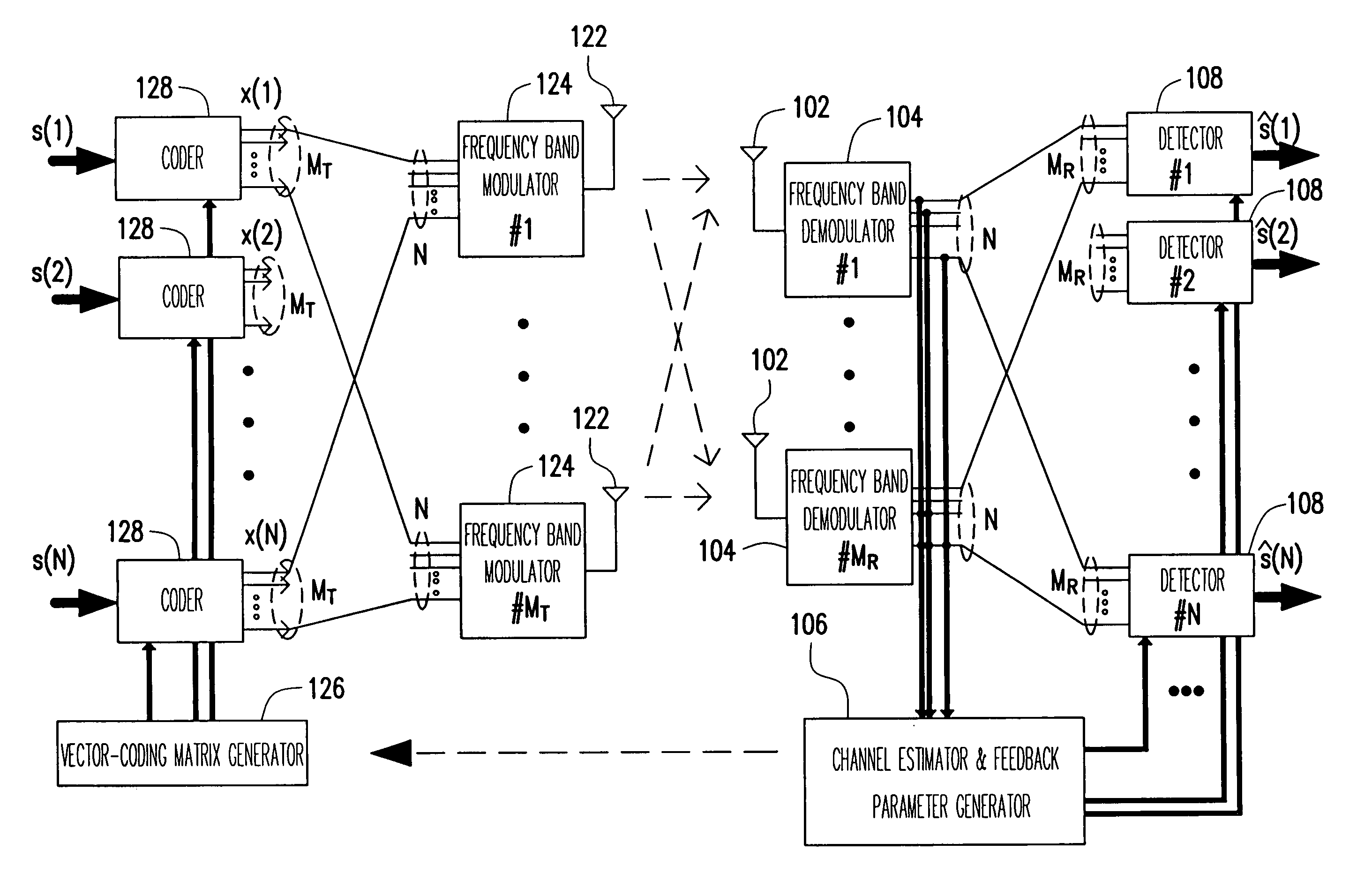

InactiveUS20070115799A1Better respondReduce complexityModulated-carrier systemsRadio transmissionChannel state informationRound complexity

The present invention provides an antenna-array-based multiple-input multiple-output orthogonal-frequency-division-multiplexing (MIMO-OFDM) system and a pre-coding and feedback method used in the same. The present invention uses QR decompositions of the MIMO channel matrixes to parameterize the channel state information (CSI) of every OFDM frequency band. In addition, the present invention feeds back the information related to θ and φ in the Givens rotation matrixes of the partial frequency bands and then uses an interpolation method to generate θ and φ in the Givens rotation matrixes of all the frequency bands, which further is able to represent the CSI of all the frequency bands. In this way, the present invention has advantages of low complexity and low feedback rate requirement.

Owner:MEDIATEK INC

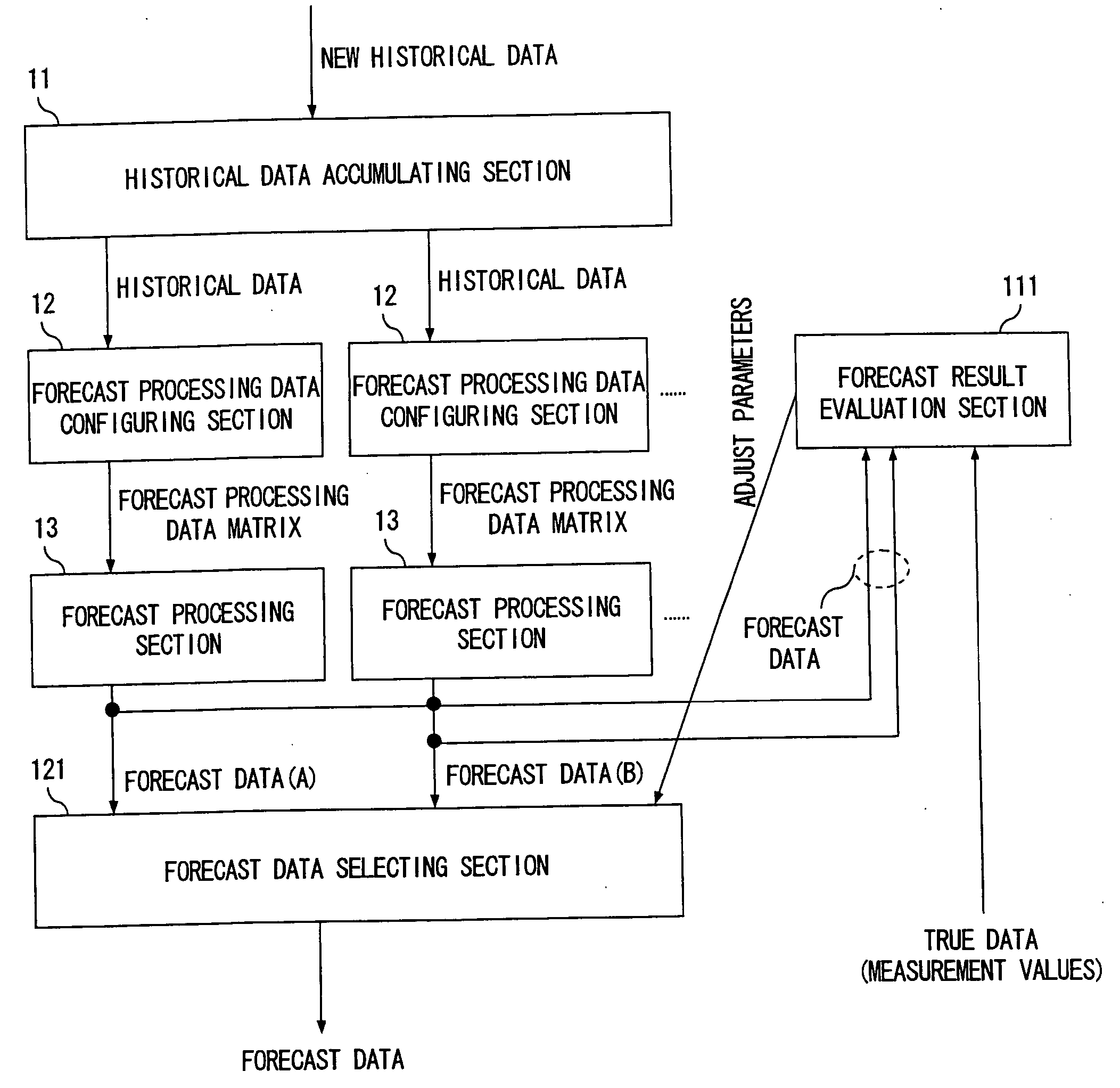

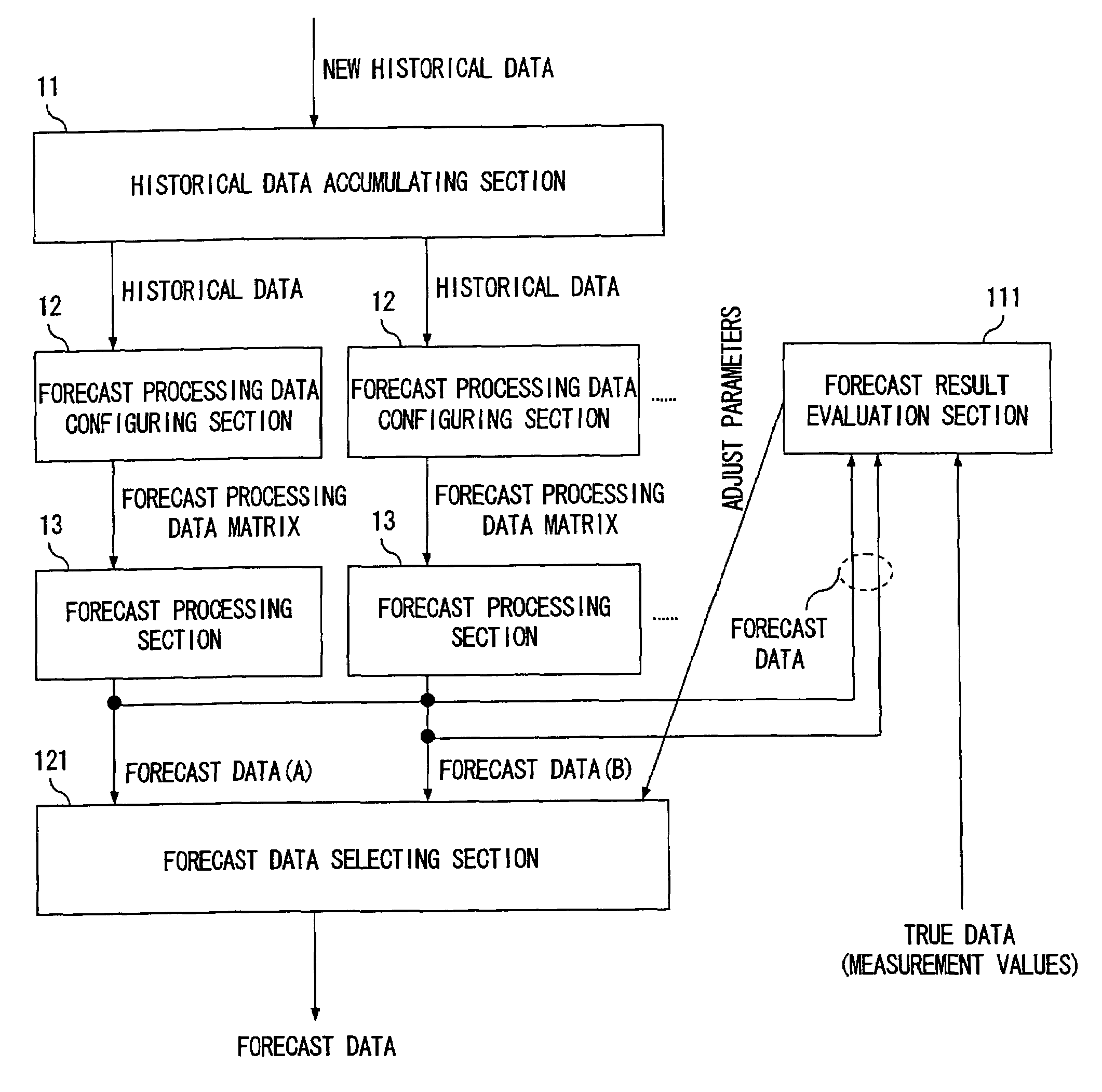

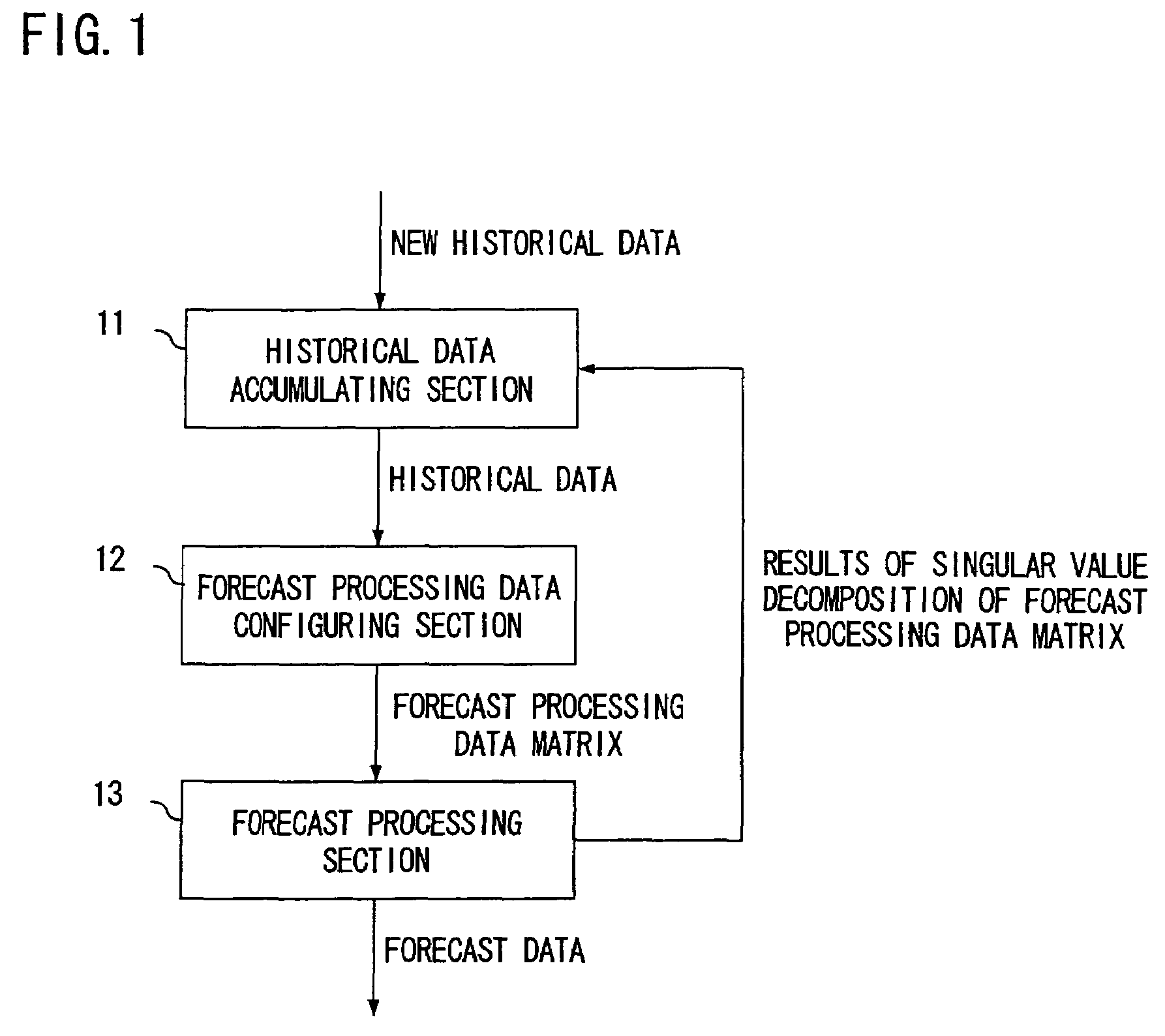

Forecasting apparatus

InactiveUS20050091176A1High data processingGood flexibilityRoad vehicles traffic controlDigital computer detailsSingular value decompositionBusiness forecasting

A forecasting apparatus for predicting future events includes a forecast processing data configuring section for configuring a data matrix including previously accumulated historical data and unknown forecast data, the data matrix having the unknown forecast data as missing elements, and a forecast processing section for estimating values of the missing elements representative of the unknown forecast data by performing singular value decomposition of the data matrix configured by the forecast processing data configuring section.

Owner:MITSUBISHI ELECTRIC CORP

Forecasting apparatus

InactiveUS7472099B2Good flexibilityHigh data processingRoad vehicles traffic controlDigital computer detailsSingular value decompositionBusiness forecasting

A forecasting apparatus for predicting future events includes a forecast processing data configuring section for configuring a data matrix including previously accumulated historical data and unknown forecast data, the data matrix having the unknown forecast data as missing elements, and a forecast processing section for estimating values of the missing elements representative of the unknown forecast data by performing singular value decomposition of the data matrix configured by the forecast processing data configuring section.

Owner:MITSUBISHI ELECTRIC CORP

Application of virtual servers to high availability and disaster recovery solutions

InactiveUS7933987B2Improve availabilityHigh dataError detection/correctionMultiple digital computer combinationsVirtualizationStorage area network

Server virtualization technology is applied to virtualize and encapsulate all unique information of a server as an image that is stored on a storage area network at one site and replicated on a storage area network at another site to provide high availability of system resources and data recovery capabilities. In one embodiment, a virtualized server system (100) includes a primary site (110), a secondary site (130), and a computer executable control application (150). The primary site (110) includes a storage area network (112), at least one primary virtual server platform (114), and at least one primary virtual server stored as at least one image (116) on the storage area network (112). The control application (150) directs replication of the primary virtual server image (116) onto a storage area network (132) at the secondary site (130) to create a corresponding replicated virtual server image (138). The control application (150) also monitors operation of the primary virtual server platform (114) and associates the replicated virtual server image (138) with a secondary virtual server (134) at the secondary site (130) in the event that a problem is detected with the primary site virtual server (114).

Owner:LEIDOS INNOVATIONS TECH INC

MIMO-OFDM system and pre-coding and feedback method therein

InactiveUS7486655B2Avoid excessive computationHigh complexityModulated-carrier systemsPolarisation/directional diversityChannel state informationRound complexity

The present invention provides an antenna-array-based multiple-input multiple-output orthogonal-frequency-division-multiplexing (MIMO-OFDM) system and a pre-coding and feedback method used in the same. The present invention uses QR decompositions of the MIMO channel matrixes to parameterize the channel state information (CSI) of every OFDM frequency band. In addition, the present invention feeds back the information related to θ and φ in the Givens rotation matrixes of the partial frequency bands and then uses an interpolation method to generate θ and φ in the Givens rotation matrixes of all the frequency bands, which further is able to represent the CSI of all the frequency bands. In this way, the present invention has advantages of low complexity and low feedback rate requirement.

Owner:MEDIATEK INC

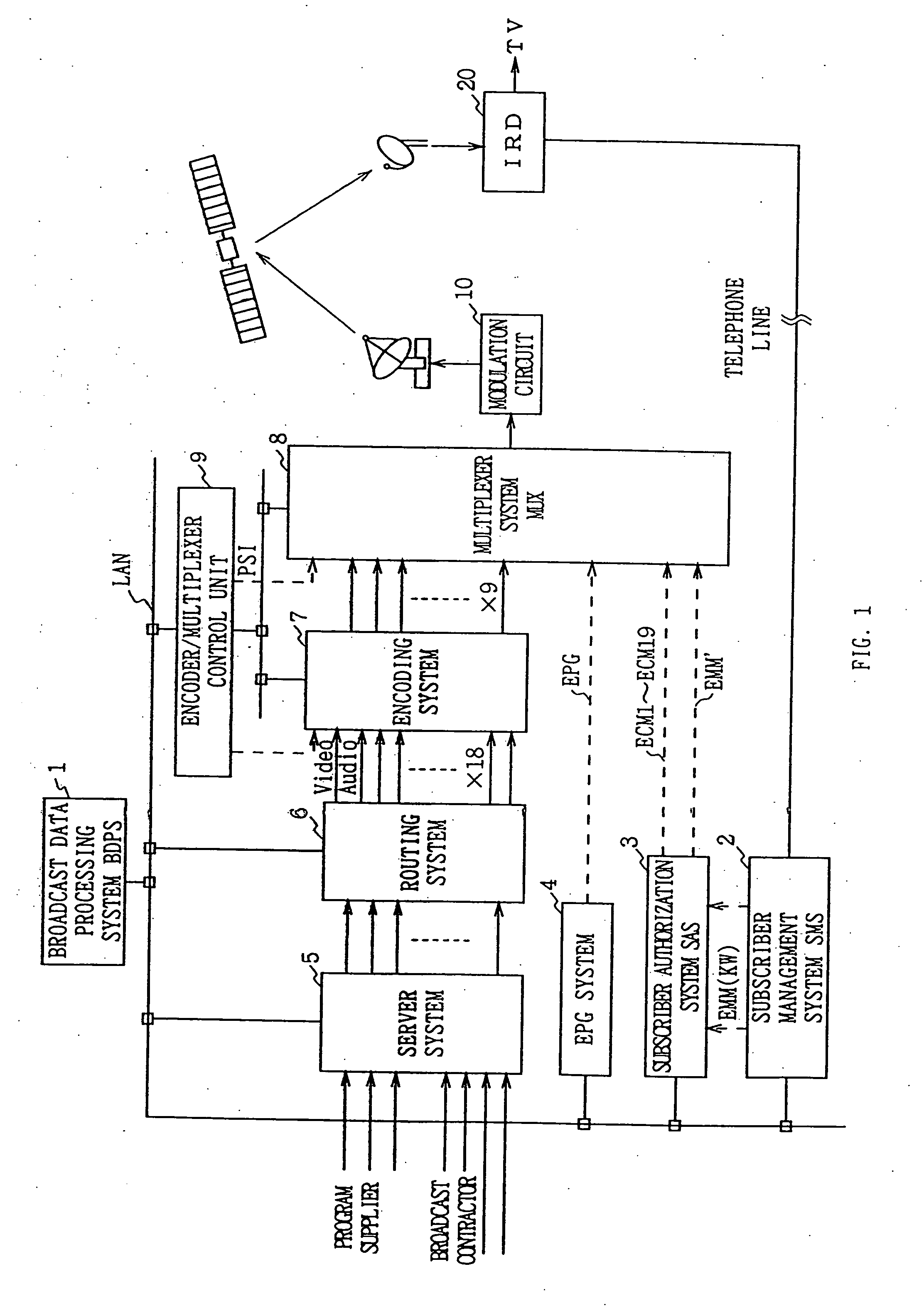

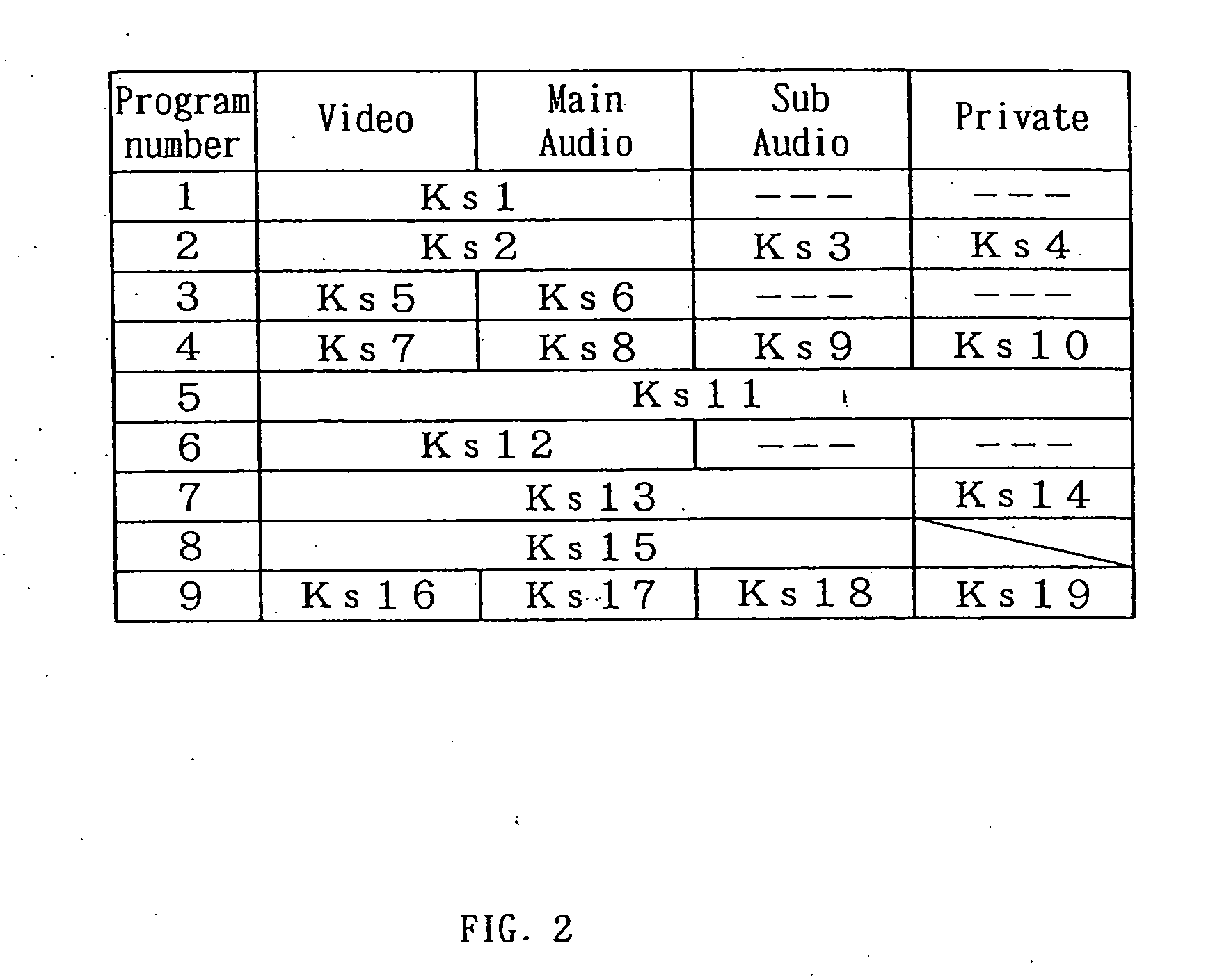

Data multiplexing device, program distribution system, program transmission system, pay broadcast system, program transmission method, conditional access system, and data reception device

InactiveUS20050226417A1Simple circuit configurationHigh dataTwo-way working systemsSelective content distributionDistribution systemTransfer system

In a data multiplexing device which multiplexes and transmits the transport stream packets of program data consisting of a plurality of data elements constructed in the form of transport stream packets, a program distribution system, a program transmission system, a pay broadcast system, a program transmission method, a conditional access system, and a data reception device according to the present invention, by generating a scramble key Ks corresponding to one or more data elements among the plurality of data elements constituting a program and by scrambling each data element, an audience can subscribe for each data element.

Owner:SONY CORP

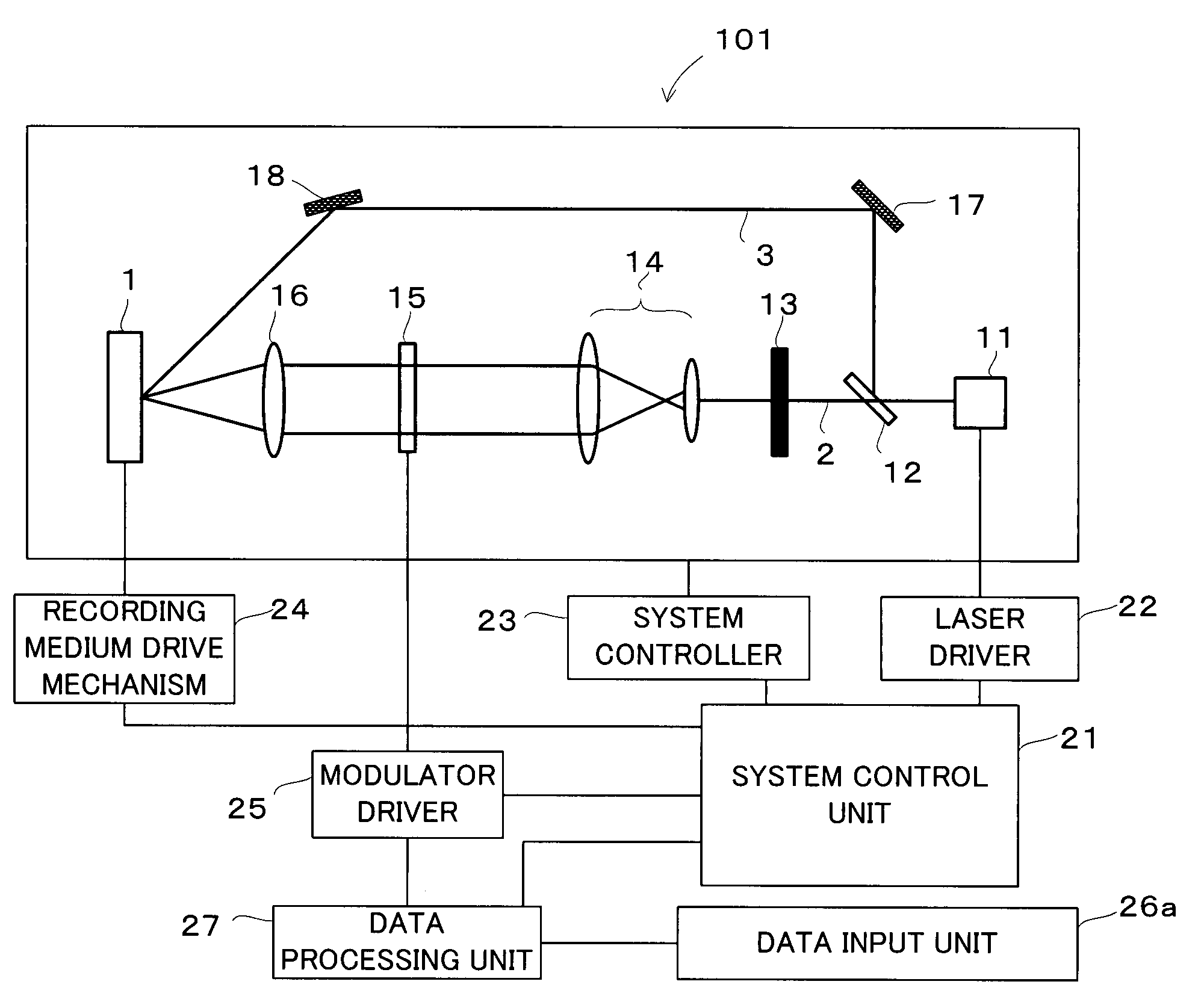

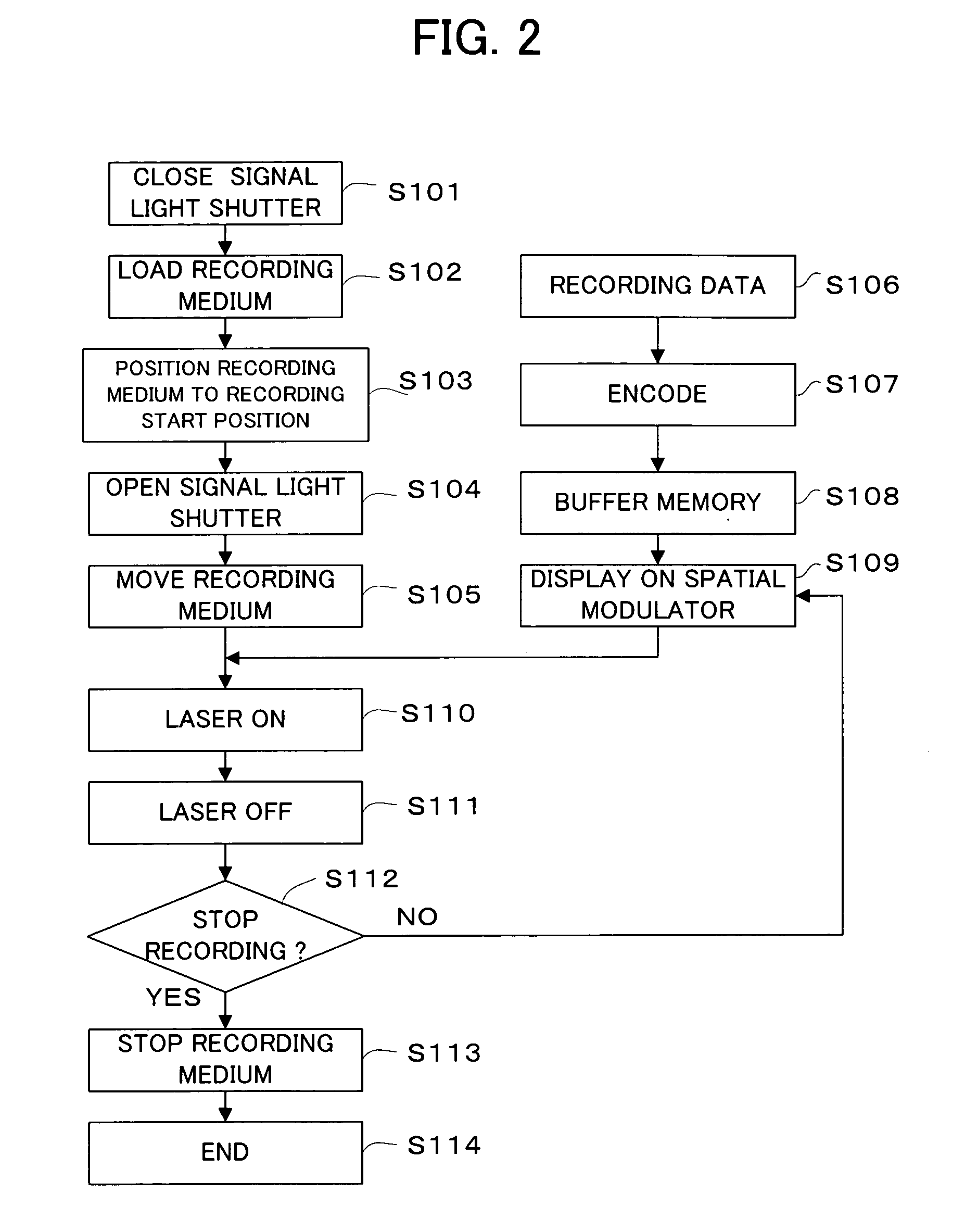

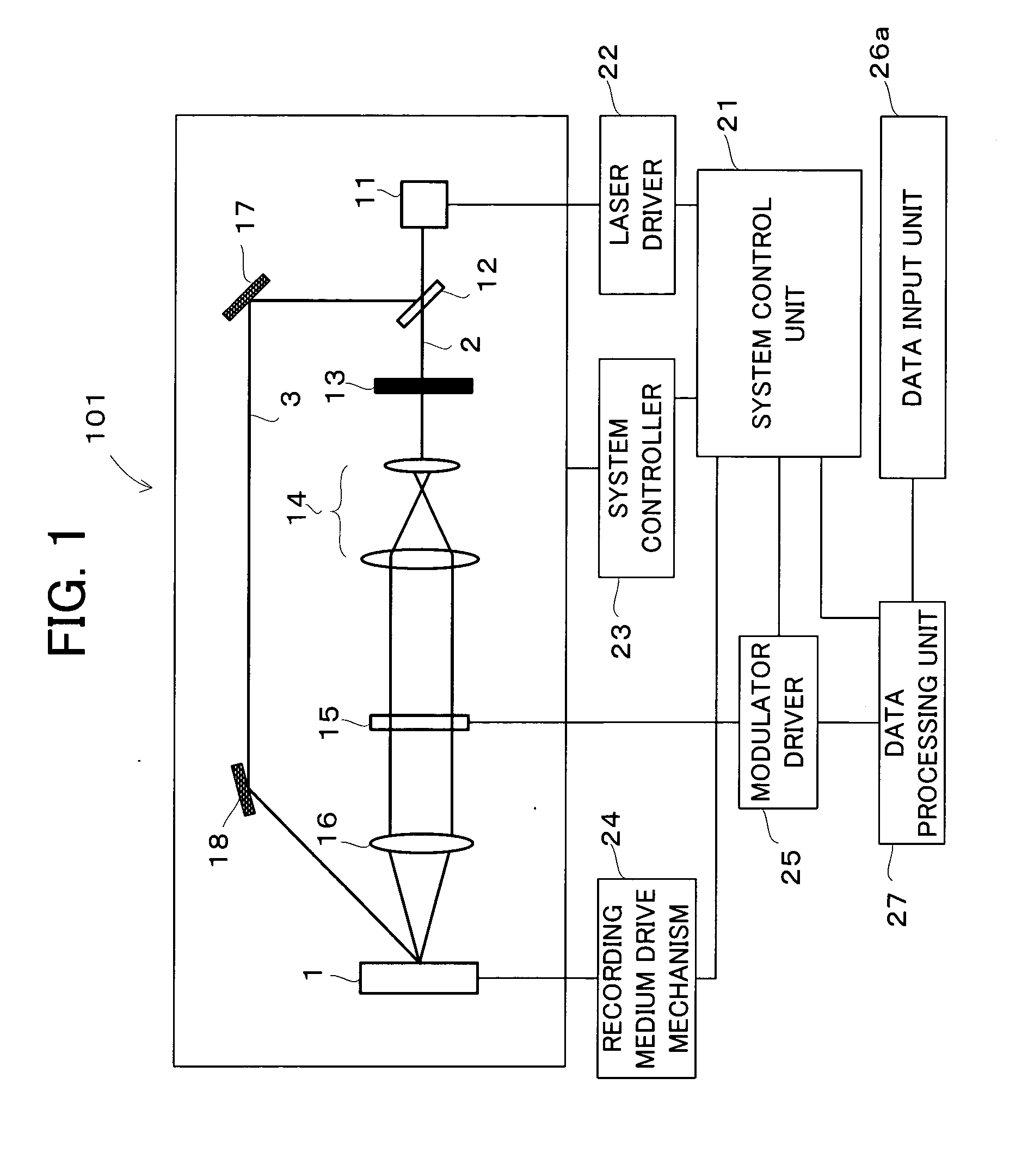

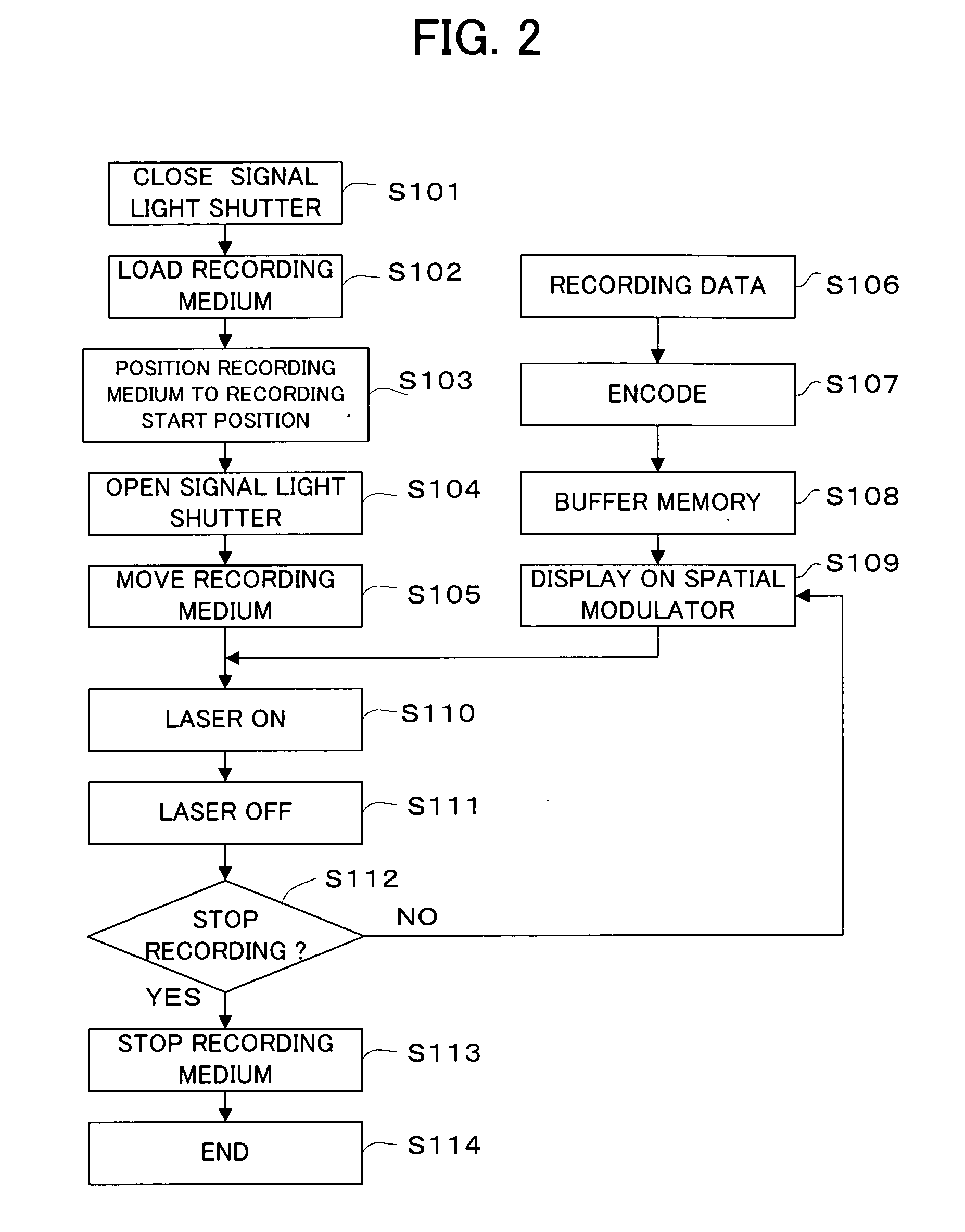

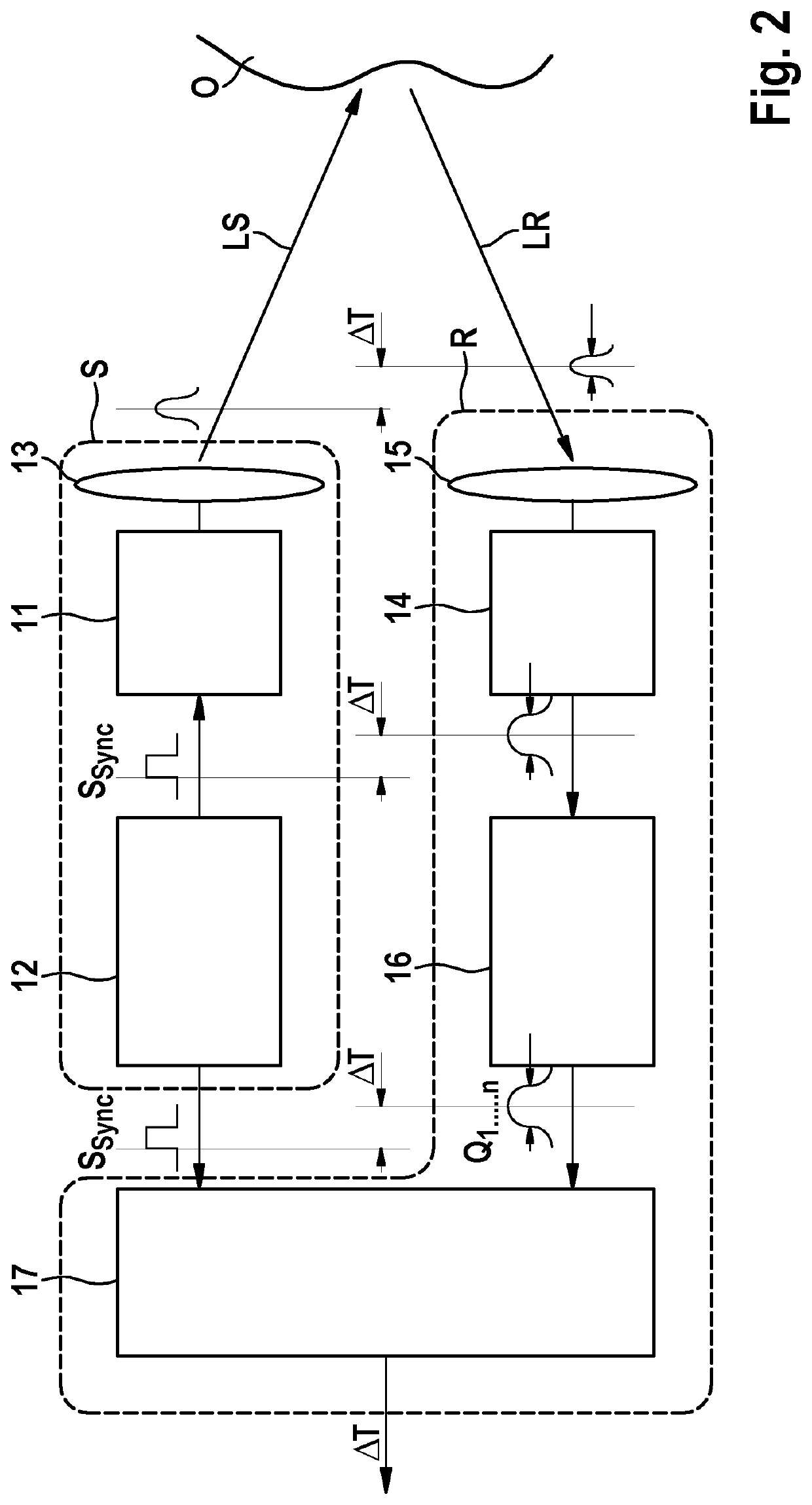

Recording device, reproduction device, and recording/reproduction device

InactiveUS7236441B2High data recordingLarge amplitude modulationOptical beam sourcesHolographic light sources/light beam propertiesFourier transform on finite groupsSignal light

An example recording apparatus includes a pulse oscillation laser, a half mirror for splitting the pulse oscillation light of the laser into a signal light and a reference light, an optical shutter disposed in the optical path of the signal light, a beam expander for converting the signal light into a light beam of a predetermined diameter, a spatial modulator for modulating the recording data into two-dimensional image information, a Fourier Transform lens for introducing the signal light modulated by the spatial modulator onto a recording medium, mirrors for introducing the reference light onto the recording medium with a predetermined angle, a system control unit, a laser driver, a system controller, a recording medium drive mechanism, a modulator driver, a data input unit, and a data processing unit.

Owner:PIONEER CORP

Cascaded-time-scale background modeling

InactiveUS20180144476A1Improve accuracyHigh bandwidthImage enhancementImage analysisPattern recognitionMedium term

Owner:QUALCOMM INC

Recording device, reproduction device, and recording/reproduction device

InactiveUS20050249095A1Large amplitude modulationGood S/N ratio reproductionOptical beam sourcesHolographic light sources/light beam propertiesFourier transform on finite groupsSignal light

A recording apparatus includes a pulse oscillation laser (11), a half mirror (12) for splitting the pulse oscillation light of the laser into a signal light (2) and a reference light (3), an optical shutter (13) disposed in the optical path of the signal light, a beam expander (14) for converting the signal light into a light beam of a predetermined diameter, a spatial modulator (15) for modulating the recording data into two-dimensional image information, a Fourier Transform lens (16) for introducing the signal light modulated by the spatial modulator onto a recording medium (1), mirrors (17, 18) for introducing the reference light onto the recording medium with a predetermined angle, a system control unit (21), a laser driver (22), a system controller (23), a recording medium drive mechanism (24), a modulator driver (25), a data input unit (26a), and a data processing unit (27).

Owner:PIONEER CORP

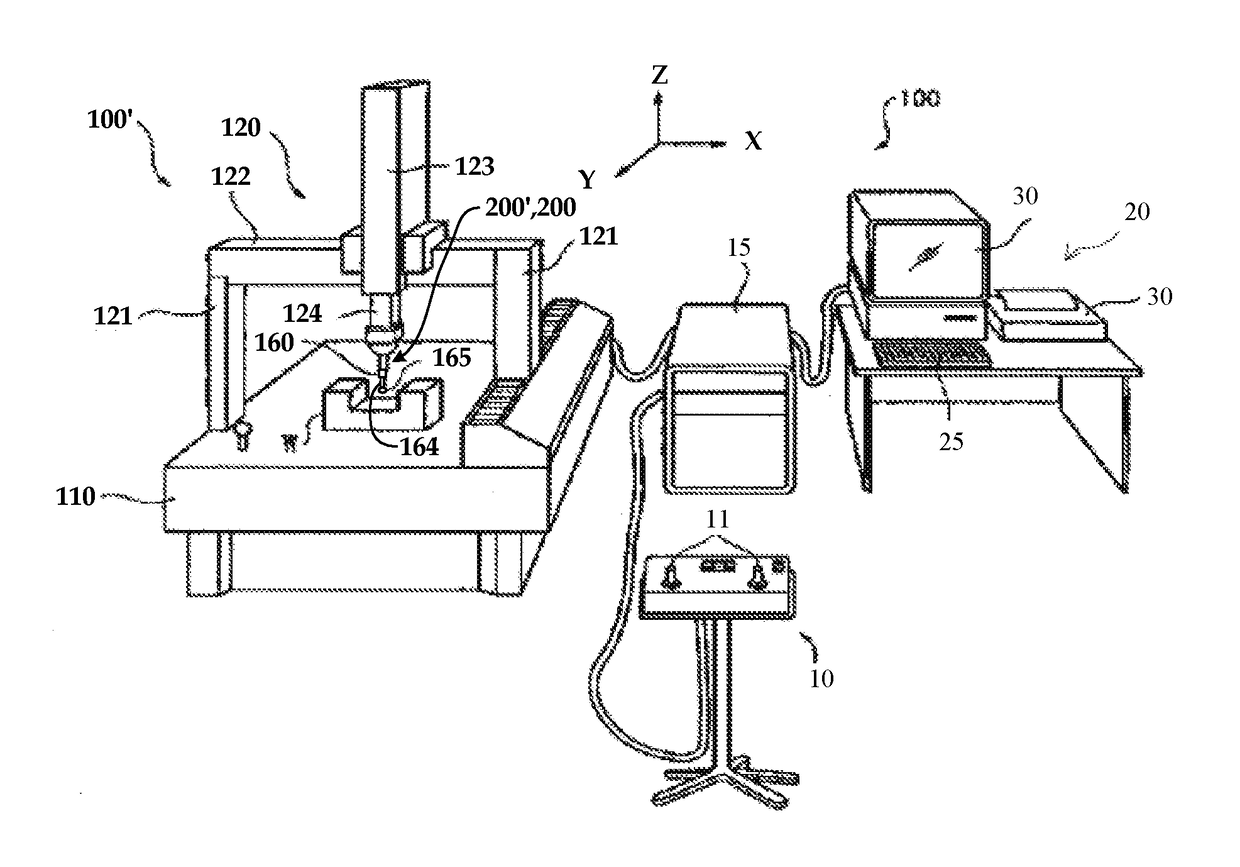

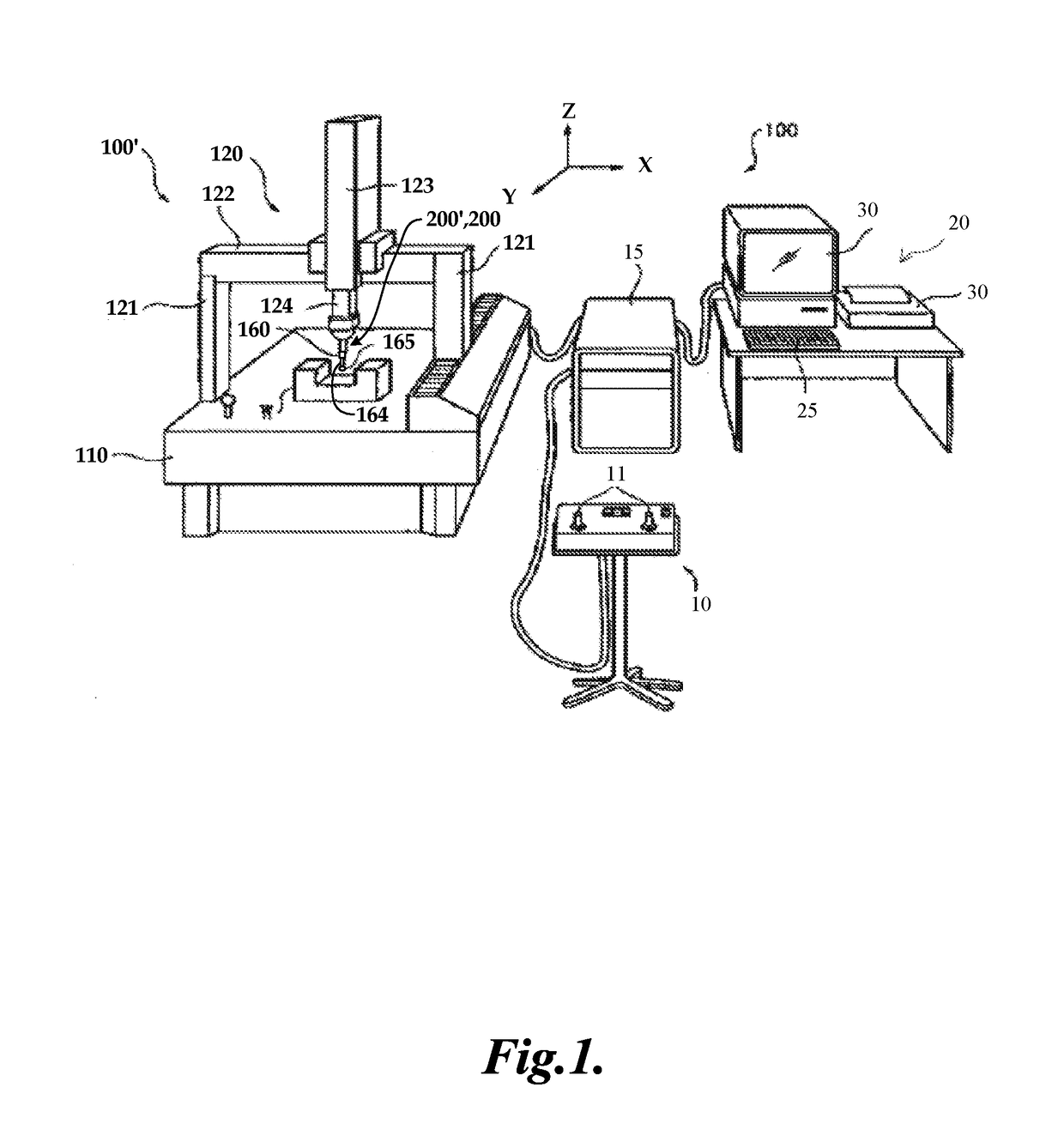

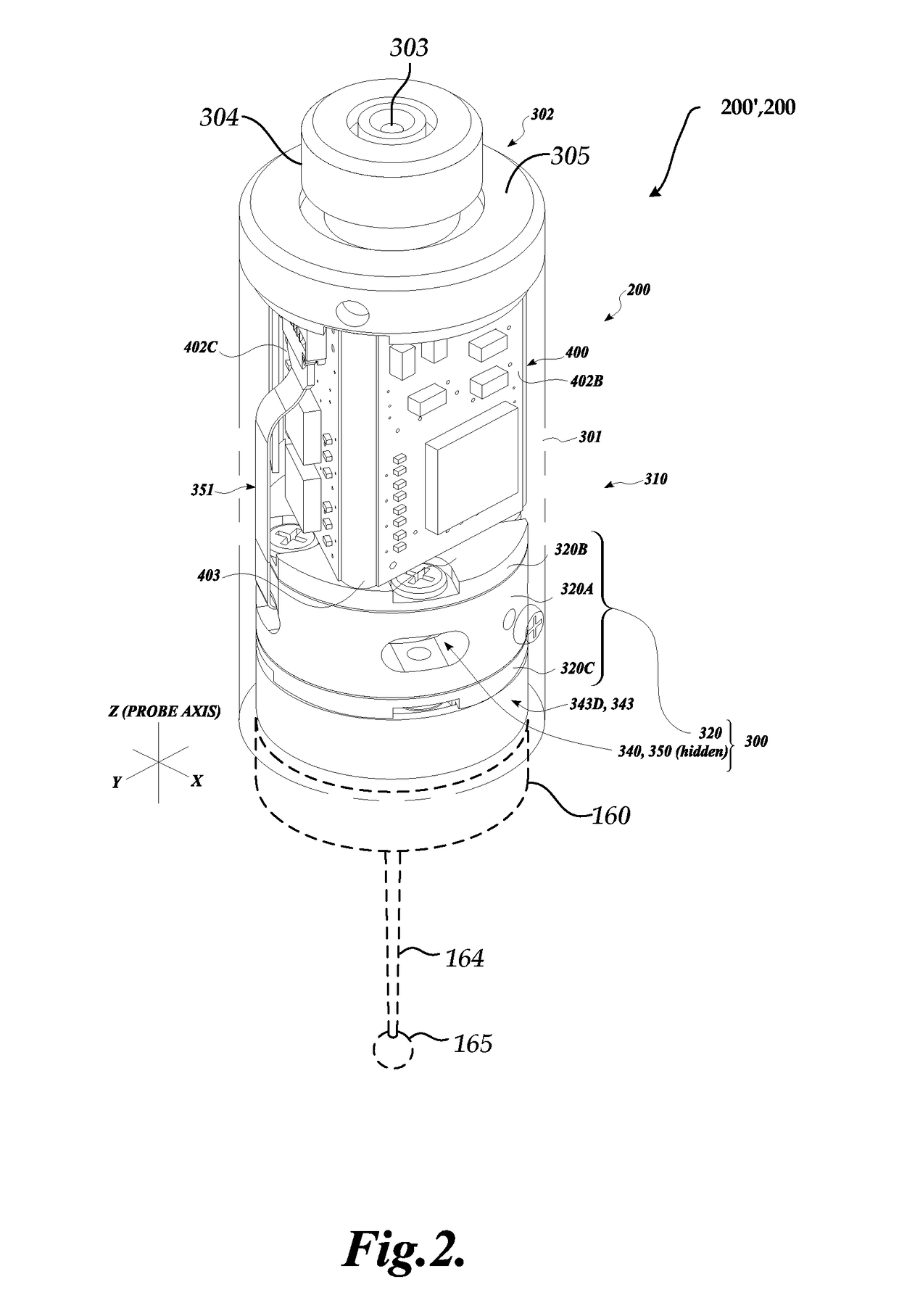

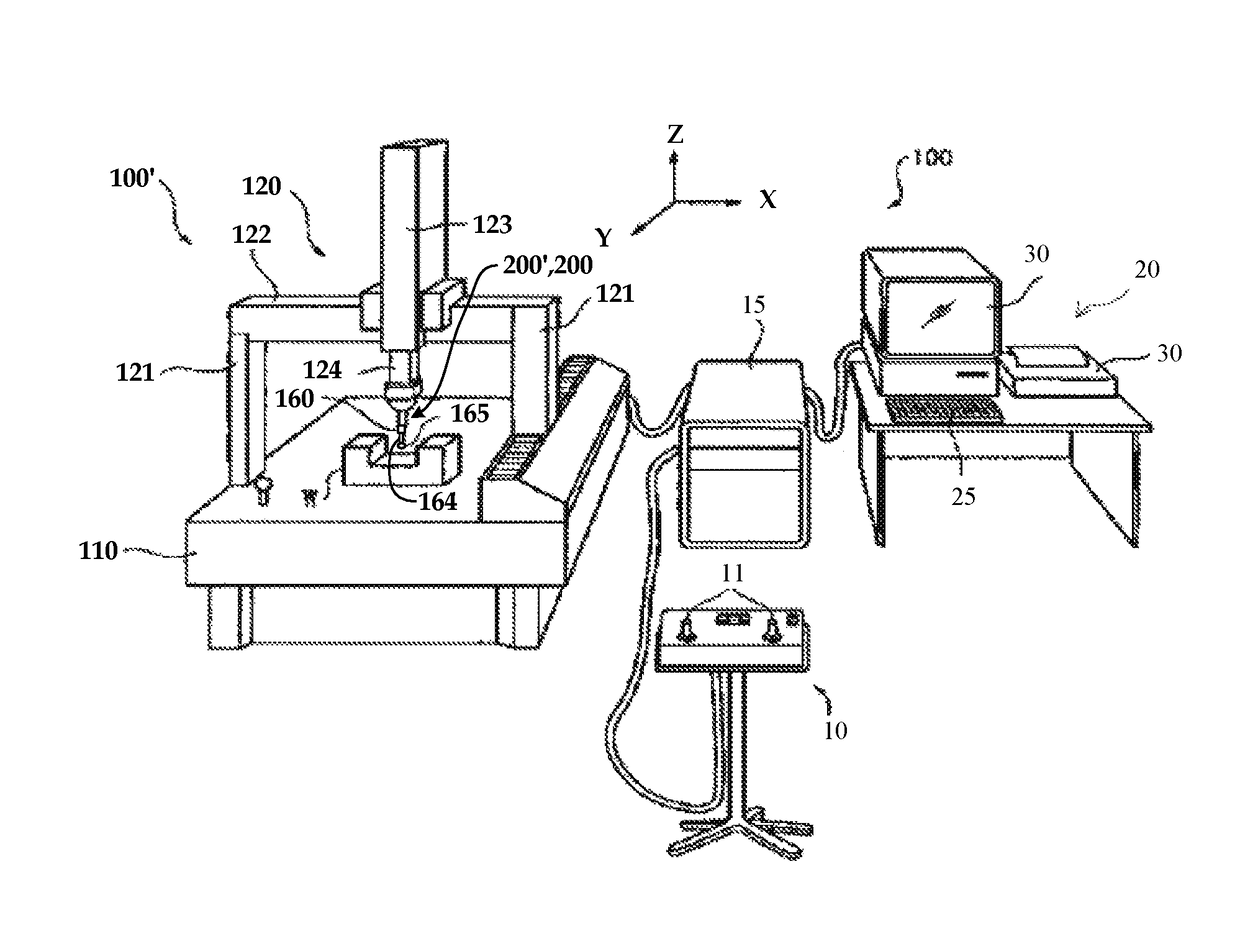

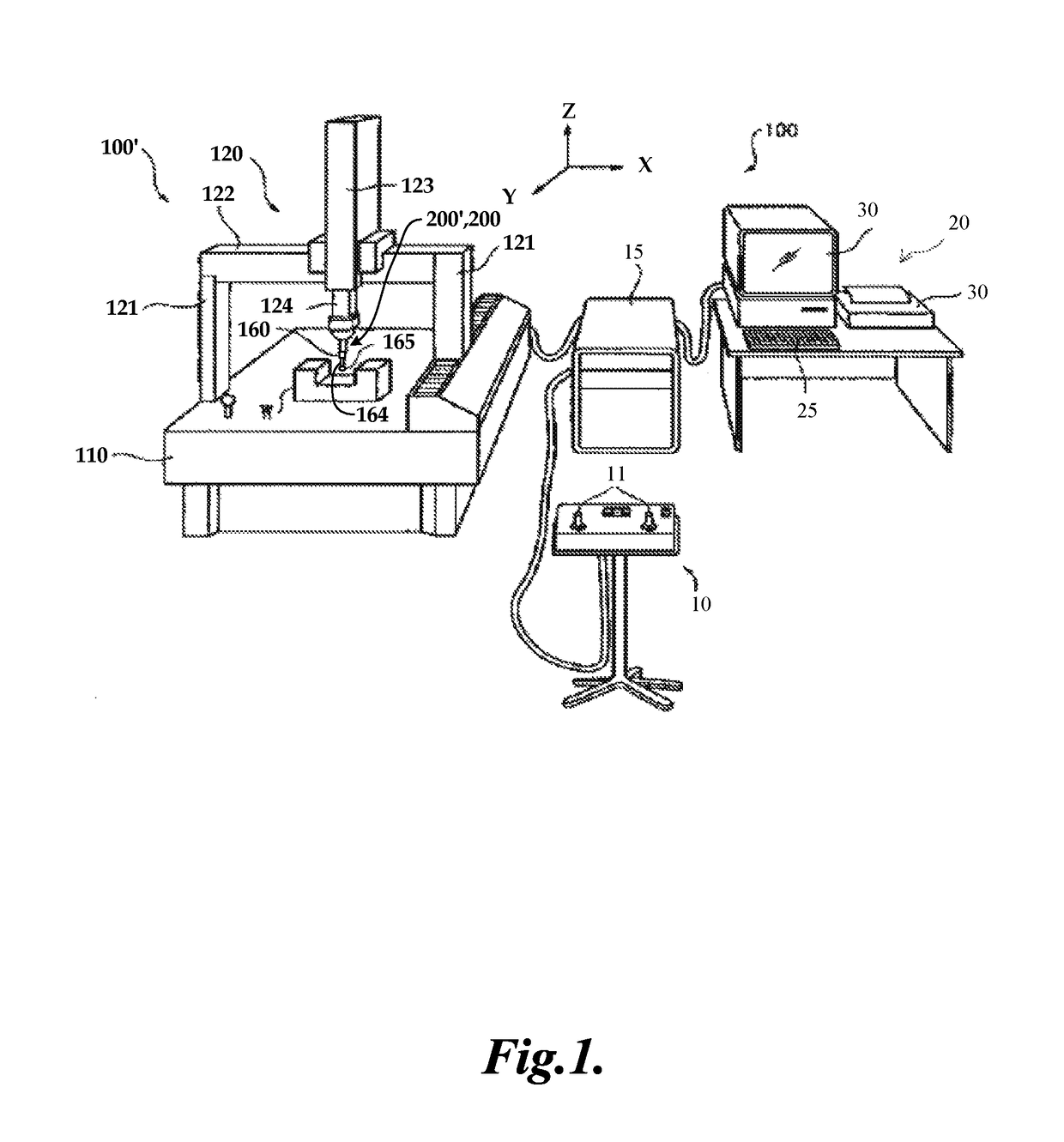

Trigger counter for measurement device with count values stored in flash memory

ActiveUS20180156594A1High reliability data recordingImprove retentionMechanical measuring arrangementsPoint coordinate measurementsMeasurement deviceCoordinate-measuring machine

A system and method are provided for operating a touch probe for a coordinate measuring machine, wherein a value is permanently stored in the touch probe corresponding to an accumulated number of trigger signals generated in the touch probe over its operating history. For a non-erase cycle during which an erasable trigger counter block (e.g., included in a flash memory) of the touch probe is not erased, increasing values of an accumulated trigger count are stored in N address locations of the erasable trigger counter block. After all of the N address locations have been used, an erase operation sequence is performed, and a new non-erase cycle is initiated for repeating the process. In various implementations, the touch probe may not include an embedded processor or battery, for which the types of circuitry and methods that may be utilized for maintaining and storing the accumulated trigger count are correspondingly limited.

Owner:MITUTOYO CORP

Microelectro mechanical system for magneto-optic data storage apparatus

InactiveUS7002226B2High dataImprove efficiencyCombination recordingPhotometry using reference valueResistAir bearing

Owner:NAT CHIAO TUNG UNIV

Head-of-line blocking (HOLB) mitigation in communication devices

InactiveUS20160337257A1Mitigating HOLBAvoid dataData switching networksData integrityHead-of-line blocking

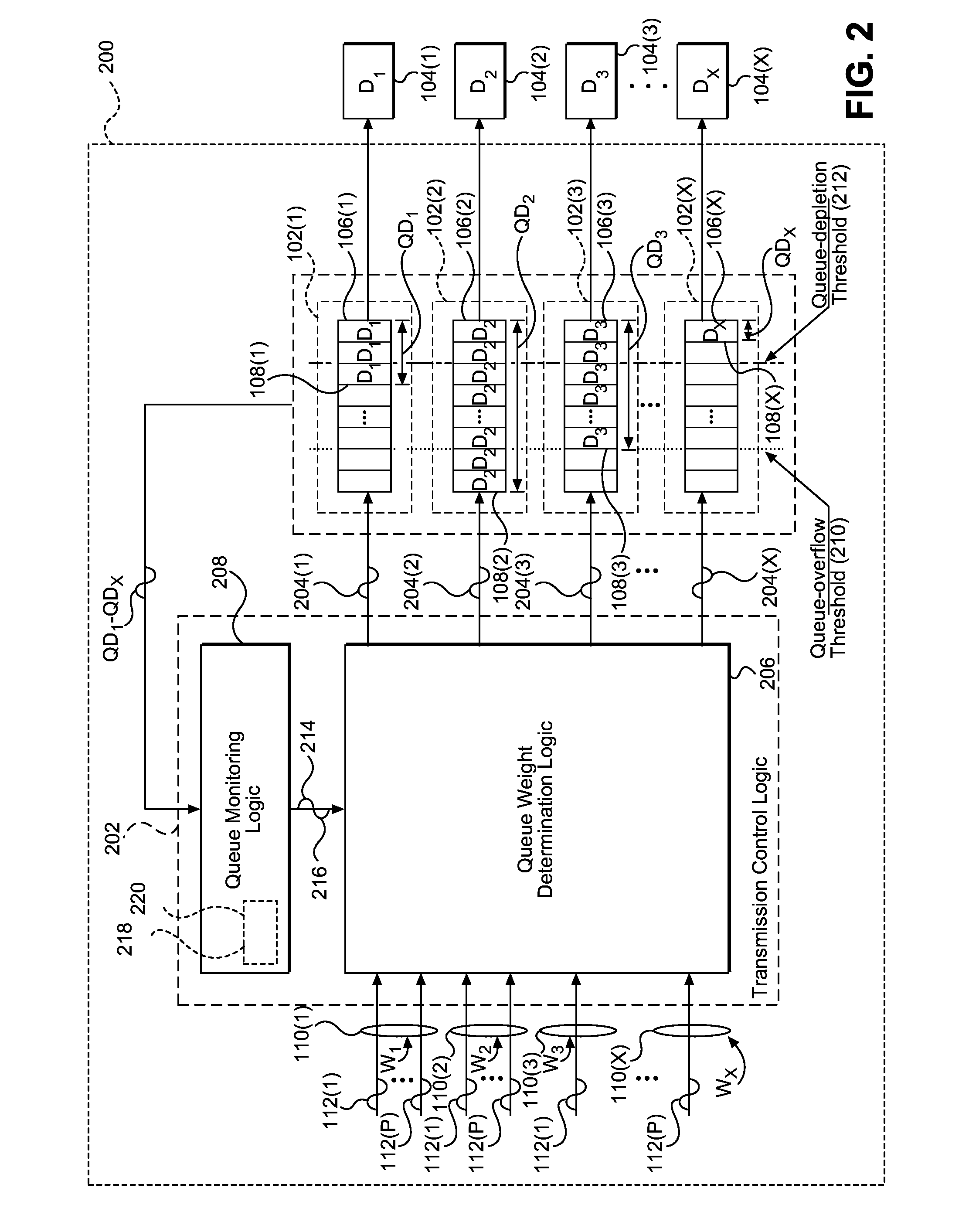

Aspects disclosed in the detailed description include head-of-line blocking (HOLB) mitigation in communication devices. Output queues employed by a communication device for transmitting data are susceptible to HOLB. In this regard, in one aspect, a queue monitoring logic is configured to detect HOLB by measuring and comparing a depth(s) of an output queue(s) against a queue-overflow threshold. If the depth(s) of the output queue(s) exceeds the queue-overflow threshold, a queue weight(s) of a corresponding input queue(s) is decreased to reduce data flow into the output queue(s), thus mitigating the HOLB in the output queue(s). In another aspect, the queue monitoring logic is configured to detect queue depletion by comparing the depth(s) of the output queue(s) against a queue-depletion threshold. By mitigating the HOLB and the data starvation in the output queue(s), it is possible to optimize the output queue(s) to achieve higher throughput and data integrity with lower power consumption.

Owner:QUALCOMM INC

Battery Management System Having a Data Interface for a Battery Module, Battery Module Having a Data Memory, Battery System Having a Battery Management System and a Battery Module, and Motor Vehicle Having a Battery System

InactiveUS20140042827A1Avoid malfunctioningHigh dataBatteries circuit arrangementsTelemetry/telecontrol selection arrangementsElectrical batteryData memory

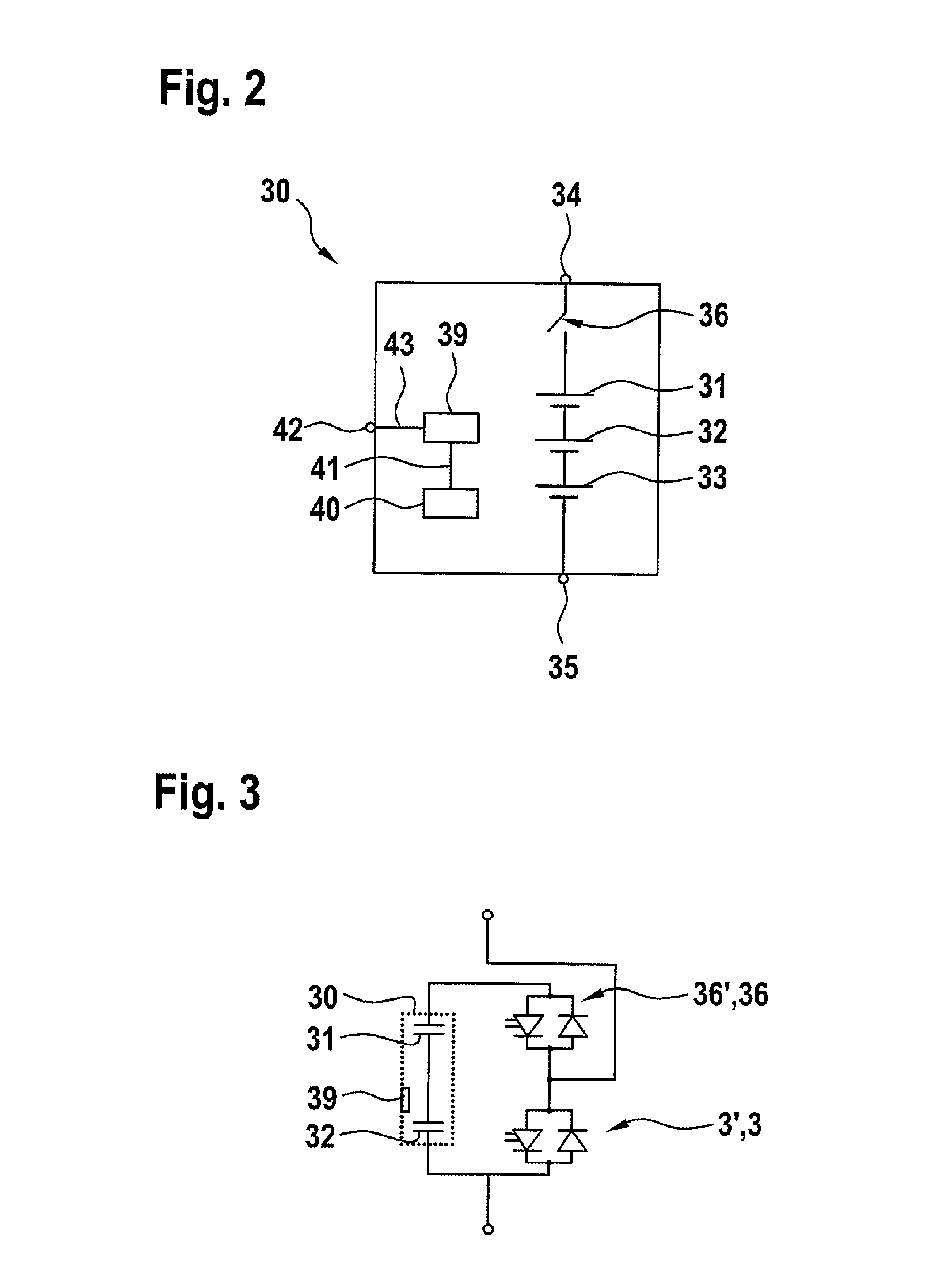

The disclosure describes a battery management system, a battery module, a battery system and a motor vehicle. In order to be able to reliably exchange battery modules, the battery module is provided with a data memory, and the battery management system is provided with a control apparatus, which can be connected to the data memory so as to transmit data, and with a bridging switch, wherein the control apparatus closes the bridging switch on the basis of the data in the data memory and therefore bridges the battery module.

Owner:ROBERT BOSCH GMBH +1

Electrical phase checking apparatus and method of metering

ActiveUS7612552B2High dataCurrent/voltage measurementDynamo-electric motor metersEngineeringVoltage sensor

An electrical phase checking apparatus includes a first voltage sensor, a first current sensor, a first binary indicator corresponding to the first voltage and current sensors, a second voltage sensor, a second current sensor, and a second binary indicator corresponding to the second voltage and current sensors. The first binary indicator is configured to indicate when a phase separation between a voltage waveform measured by the first voltage sensor and a current waveform measured by the first current sensor is not more than a first value, and the second binary indicator is configured to indicate when a phase separation between a voltage waveform measured by the second voltage sensor and a current waveform measured by the second current sensor is not more than a second value.

Owner:DENT INSTR INC

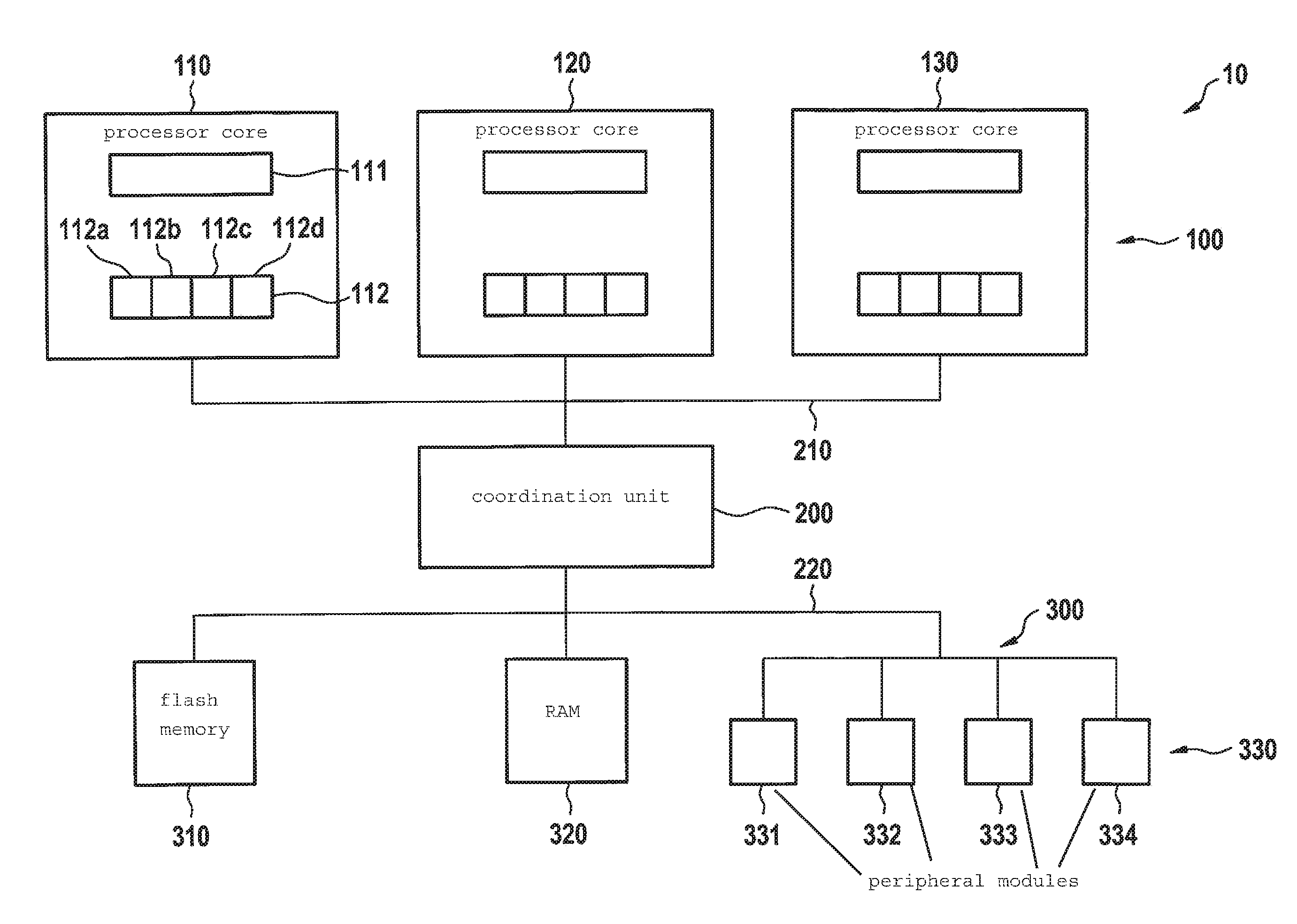

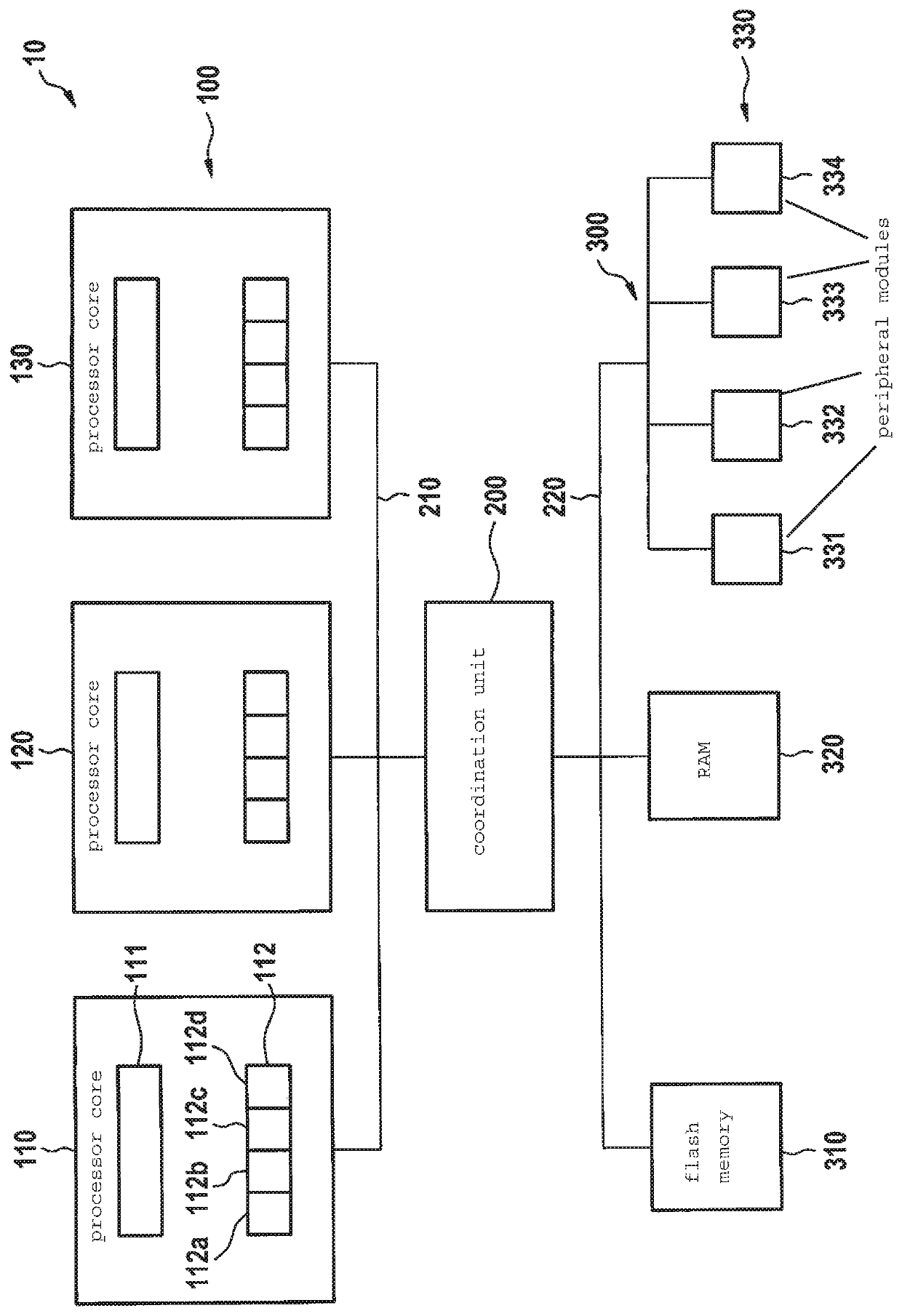

Control device for a motor vehicle

ActiveUS20160299839A1Avoid access violationsImprove data reading speedMemory architecture accessing/allocationMemory adressing/allocation/relocationMotorized vehicleLocal memories

A control device for a motor vehicle, the control device including at least two processor cores and a global memory, each processor core respectively including a local memory and each processor core being set up to access only its own local memory and being set up to access neither the local memories of the other processor cores nor the global memory, a coordination unit being set up to read in data from the global memory of the control device and to write it to the local memories of the individual processor cores, and to read in data from the local memories of the individual processor cores and to write it to the global memory and / or to the local memory of the other processor cores.

Owner:ROBERT BOSCH GMBH

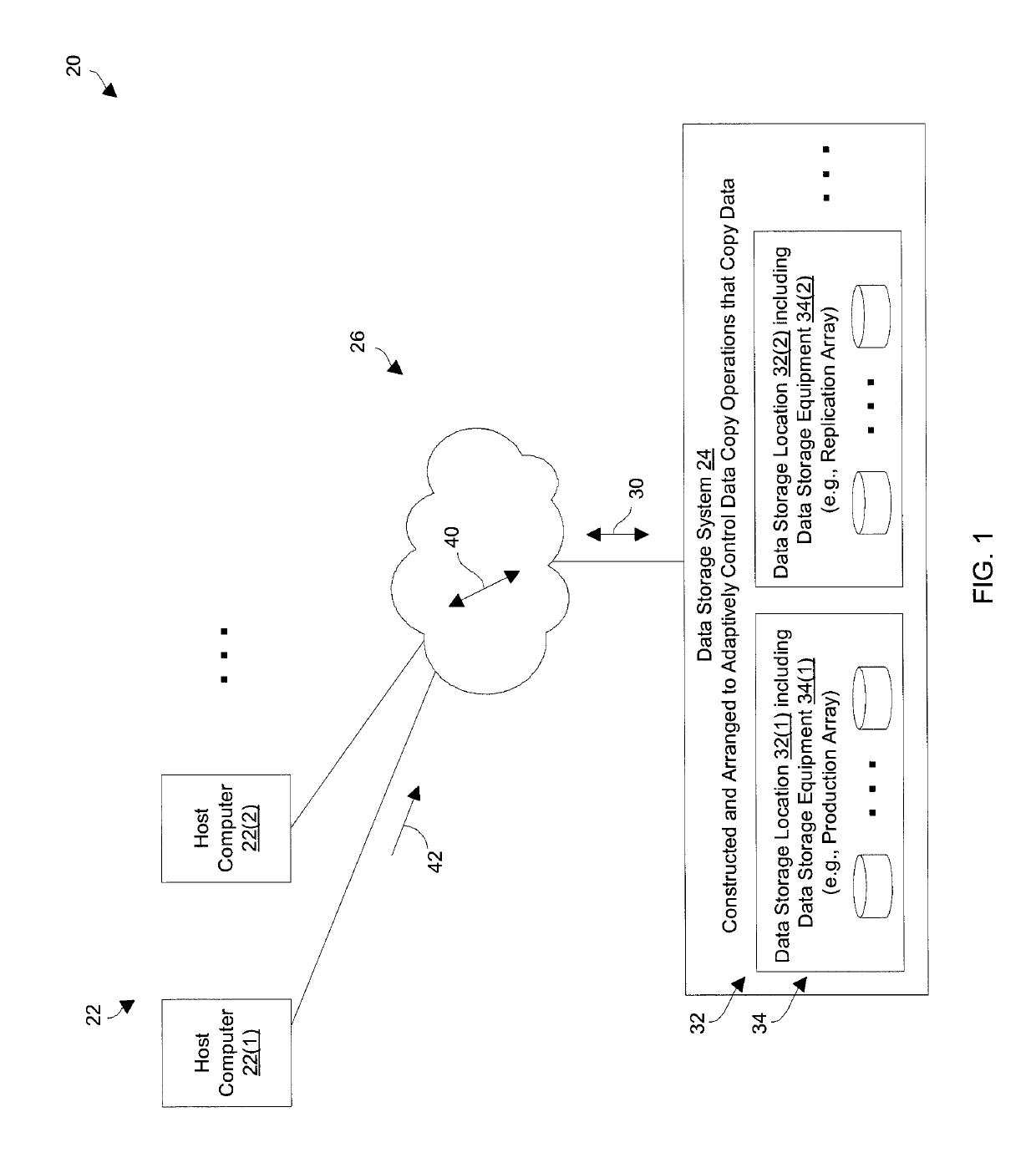

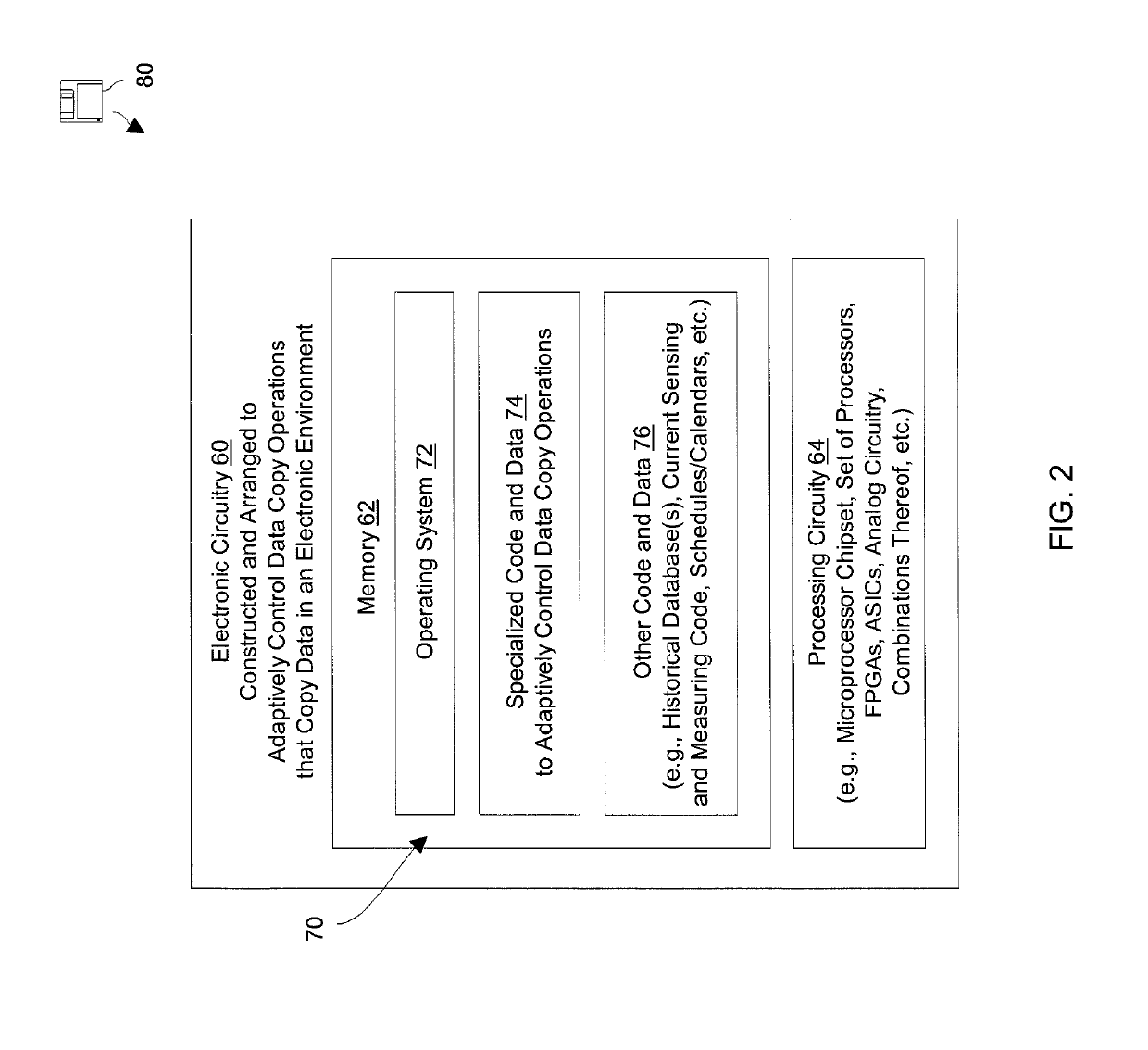

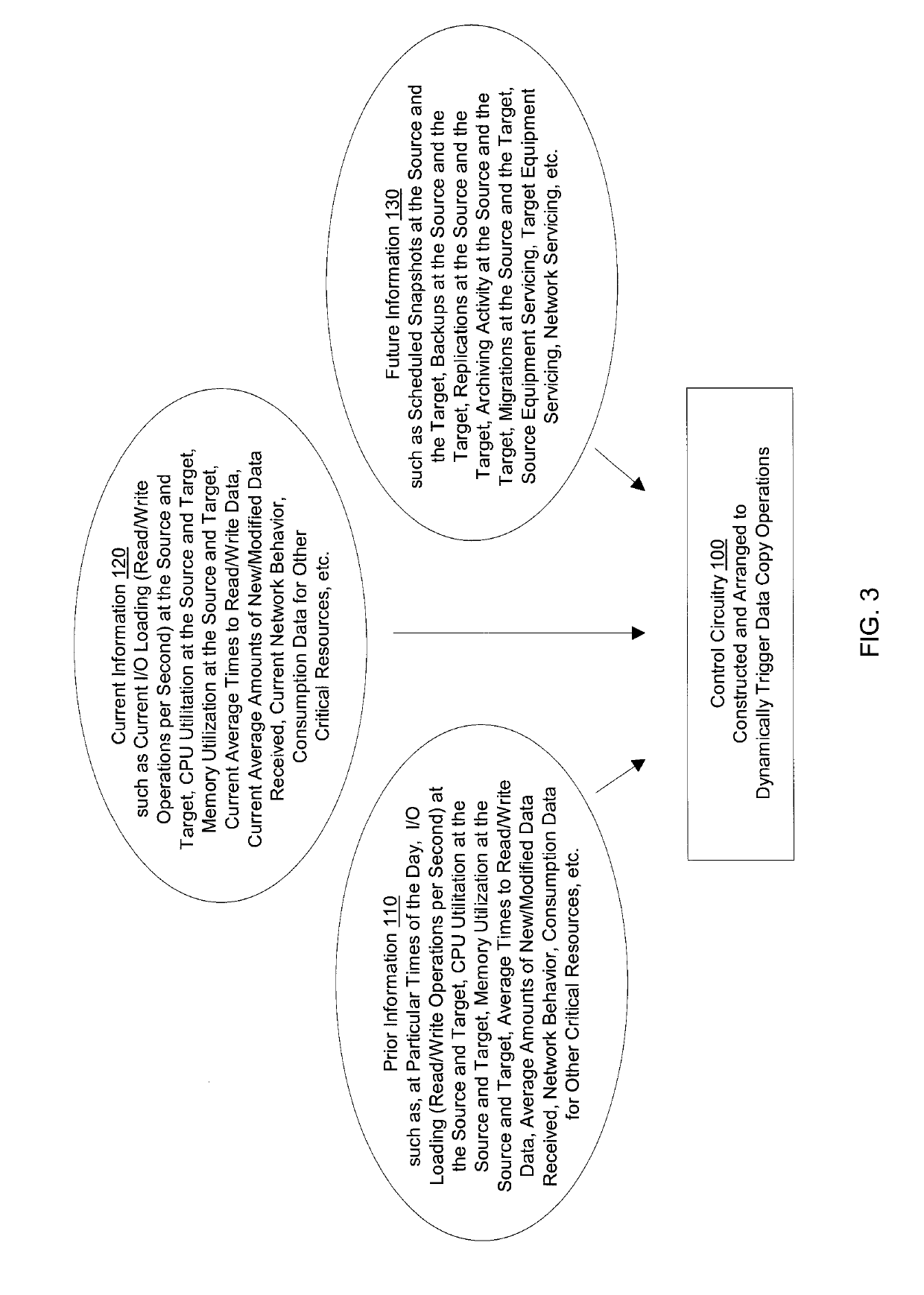

Adaptively controlling data copy operations that copy data in an electronic environment

ActiveUS10261718B1High availability and data protectionTransparent operationInput/output to record carriersMemory systemsAdaptive controlDatabase

A technique controls data copy operations that copy data within an electronic environment. The technique involves performing, by processing circuitry, an initial series of data copy operations that copy data from a source location to a target location in accordance with an initial series of data copy triggers. The technique further involves receiving, by the processing circuitry, a set of electronic environment measurements from the electronic environment. The technique further involves making, by the processing circuitry, an adjustment to a next data copy trigger based on the set of electronic environment measurements, the adjustment modifying when a next data copy operation takes place after the initial series of data copy operations, the next data copy operation copying data from the source location to the target location.

Owner:EMC IP HLDG CO LLC

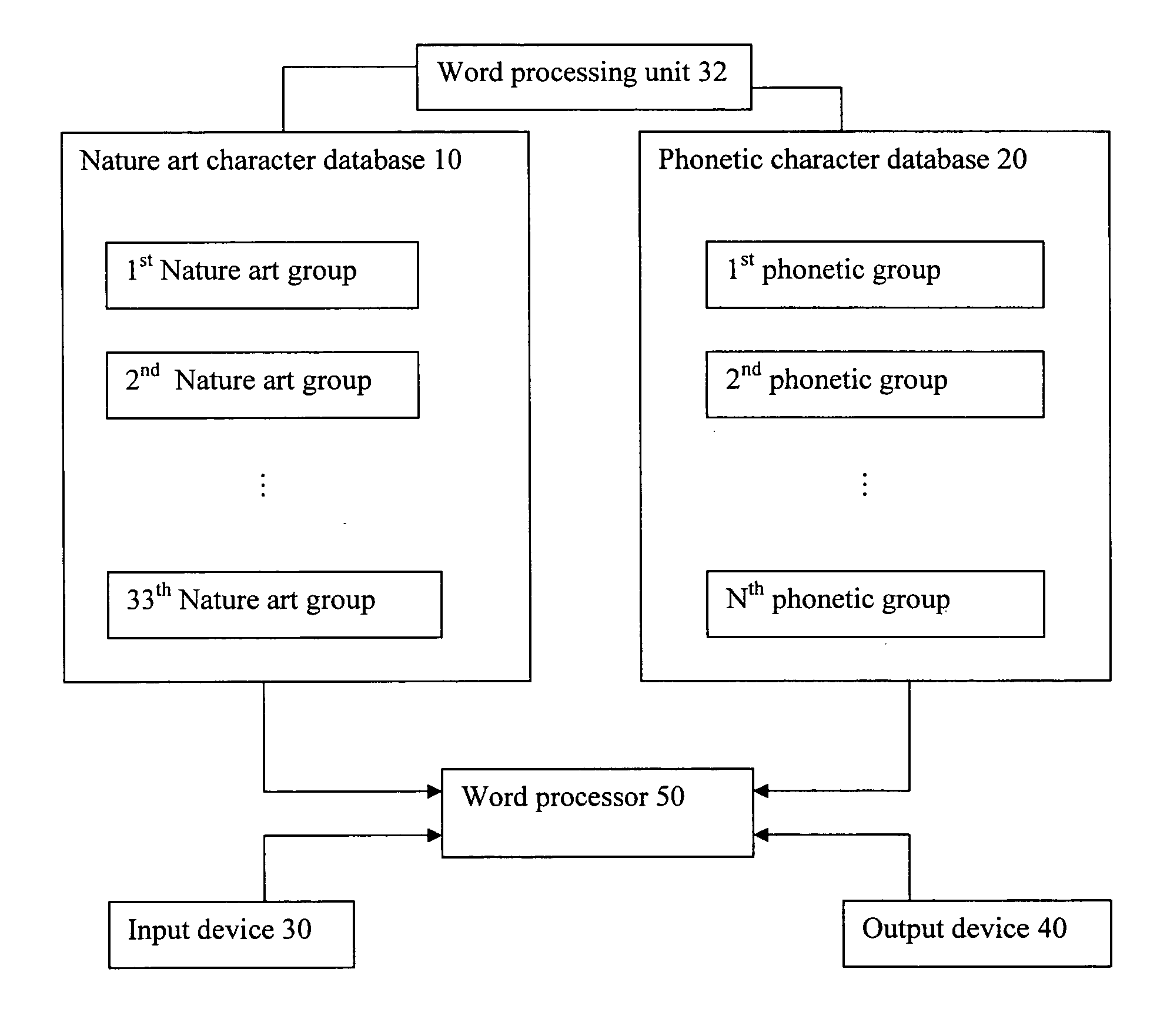

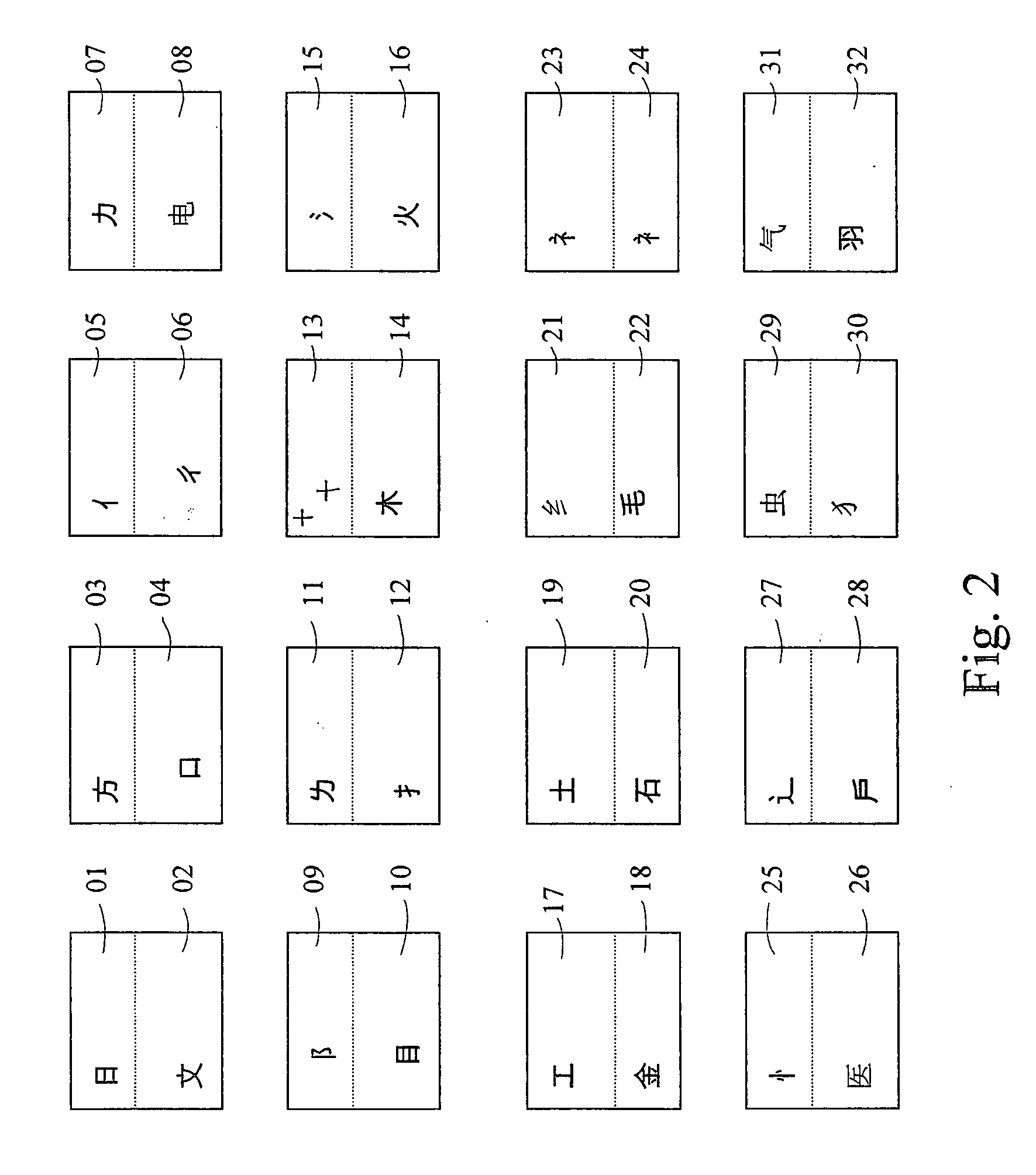

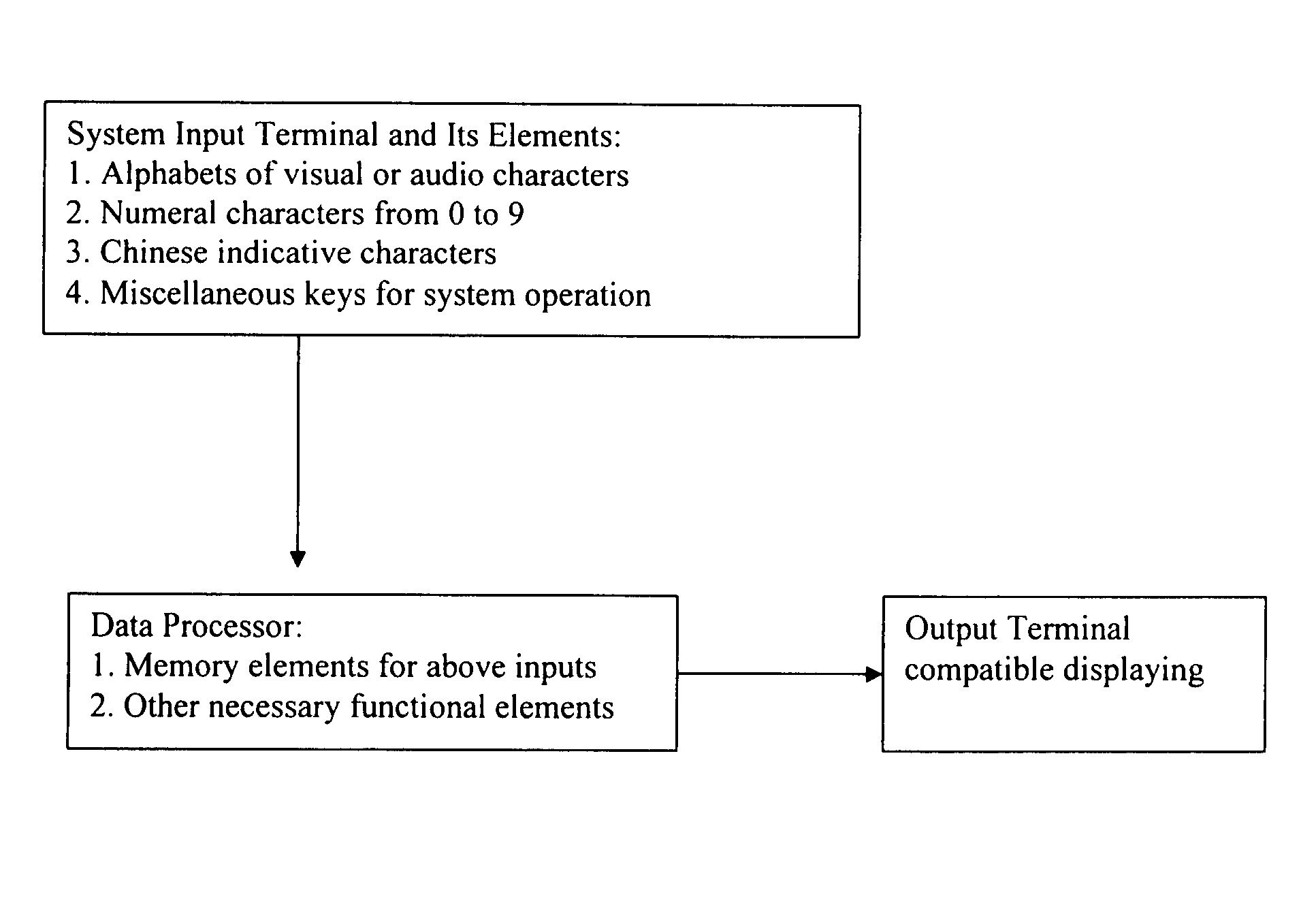

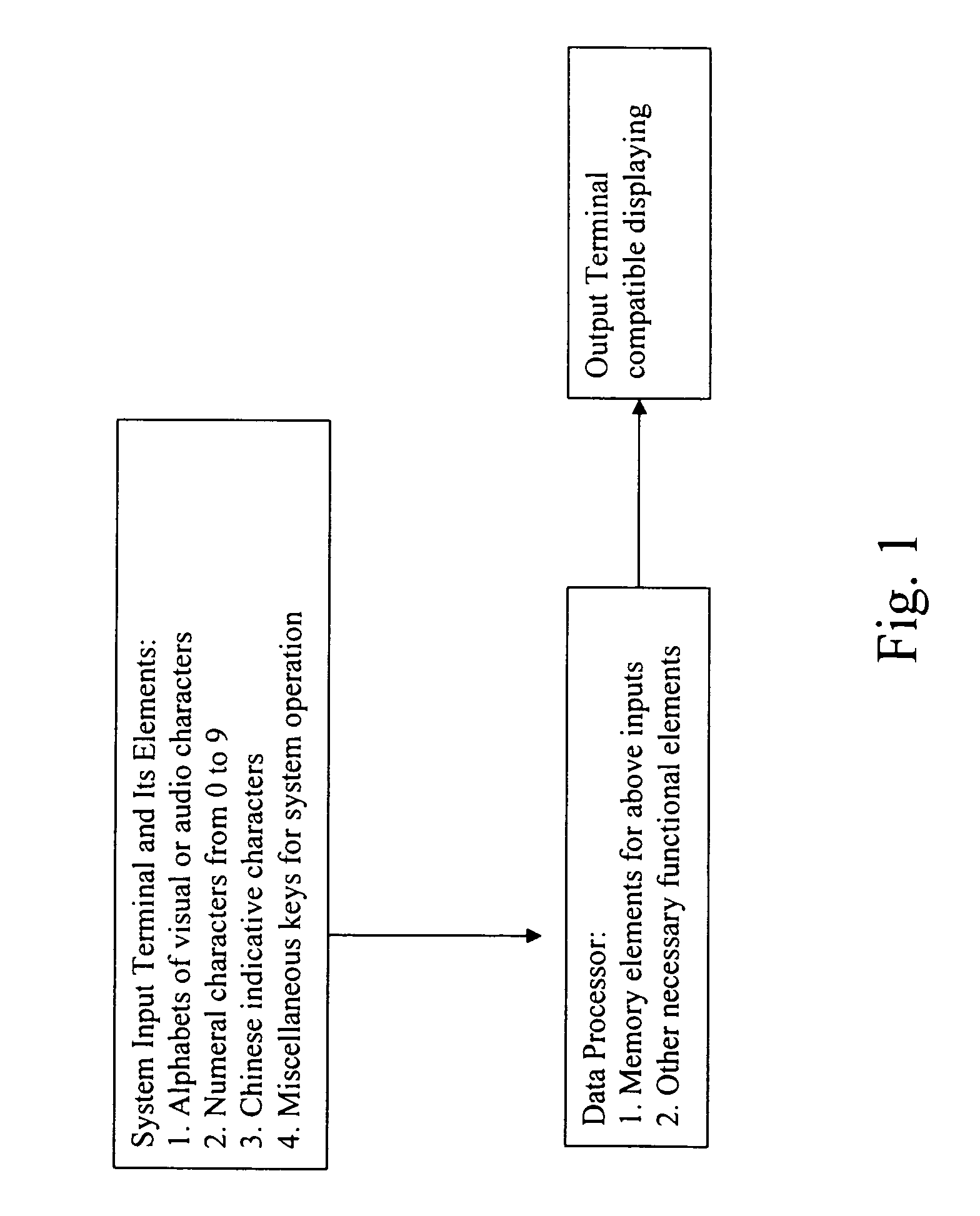

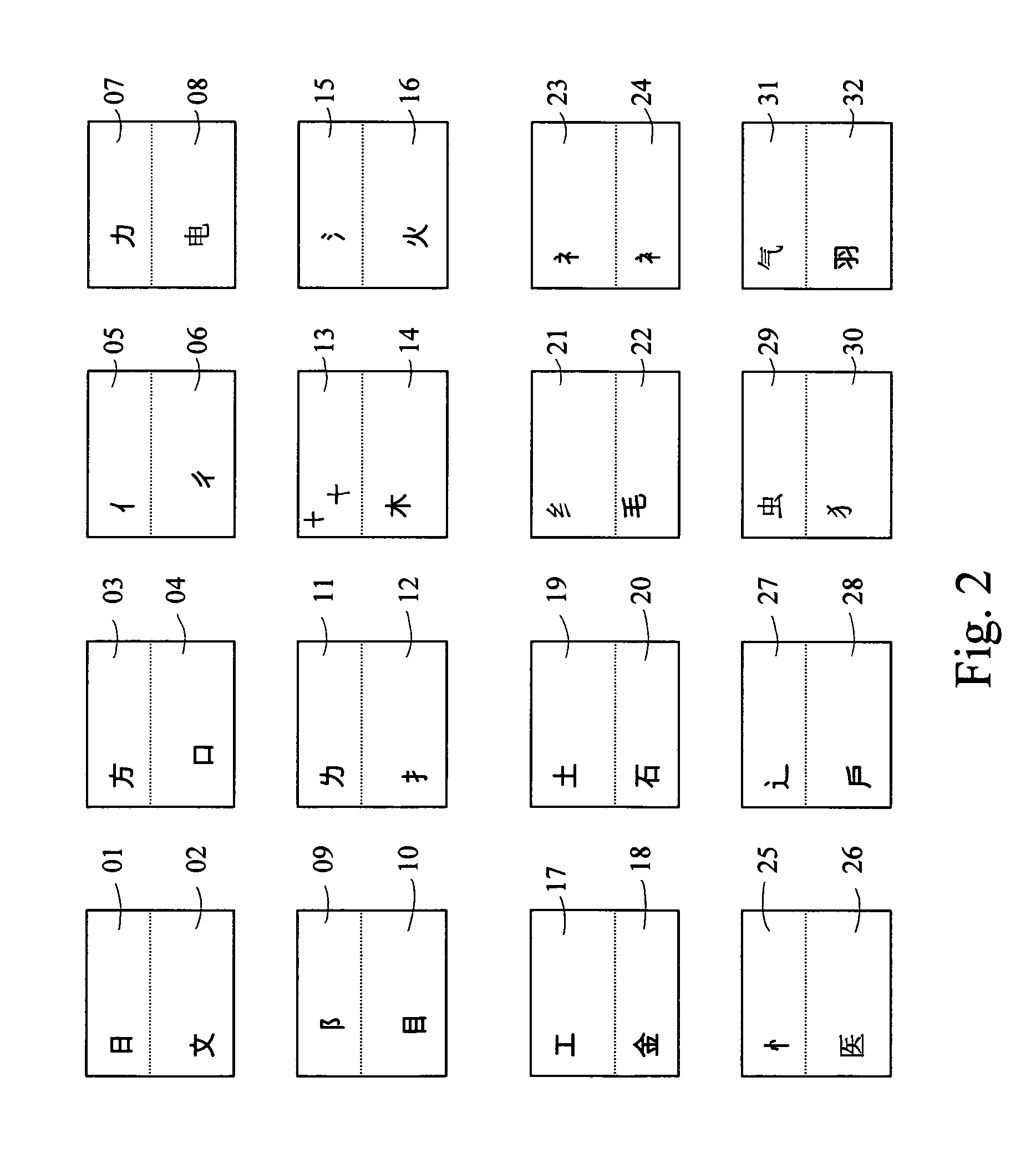

Automated word processor for Chinese style languages

InactiveUS20070288229A1Improve accuracyLow costNatural language translationSpecial data processing applicationsWord processingHuman language

Owner:LIU CHANG PO

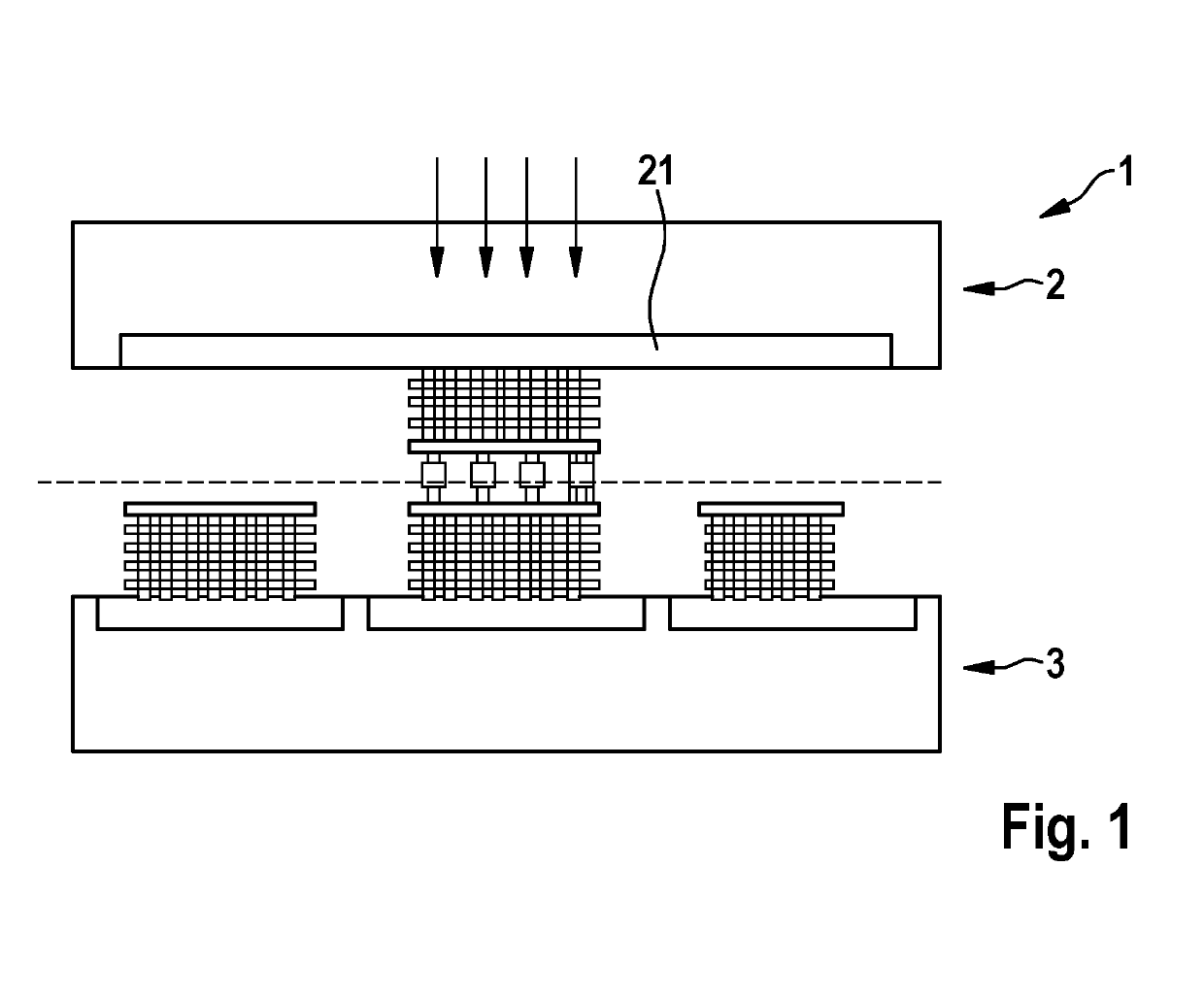

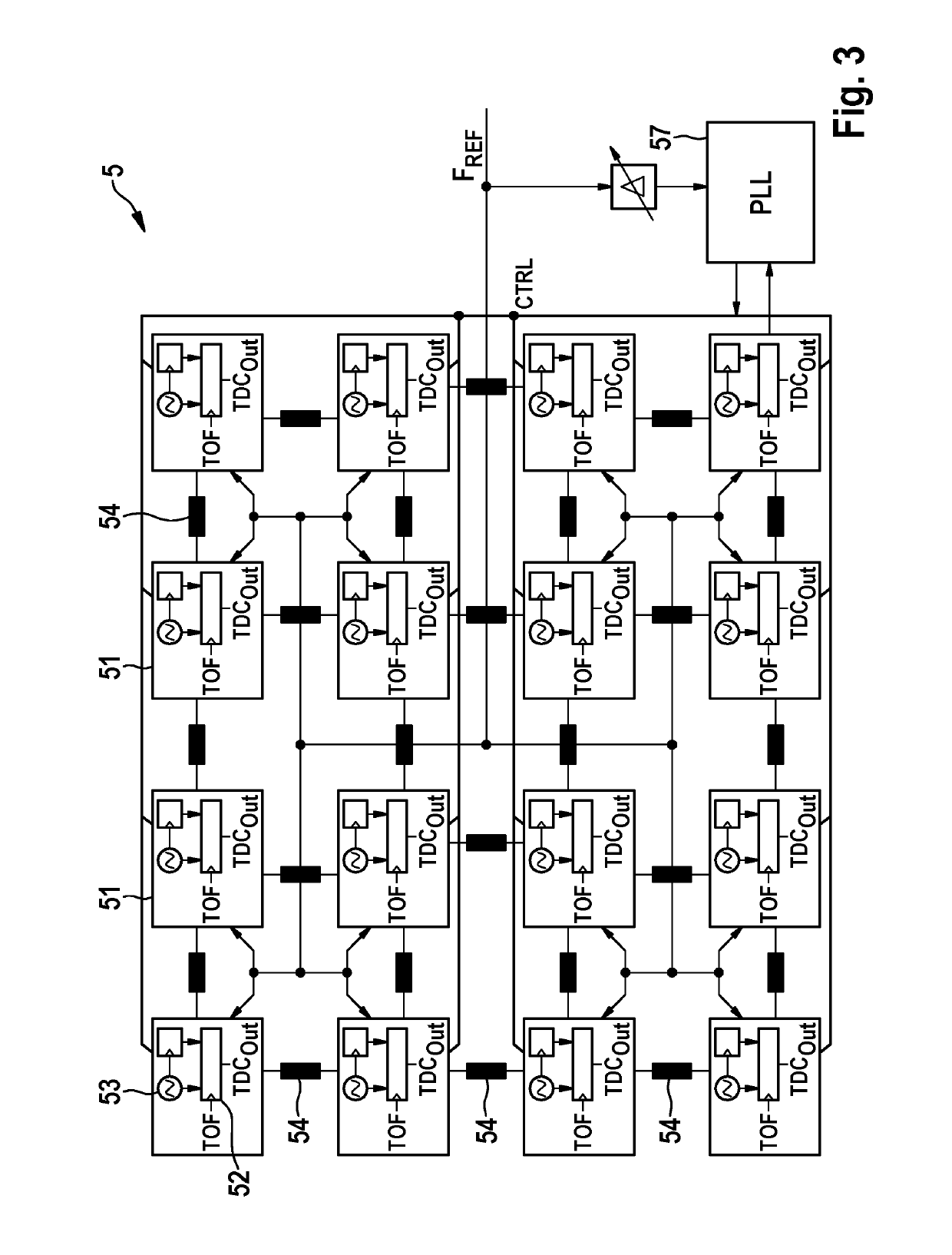

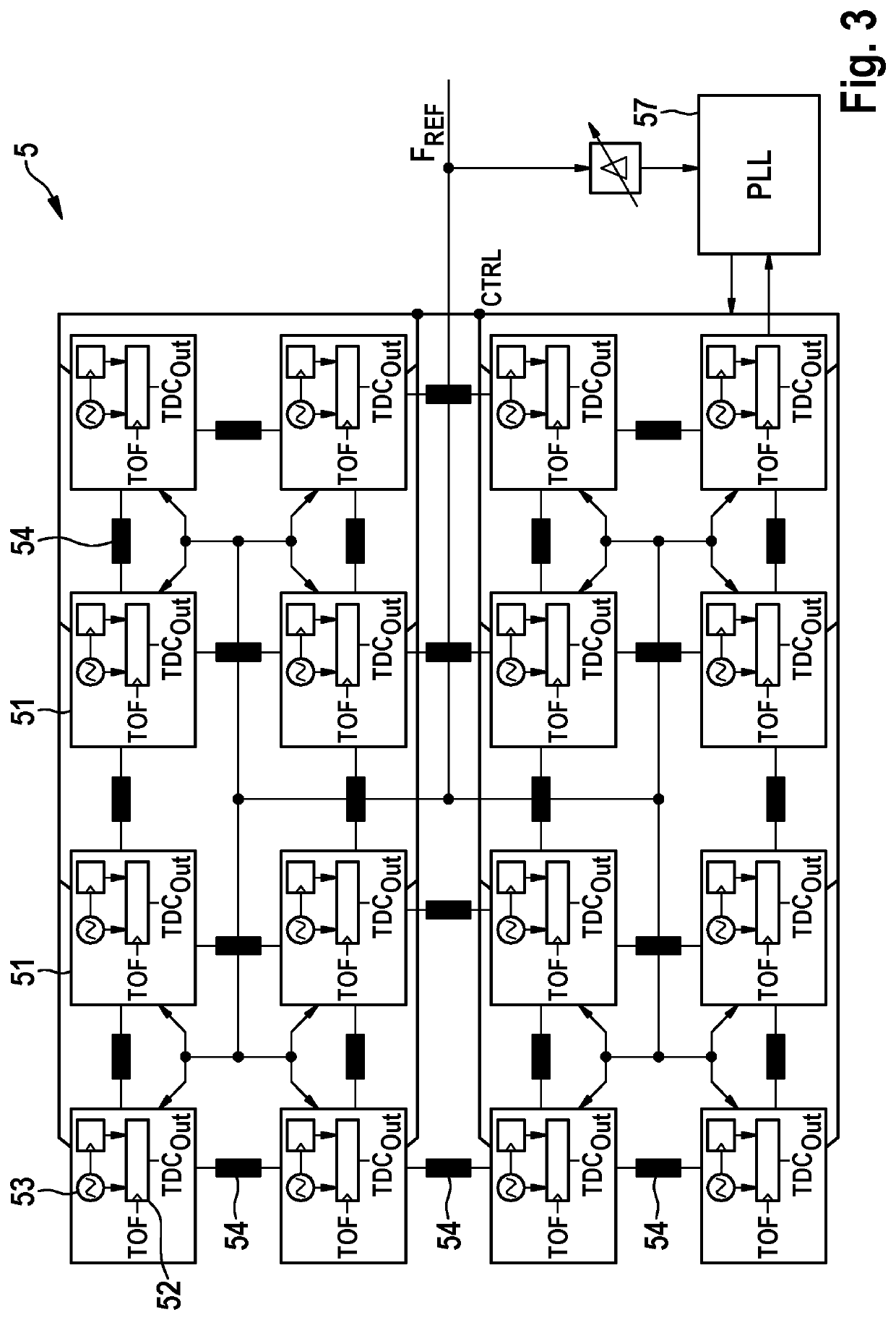

Oscillator arrangement for time-to-digital converter for large array of time-of-flight image sensor devices

ActiveUS20190305784A1Reducing calibration requirementDifficult to calibrateMultiple-port networksPulse automatic control3d imageFundamental frequency

An oscillator arrangement for time-to-digital converters for a 3D image sensor device includes a plurality of oscillators arranged as an array each oscillator being associated to one time-to-digital converter, and at least one coupling unit respectively arranged between at least two of the oscillators, so that oscillation in the at least two oscillators at a fundamental frequency is synchronized between the at least two coupled oscillators.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

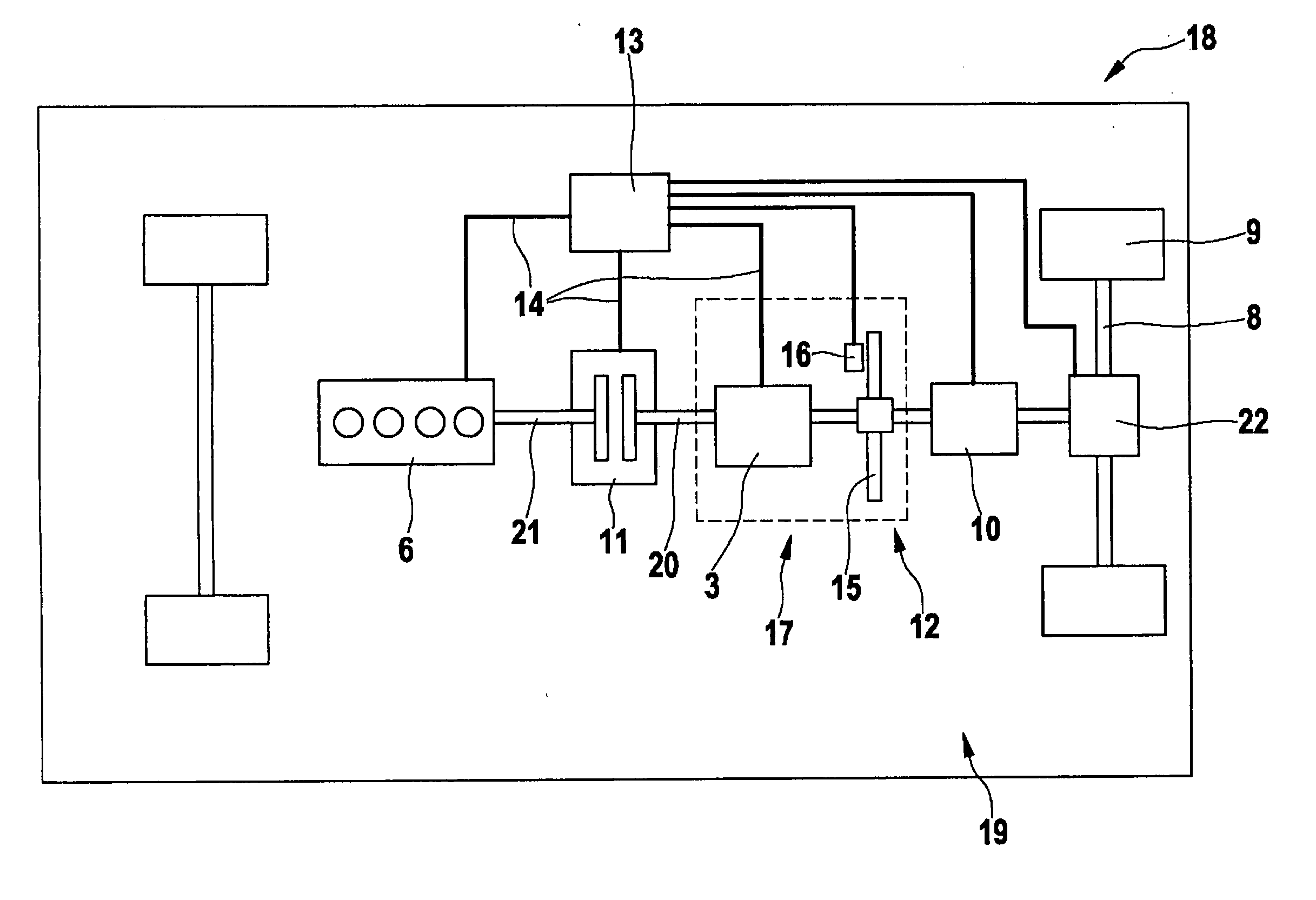

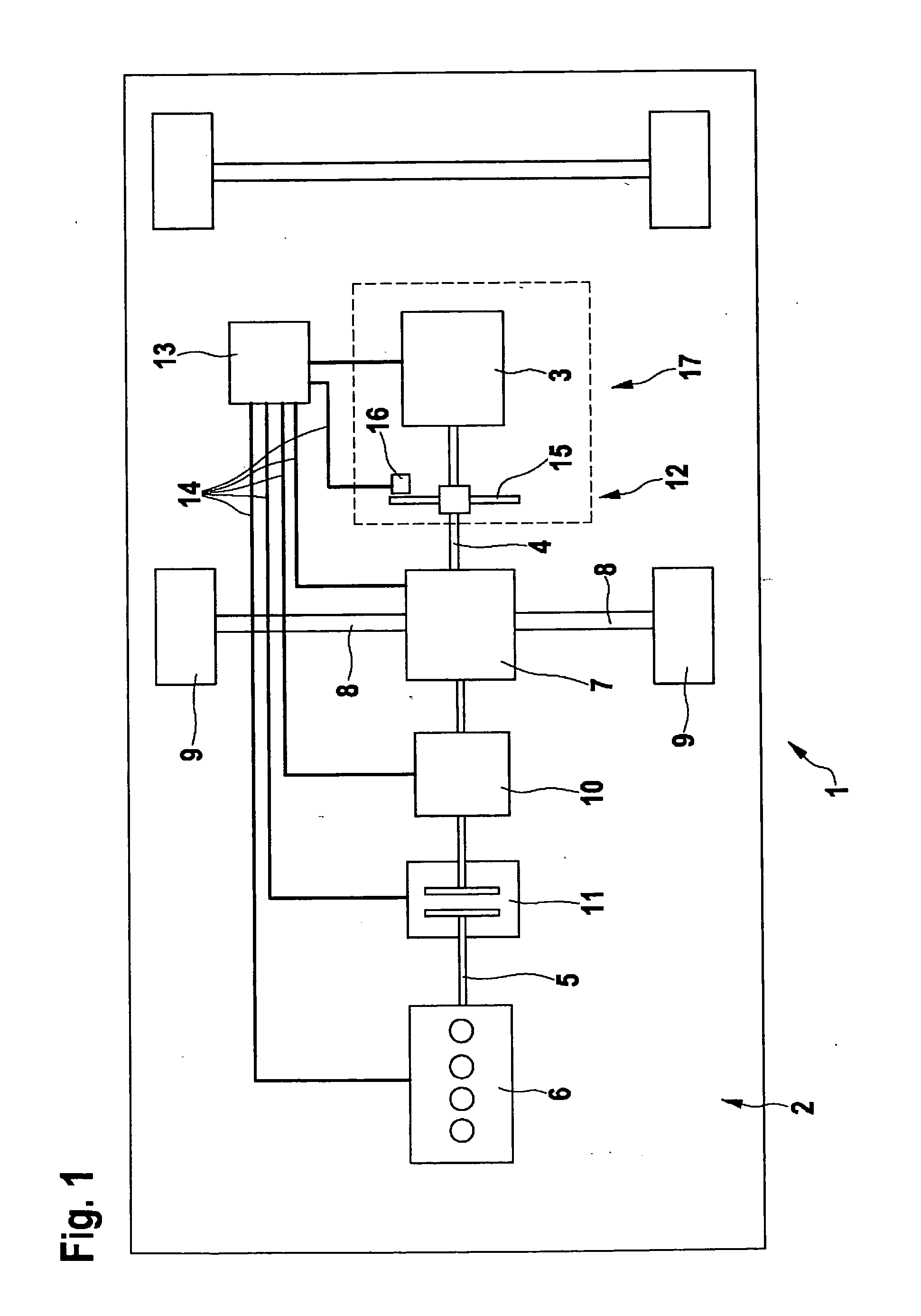

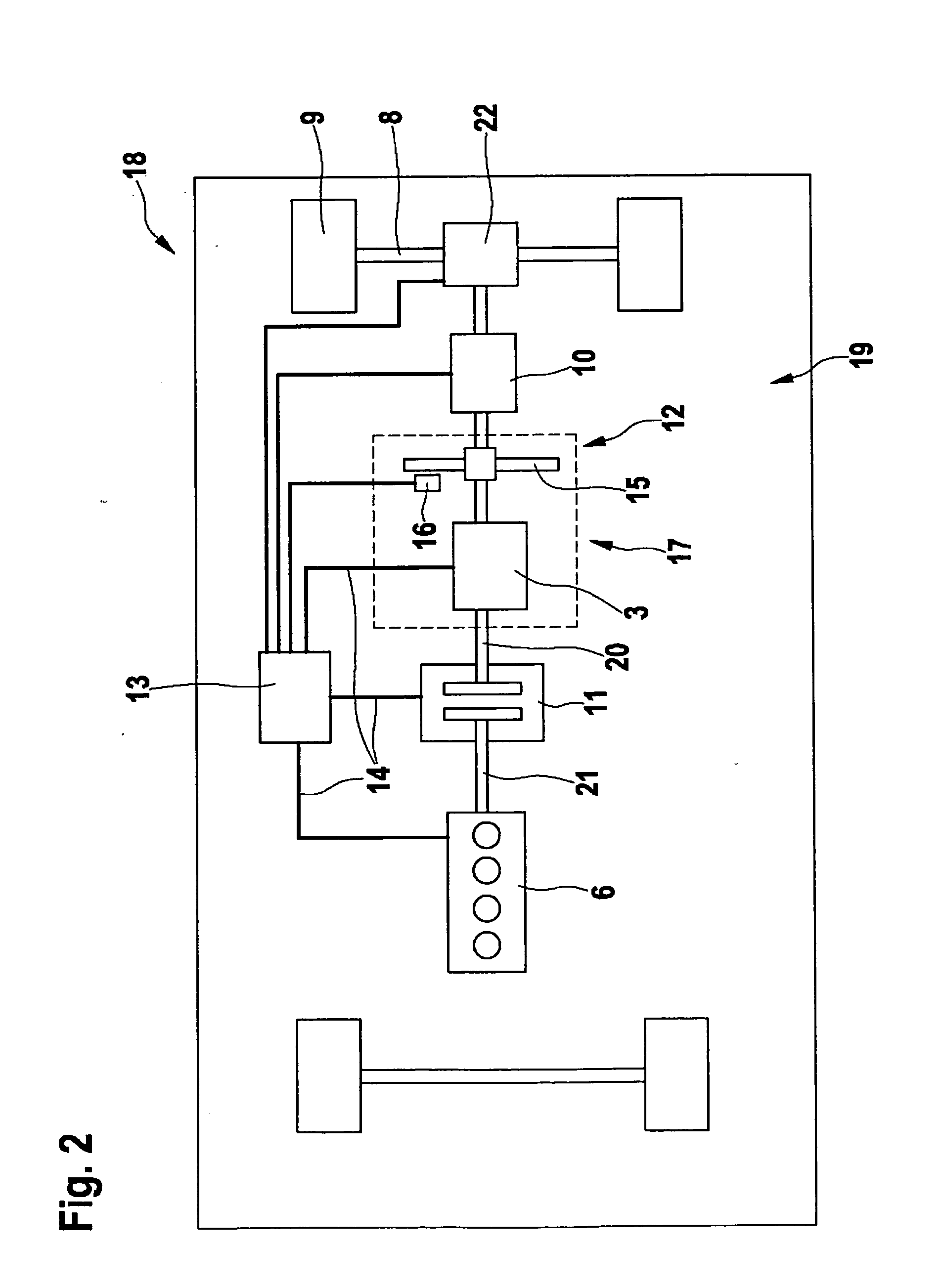

Hybrid drive system

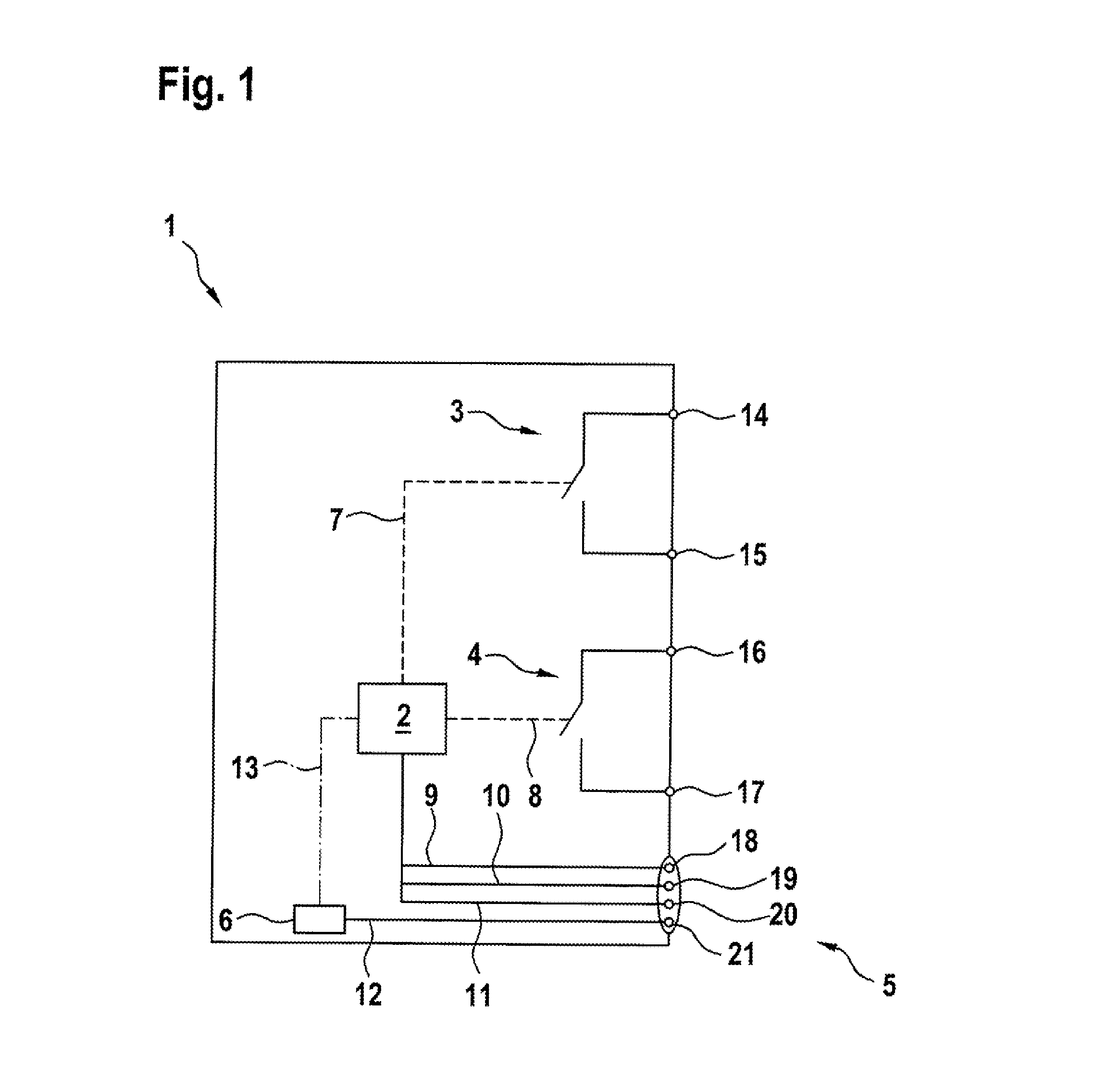

InactiveUS20110208379A1Accurate statementLow costDigital data processing detailsRailway vehiclesHybrid driveHybrid power

A hybrid drive system (2, 19) for a motor vehicle (1, 18) has an electric motor (3) and an internal combustion engine (6). The electric motor (3) and the internal combustion engine (6) are at least temporarily coupled (7, 10, 11) to each other at a fixed speed ratio. The speed of the hybrid drive system (2, 19) is sensed by a speed sensing device (12). The data obtained in said manner are used for at least partially controlling the electric motor (3) and the internal combustion engine (6).

Owner:ROBERT BOSCH GMBH

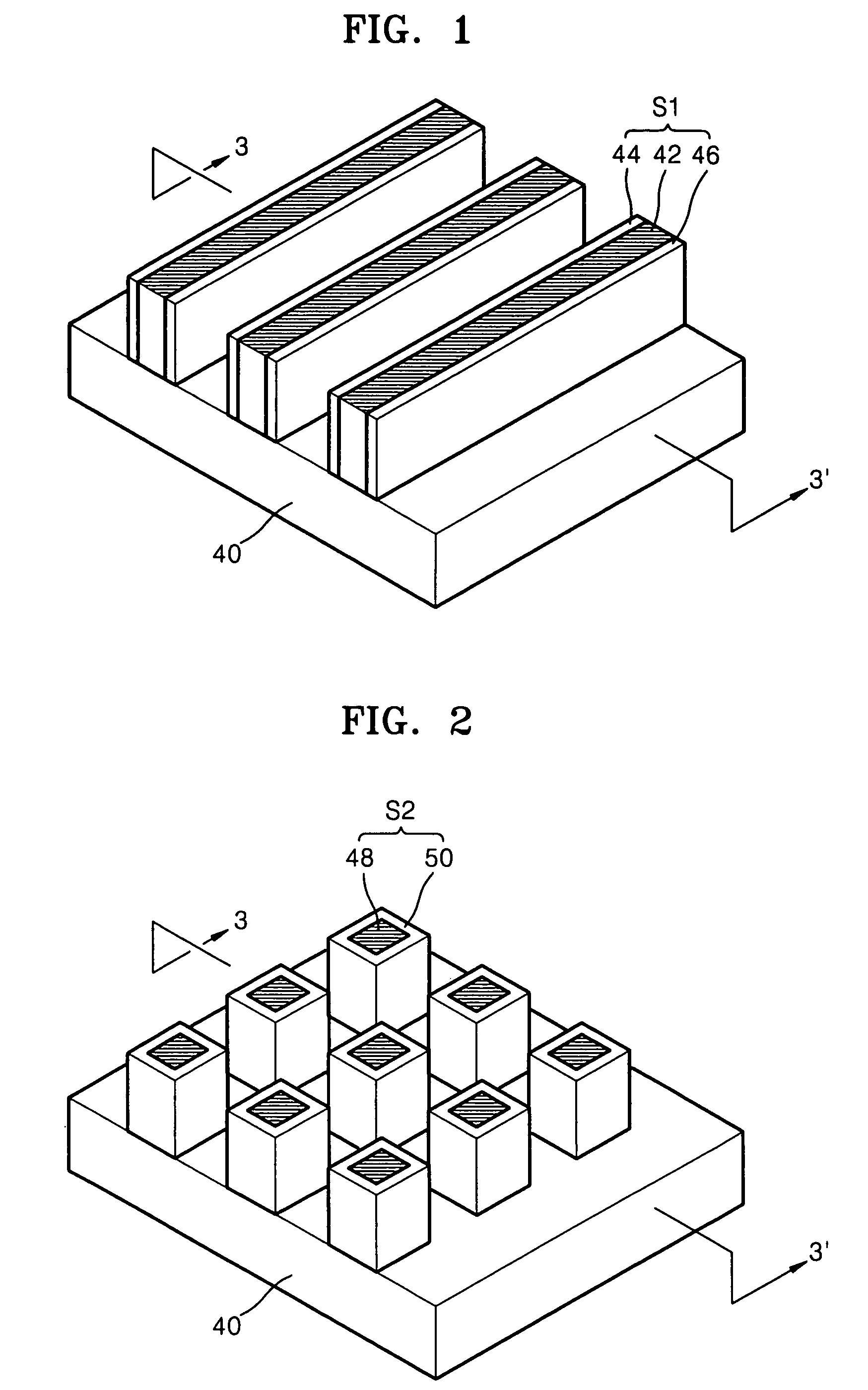

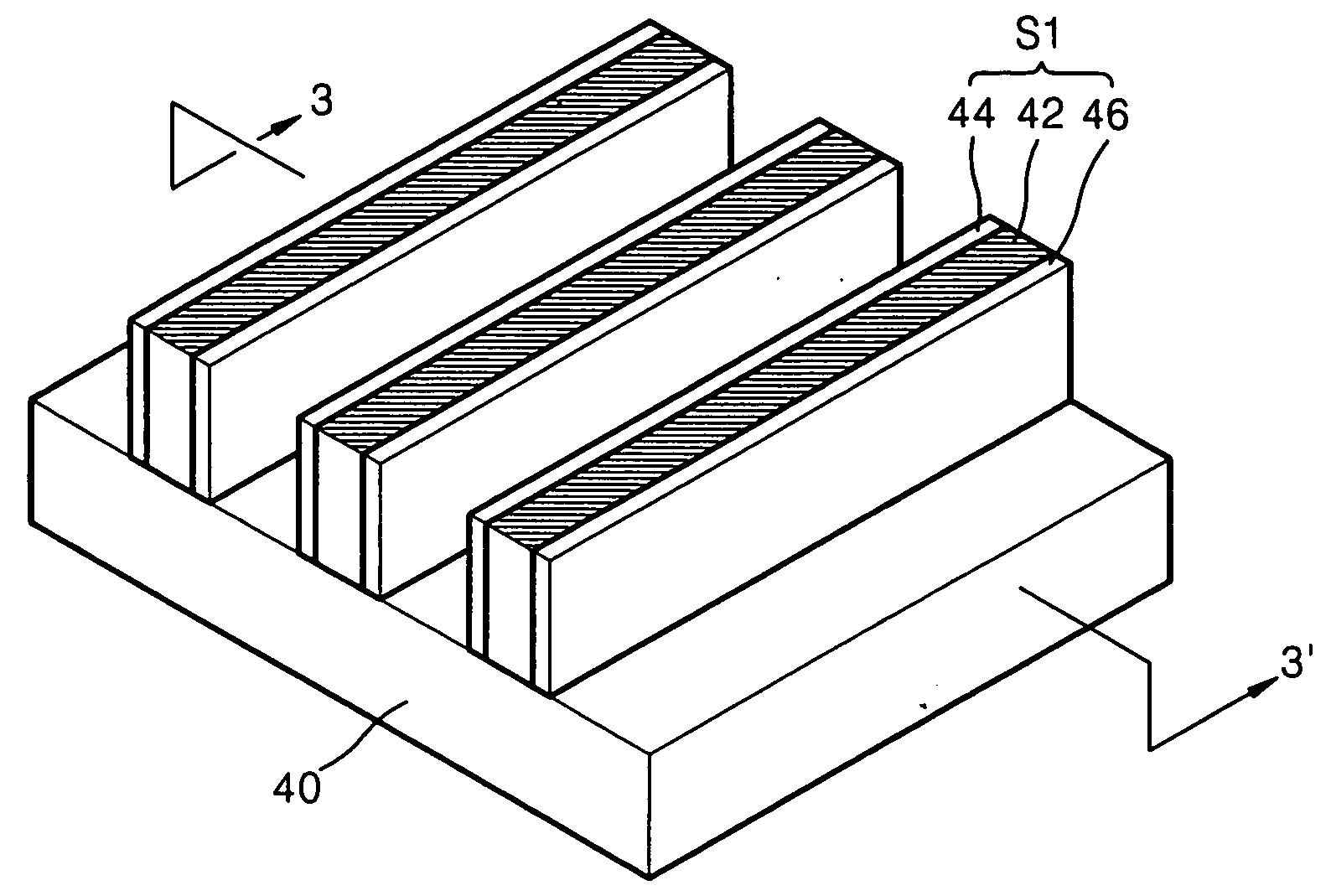

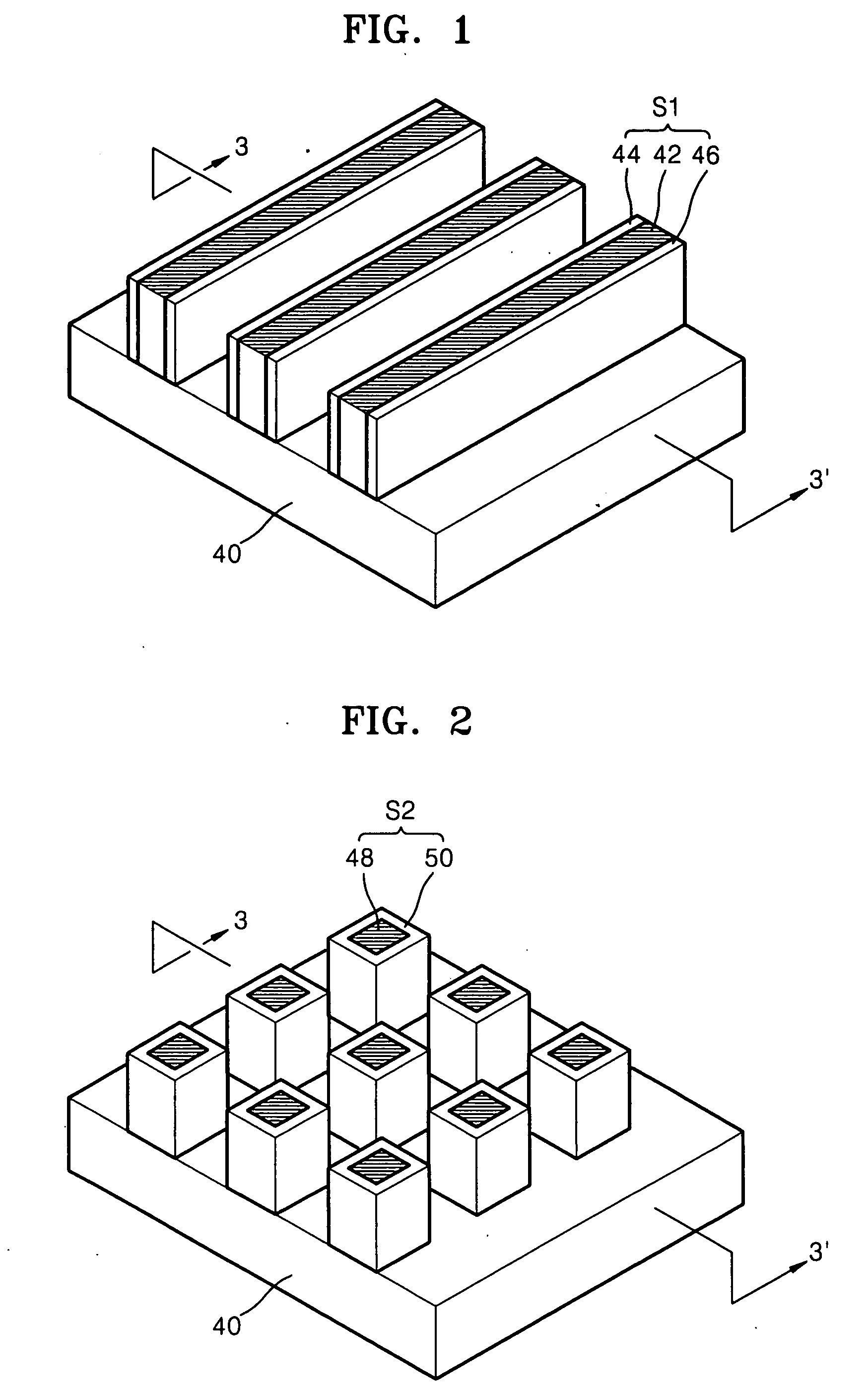

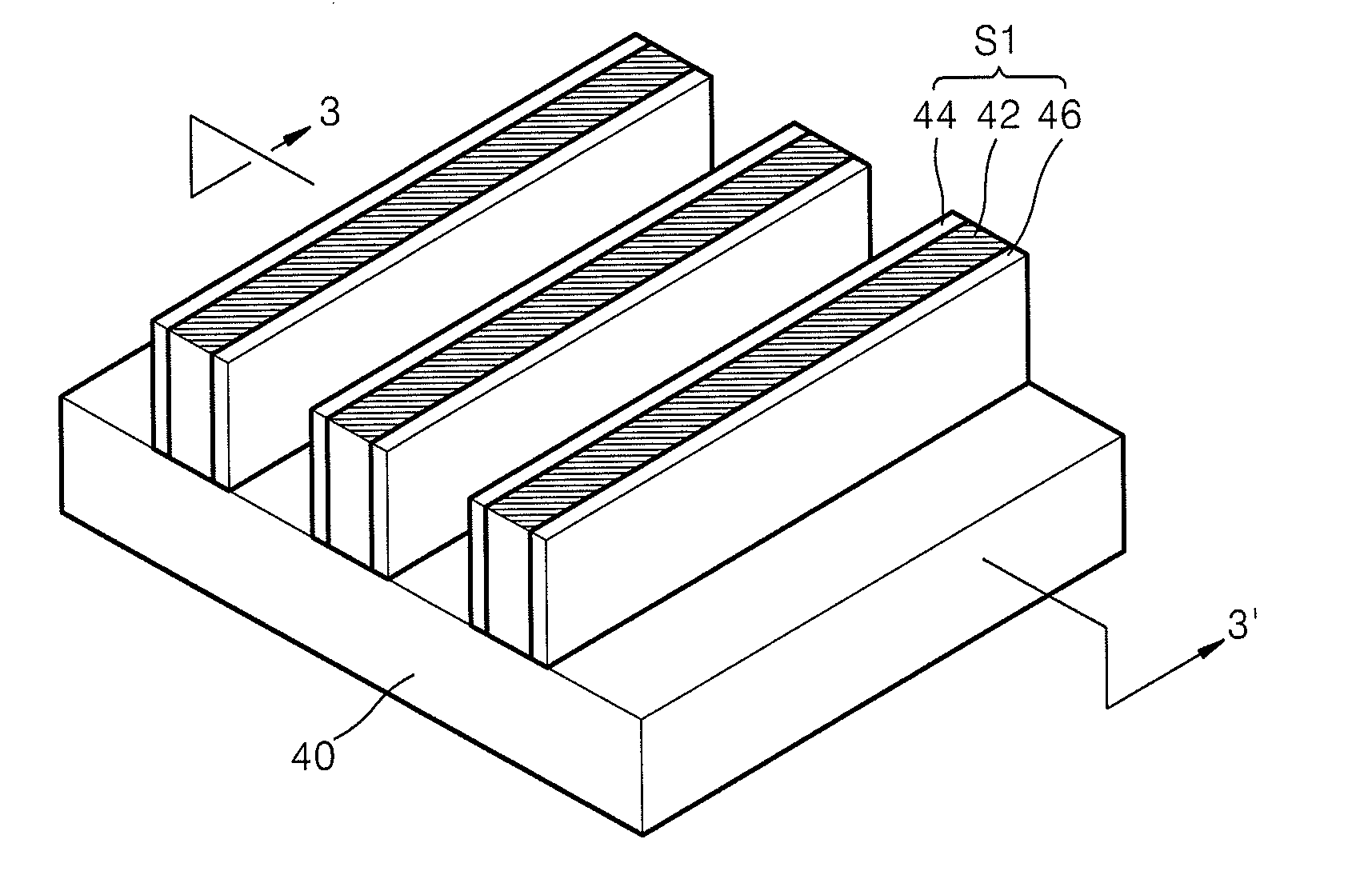

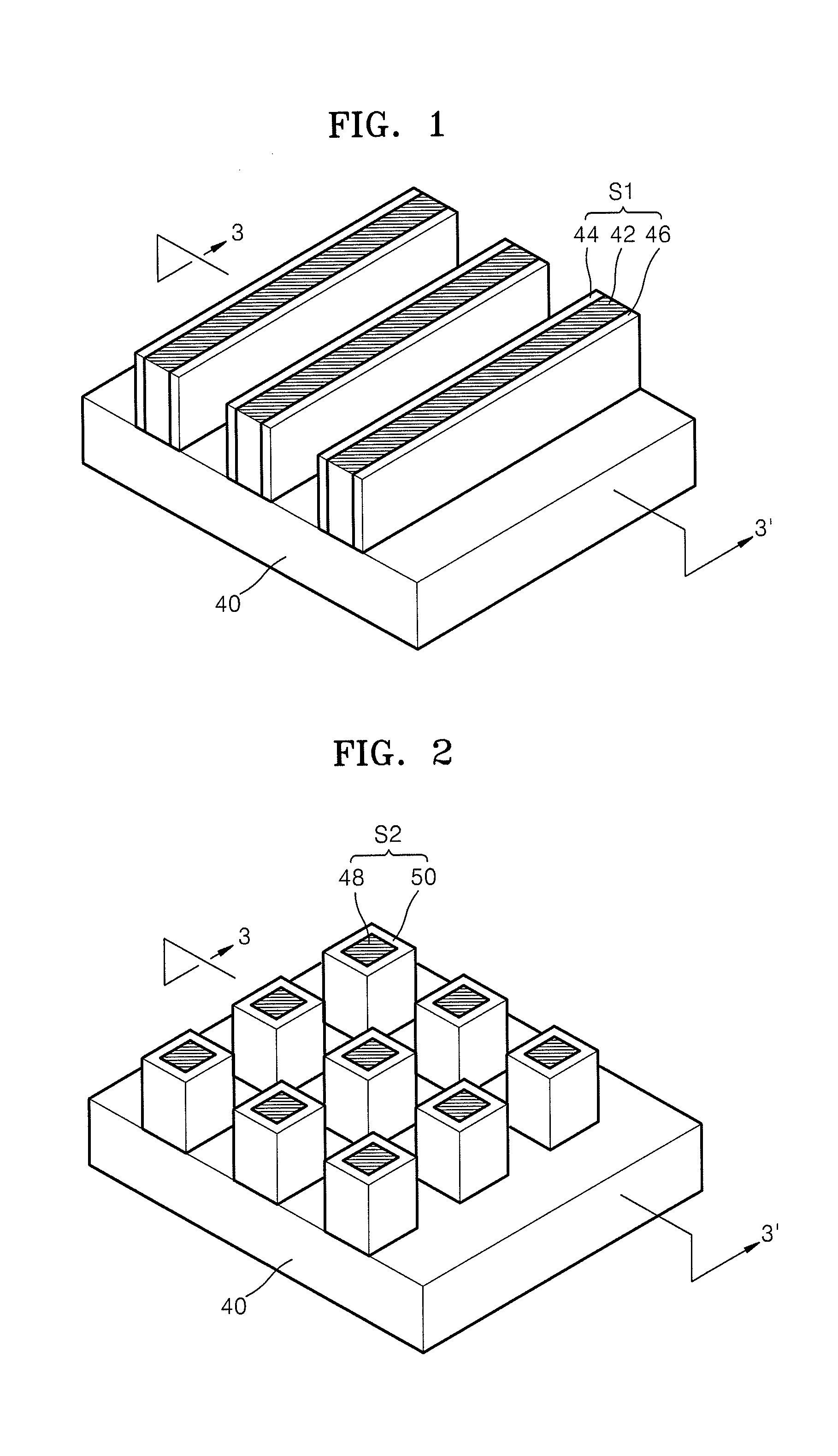

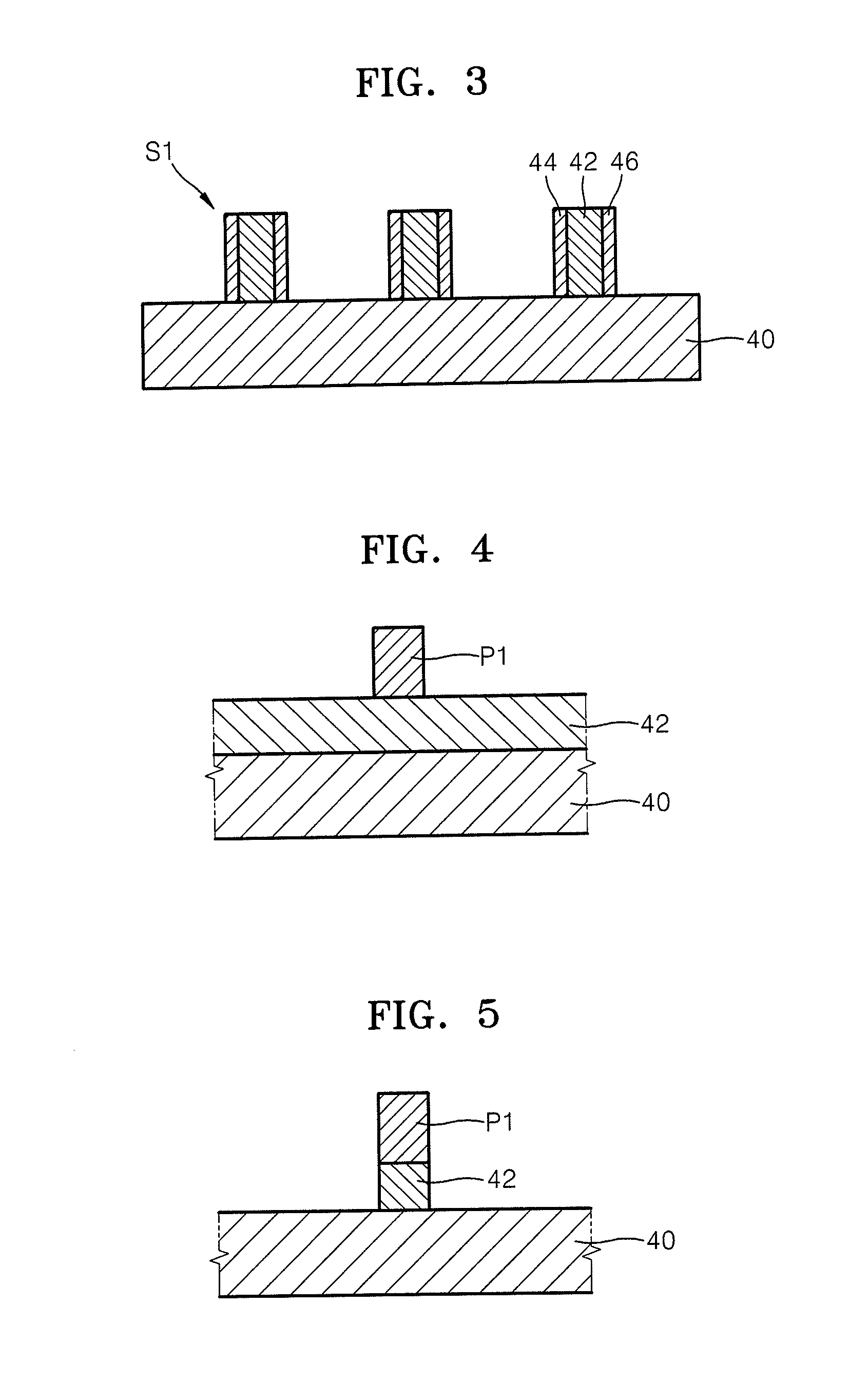

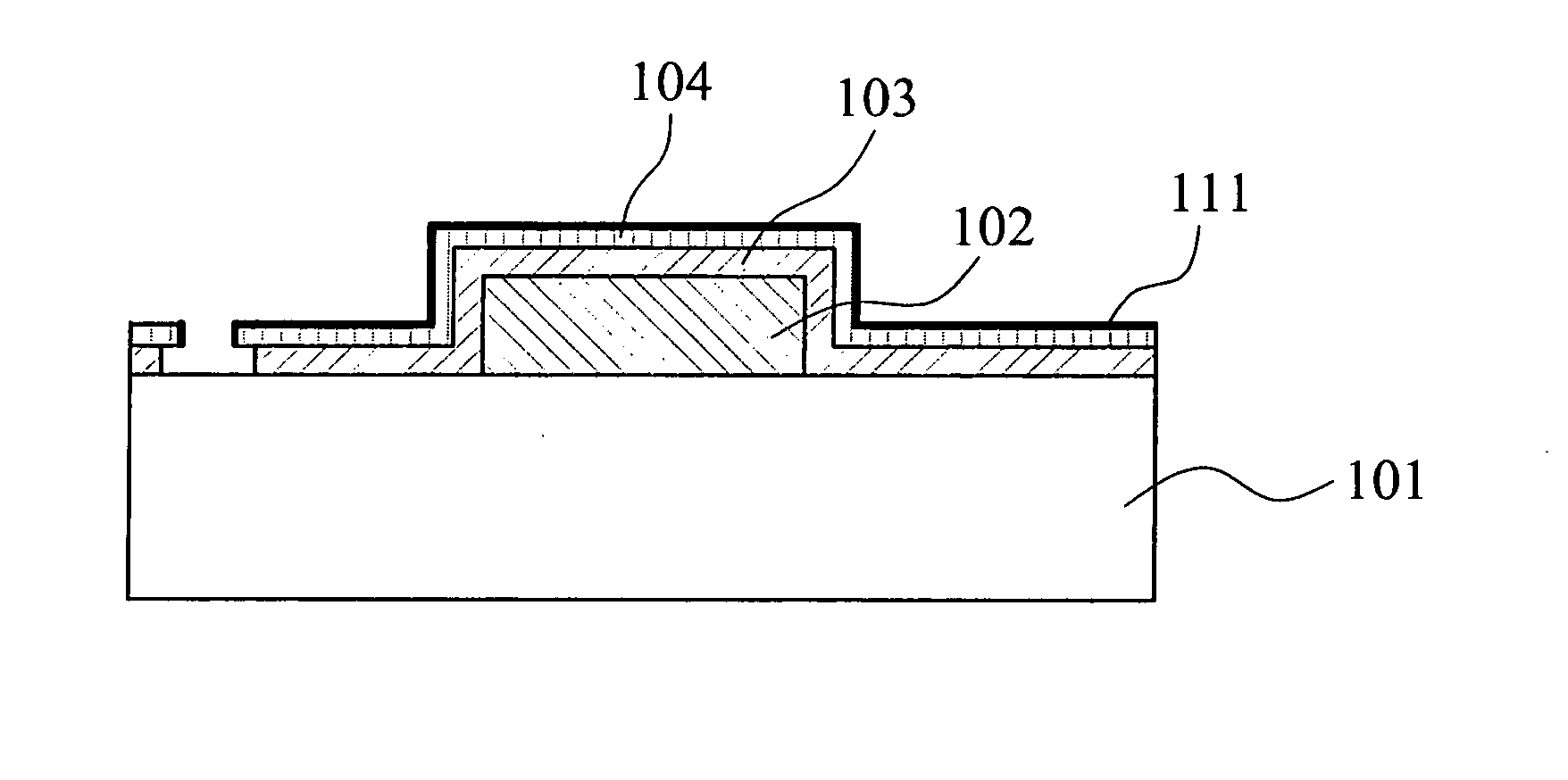

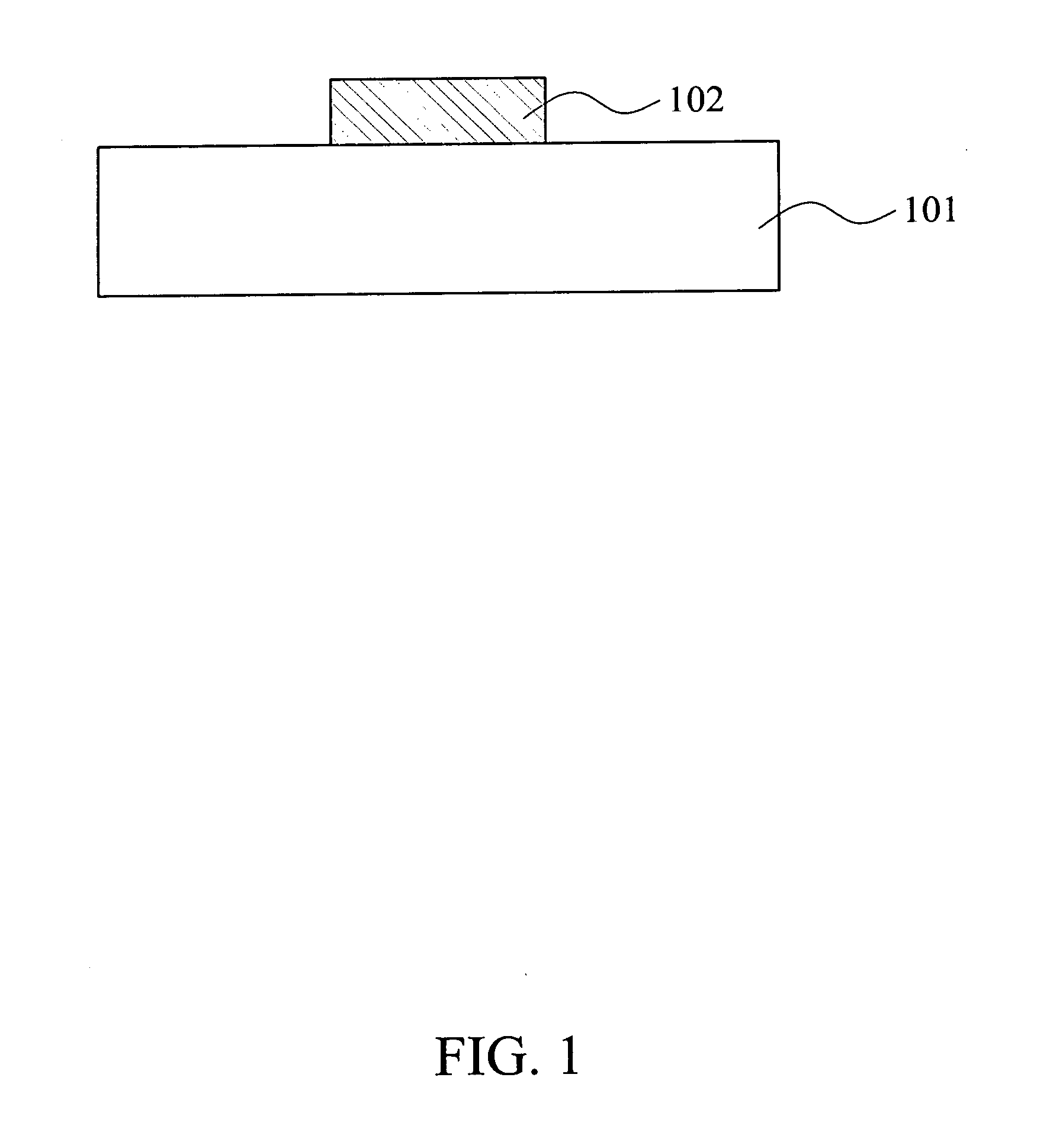

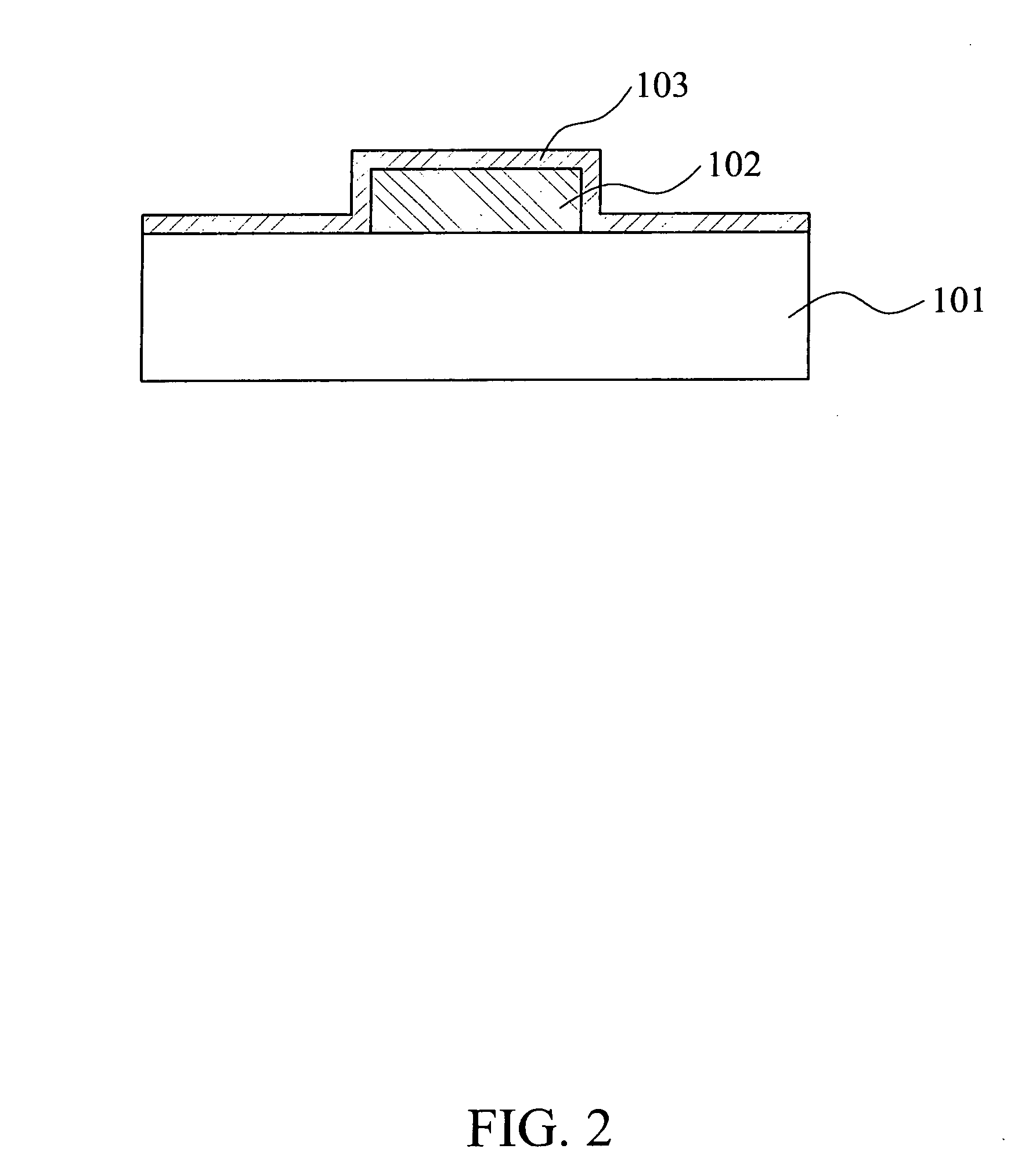

Ferroelectric recording medium

InactiveUS7660146B2Increased data recording densityHigh data recording densityNanotechFerroelectric carrier recordingEngineeringRecording layer

Provided are a ferroelectric recording medium and a method of manufacturing the same. The ferroelectric recording medium includes a substrate, a plurality of supporting layers which are formed on the substrate, each of the supporting layers having at least two lateral surfaces; and data recording layers formed on the lateral surfaces of the supporting layers. First and second data recording layers may be respectively disposed on two facing lateral surfaces of each of the supporting layers. The supporting layers may be polygonal pillars having at least three lateral surfaces. A plurality of the supporting layers can be disposed at uniform intervals in a two-dimensional array.

Owner:SAMSUNG ELECTRONICS CO LTD

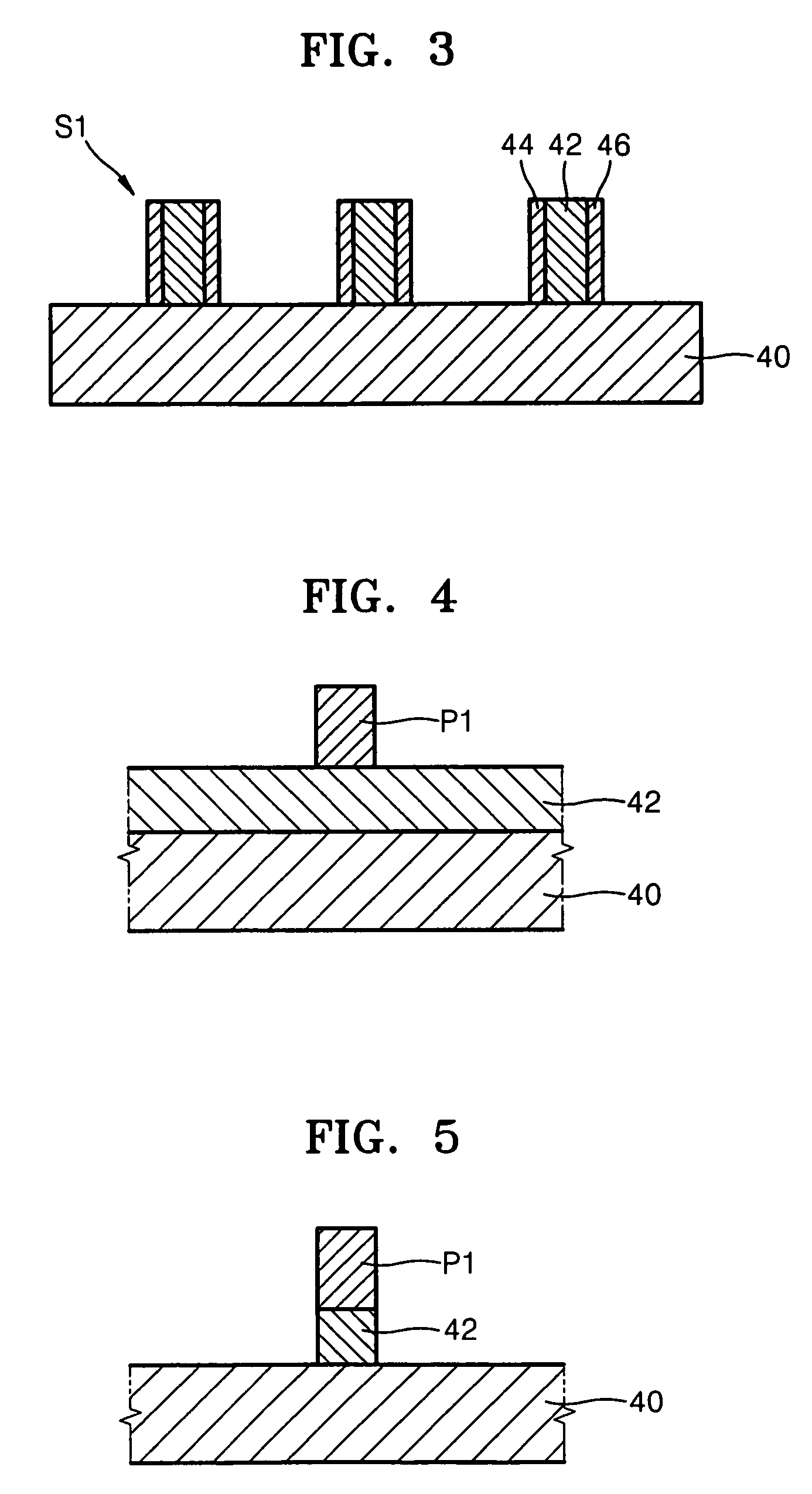

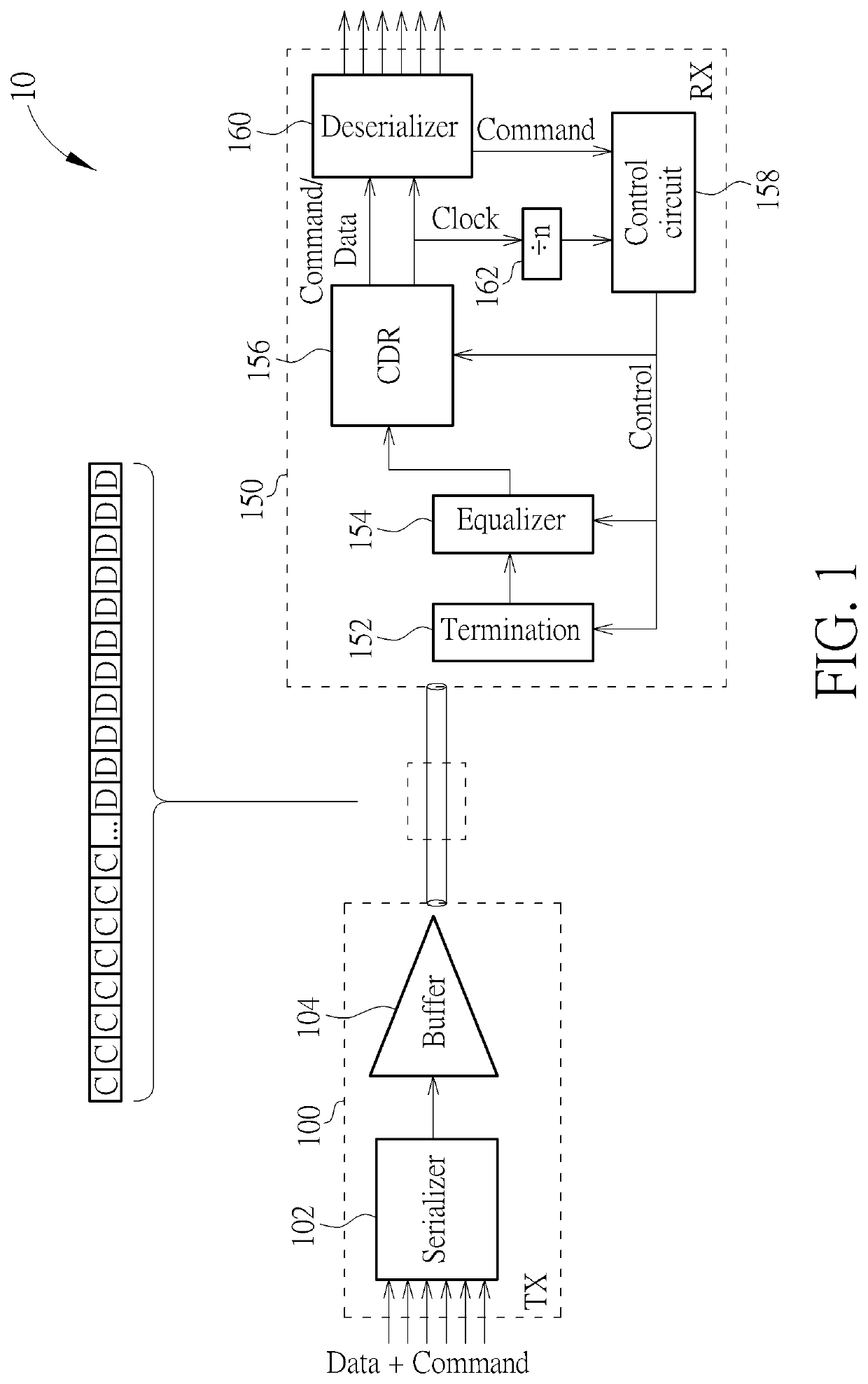

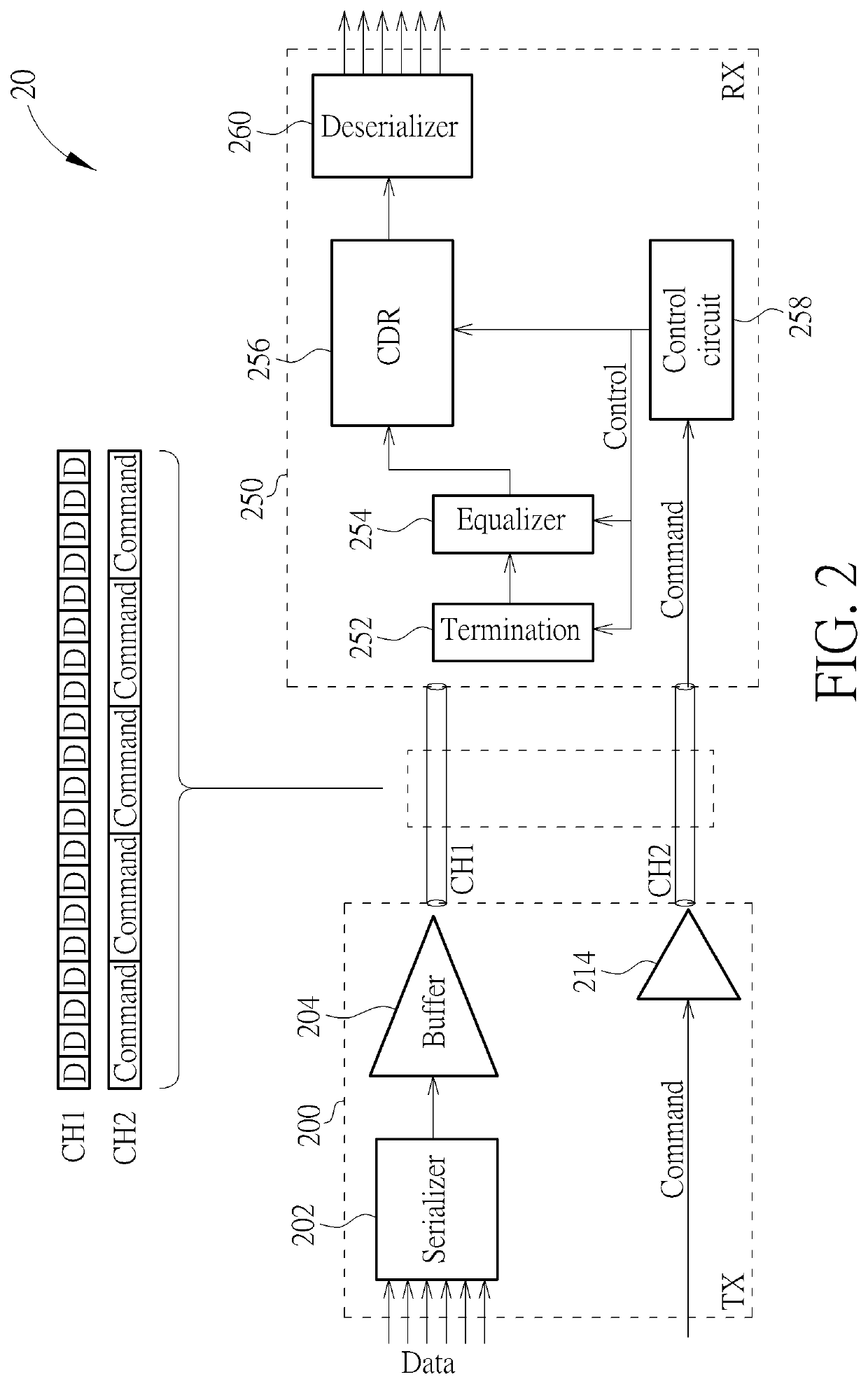

Receiver and transmitter for high speed data and low speed command signal transmissions

ActiveUS11088818B1Increase speedHigh dataSynchronisation receiversSynchronisation transmittersControl signalData signal

A receiver is configured to receive a series of command signals and a series of data signals. The receiver includes a first clock and data recovery (CDR) circuit, a control circuit and a second CDR circuit. The first CDR circuit is configured to process the series of command signal to generate a clock signal. The control circuit, coupled to the first CDR circuit, is configured to generate a control signal according to the series of command signals and the clock signal received from the first CDR circuit. The second CDR circuit, coupled to the control circuit, is configured to process the series of data signals according to the control signal received from the control circuit.

Owner:NOVATEK MICROELECTRONICS CORP

Ferroelectric recording medium and method of manufacturing the same

InactiveUS20080102290A1Increased data recording densityHigh data recording densityNanotechDecorative surface effectsEngineeringRecording layer

Provided are a ferroelectric recording medium and a method of manufacturing the same. The ferroelectric recording medium includes a substrate, a plurality of supporting layers which are formed on the substrate, each of the supporting layers having at least two lateral surfaces; and data recording layers formed on the lateral surfaces of the supporting layers. First and second data recording layers may be respectively disposed on two facing lateral surfaces of each of the supporting layers. The supporting layers may be polygonal pillars having at least three lateral surfaces. A plurality of the supporting layers can be disposed at uniform intervals in a two-dimensional array.

Owner:SAMSUNG ELECTRONICS CO LTD

Control device for a motor vehicle

ActiveUS10657039B2Avoid it happening againHigh dataMemory architecture accessing/allocationMemory adressing/allocation/relocationComputer architectureEngineering

Owner:ROBERT BOSCH GMBH

Oscillator arrangement for time-to-digital converter for large array of time-of-flight image sensor devices

ActiveUS10637485B2Difficult to calibrateHigh dataMultiple-port networksPulse automatic control3d imageSoftware engineering

An oscillator arrangement for time-to-digital converters for a 3D image sensor device includes a plurality of oscillators arranged as an array each oscillator being associated to one time-to-digital converter, and at least one coupling unit respectively arranged between at least two of the oscillators, so that oscillation in the at least two oscillators at a fundamental frequency is synchronized between the at least two coupled oscillators.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

Automated word processor for chinese-style languages

InactiveUS7319950B2Low costSimple and effective and reliableNatural language translationSpecial data processing applicationsChinese charactersChinese word

Owner:LIU CHANG PO

Trigger counter for measurement device with count values stored in flash memory

ActiveUS10101141B2Easy to useEasy to monitorMechanical measuring arrangementsPoint coordinate measurementsMeasurement deviceCoordinate-measuring machine

A system and method are provided for operating a touch probe for a coordinate measuring machine, wherein a value is permanently stored in the touch probe corresponding to an accumulated number of trigger signals generated in the touch probe over its operating history. For a non-erase cycle during which an erasable trigger counter block (e.g., included in a flash memory) of the touch probe is not erased, increasing values of an accumulated trigger count are stored in N address locations of the erasable trigger counter block. After all of the N address locations have been used, an erase operation sequence is performed, and a new non-erase cycle is initiated for repeating the process. In various implementations, the touch probe may not include an embedded processor or battery, for which the types of circuitry and methods that may be utilized for maintaining and storing the accumulated trigger count are correspondingly limited.

Owner:MITUTOYO CORP

Ferroelectric recording medium and method of manufacturing the same

InactiveUS20100089867A1Increased data recording densityHigh data recording densityNanotechDecorative surface effectsEngineeringRecording layer

Owner:SAMSUNG ELECTRONICS CO LTD

Microelectro mechanical system for magneto-optic data storage apparatus

InactiveUS20050194515A1High optical data storage and rewritable efficiencyHigh dataCombination recordingPhotometry using reference valueHigh densityElectrical resistance and conductance

The present invention relates to a Microelectro mechanical system structure. More specifically the invention relates to utilize a sacrificial layer to fabricate an air bearing structure, followed by forming an aperture, and reducing the aperture to nano-scale by electroplating. And then, by using of two thick film photoresist films for twice electroplating fabrication, for fabricate metal microcoils having high aspect ratio structure and interconnection metal line, to achieve efficiencies of utilizing area and reducing resistance. Moreover, proceed lithography depends on different portions and exposure dose. Then form a single photoresist film to have a specific dimension and thickness structure, finally, by using reflow process, forming a magneto-optic (MO) pickup head comprises of Supersphere Solid Immersion Lens (SSIL), nano-aperture, microcoils and air bearing by using an integrated fabrication, with advantages such as no high cost device and precise apparatus are required in the process of fabrication, mass production in batch fabrication, without step of assembly, for high-density data storage and rewritable record.

Owner:NATIONAL CHIAO TUNG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com