Electronic chip self-adaptive micro-channel cooling device and manufacturing method thereof

An electronic chip and cooling device technology, applied in cooling/ventilation/heating transformation, circuits, electrical components, etc., can solve the problems of difficult to achieve chip-level integration, complex structure, etc., achieve high-efficiency chip local adaptive adjustment, convenient production, Simple effect of structure and flow organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

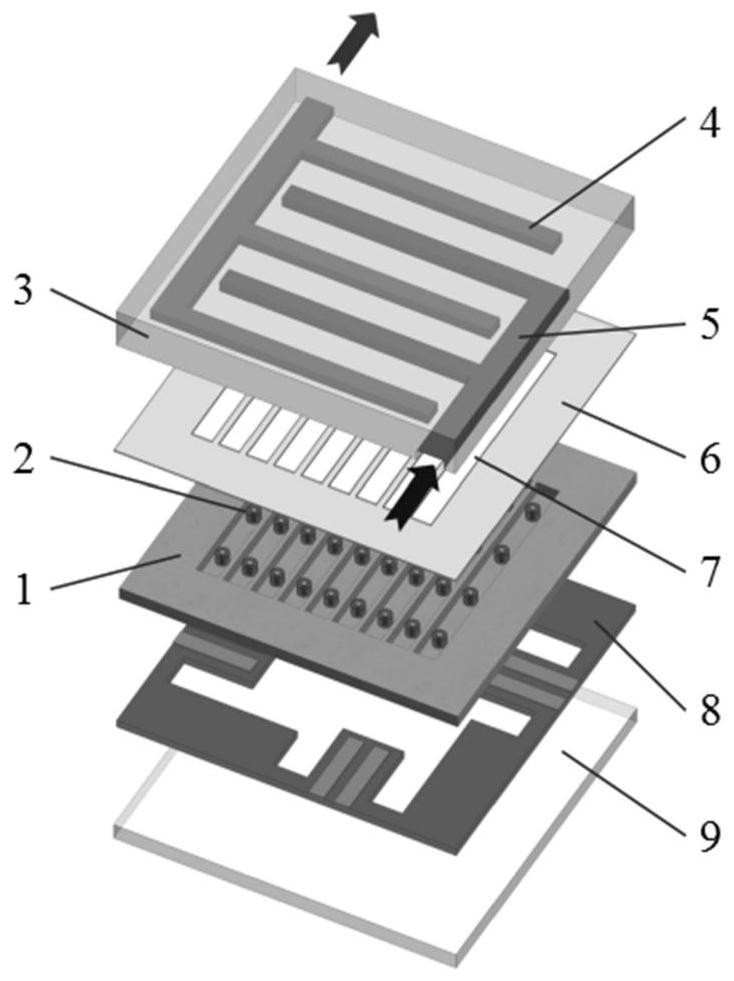

[0044] combine figure 1, an adaptive microchannel cooling device for electronic chips, which includes a square silicon chip with a microchannel structure on one side for simulating an actual chip, a hydrogel microvalve 2, a manifold distributor / collector 3, and a sealing film layer 6 , Hollow slot 7, PCB8 and substrate 9. The hydrogel microvalve 2 is integrated in the microchannel, and the manifold distribution / collector 3 is arranged above the microchannel and connected with the microchannel to realize distribution of working fluid to the microchannel and recovery of working fluid discharged from the microchannel , A rubber film is used to seal between the manifold distributor / collector 3 and the microchannel.

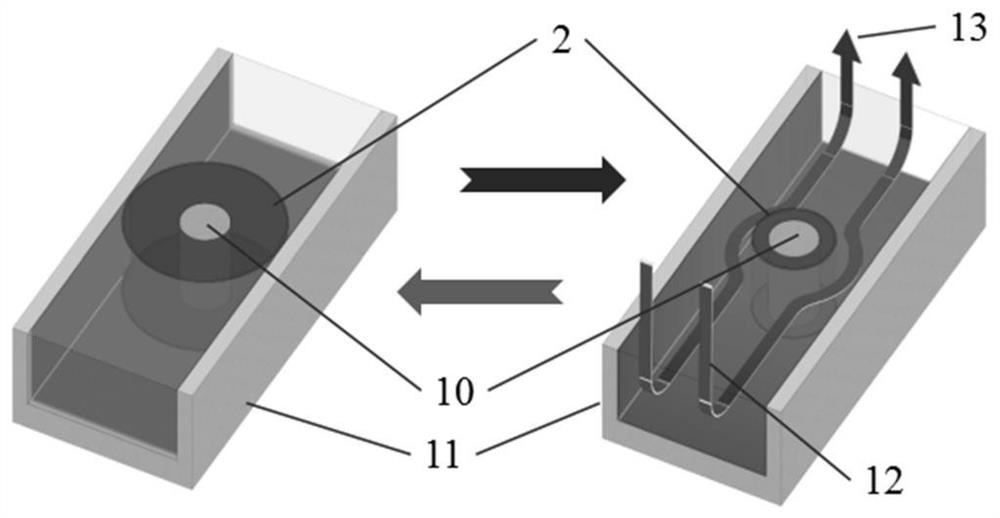

[0045] Nine parallel microchannels are processed in the center of one side of the analog chip 1 by deep reactive ion etching technology, occupying a total area of 10.6mm×10.4mm, with a depth of 0.22mm and a rectangular cross-section. Four microcolumn structures 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com