Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76 results about "Mechanical overload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The failure or fracture of a product or component as a result of a single event is known as mechanical overload. It is a common failure mode, and may be contrasted with fatigue, creep, rupture, or stress relaxation. The terms are used in forensic engineering and structural engineering when analysing product failure. Failure may occur because either the product is weaker than expected owing to a stress concentration, or the applied load is greater than expected and exceeds the normal tensile strength, shear strength or compressive strength of the product.

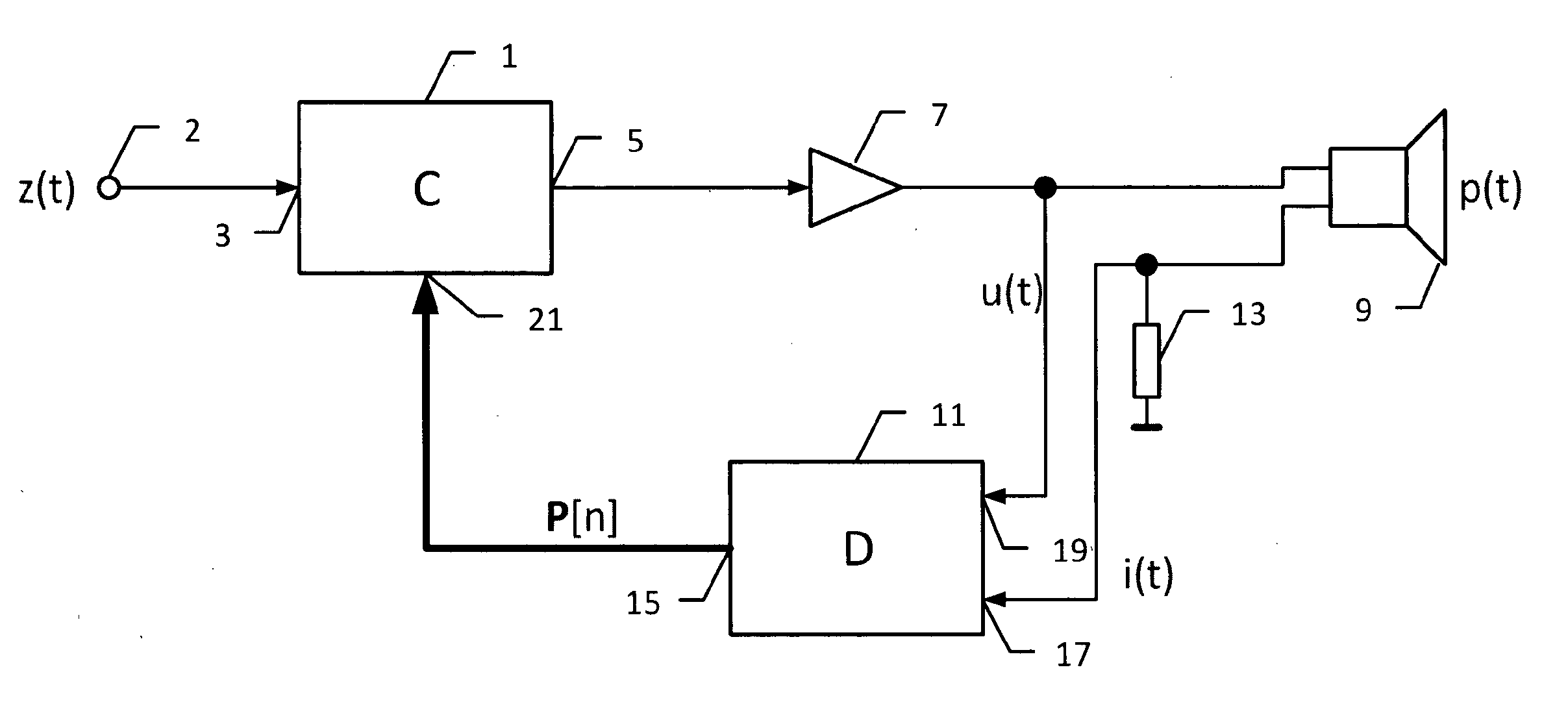

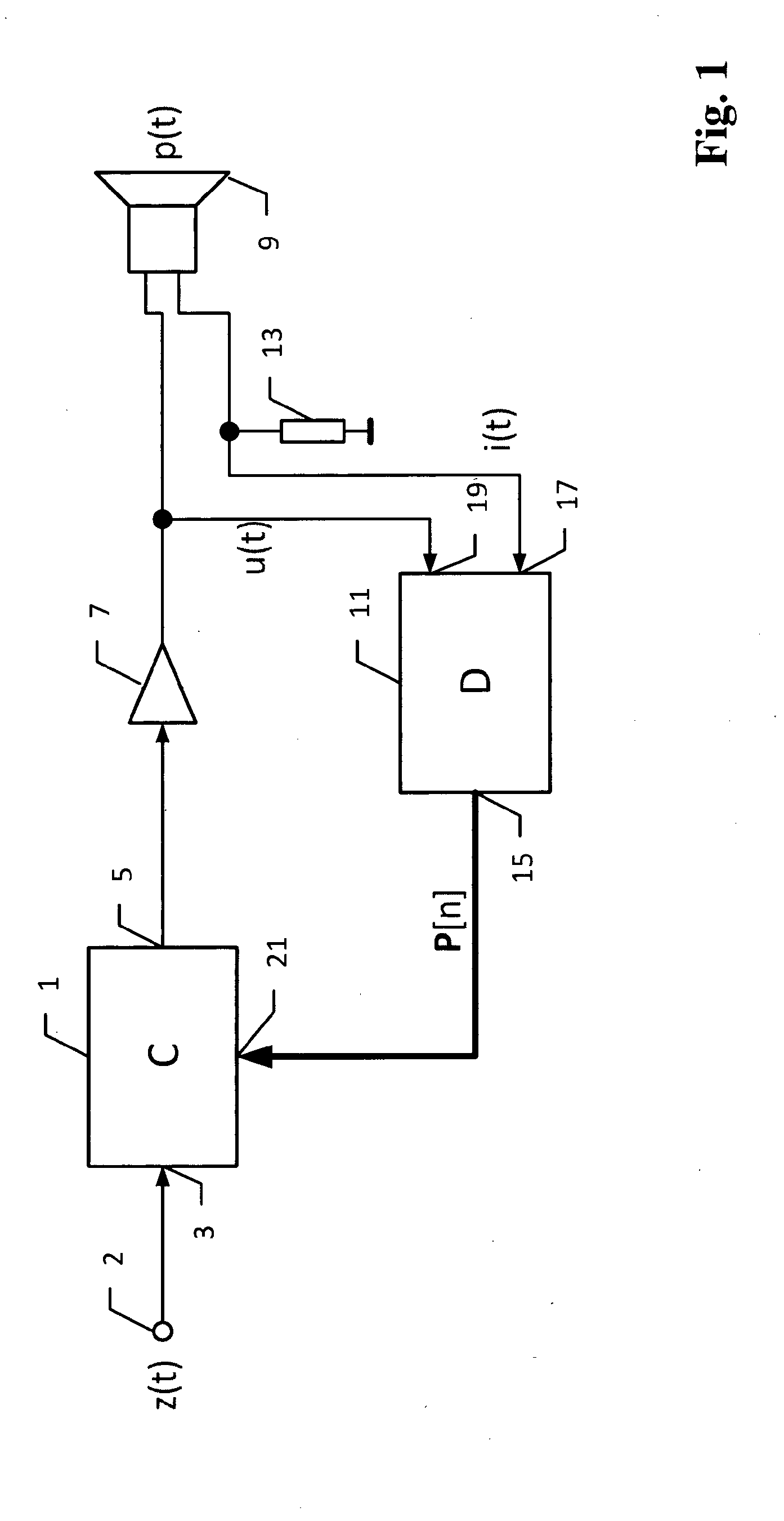

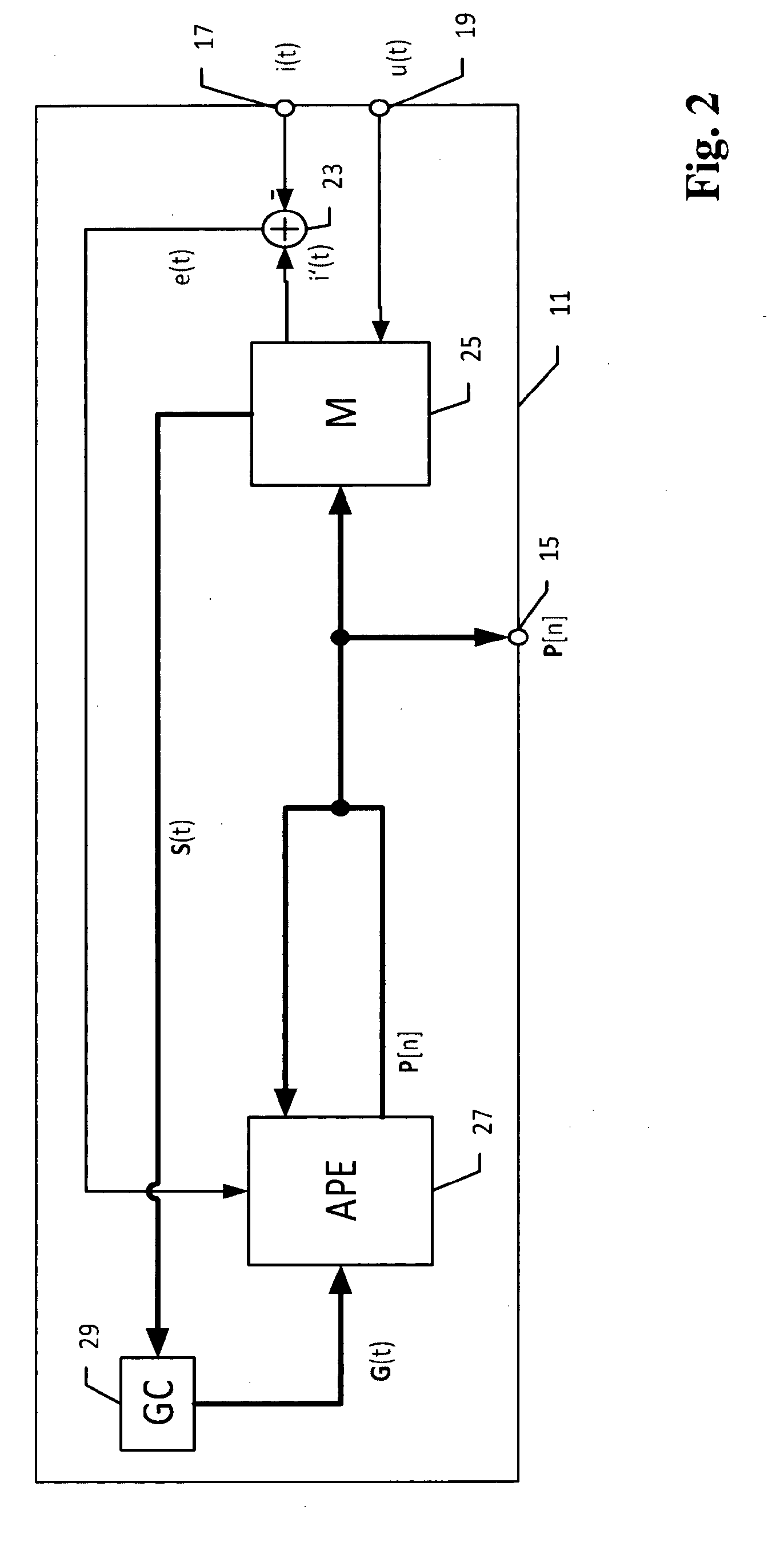

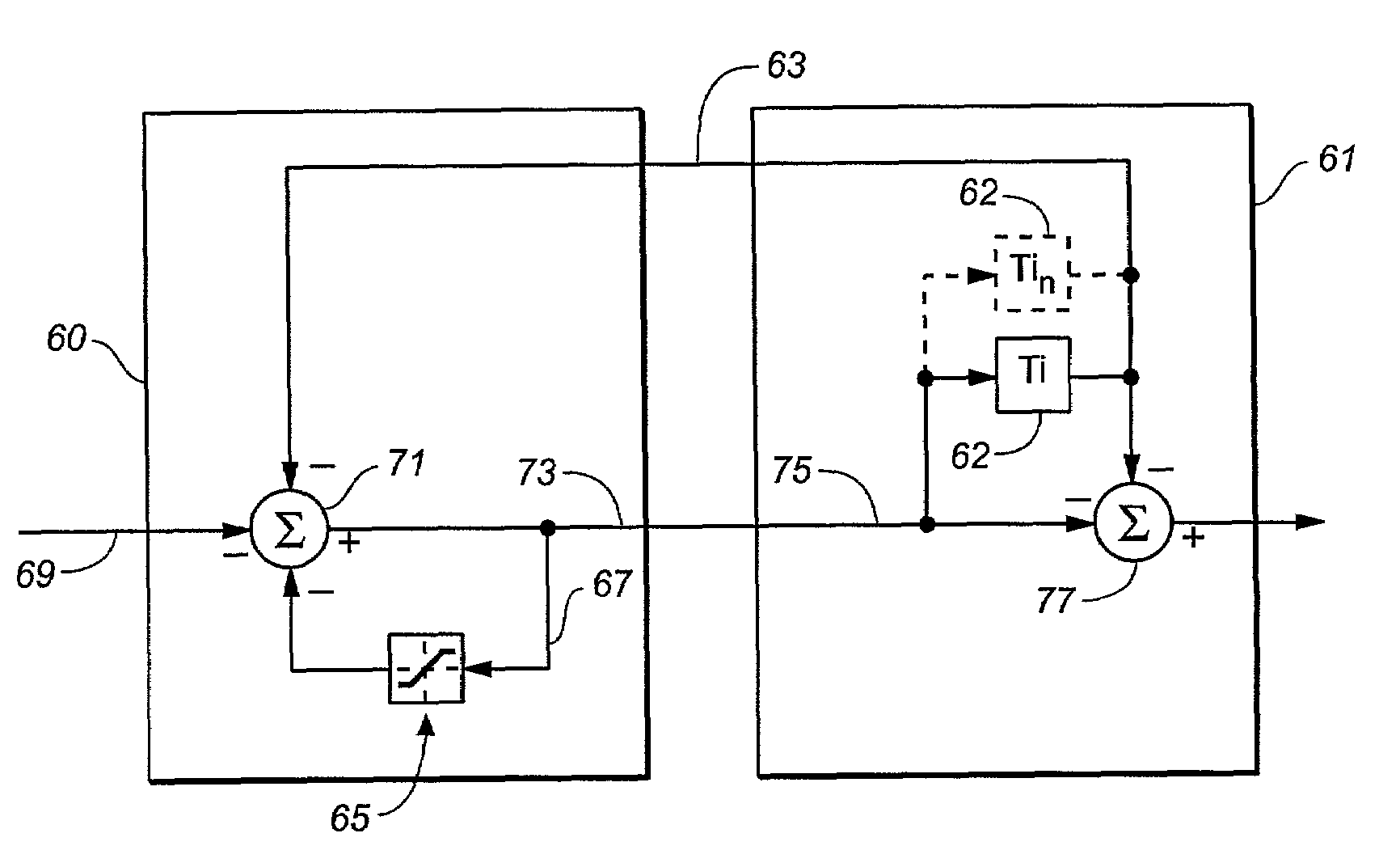

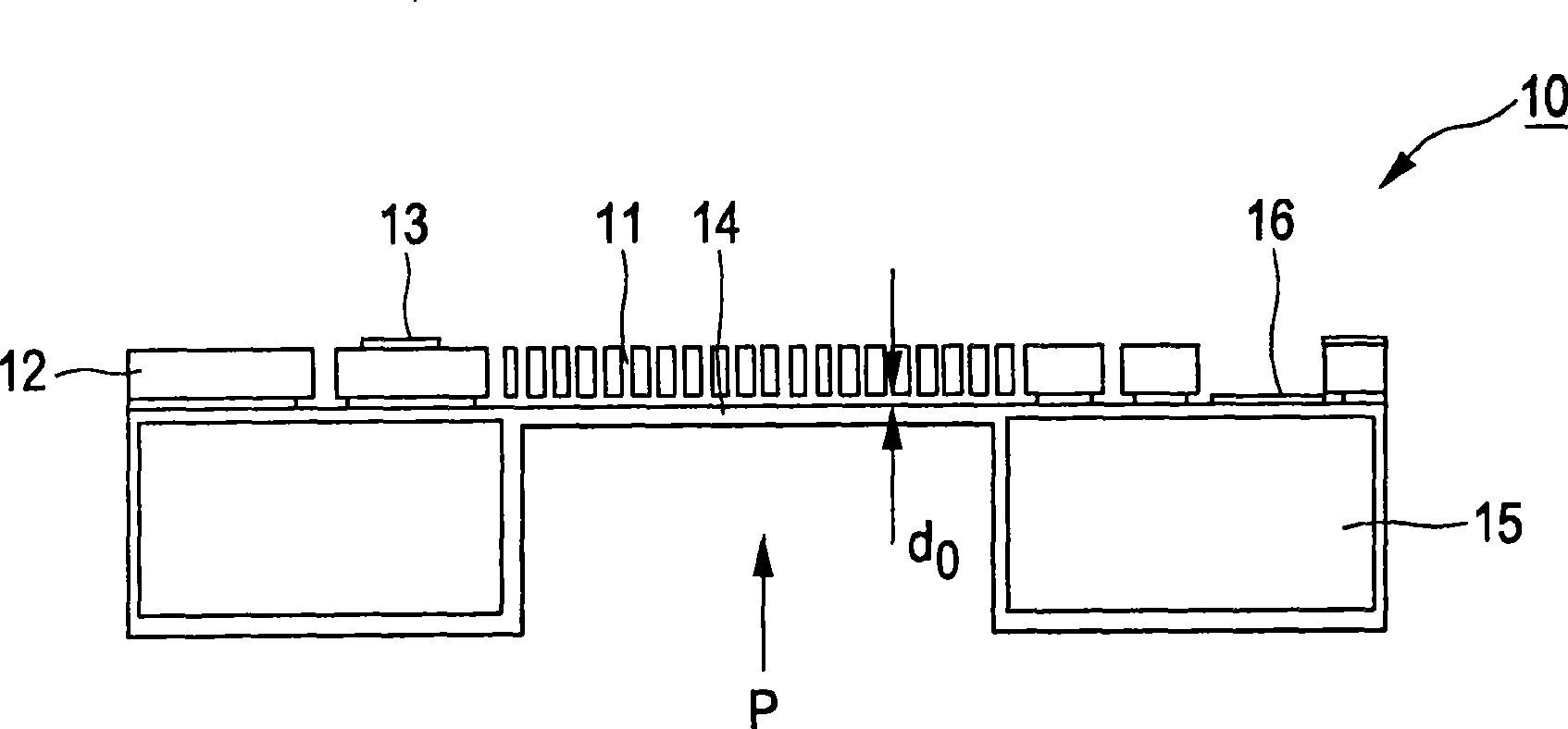

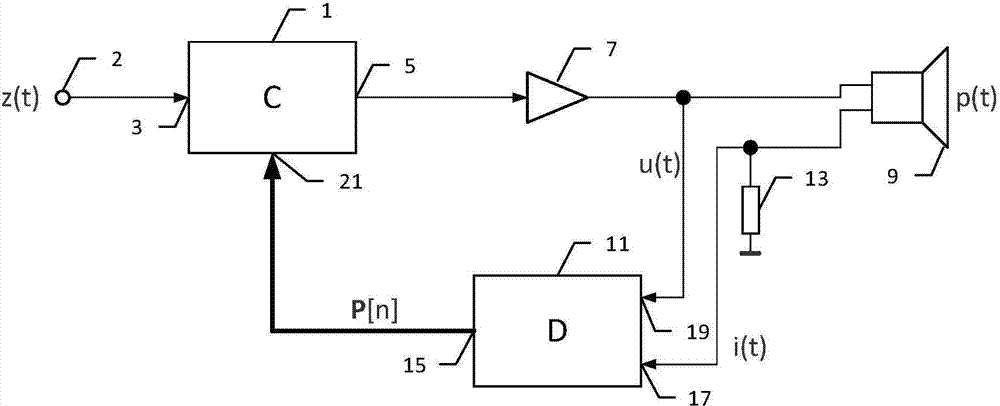

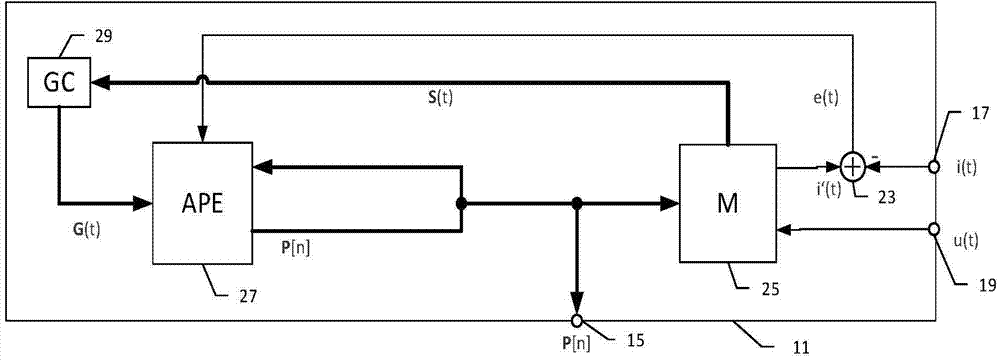

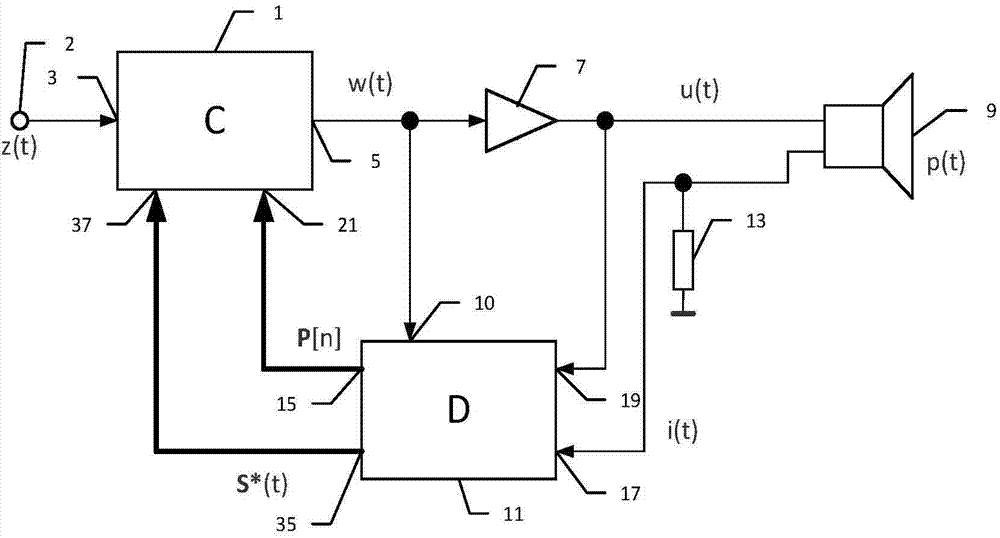

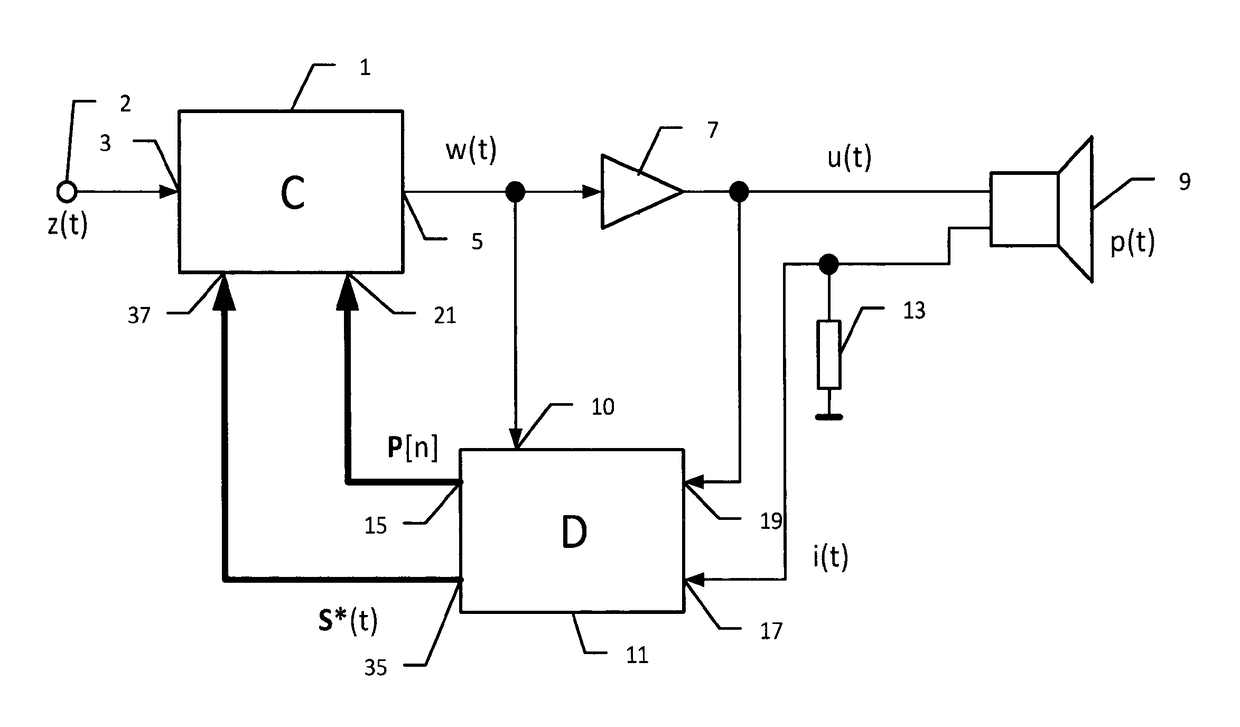

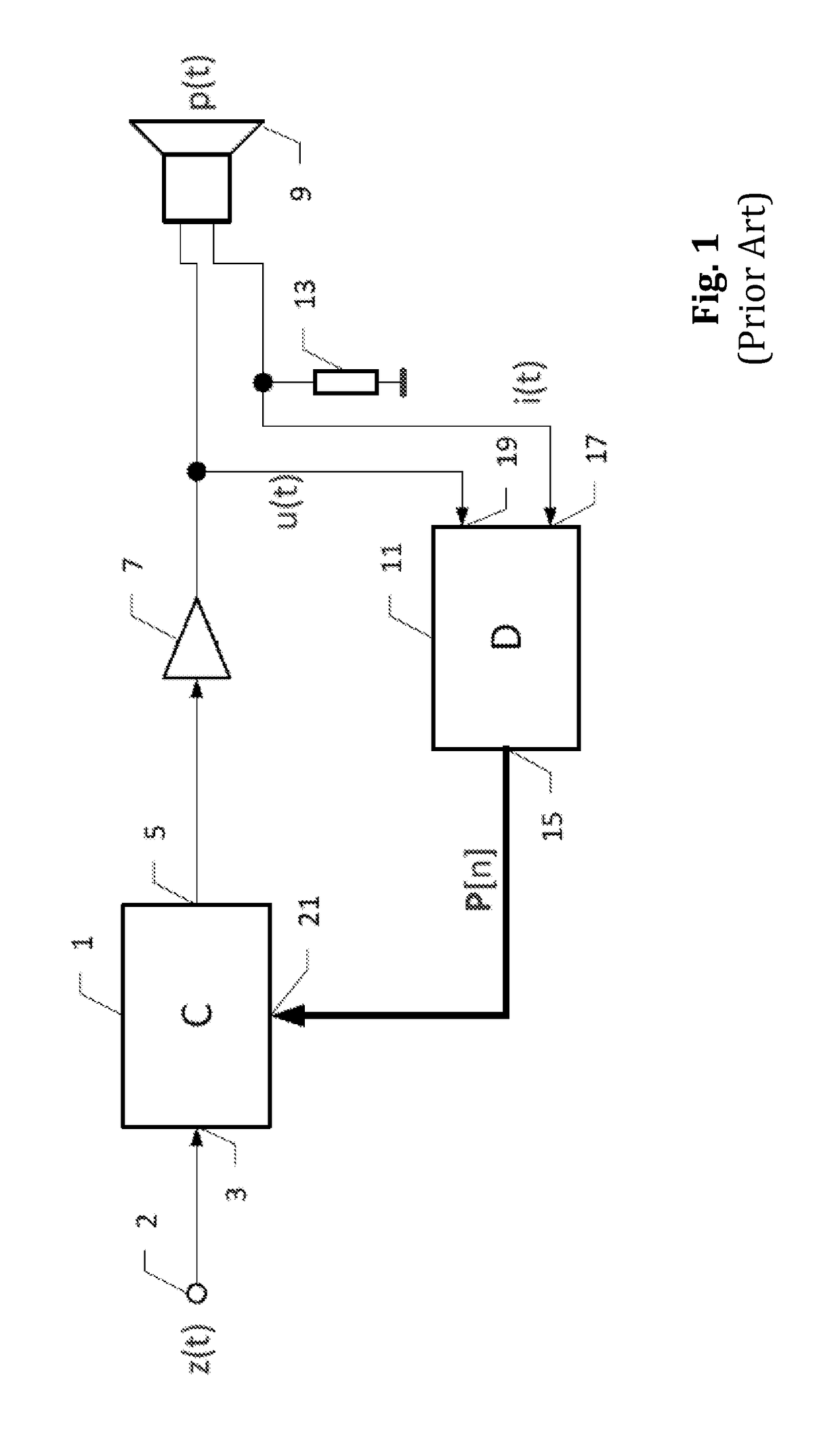

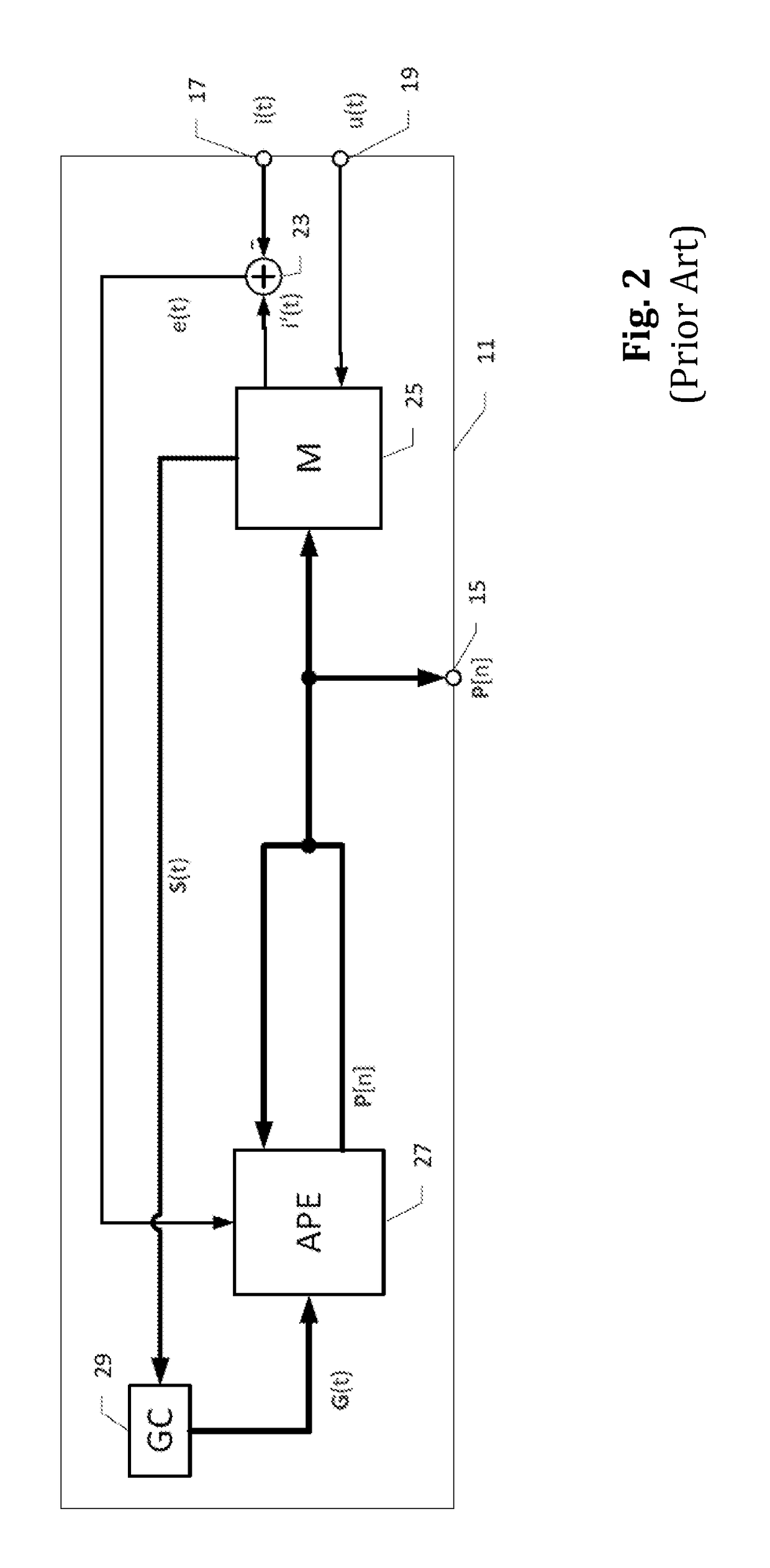

Method and arrangement for controlling an electro-acoustical transducer

ActiveUS20150319529A1Sufficient amplitudeSufficient sound qualityTransducer protection circuitsTransducer acoustic reaction preventionAudio power amplifierTransducer

An arrangement and method for converting an input signal into a mechanical or acoustical output signal by using a transducer and additional means for generating a desired transfer behavior and for protecting said transducer against overload. Transducers of this kind are for example loudspeaker, headphones and other mechanical or acoustical actuators. The additional means comprise a controller, a power amplifier and a detector. The detector identifies parameters of the transducer model if the stimulus provides sufficient excitation of the transducer. The detector permanently identifies time variant properties of the transducer for any stimulus supplied to the transducer. The controller provided with this information generates a desired linear or nonlinear transfer behavior; in particular electric control linearizes, stabilizes and protects the transducer against electric, thermal and mechanical overload at high amplitudes of the input signal.

Owner:KLIPPEL WOLFGANG

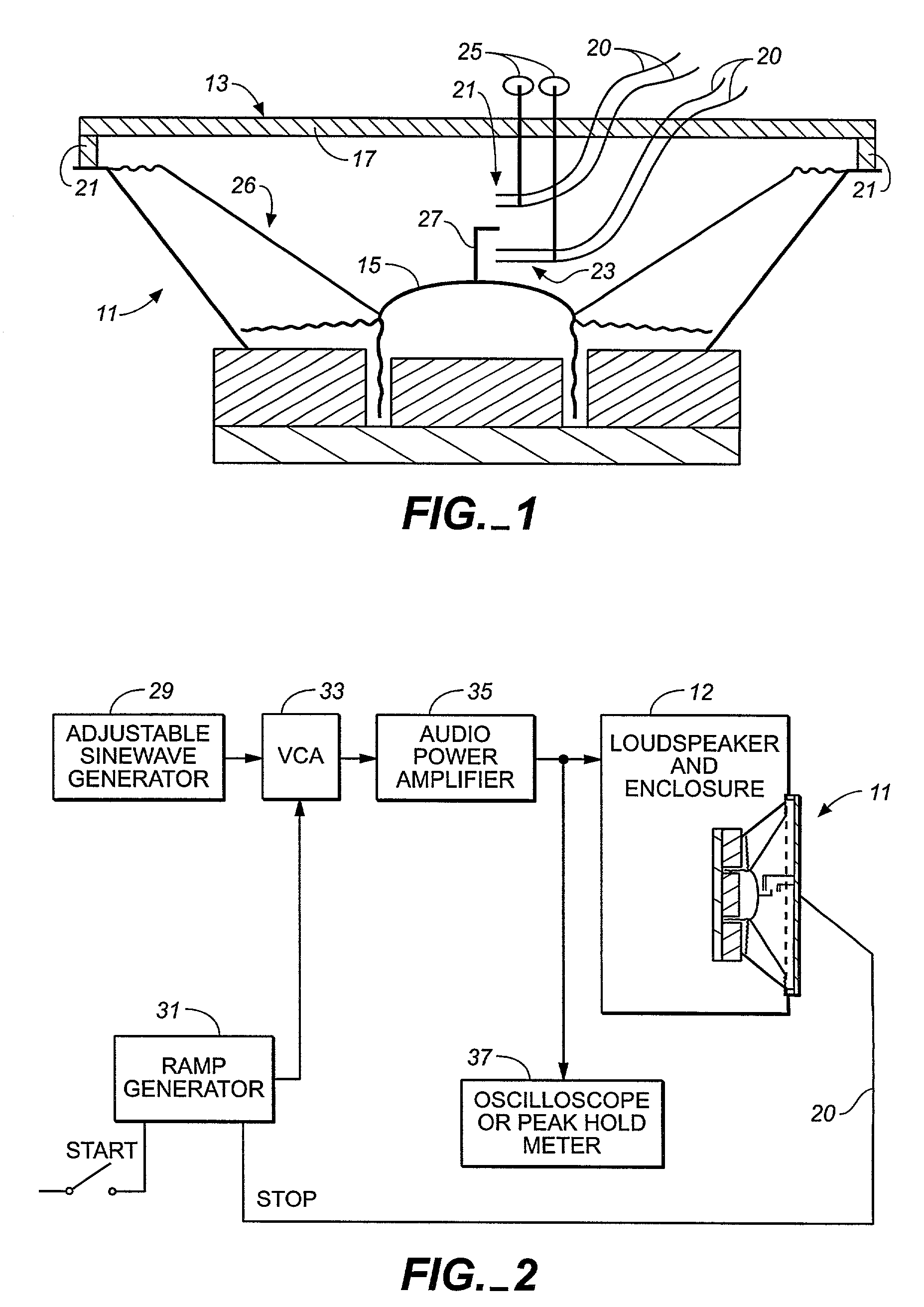

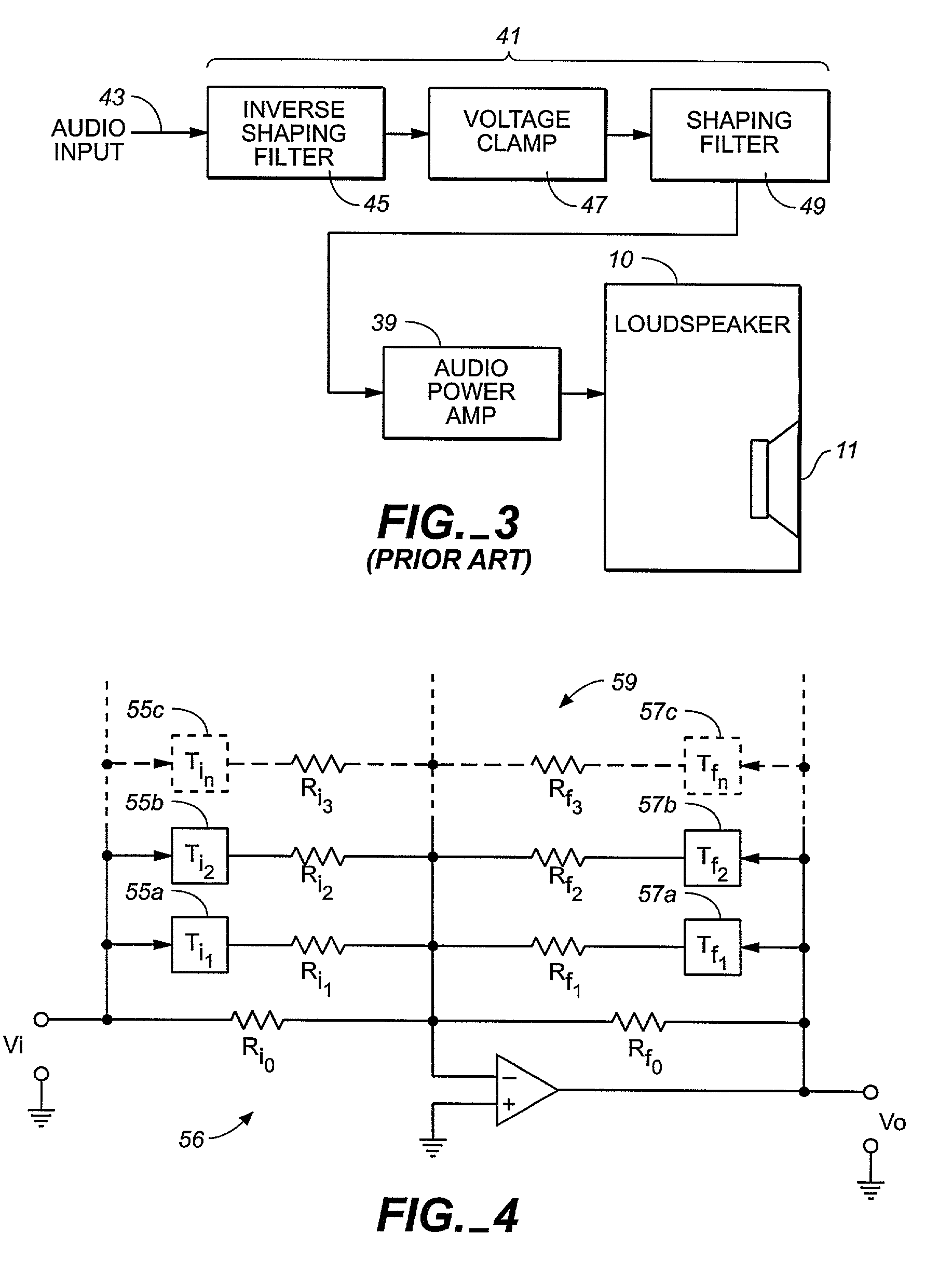

Frequency dependent excursion limiter

ActiveUS6931135B1Lower potentialReduce in quantityTransducer protection circuitsTransducer casings/cabinets/supportsTransducerMechanical overload

A circuit and method provides for the protection of transducers from over excursion, particularly for the protection of transducers for audio loudspeakers. A frequency dependent excursion limiter circuit has an initial summing stage followed by a shaping filter stage. A clamping function is provided at the summing stage, or at a separate stage between the summing stage and the shaping filter stage, for clamping the driving signal at a predetermined maximum voltage if the driving signal exceeds the predetermined maximum voltage level. The shaping filter stage provides a frequency response shaping function based on a predetermined frequency response shaping criteria which is related to the frequency dependent excursion limits of the transducers being protected from mechanical overload. An inverse shaping filter function is provided at the initial summing stage by providing feedback from the shaping filter stage, thus eliminating the need for a separate inverse shaping filter circuit before clamping. The inverse shaping filter function allows low level signals below clamping to pass through the circuit unaffected.A frequency dependent excursion limiter circuit is also provided in the closed loop circuit of servo feedback system for protecting transducers in a servo feedback system from over excursion.

Owner:MEYER SOUND LABORATORIES

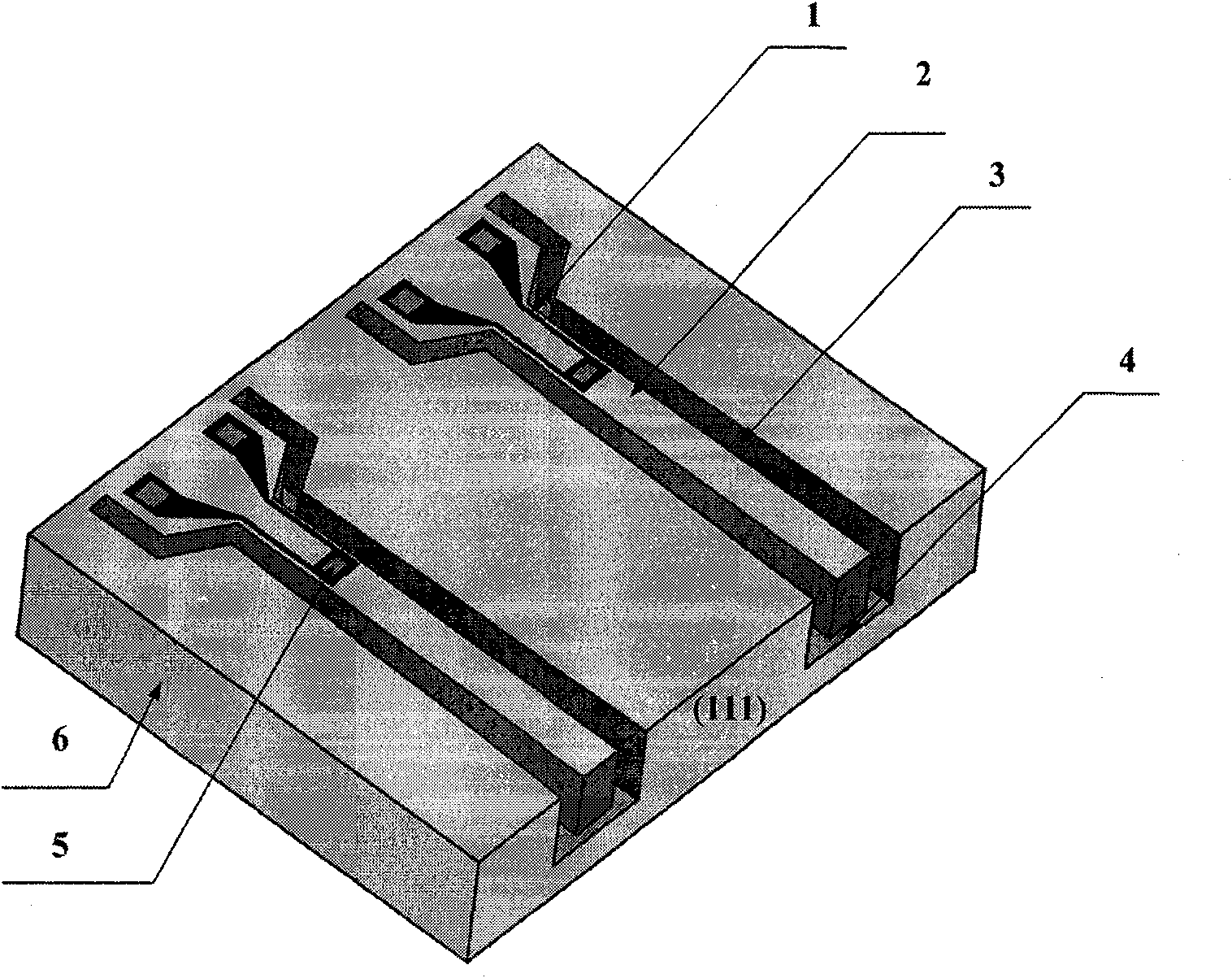

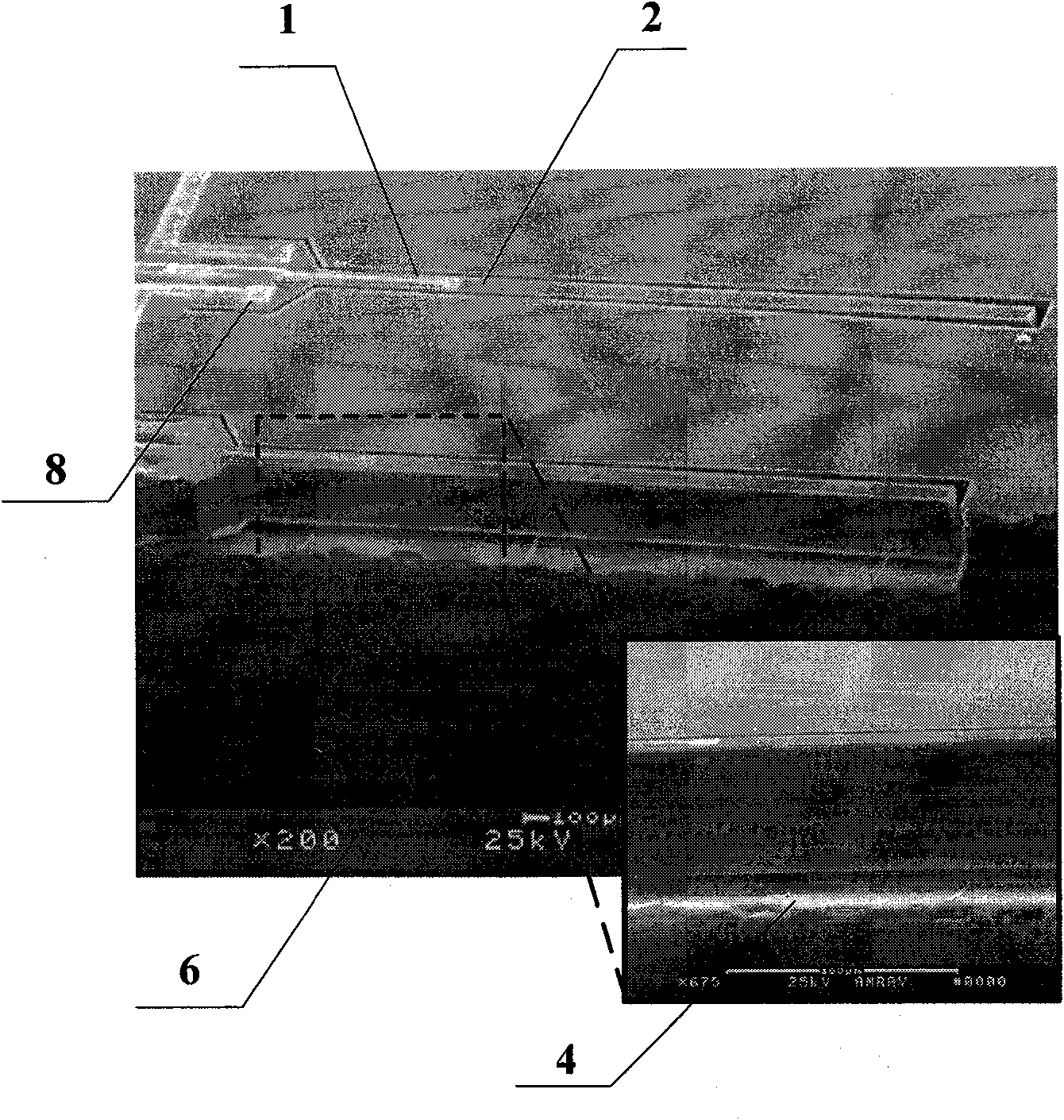

Cantilever beam acceleration transducer manufactured by micro-machining on single side of single silicon chip and method

ActiveCN101968495AHigh sensitivityImprove stabilityAcceleration measurement using interia forcesDecorative surface effectsEtchingAccelerometer

The invention relates to a cantilever beam acceleration transducer manufactured by micro-machining on a single side of a single silicon chip and a manufacturing method. The acceleration transducer is characterized in that: an accelerometer is manufactured by micro-mechanical single side machining through the single silicon chip, so that stress caused by the bonding process of a plurality of chipsand different materials is avoided. In order to realize a single side-machined cantilever beam sensitive structure, the cantilever beam structure is released by transversely etching the bottom of thecantilever beam by an anisotropic corrosion method after deep structural etching. The structure provides air squeeze-film damping and mechanical overload protection in a sensitive direction, solves the problem of the absence of air squeeze-film damping in the vertical sensitive direction of the conventional structure and prevents parasitic signal interference caused by structural resonance in thevertical direction. The acceleration transducer has the characteristics of particular suitability for measuring a high g value, simple structure, small size of the chip and the like. Simultaneously, a single side process can use low-cost single throwing silicon chips, is suitable for low-cost mass manufacturing and has higher performance and wide application prospects.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

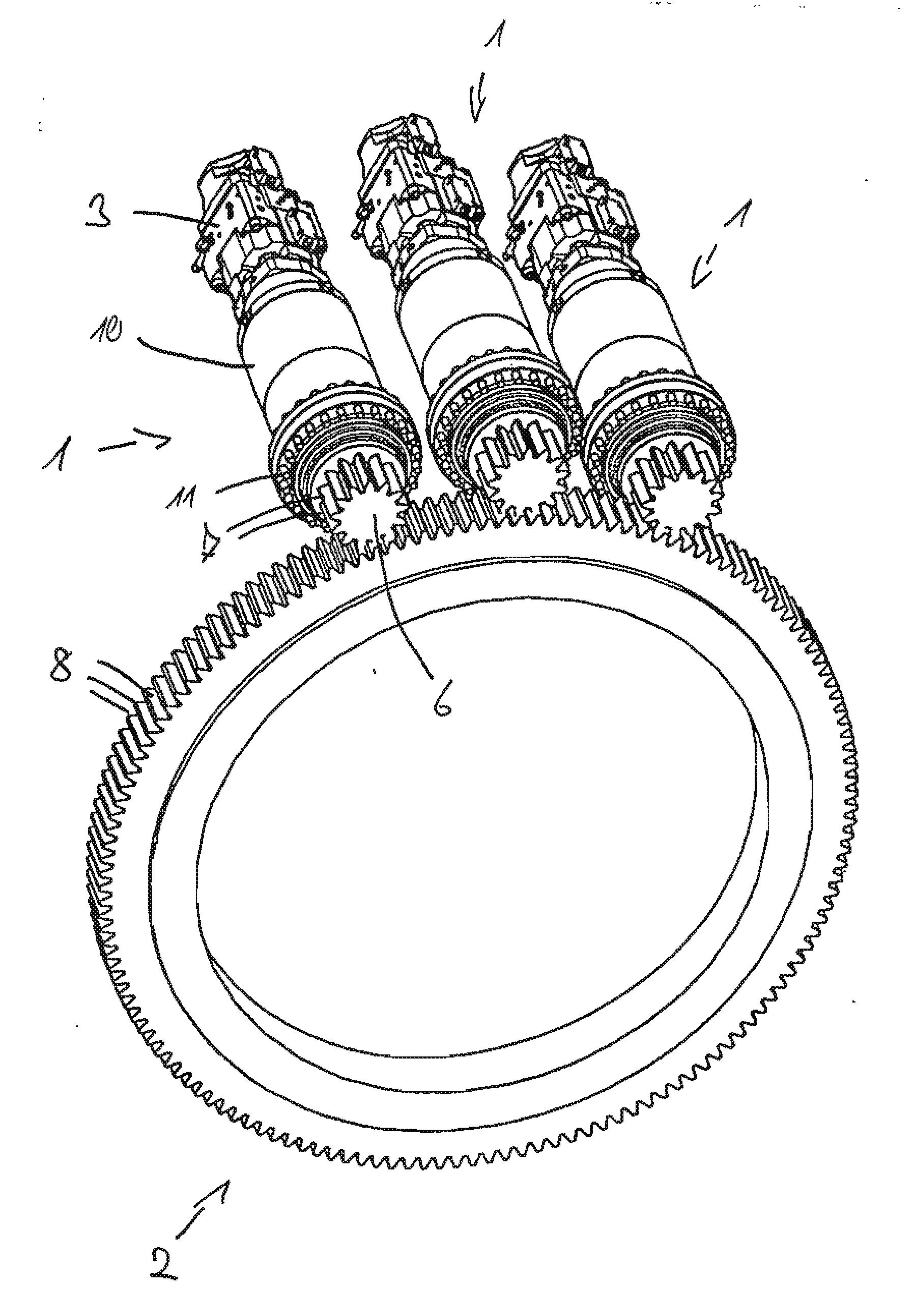

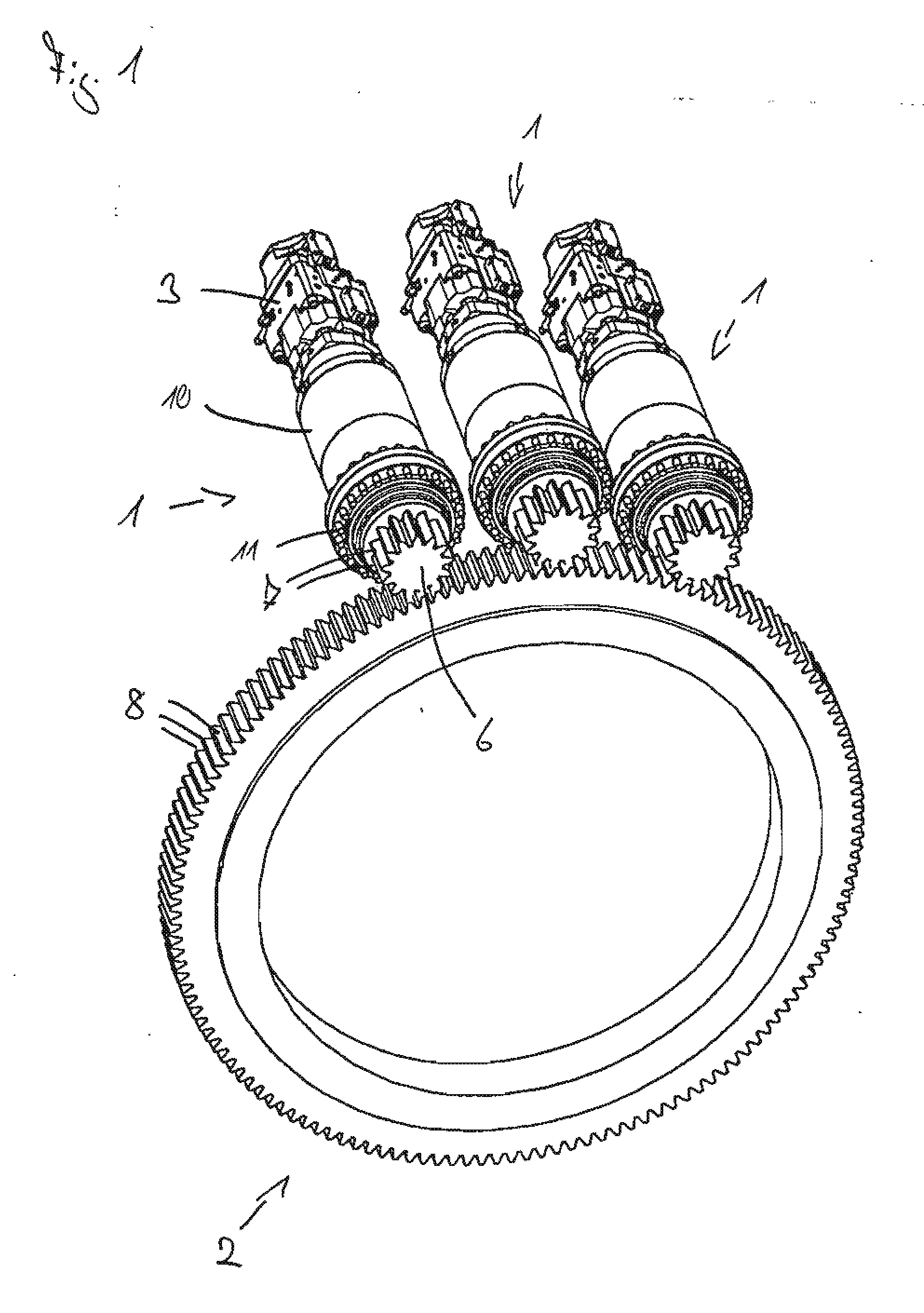

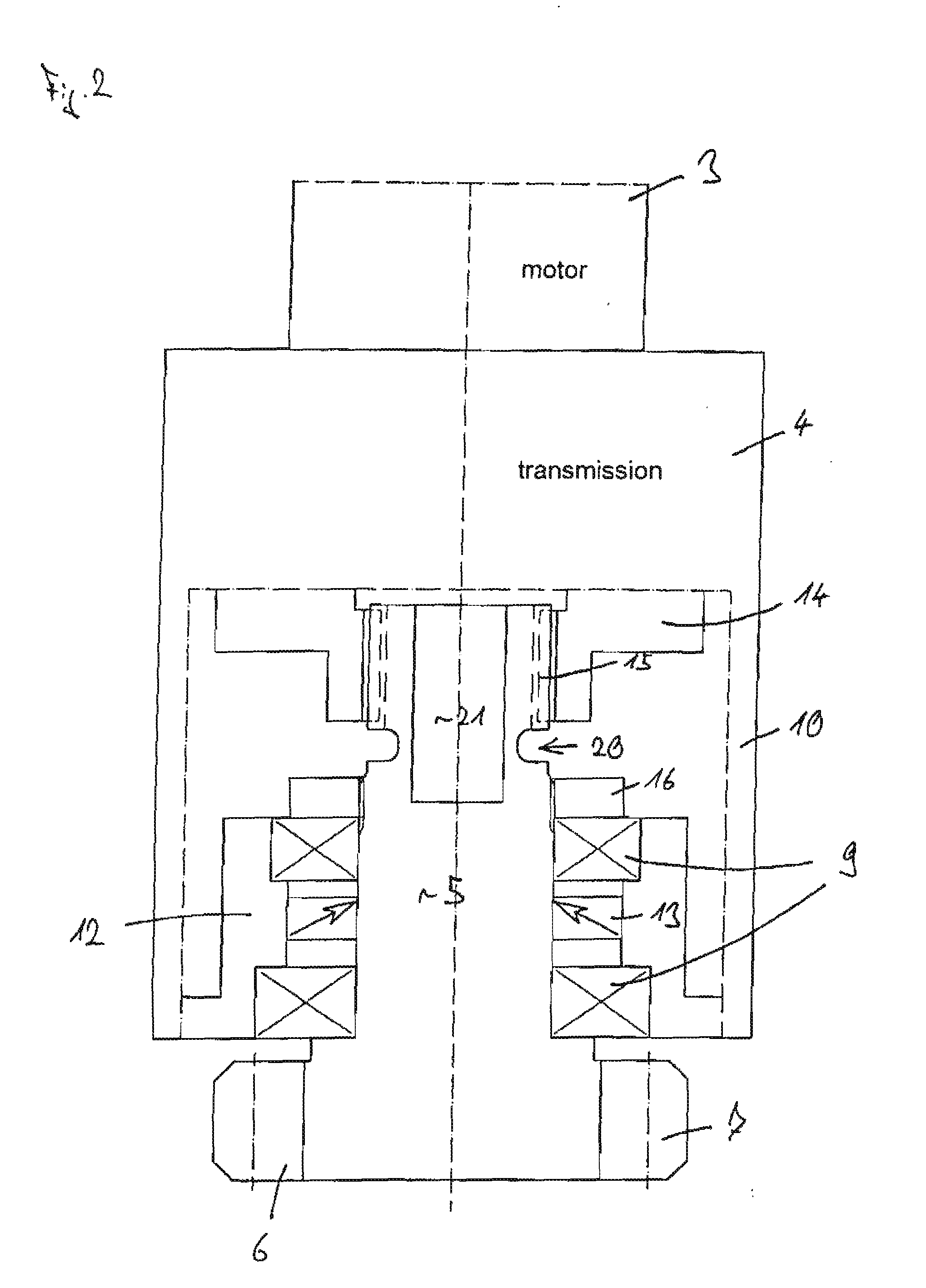

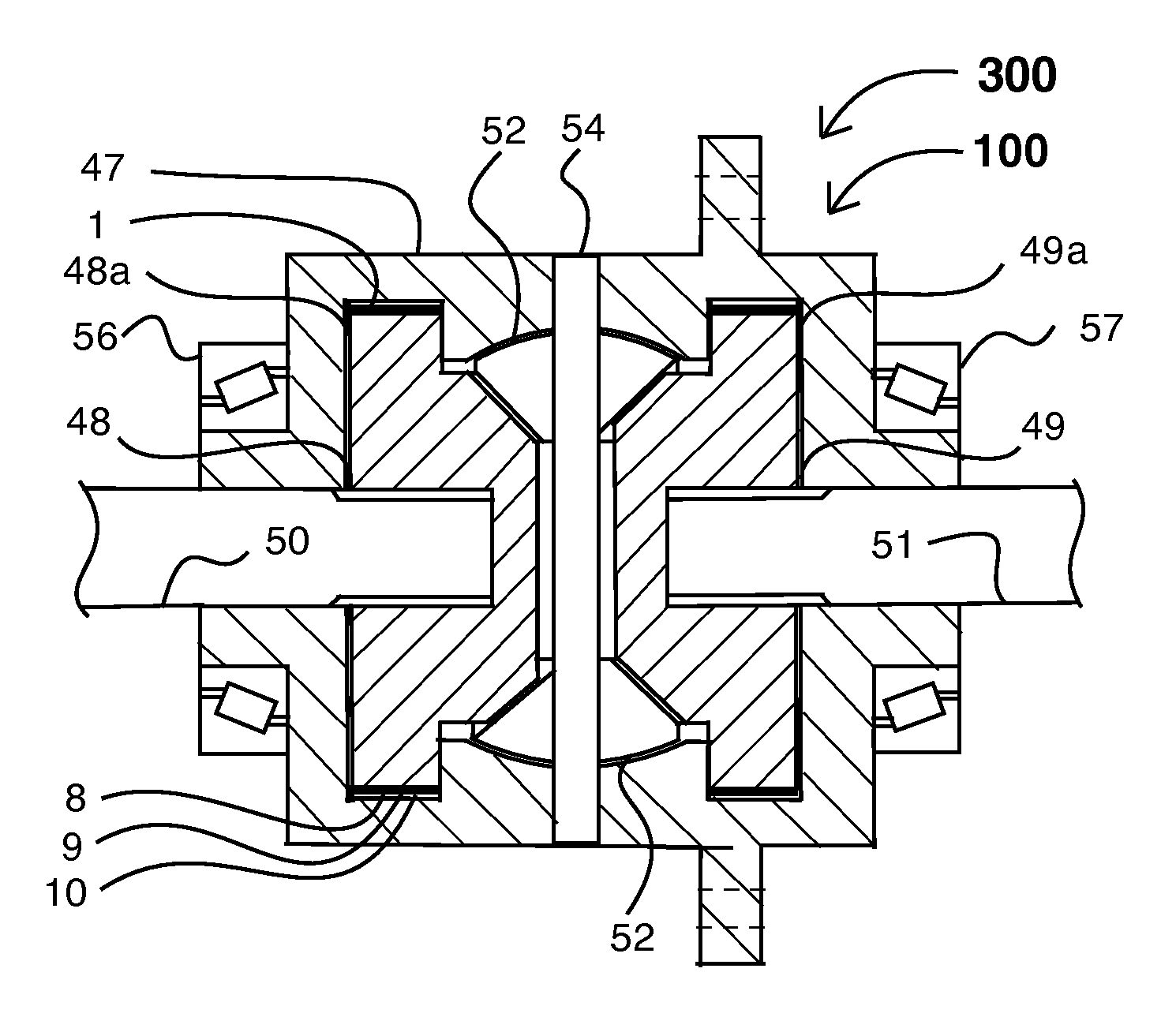

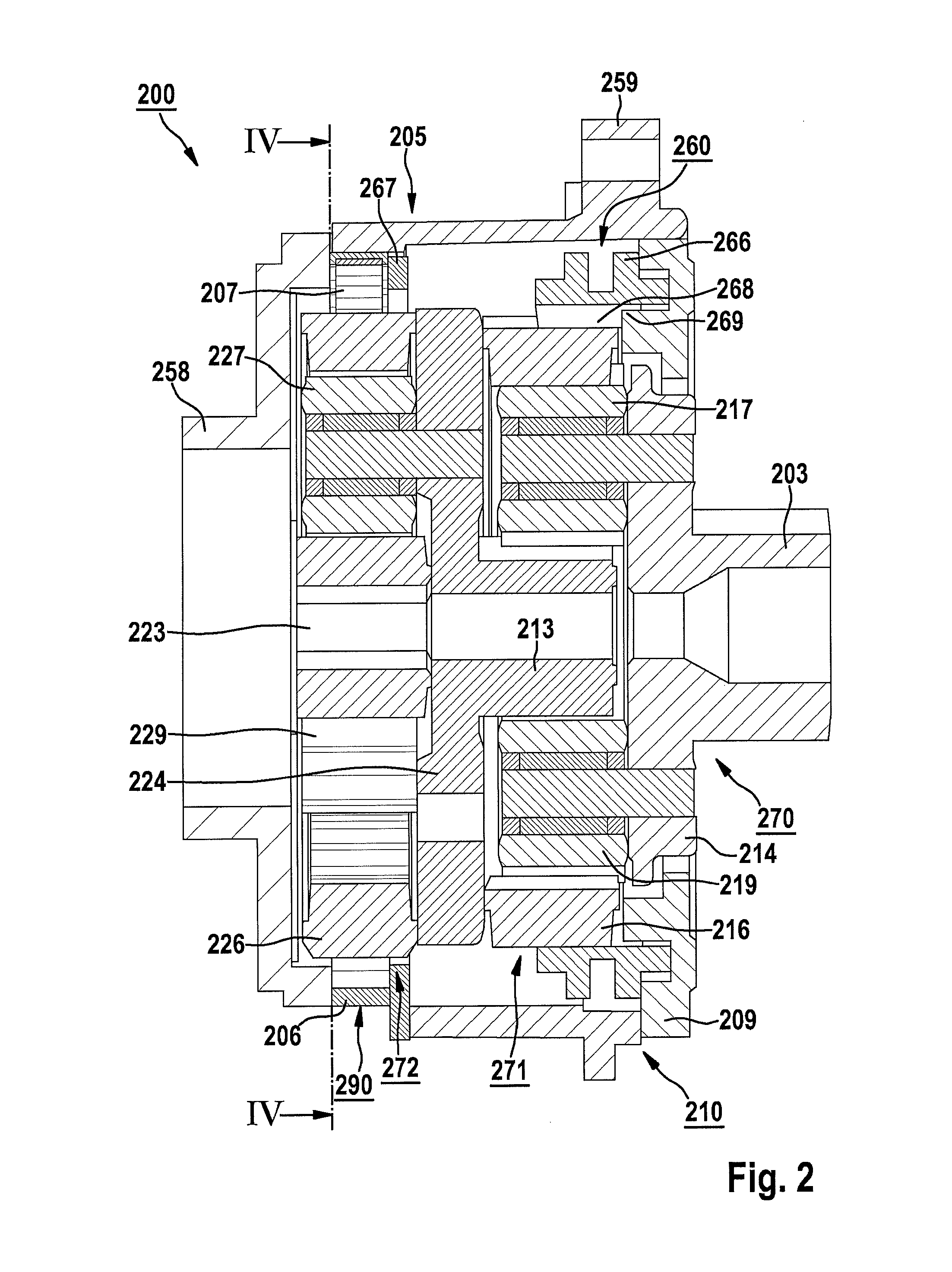

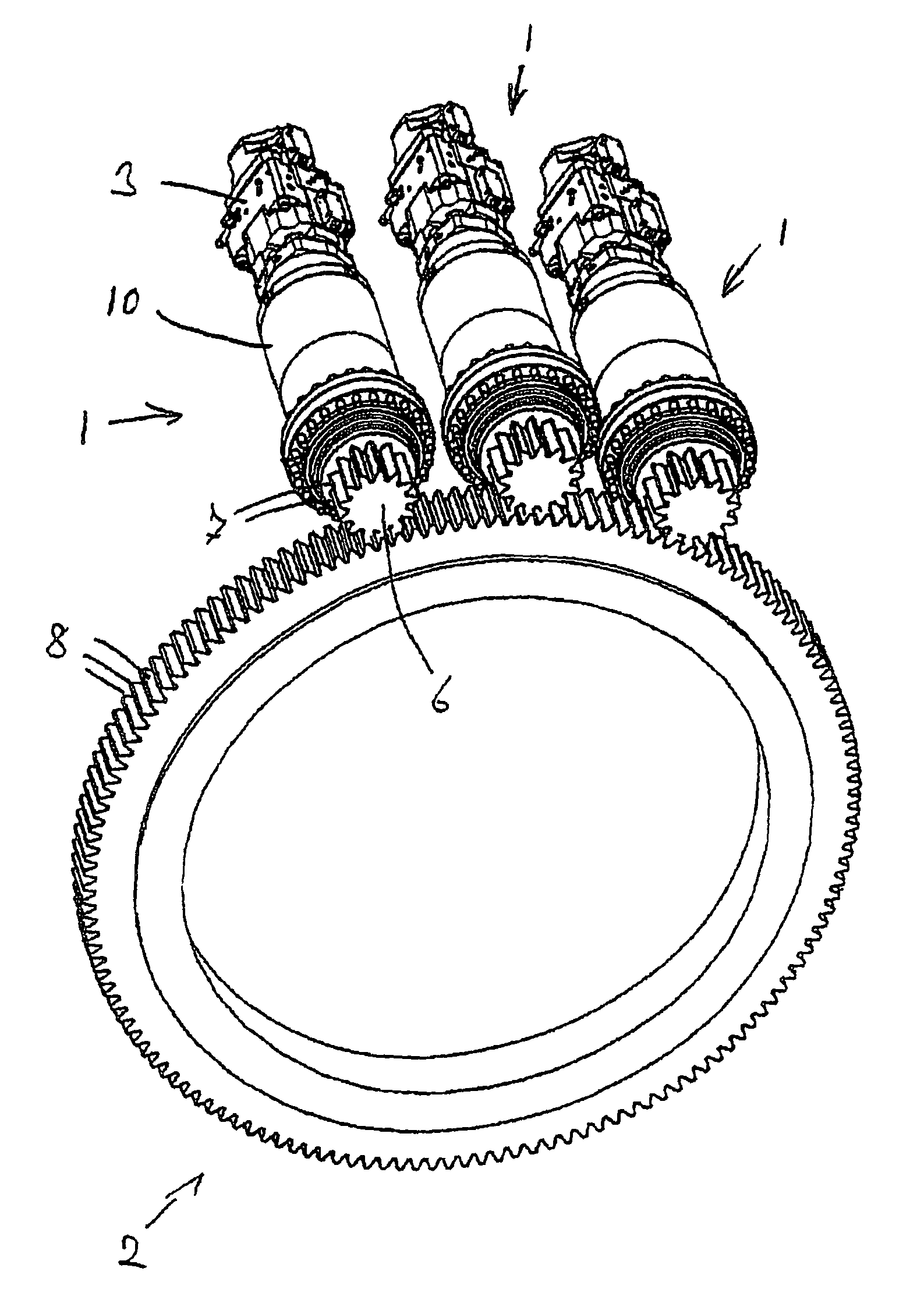

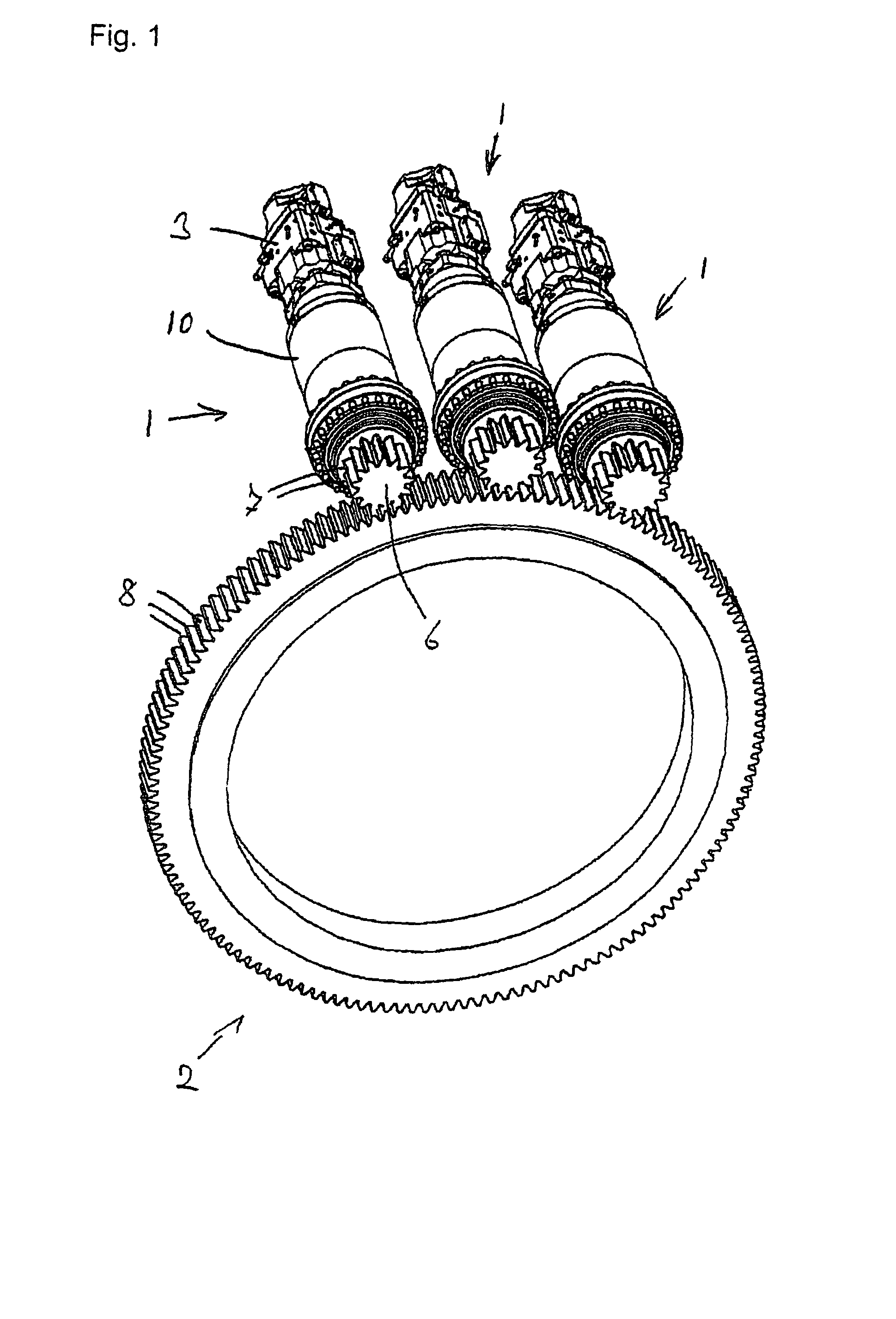

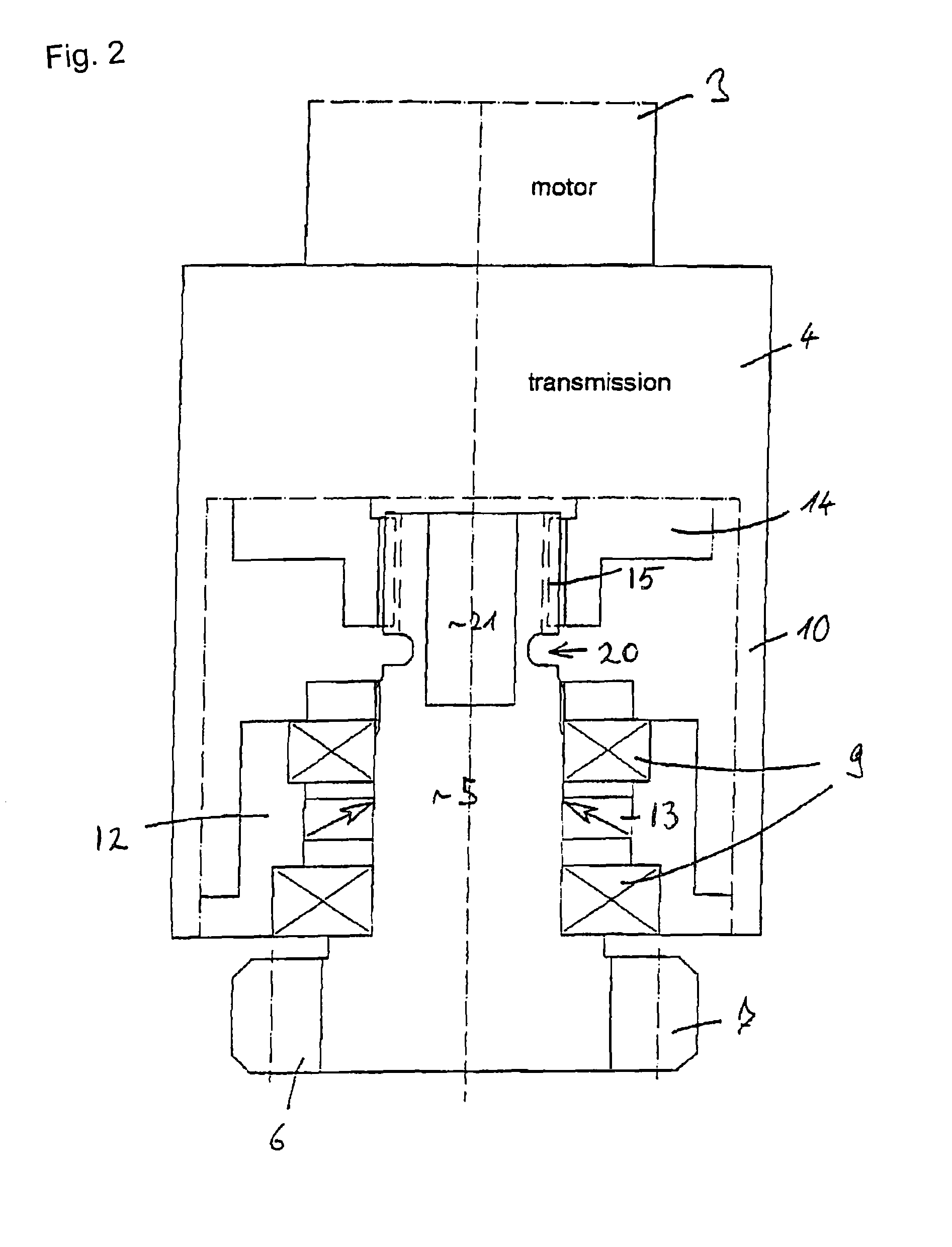

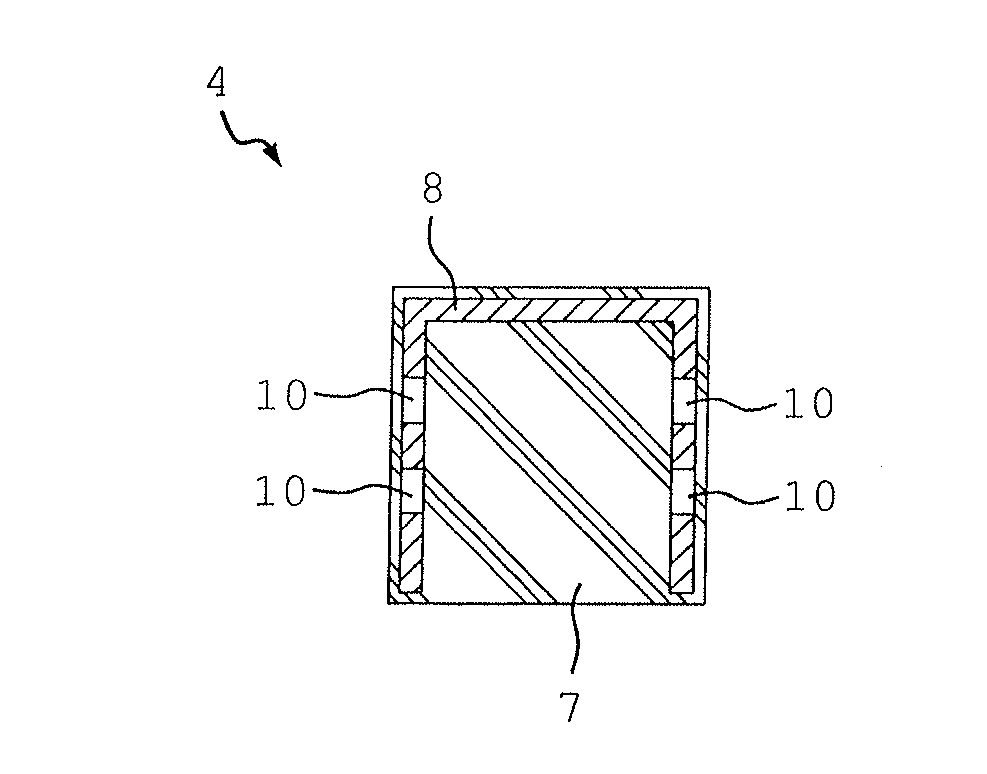

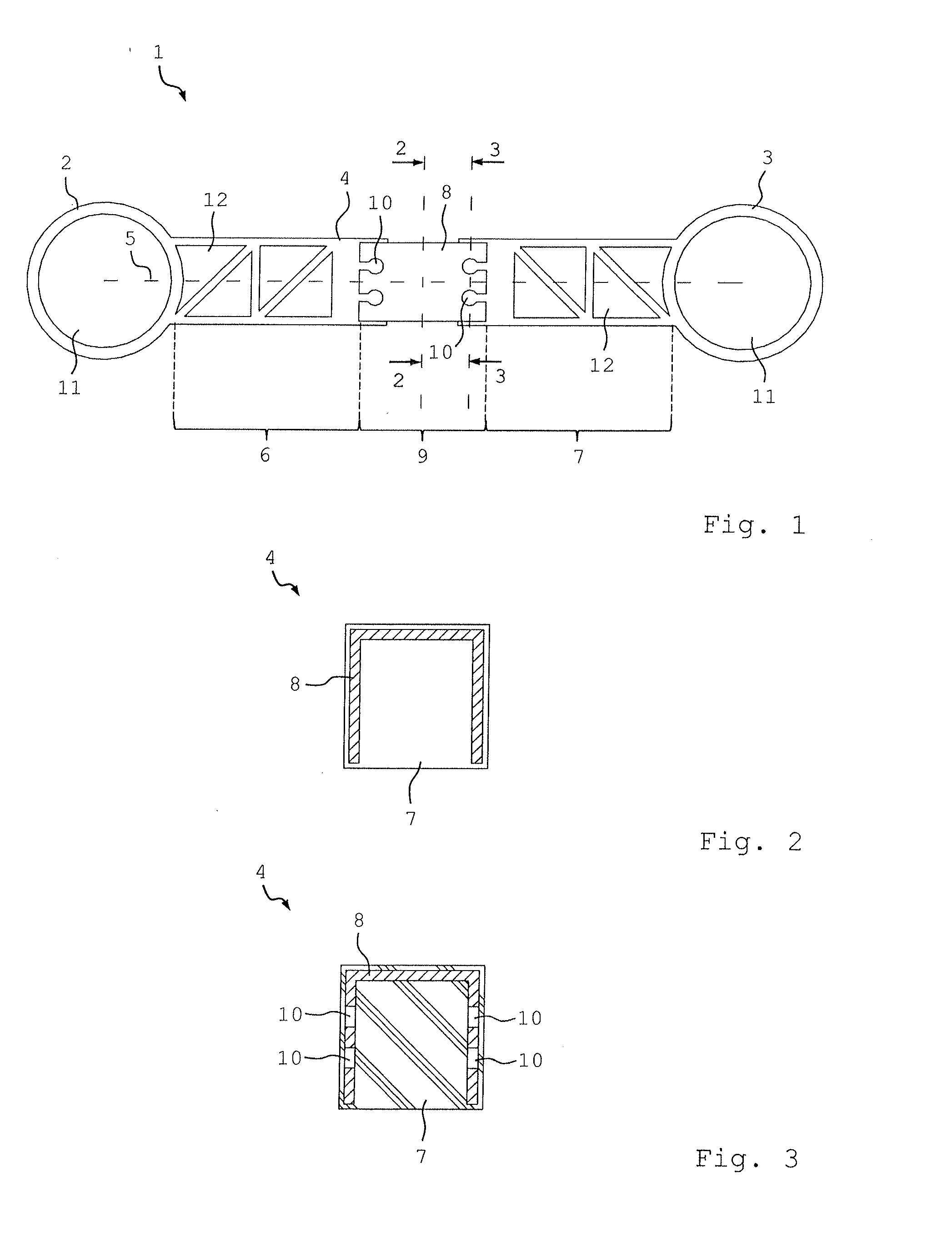

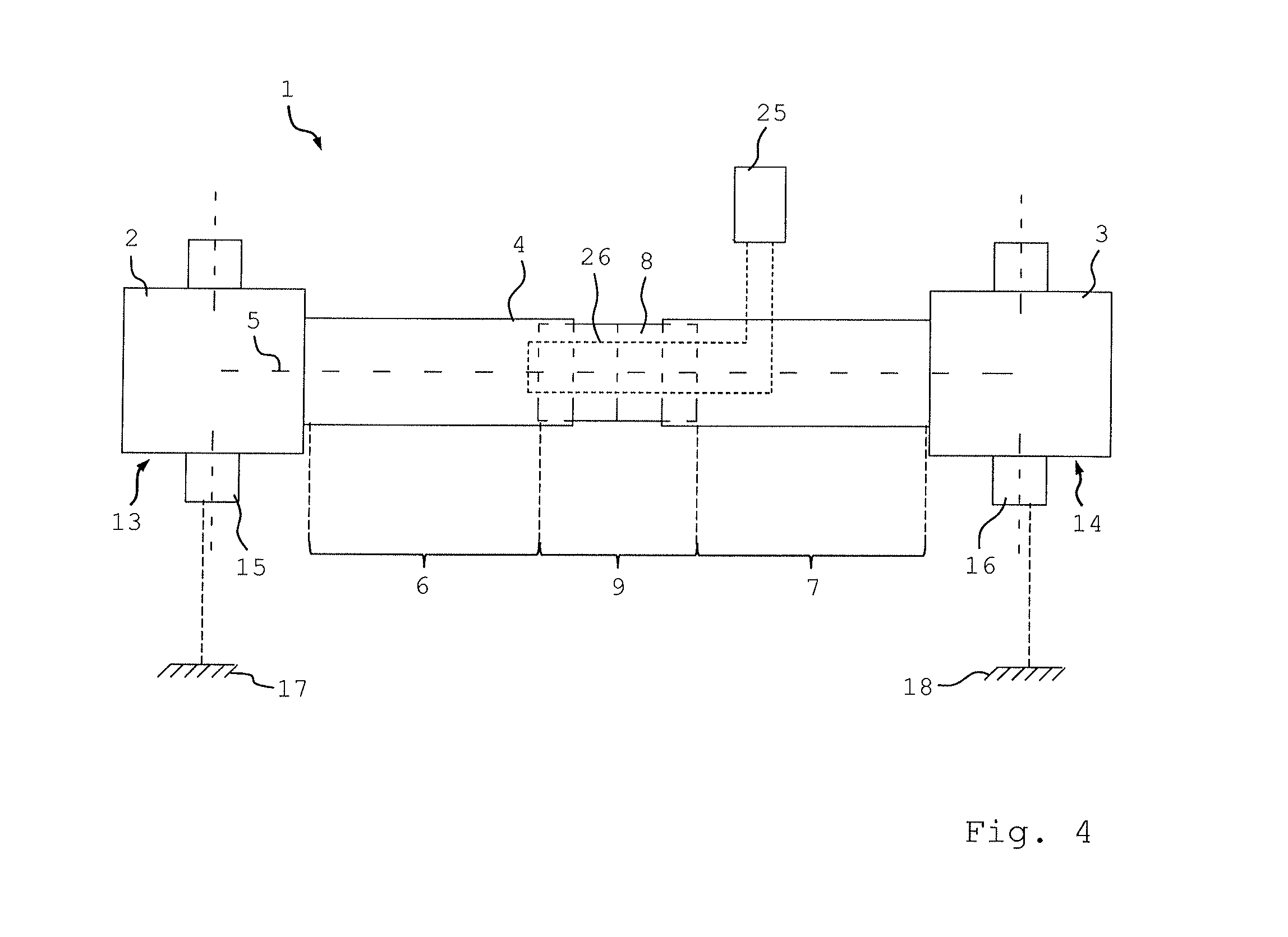

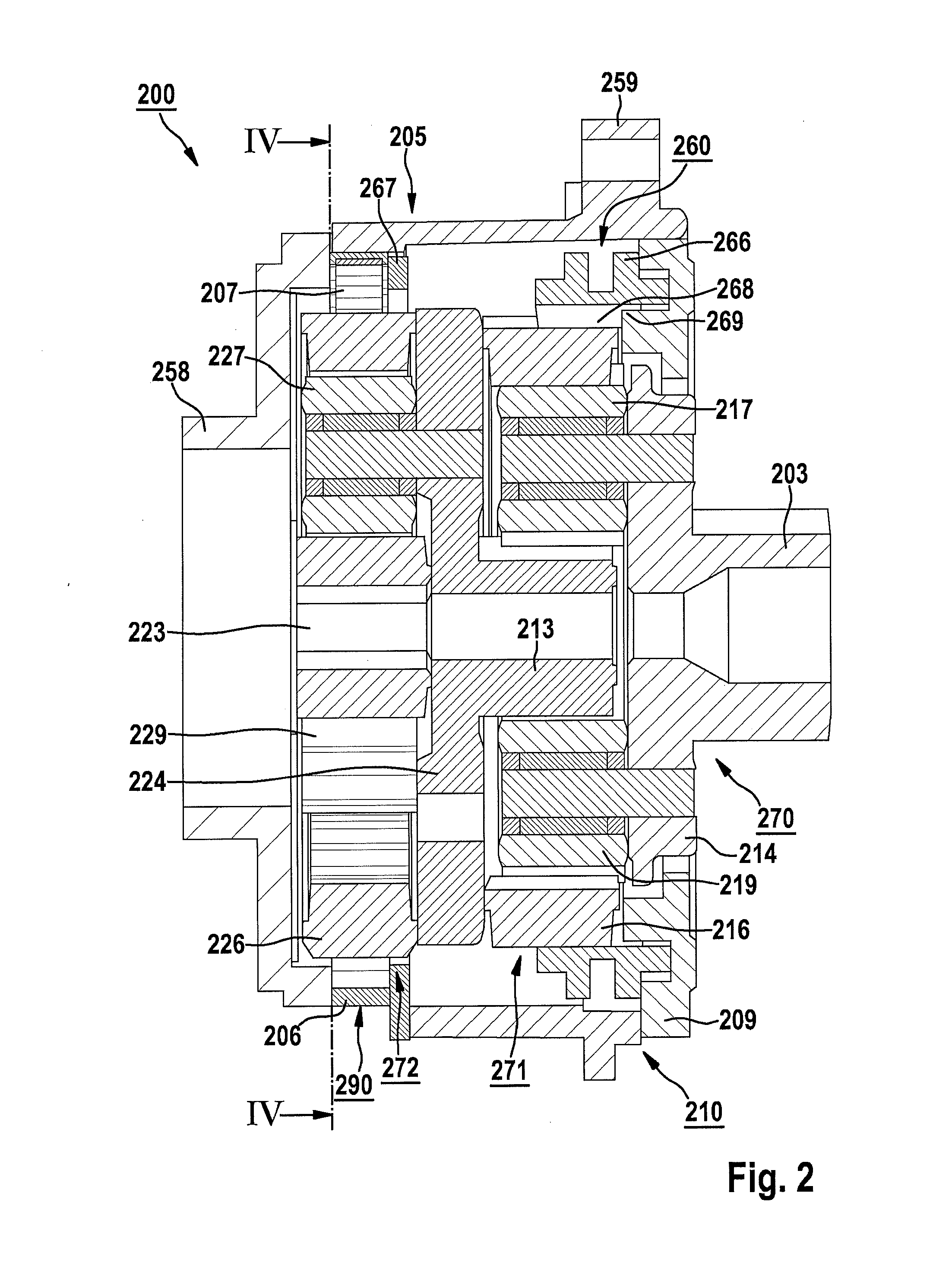

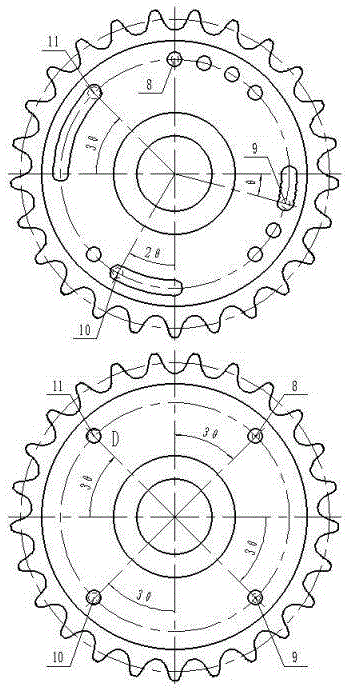

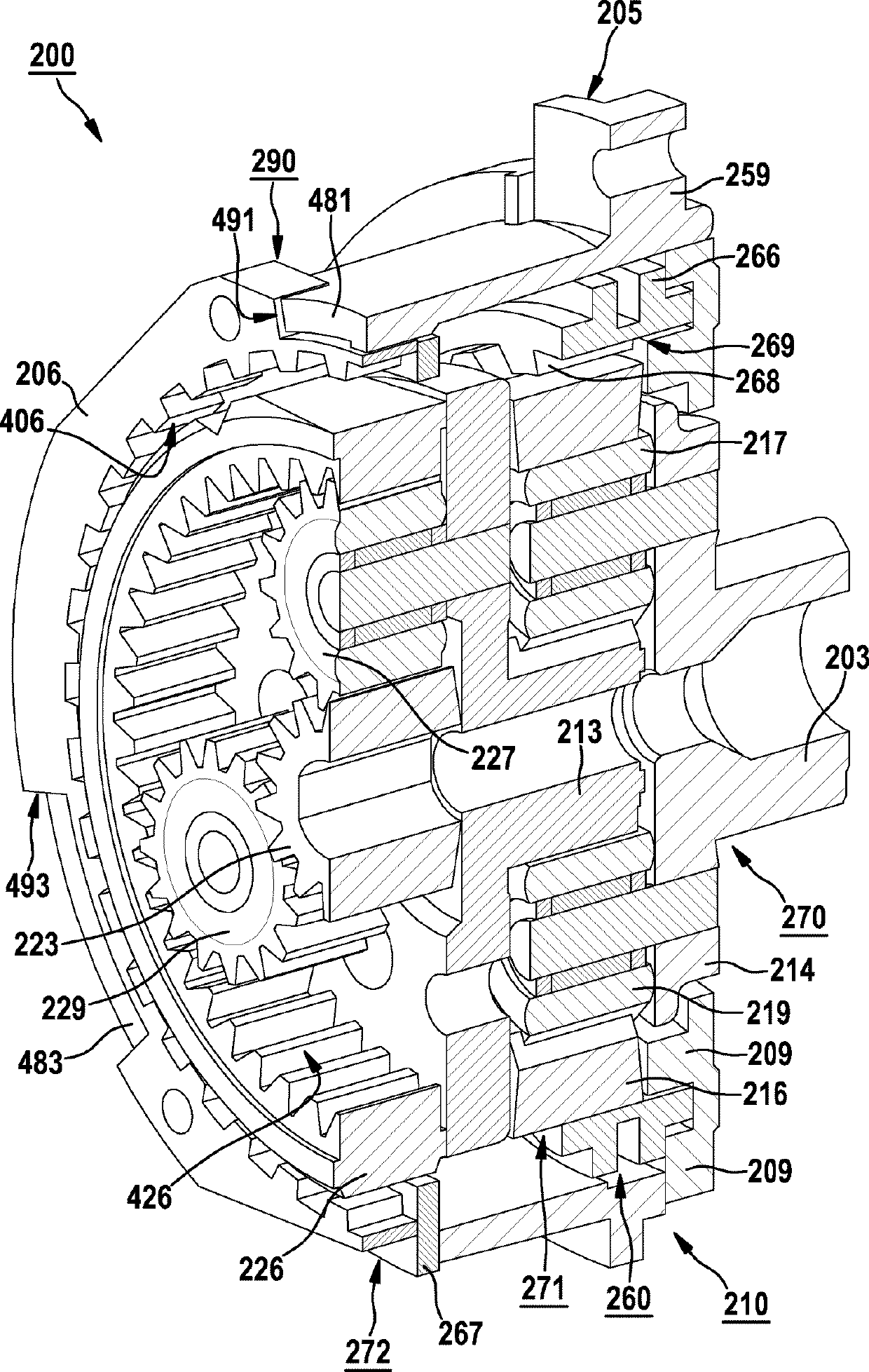

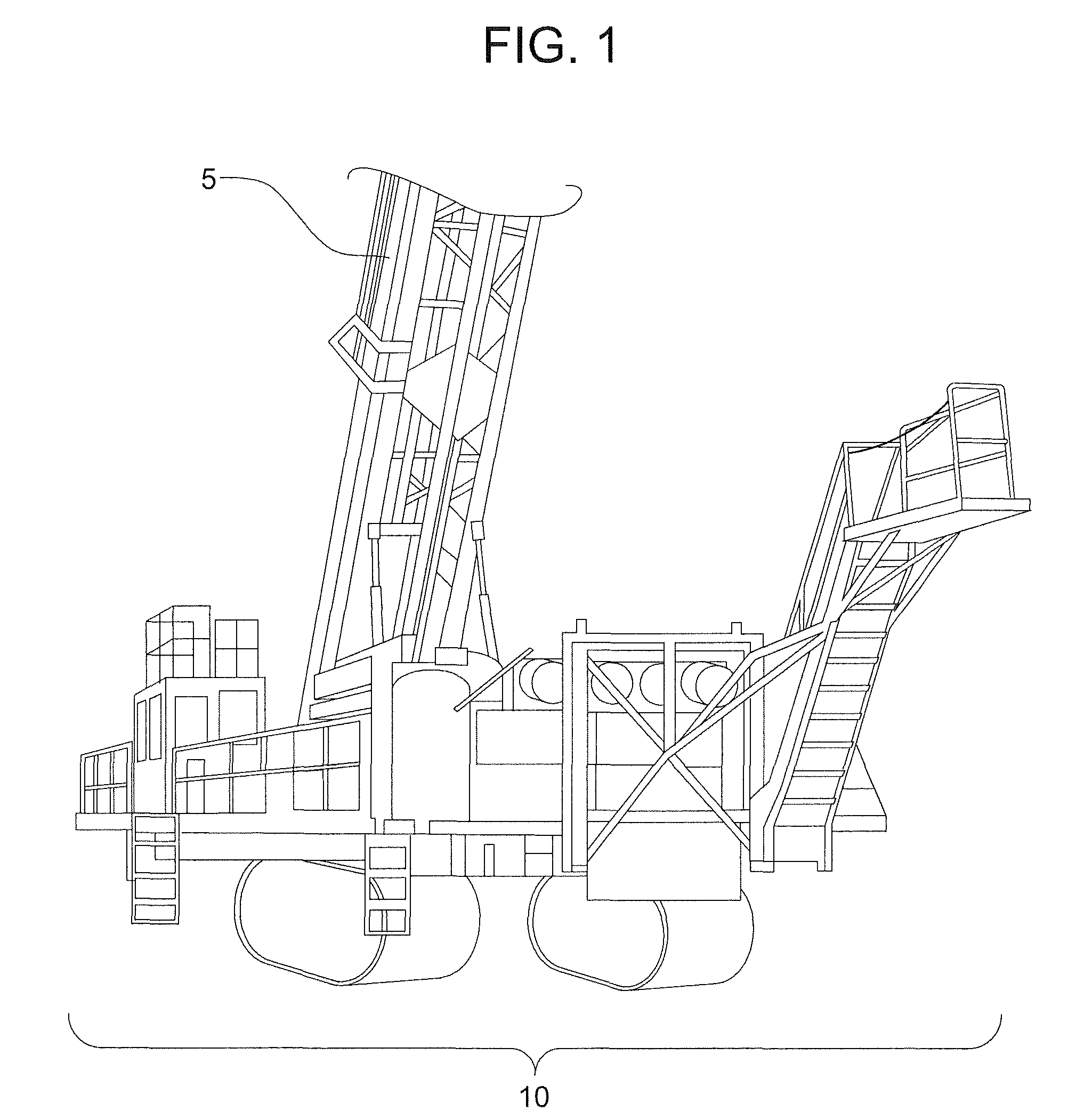

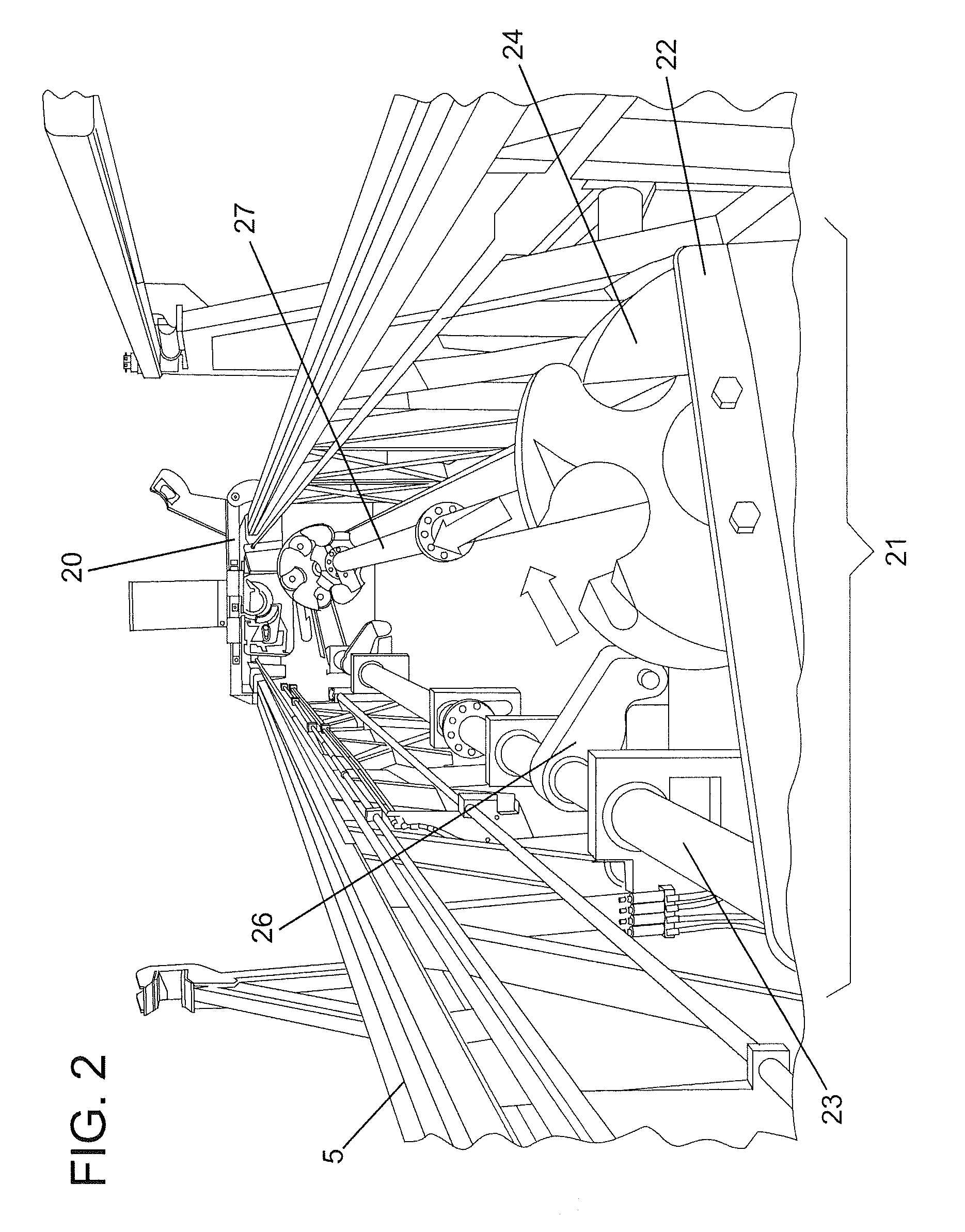

Drive unit with overload protection for driving a ring gear

ActiveUS20110027006A1Protect teethSoil-shifting machines/dredgersEngineering emergency devicesDrive shaftMechanical overload

This invention relates to a drive unit for driving a ring gear, comprising a motor, a transmission and a drive shaft, on which a pinion is arranged for driving the ring gear, wherein the drive unit includes a mechanical overload protection. In accordance with the invention the overload protection is arranged between the transmission and the pinion.

Owner:LIEBHERR COMPONENTS BIBERACH GMBH

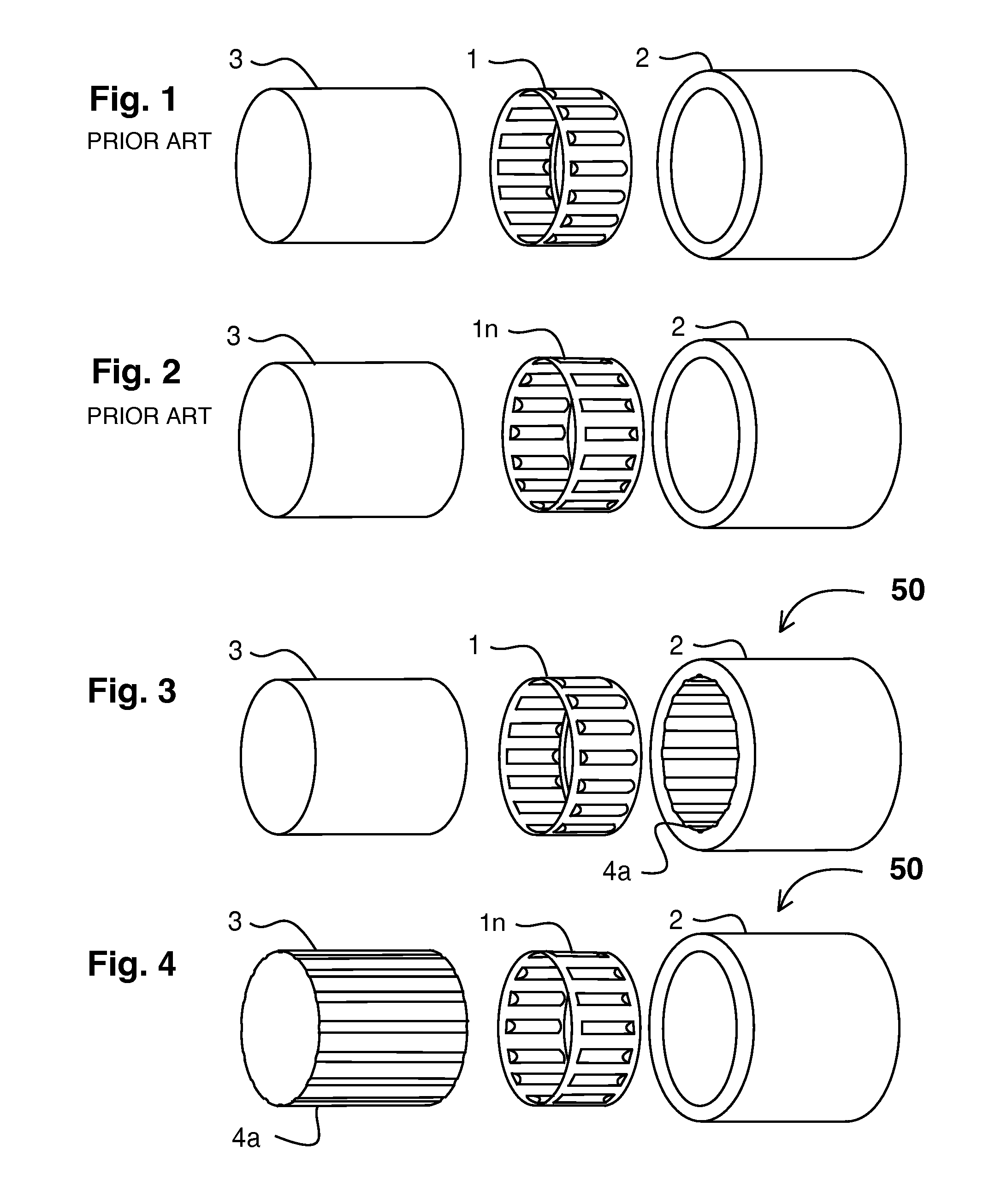

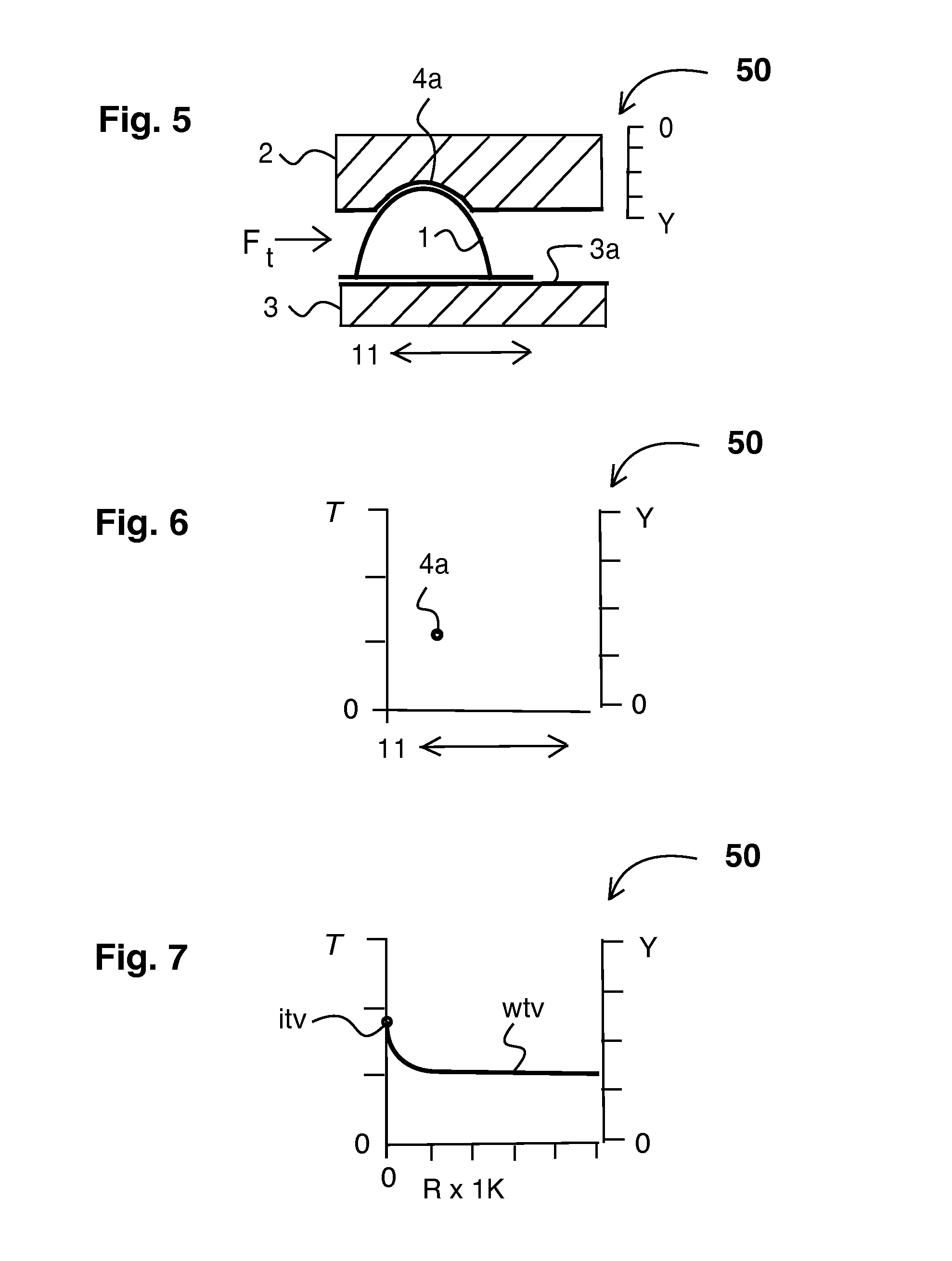

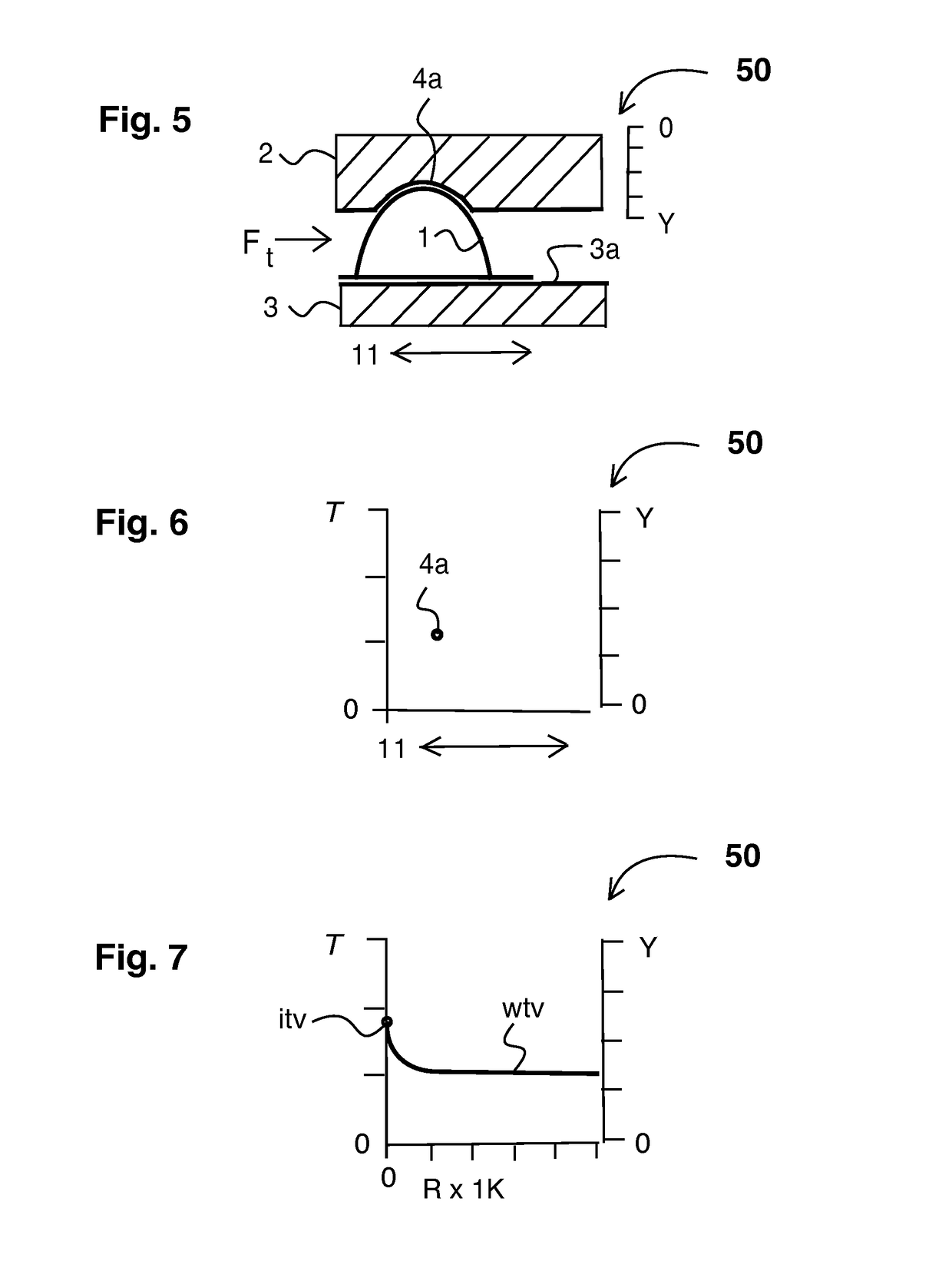

Torque Limiting System

InactiveUS20160230866A1Simple and durable and cost-effectiveImprove functionalitySlip couplingCouplings for rigid shaftsLow speedLimited-slip differential

The present invention relates to torque transfer and torque limiting system technology and applications. This invention relates to providing improved torque limiting systems that employ tolerance rings for controlling transmitting power between a single power-input shaft and one or more power-output shafts, which can protect mechanical equipment and drivetrains from damage by mechanical overload. Relating to motor vehicle differentials, the present invention can control differentiation between two power-output shafts, or drive shafts by providing friction internal to said differential and limit “undesirable” slip or differentiation between wheels, as might occur when one wheel encounters a low-traction condition, providing a limited-slip differential.

Owner:BAIR LING TECH LLC

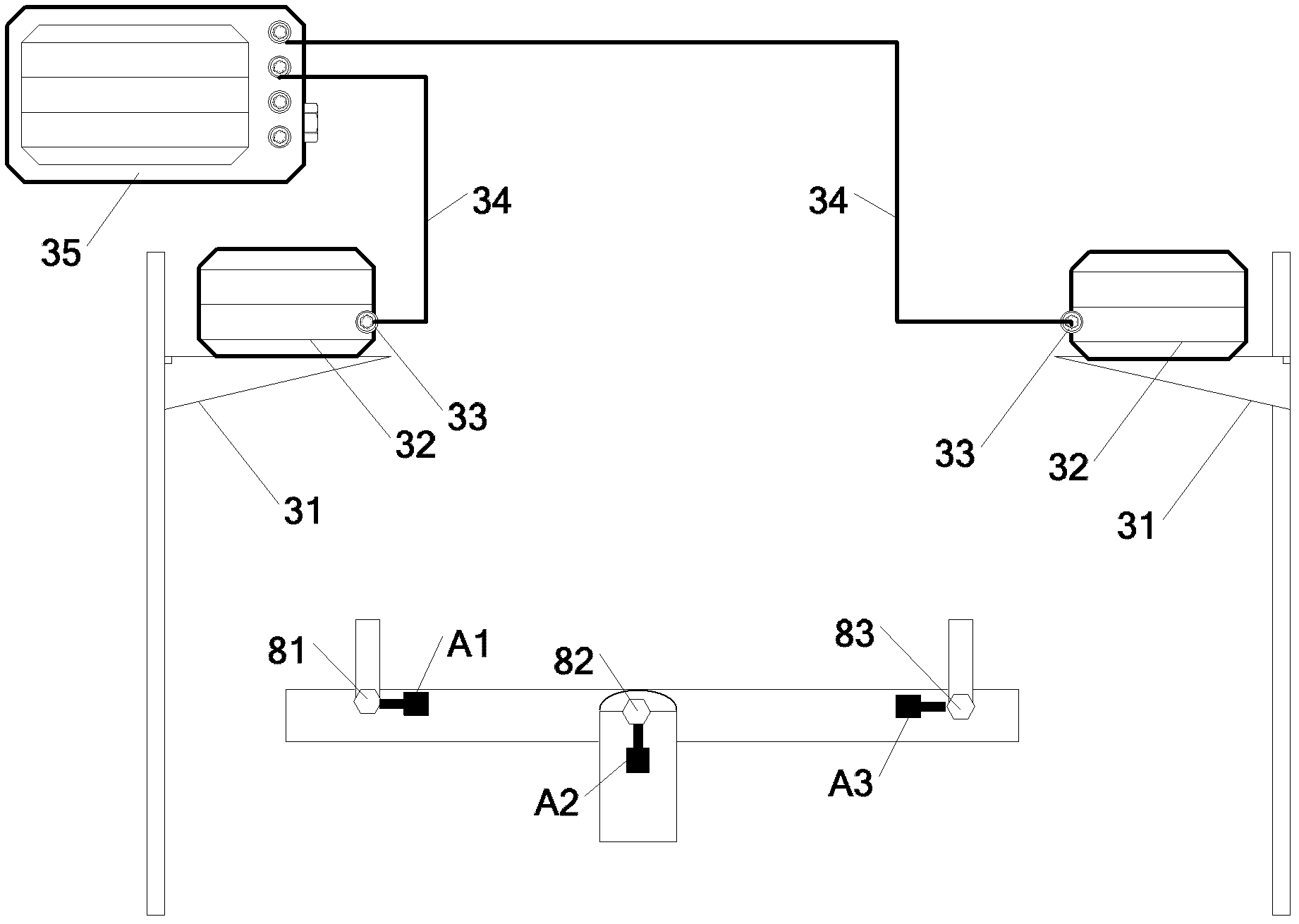

Method, system and device for monitoring mechanical structural parts using rfid tags

InactiveCN102289644ARealize automatic monitoringEnsure personal safetyConnecting rodsScrewsSecure stateMechanical overload

The invention discloses a method, system and device for monitoring mechanical structural parts by using RFID tags, which can be used for fixed-length or fixed-shaped fasteners that bear tension, compression, twisting, shearing and other forces in mechanical devices that bear mechanical and motion loads , to monitor. This solution uses RFID tags with customized shapes, and uses the characteristics that the communication status of RFID tags is extremely sensitive to changes in circuit or antenna size and shape, to form a solution to the small displacement, looseness, loss, Real-time perception and detection of fracture and other states can achieve real-time monitoring of the safety status of mechanical devices. By adopting this scheme, the positioning and continuous monitoring of key fasteners or structural parts in the mechanical device can be carried out at low cost, and an alarm can be issued in time to avoid further damage to the faulty structure and cause catastrophic accidents. This solution is suitable for monitoring scenarios of various mechanical devices including heavy-duty mechanical devices involving personal safety.

Owner:黄晓虎 +1

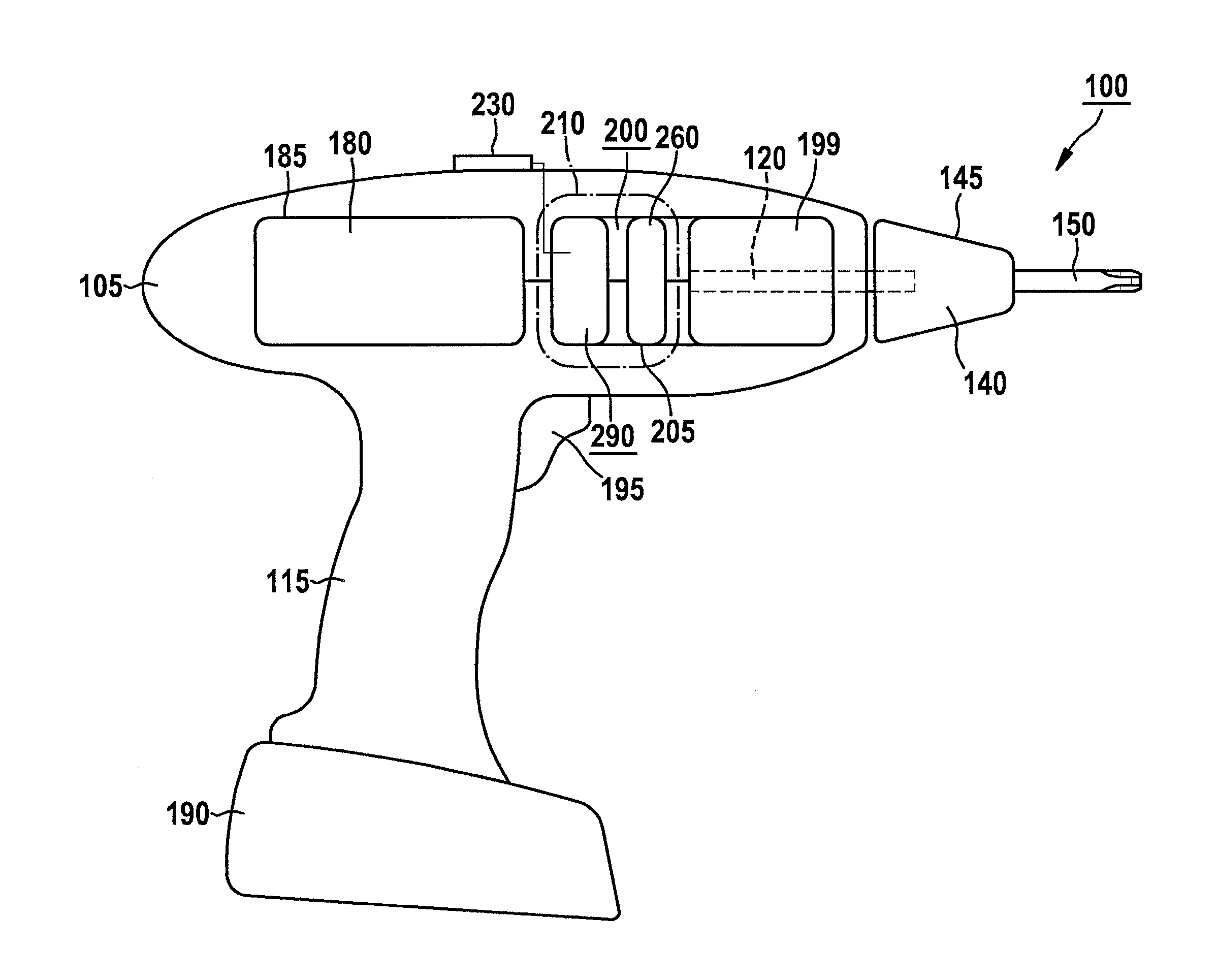

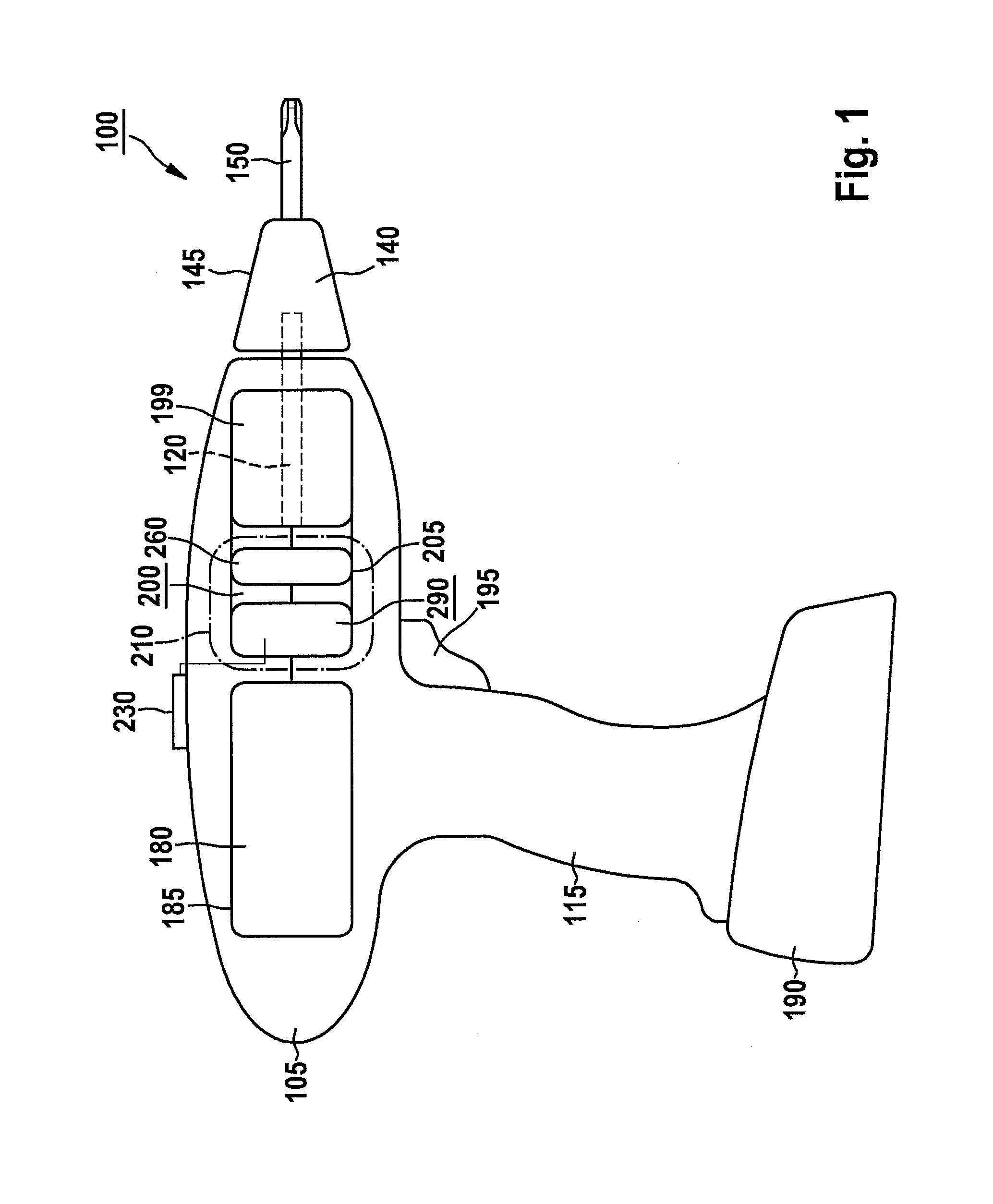

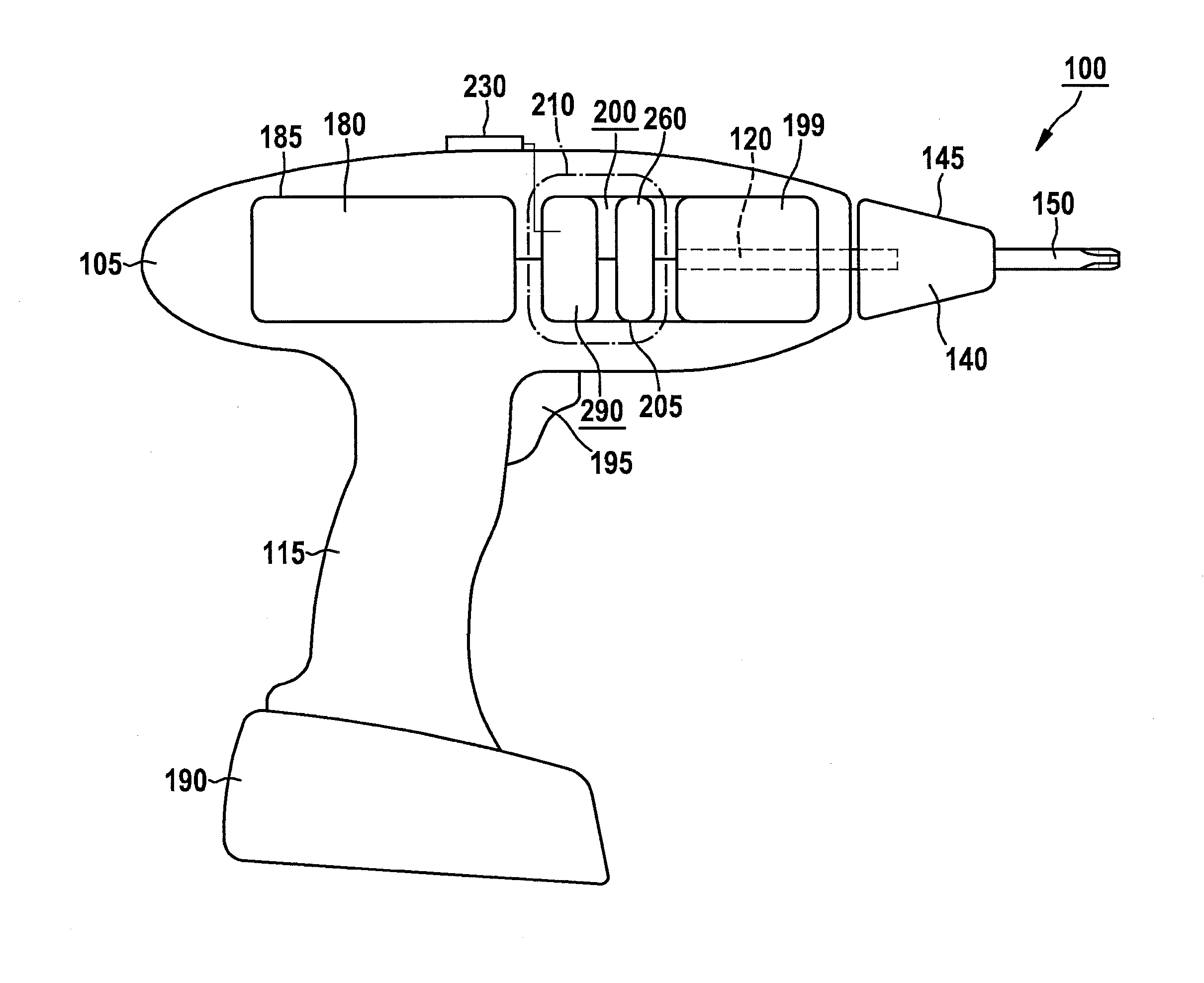

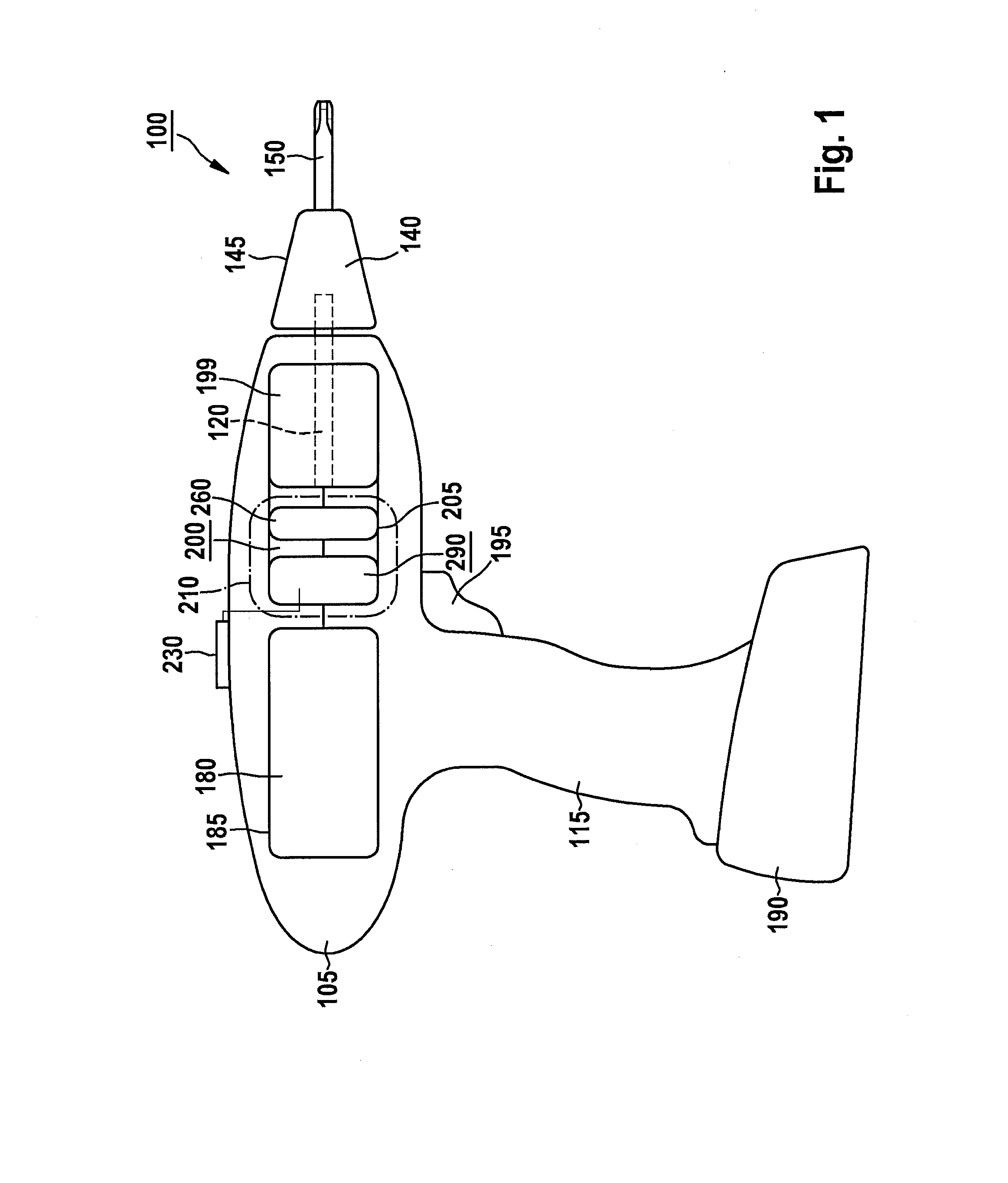

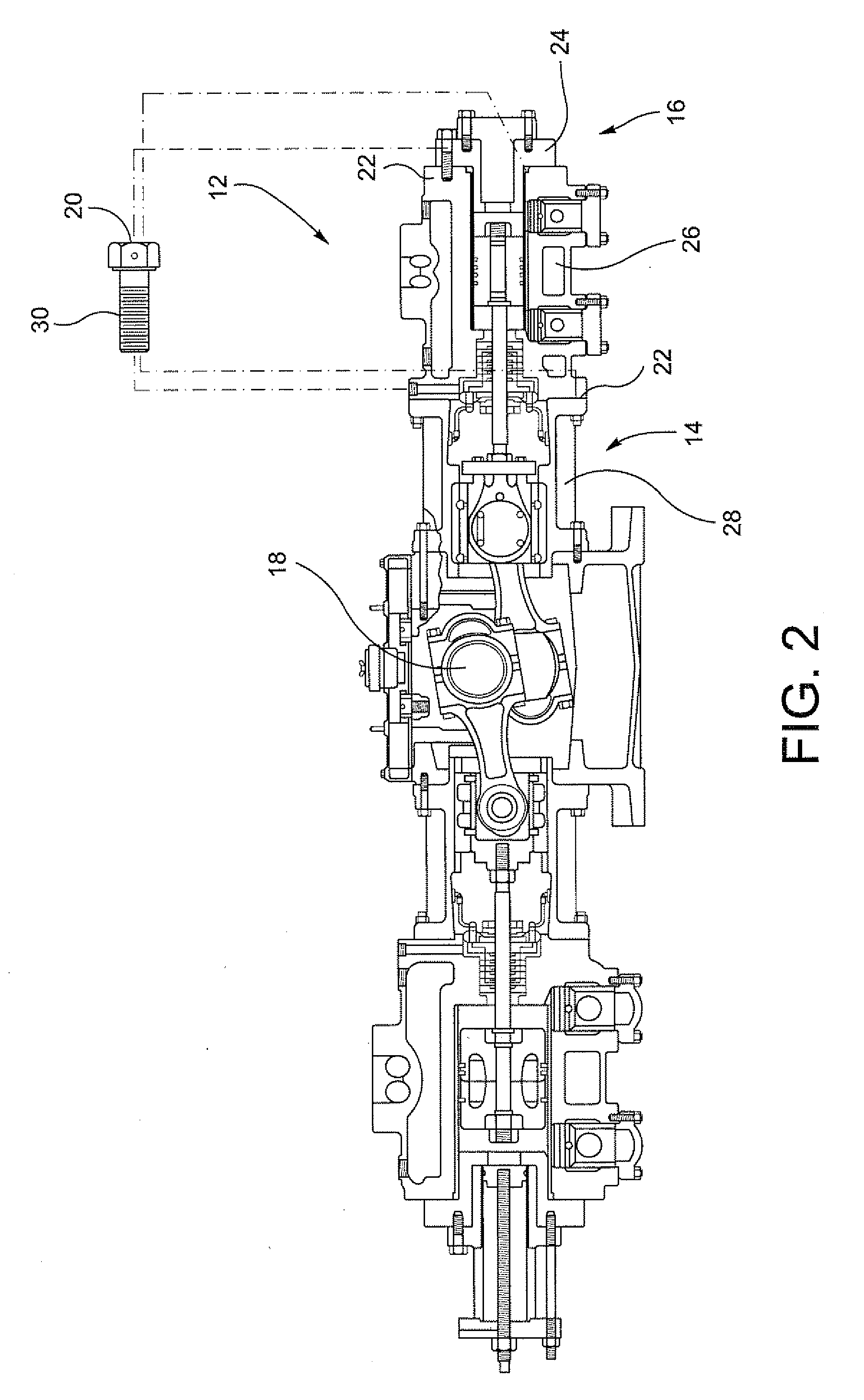

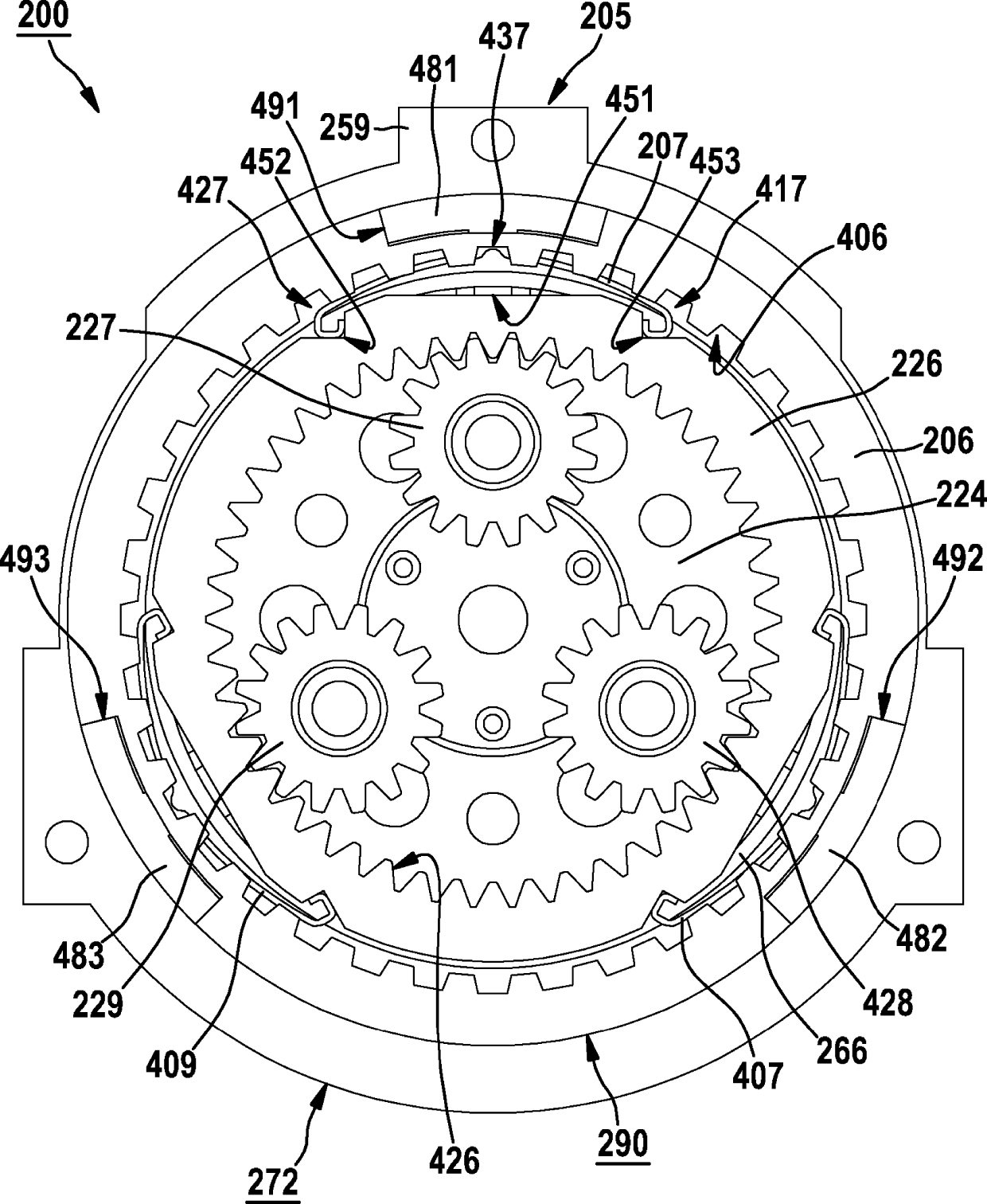

Handheld power tool having a reduction gear unit

ActiveUS9109670B2Effectively and reliably preventedSlip couplingToothed gearingsDrive shaftMechanical overload

In a handheld power tool having a reduction gear unit, drivable by a motor, for driving a drive shaft, the reduction gear unit being situated in a gear housing and being shiftable via a gearshift at least between a first gear having a comparatively high torque and a second gear having a comparatively low torque, the reduction gear unit is assigned a mechanical overload protection device which is designed to limit the reduction gear unit during operation of the handheld power tool, if a torque, transferred from the drive shaft to the reduction gear unit, exceeds a machine-specific limiting value.

Owner:ROBERT BOSCH GMBH

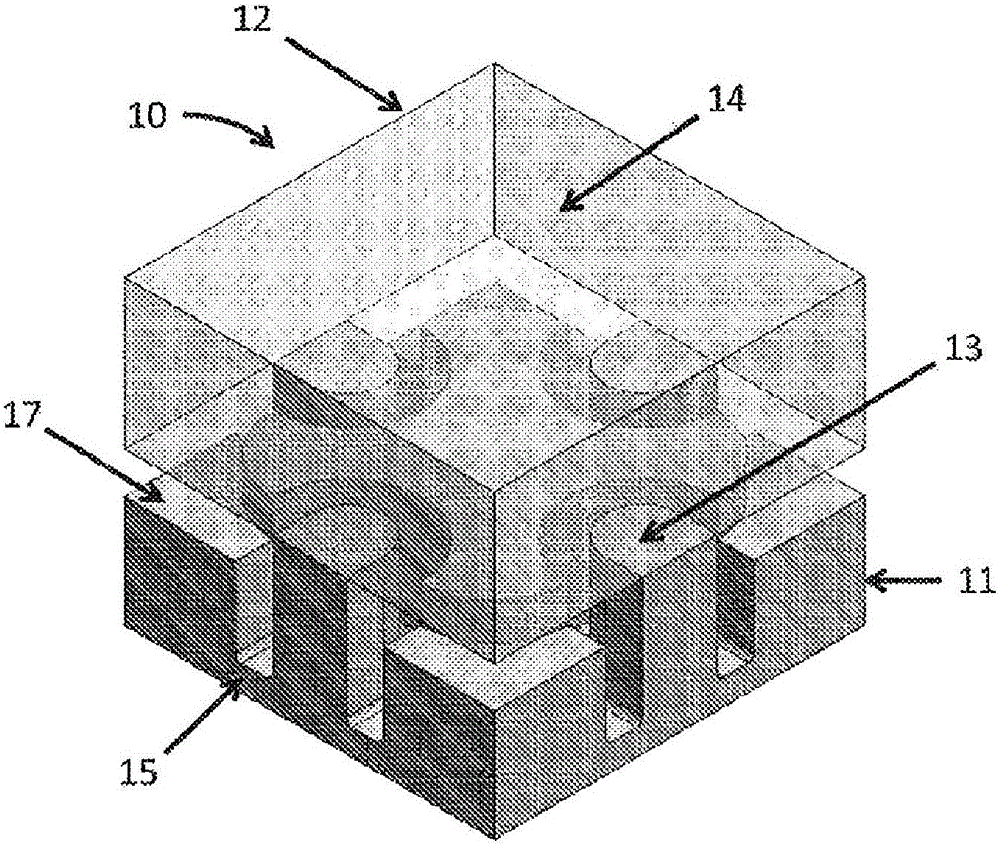

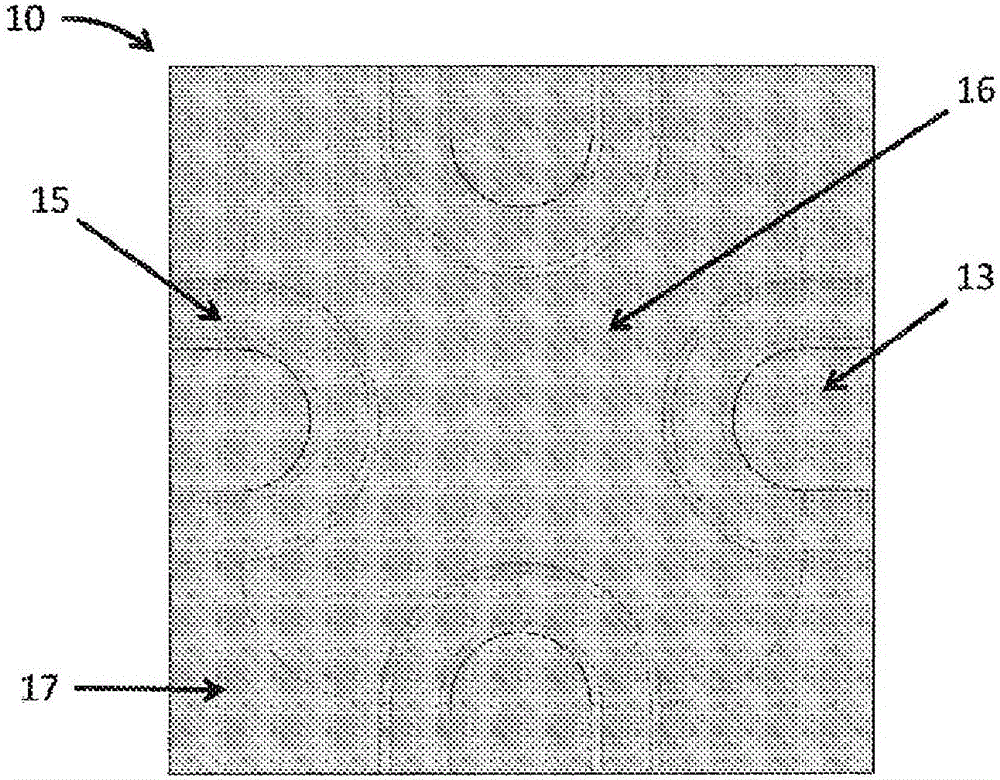

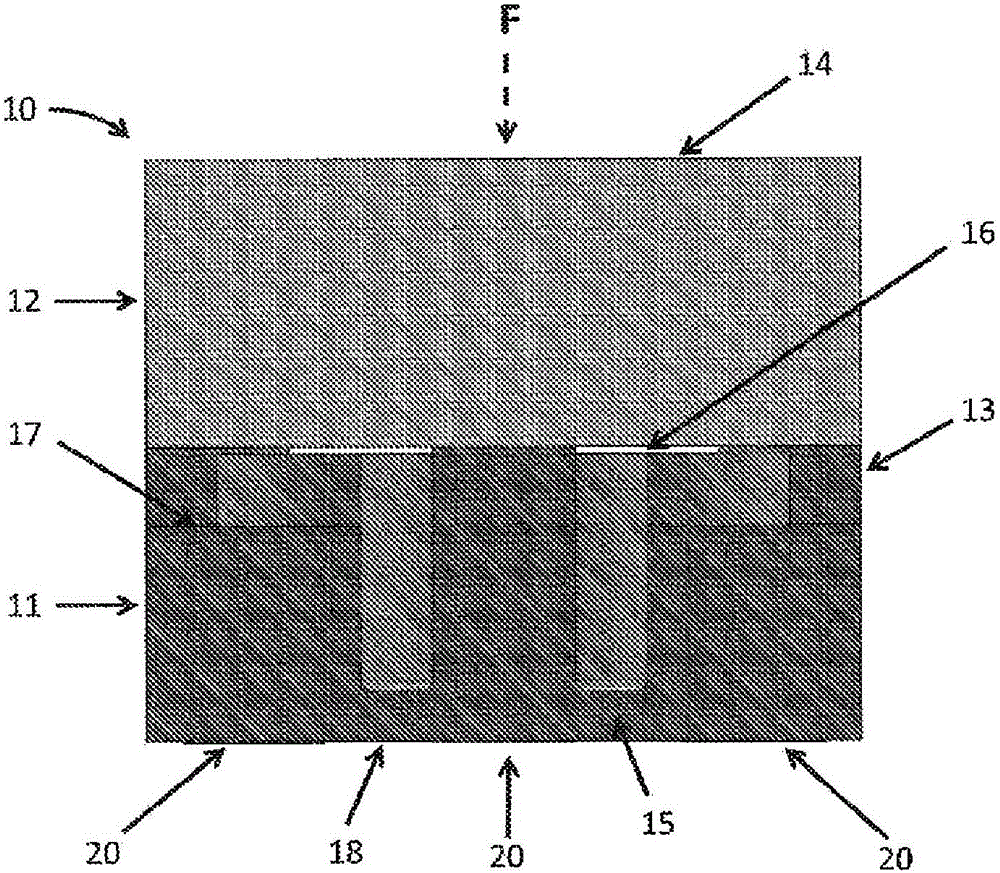

Miniaturized and ruggedized wafer level MEMS force sensors

ActiveCN105934661AAvoid enteringControl displacementTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesMechanical overloadEngineering

Described herein is a miniaturized and ruggedized wafer level MEMS force sensor composed of a base and a cap. The sensor employs multiple flexible membranes, a mechanical overload stop, a retaining wall, and piezoresistive strain gauges.

Owner:触控解决方案股份有限公司

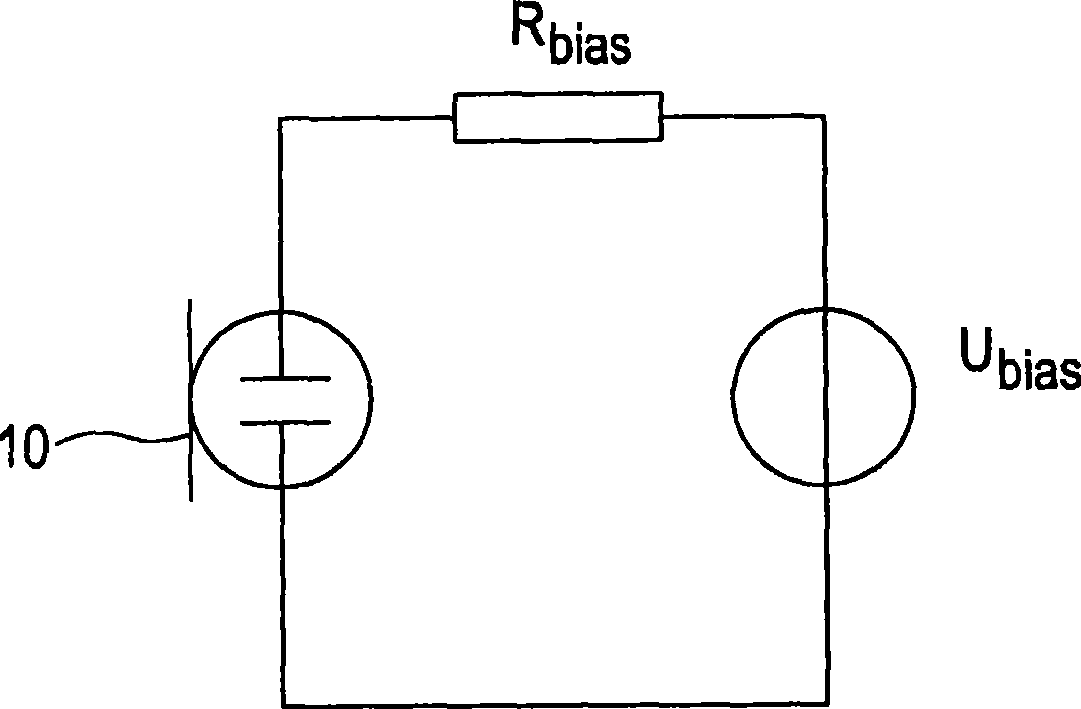

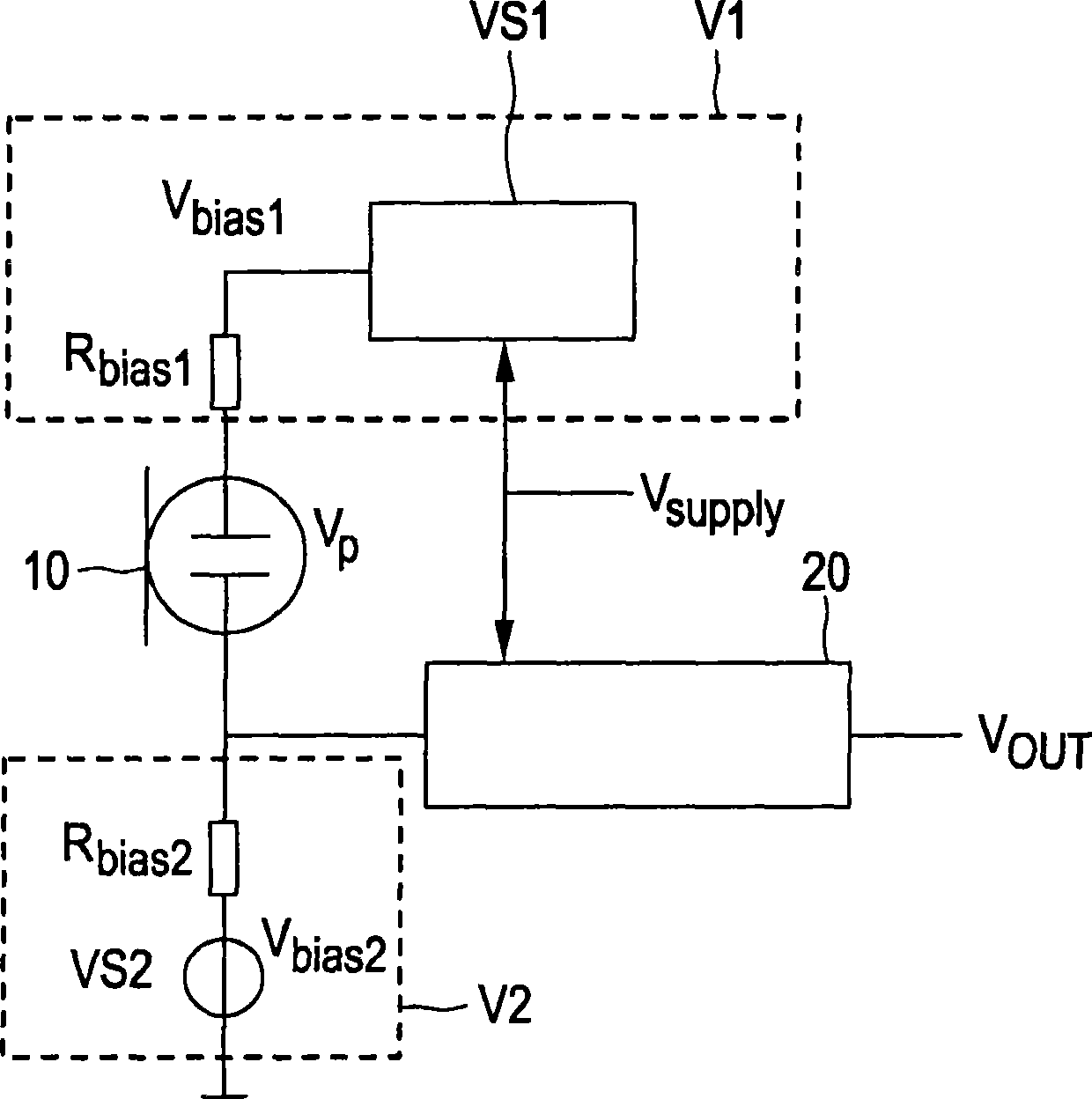

Capacitive MEMS sensor device

ActiveCN101443633APromote recoveryAirburst noise minimizationSemiconductor electrostatic transducersTransducer protection circuitsMechanical overloadEngineering

The present invention relates to a capacitive MEMS sensor device for sensing a mechanical quantity. To provide such a capacitive MEMS sensor device which enables fast recovery from (near) sticking after a mechanical overload situation it is proposed that the sensor device comprises: - a first bias voltage unit (V1) for supplying a first bias voltage (Vbias 1) to a first plate of said MEMS sensing element, - a second bias voltage unit (V2) for supplying a second bias voltage (Vbias2) to the second plate of said MEMS sensing element, - a signal processing (20) unit for processing said electrical quantity into an output signal (VOUT), - a comparator unit (21) for comparing said output (VOUT) signal to a reference signal (Vref) for detection of an overload condition of said MEMS sensing element (10) and for outputting a comparator signal, - a control unit (22) for controlling the discharge of said MEMS sensing element (10) in case of an overload condition signalled by said comparator signal by connecting, in case of an overload condition, said first plate to a first discharge terminal (D) during a first time interval (T1) and said second plate to a second discharge terminal (D) during a second time interval (T2).

Owner:III HLDG 6

Drive unit with overload protection for driving a ring gear

Owner:LIEBHERR COMPONENTS BIBERACH GMBH

Vehicle component

ActiveUS20140232081A1Negative effectObtained inexpensivelyConnecting rodsShaftsMechanical overloadElectrical and Electronics engineering

A vehicle component with at least two connection points, a structural component that extends between the connection points and rigidly connects them with one another. The structural component comprises at least one insert made of a ductile material and at least two connection zones that support or form the two connection points, at least one of the zones comprises plastic. The structural component comprises at least one intermediate section that connects the two connection zones rigidly to one another and comprises the insert or is formed by the insert, this section is more ductile than at least one of the two connection zones and, in relation to a mechanical overload of the structural component, forms a locally delimited weak-point or region.

Owner:ZF FRIEDRICHSHAFEN AG

Cable suspension device

InactiveUS9010695B2Reduce pressureMaintaining distance between parallel conductorsPipe supportsMechanical overloadBiomedical engineering

Owner:NKT CABLES GRP

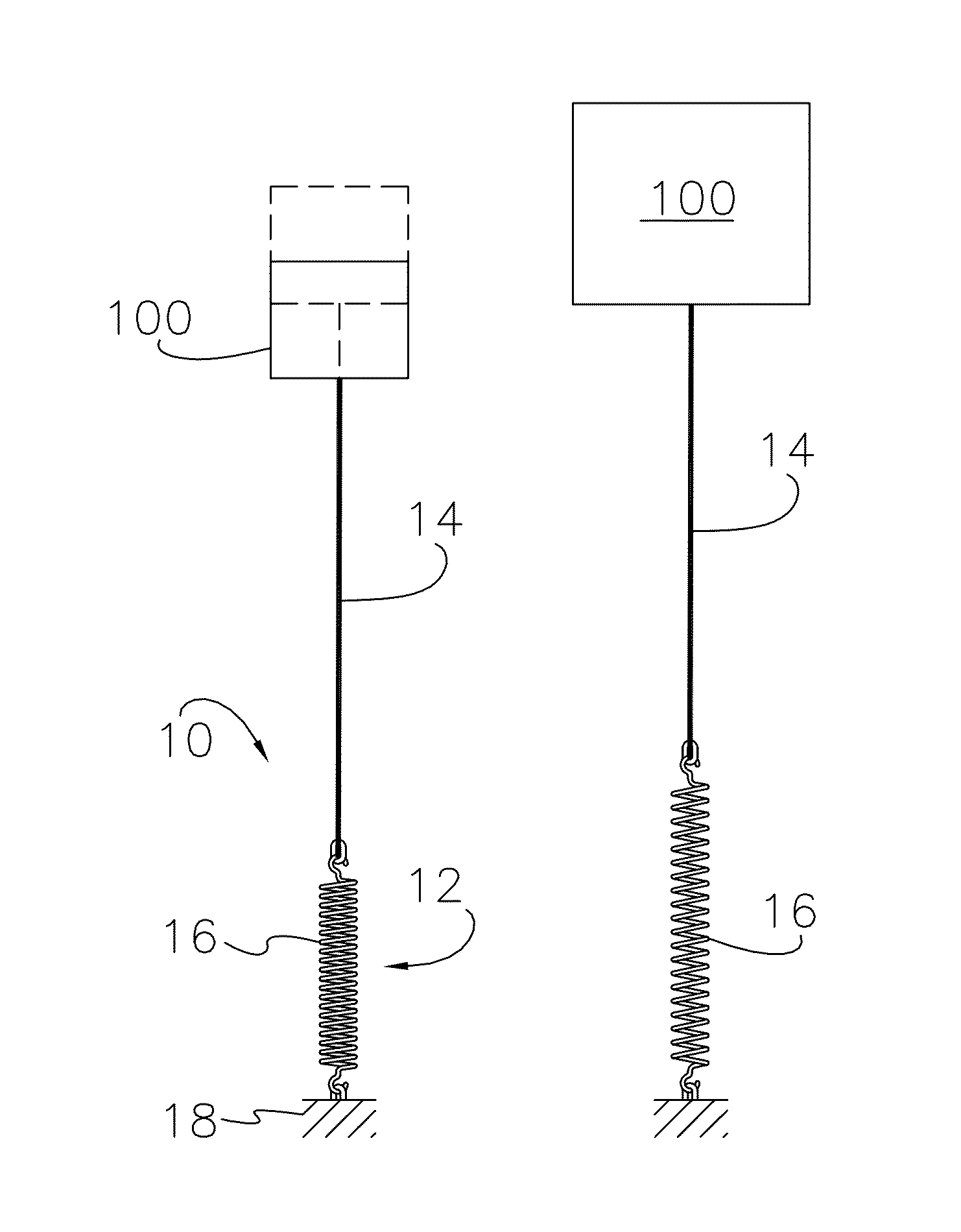

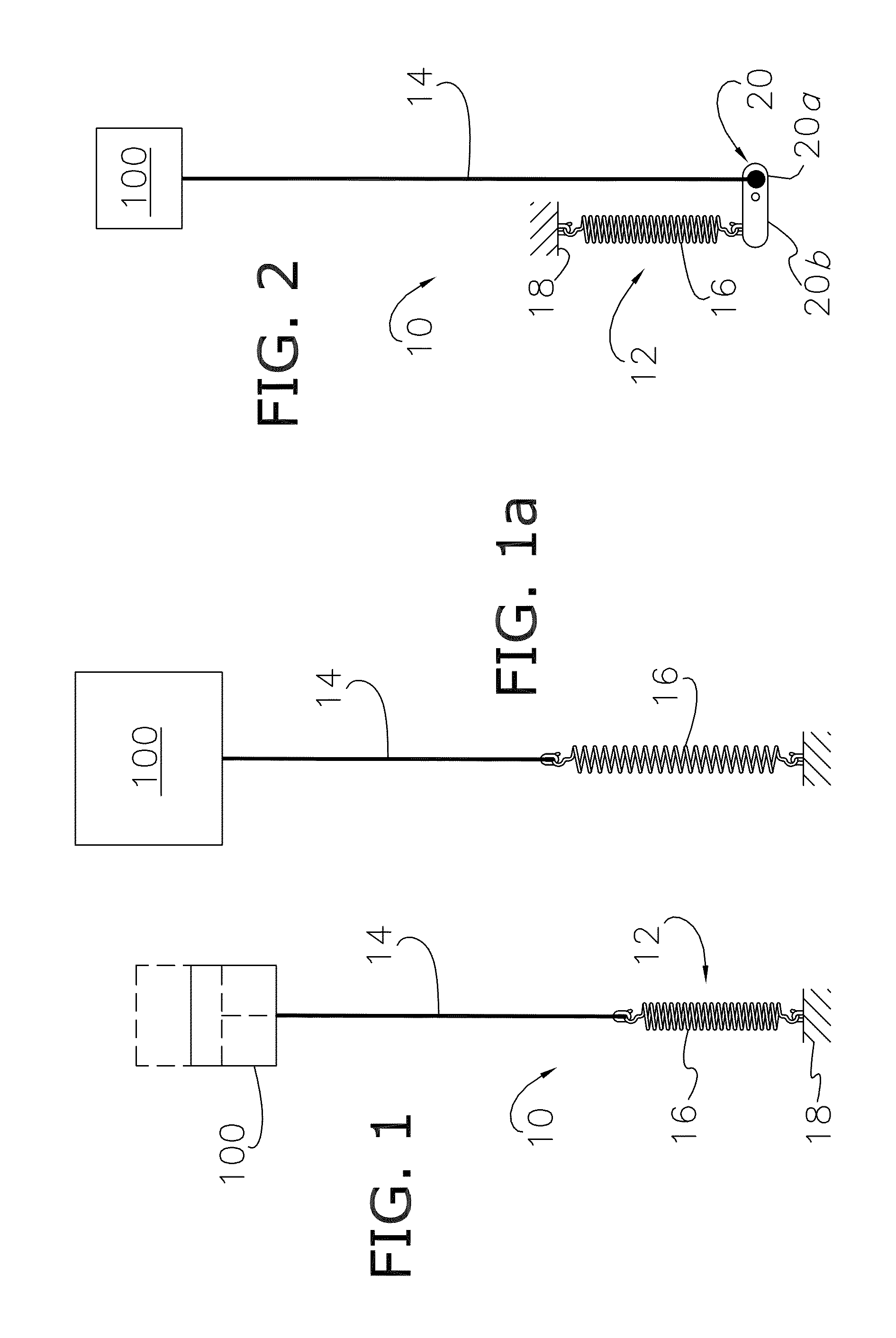

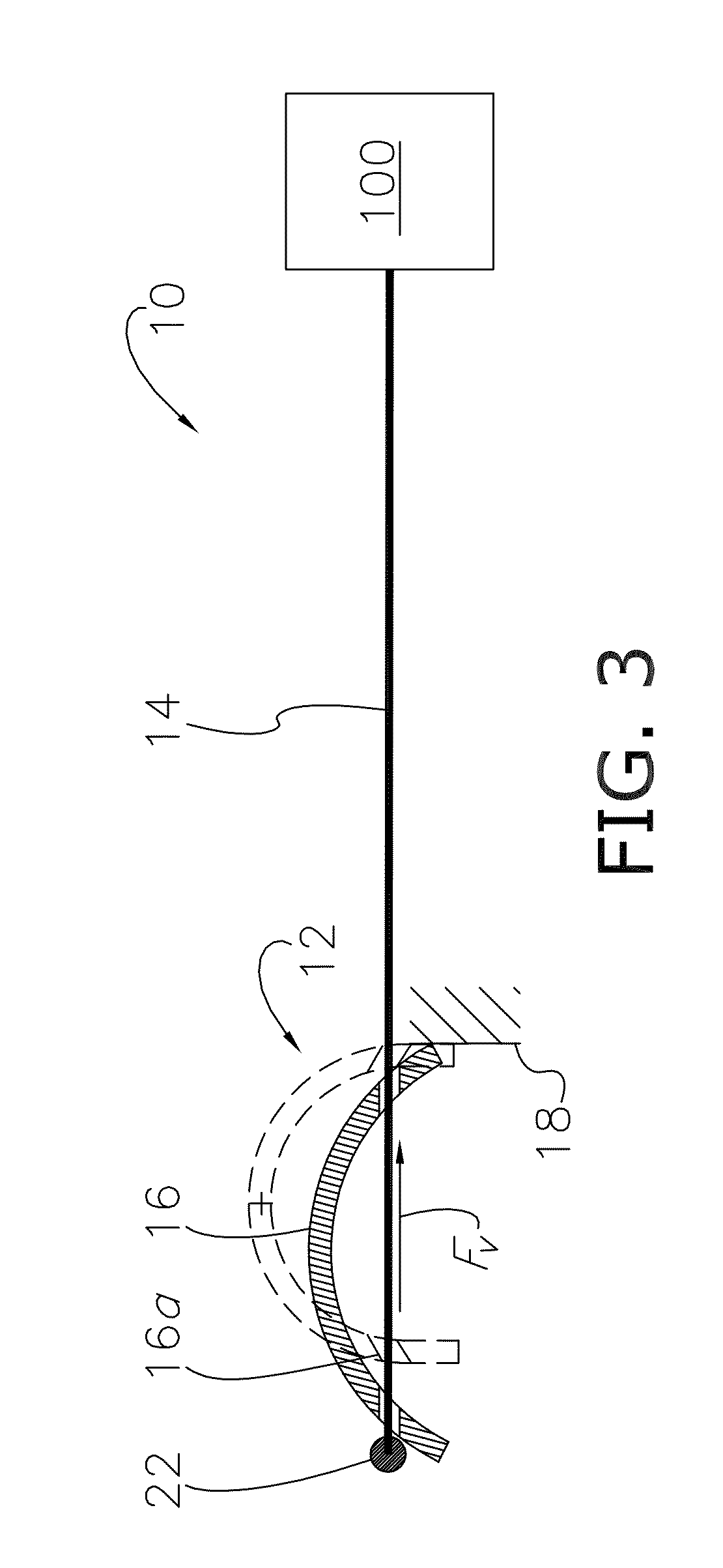

Mechanical overload protection utilizing superelastic shape memory alloy actuation

ActiveUS20140026679A1Force measurement by permanent gauge deformationMeasurement arrangements for variableMechanical overloadShape-memory alloy

An actuation assembly adapted for driving a load, and protecting against overload conditions, includes an actuator defining a stroke, and a resistive member, such as a superelastic shape memory alloy spring, drivenly coupled to the actuator, so as to be displaced over the stroke when an overload condition exists, and defining a non-linear force versus displacement profile.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method and arrangement for controlling an electro-acoustical transducer

ActiveCN104756519ATransducer protection circuitsTransducer acoustic reaction preventionTransducerMechanical overload

An arrangement and method for converting an input signal z(t) into a mechanical or acoustical output signal p( t) by using a transducer (9) and additional means for generating a desired transfer behavior and for protecting said transducer against overload. Transducers of this kind are for example loudspeaker, headphones and other mechanical or acoustical actuators. The additional means comprise a controller (1), a power amplifier (7) and a detector (11). The detector identifies parameters P[n] of the transducer model if the stimulus provides sufficient excitation of the transducer. The detector permanently identifies time variant properties S*(t) of the transducer for any stimulus supplied to the transducer. The controller provided with this information generates a desired linear or nonlinear transfer behavior; in particular electric control linearizes, stabilizes and protects the transducer against electric, thermal and mechanical overload at high amplitudes of the input signal.

Owner:沃尔夫冈·克利佩尔

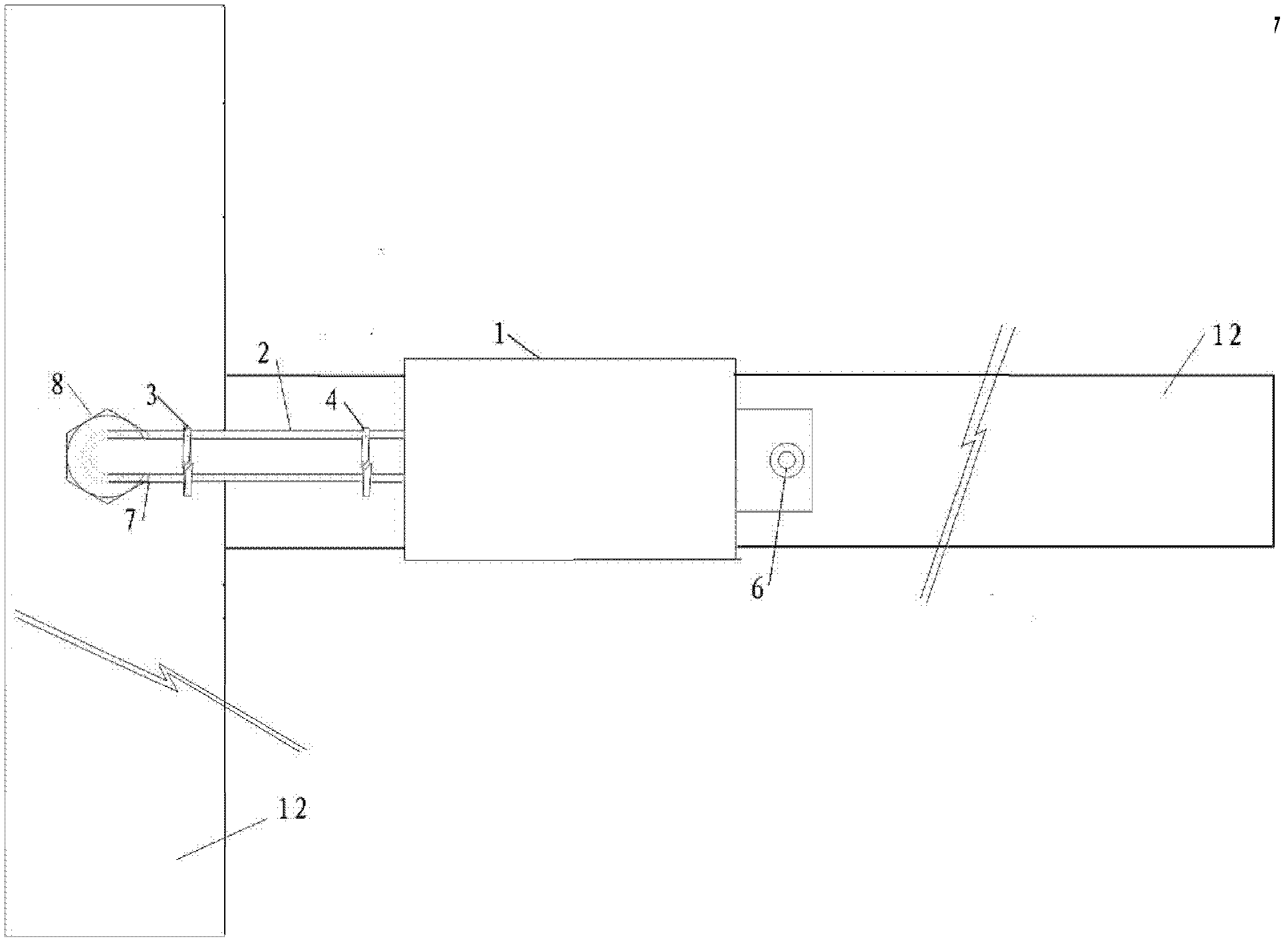

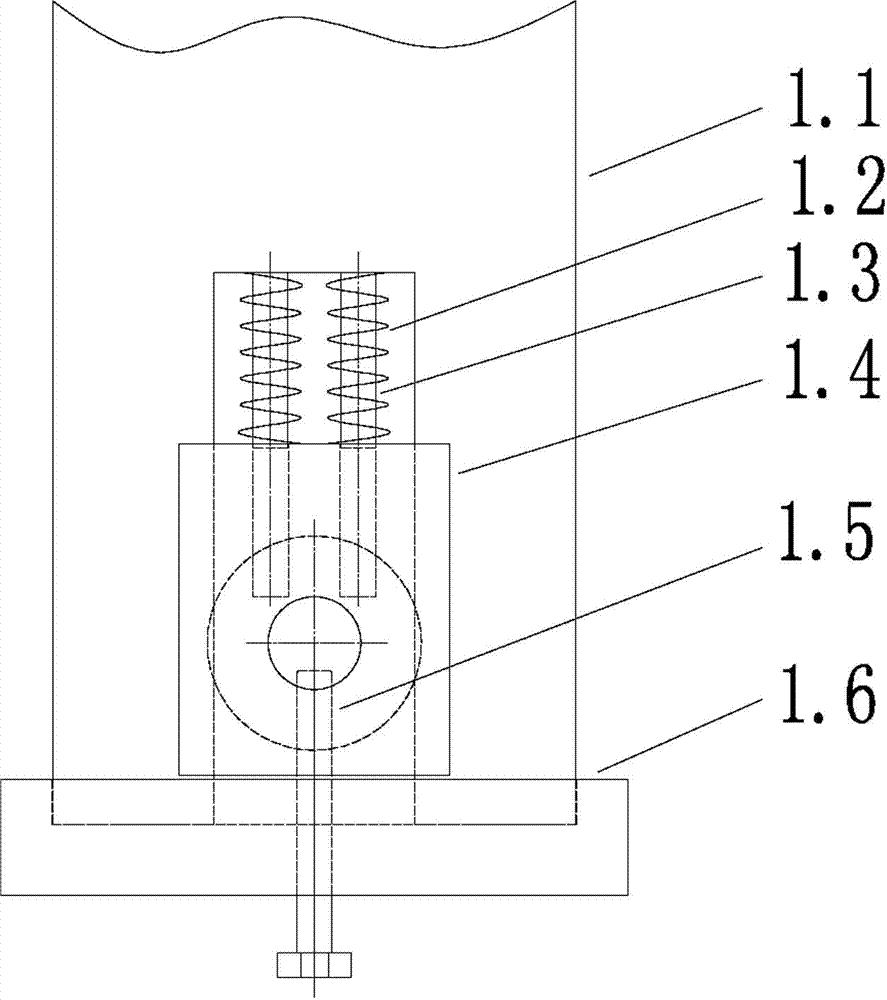

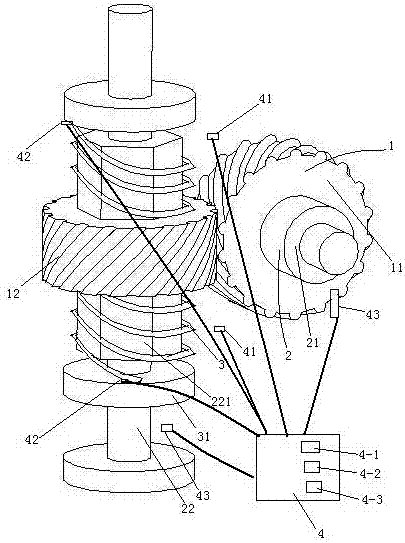

Numerical control tool rest cutting overload protection device

ActiveCN106984995AEffective protectionSimplify the exclusion processMaintainance and safety accessoriesNumerical controlProtection mechanism

The invention discloses a numerical control tool rest cutting overload protection device. The protection device comprises a drive-side shaft sleeve, steel balls, a reset shaft sleeve, cylindrical stopping blocks, a left pushing plate, long springs, short springs, long spring sleeves, short spring sleeves, a right pushing plate, a driven-side shaft sleeve and an adjusting shaft sleeve; one side of the driven-side shaft sleeve is connected with the drive-side shaft sleeve, and the other side of the driven-side shaft sleeve is connected with the adjusting shaft sleeve; the reset shaft sleeve is located on the outer side of the driven-side shaft sleeve; grooves are formed in the end face of the drive-side shaft sleeve, first steel ball holes are formed in the driven-side shaft sleeve, the steel balls are arranged in the first steel ball holes, and when torque needs to be transmitted, the steel balls are pressed into the grooves of the drive-side shaft sleeve through the springs. According to the numerical control tool rest cutting overload protection device, the fault removing process is simplified by adopting a mechanical overload protection mechanism; through a critical force adjusting mechanism composed of the springs and the pushing plates, the magnitude of critical force can be changed, and the reliability and the practicability of the overload critical force adjusting mechanism under a certain threshold value can be guaranteed.

Owner:SOUTHEAST UNIV

Handheld power tool having a reduction gear unit

ActiveUS20140051539A1Effectively and reliably preventedSlip couplingToothed gearingsDrive shaftMechanical overload

In a handheld power tool having a reduction gear unit, drivable by a motor, for driving a drive shaft, the reduction gear unit being situated in a gear housing and being shiftable via a gearshift at least between a first gear having a comparatively high torque and a second gear having a comparatively low torque, the reduction gear unit is assigned a mechanical overload protection device which is designed to limit the reduction gear unit during operation of the handheld power tool, if a torque, transferred from the drive shaft to the reduction gear unit, exceeds a machine-specific limiting value.

Owner:ROBERT BOSCH GMBH

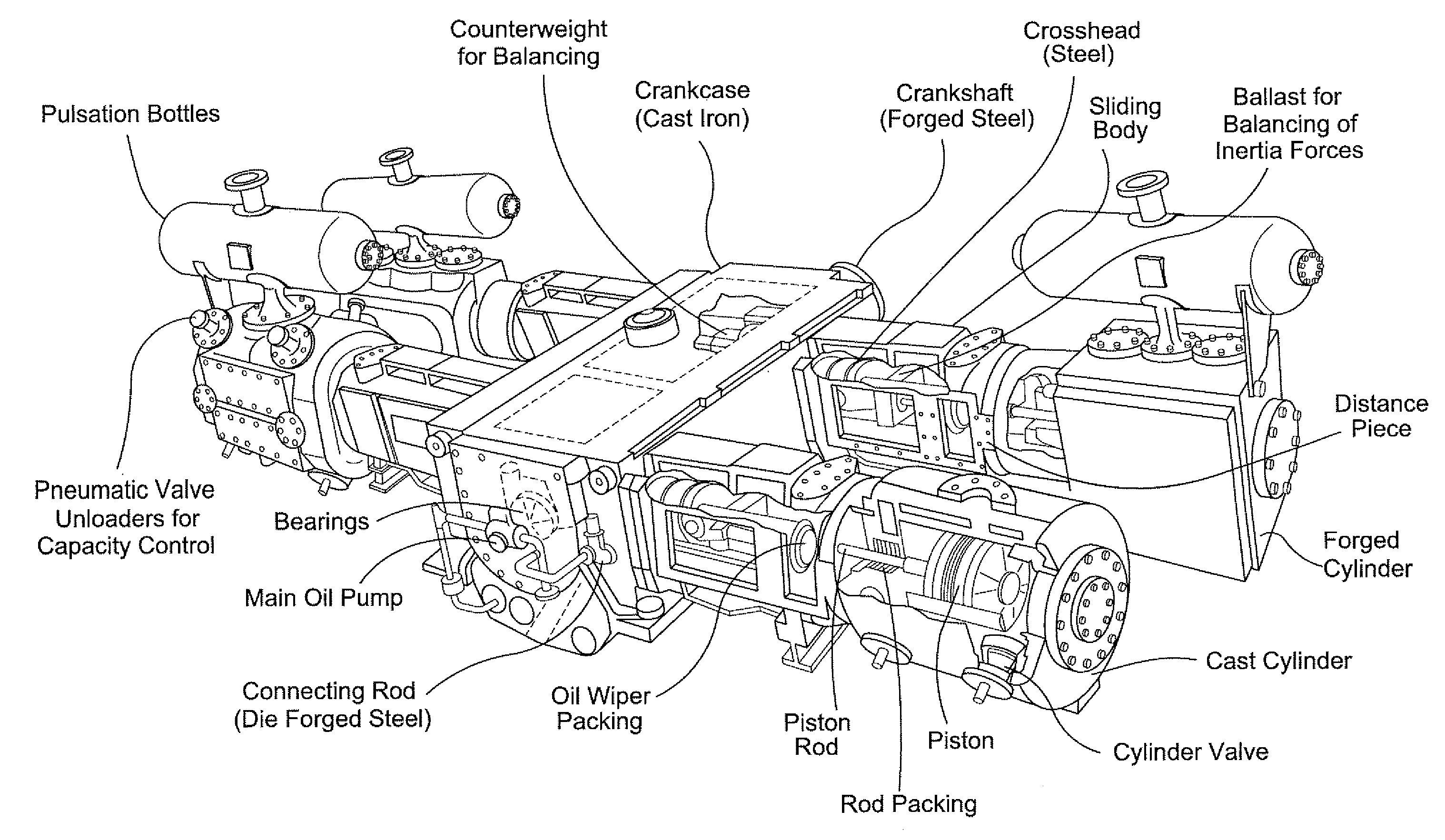

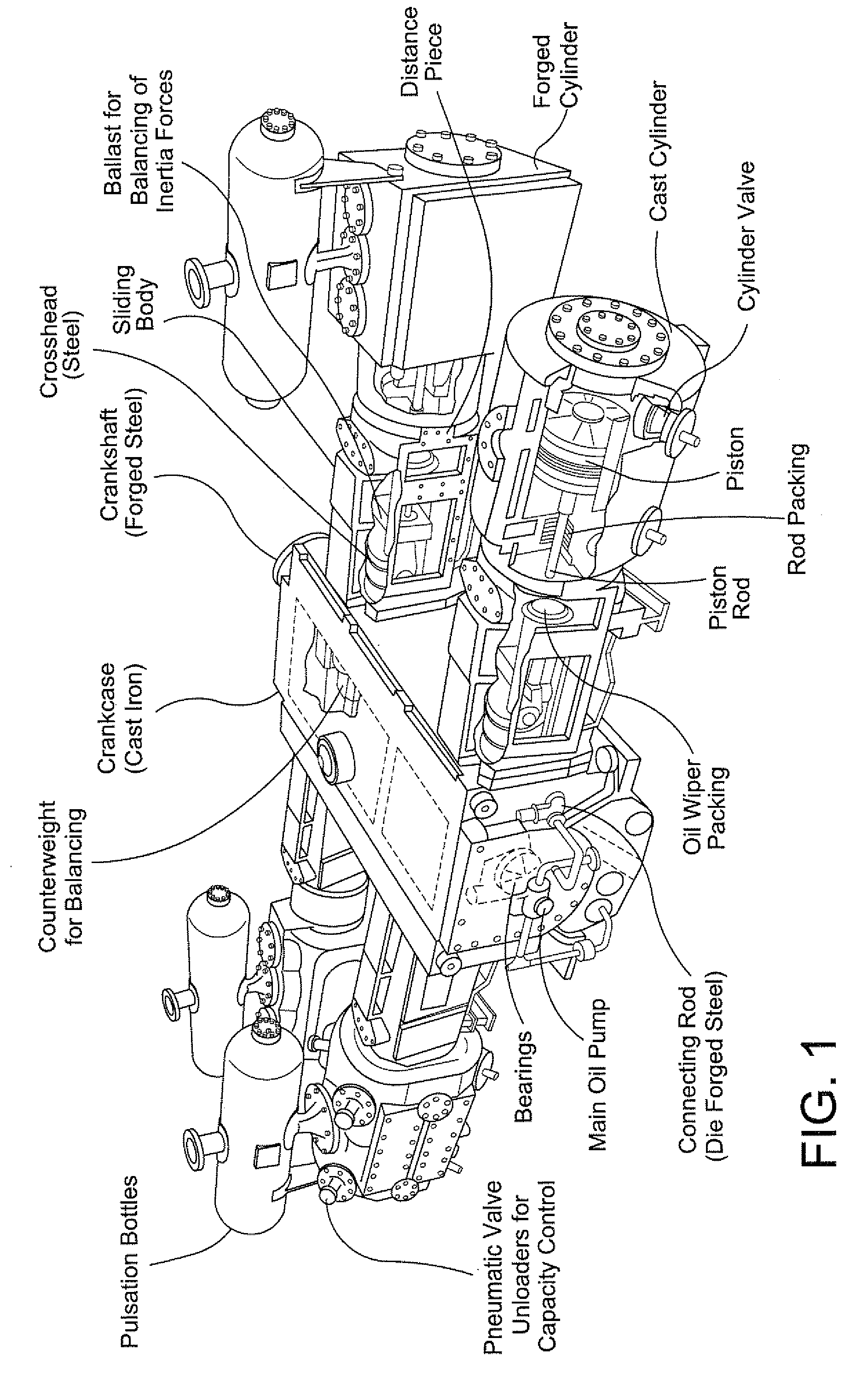

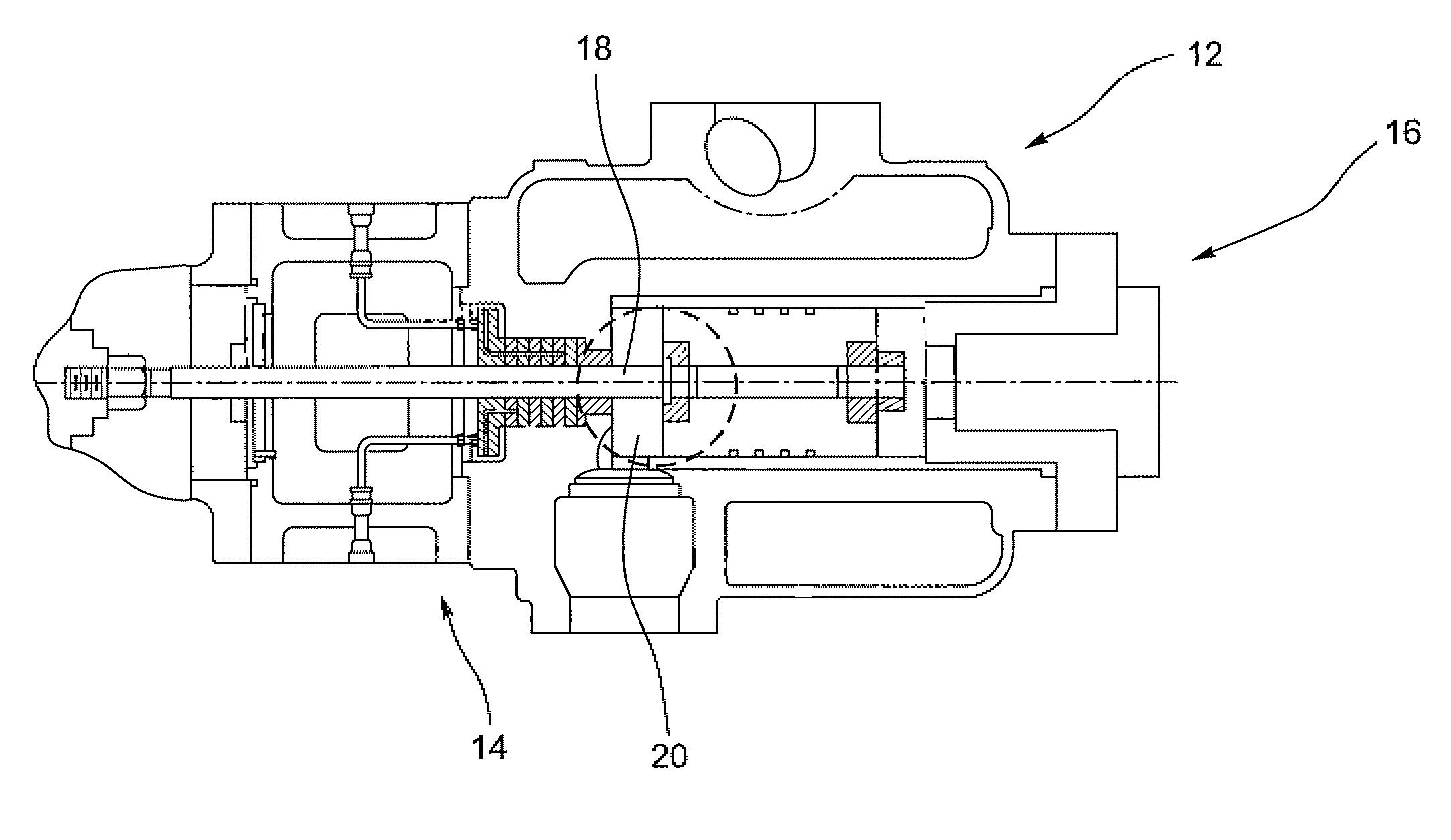

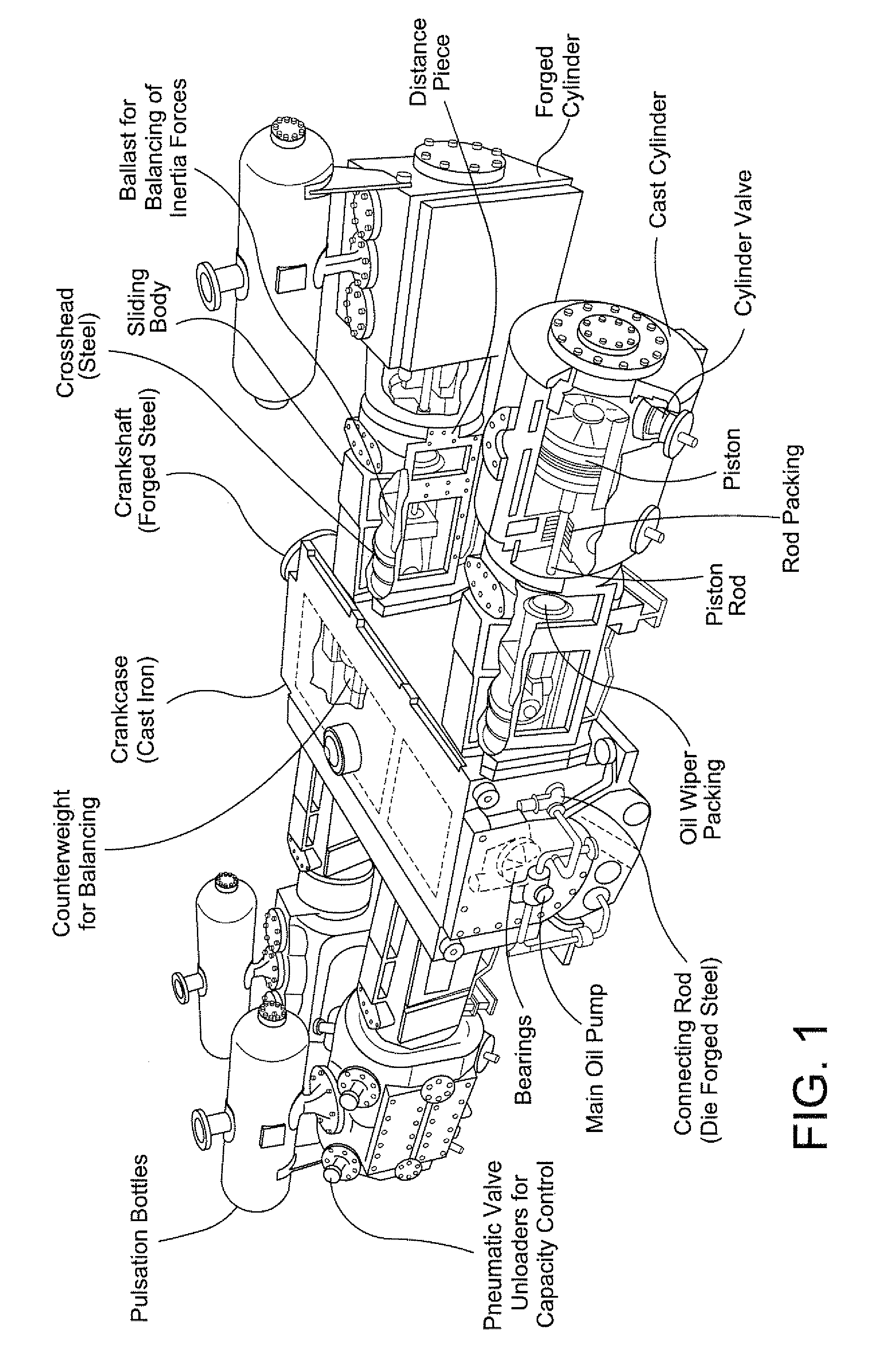

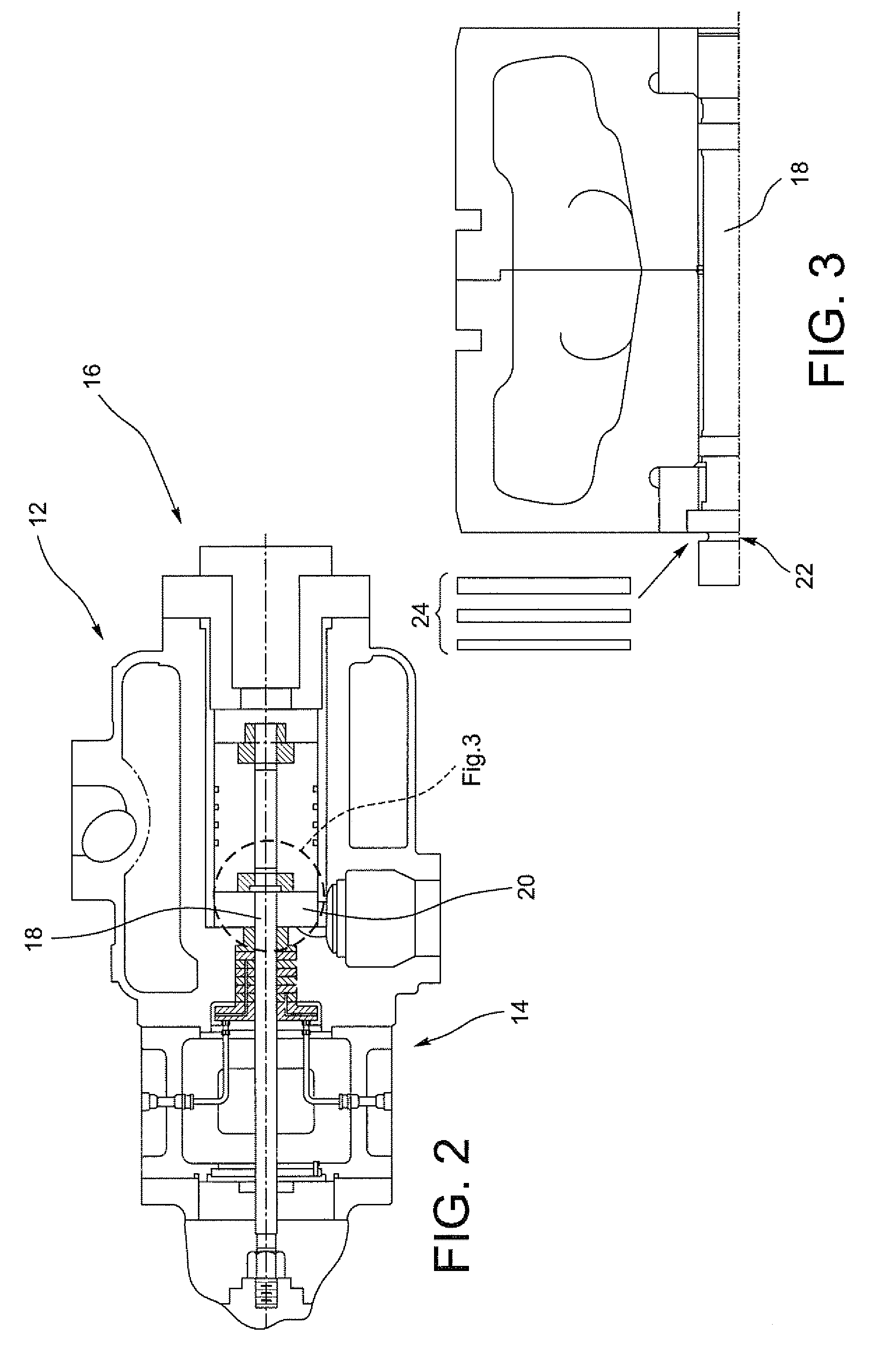

Method for Prevention/Detection of Mechanical Overload in a Reciprocating Gas Compressor

ActiveUS20080206069A1Positive displacement pump componentsPump parameterGas compressorMechanical overload

Mechanical overloads in a reciprocating gas compressor can cause irreparable damage to compressor components if the source of the overloads is not repaired. A method of detecting mechanical overloads includes applying an overload indicator across an interface between components in the compressor, and observing a mechanical condition of the overload indicator. The mechanical condition of the overload indicator is indicative of whether the compressor experienced a mechanical overload. By placing the indicator in an appropriate location in the compressor, overload conditions can be checked during routine inspections and maintenance checks.

Owner:NUOVO PGNONE HOLDING SPA

Torque limiting system

InactiveUS10125854B2Simple and durable and cost-effectiveImprove functionalitySlip couplingCouplings for rigid shaftsLow speedDrive shaft

The present invention relates to torque transfer and torque limiting system technology and applications. This invention relates to providing improved torque limiting systems that employ tolerance rings for controlling transmitting power between a single power-input shaft and one or more power-output shafts, which can protect mechanical equipment and drivetrains from damage by mechanical overload. Relating to motor vehicle differentials, the present invention can control differentiation between two power-output shafts, or drive shafts by providing friction internal to said differential and limit “undesirable” slip or differentiation between wheels, as might occur when one wheel encounters a low-traction condition, providing a limited-slip differential.

Owner:BAIR LING TECH LLC

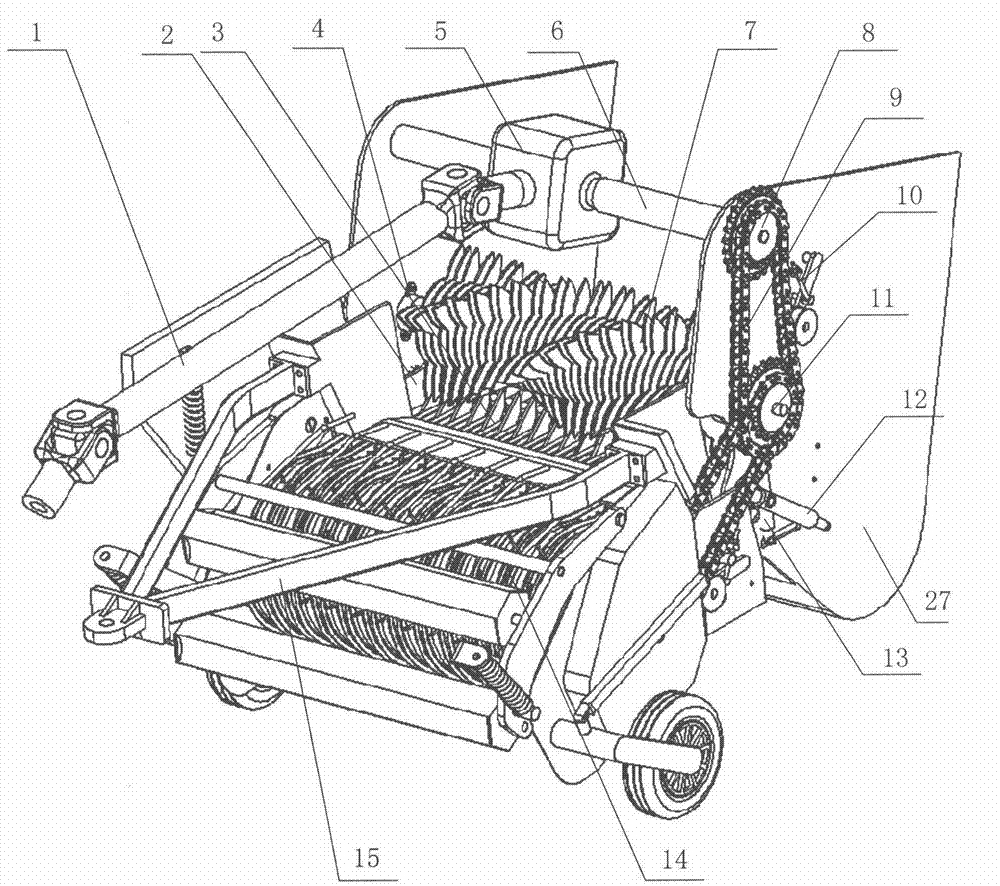

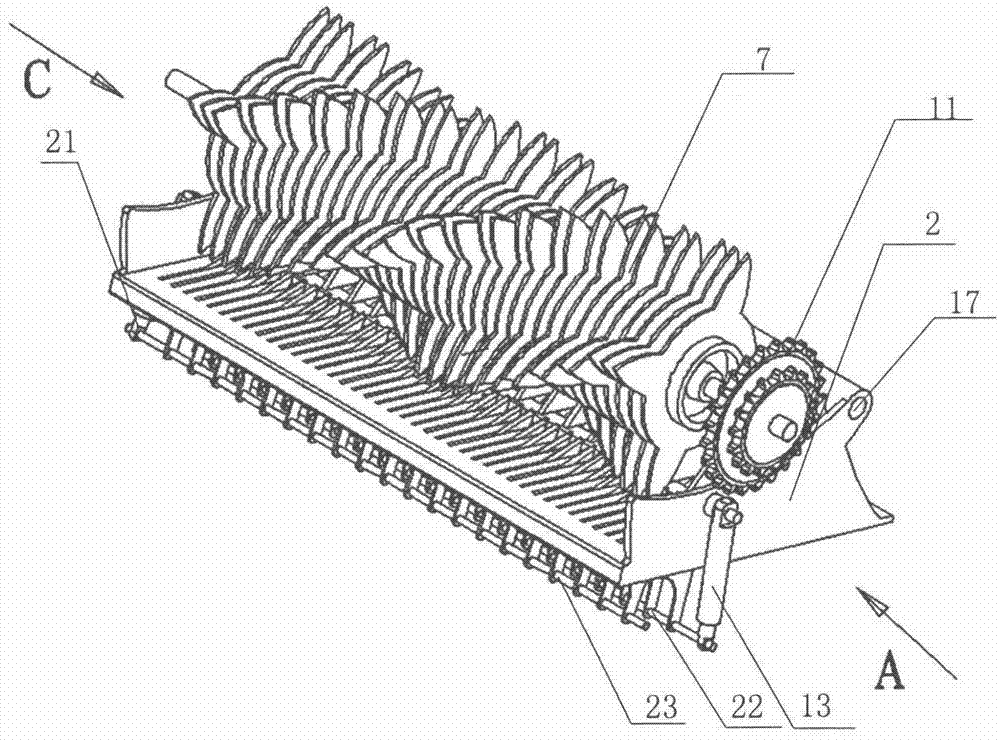

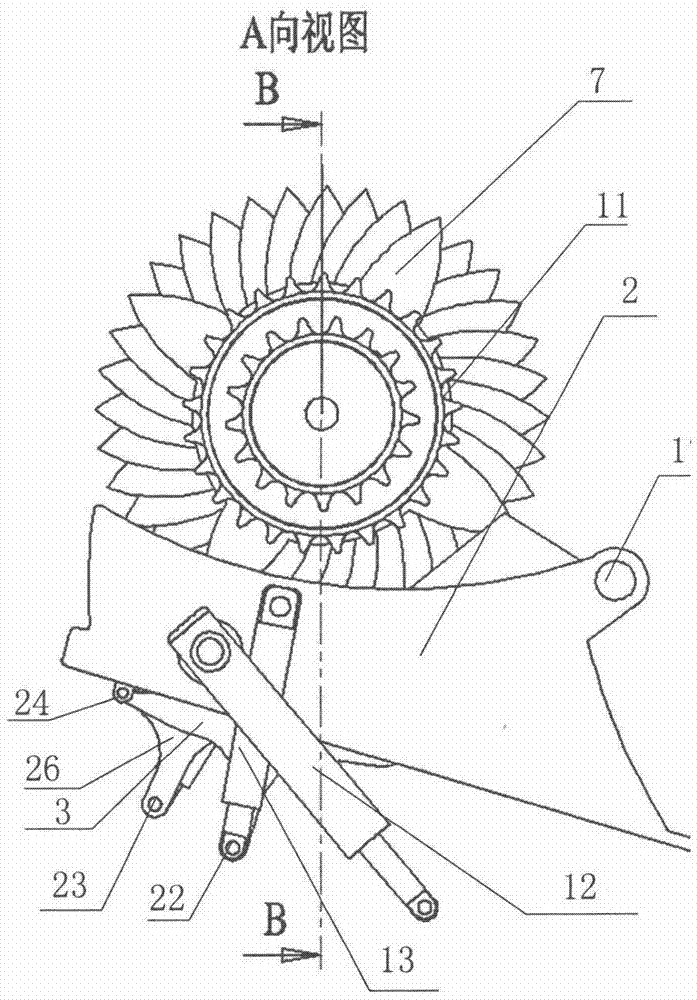

Forced grass-crushing and feeding anti-blocking device of round baler

The invention discloses a forced grass-crushing and feeding anti-blocking method and device after a round baler picks up materials, and relates to the technical field of straw harvesting and baling. By adopting a double anti-blocking protective technology that the openness of a lower jaw is adjusted by using a controller and a mechanical overload protection device is arranged, when the controller commands the movable lower jaw to enlarge the openness so as not to alleviate the load of a roll shaft of a spiral cutter or the controller fails, a safety bolt is sheared off so as to realize overload protection of the forced grass-crushing and feeding device. The device is capable of uniformly crushing and feeding grass and effectively preventing the feed inlet from being blocked, and is safe and reliable to use; and the operational efficiency of the round baler is improved.

Owner:JIANGSU UNIV

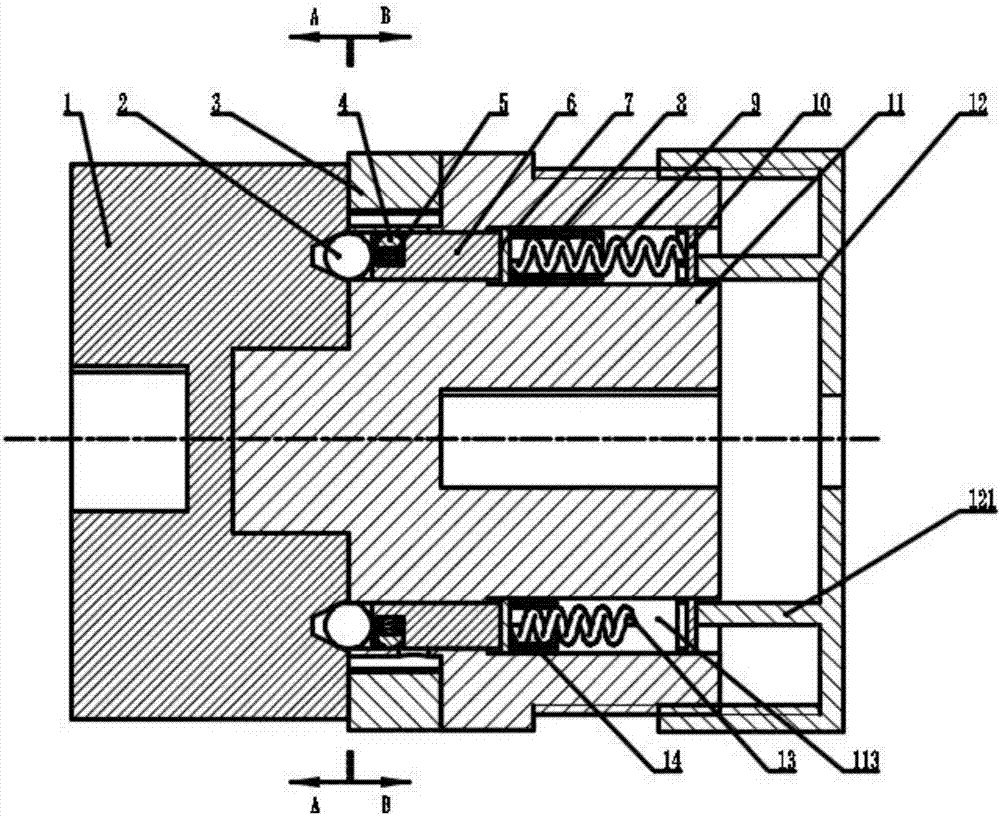

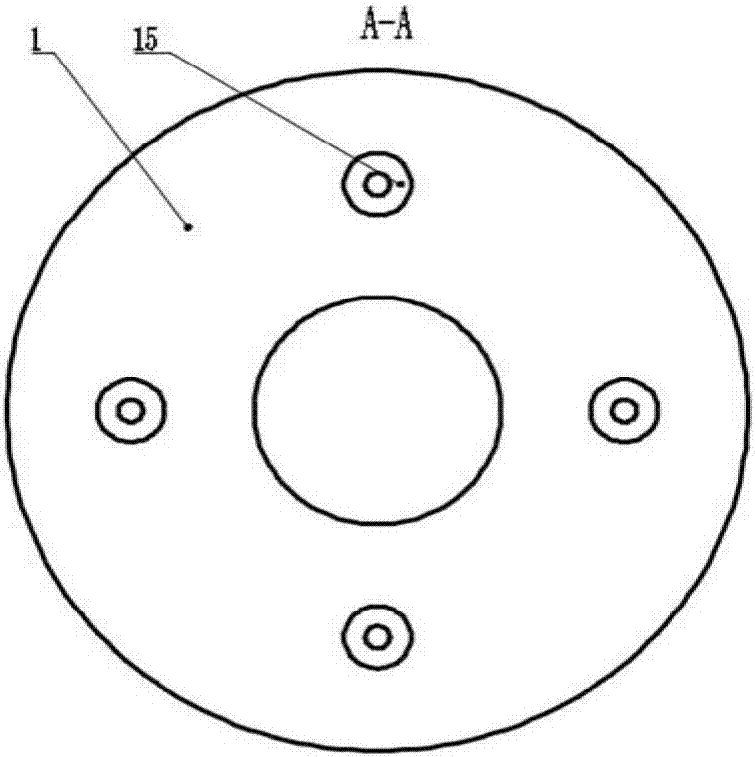

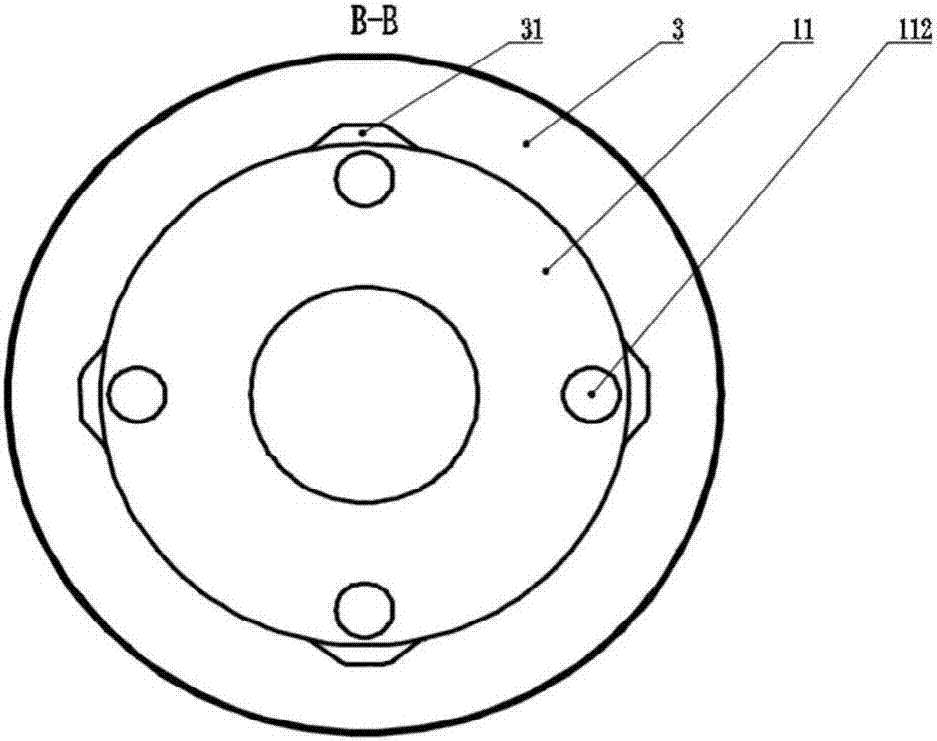

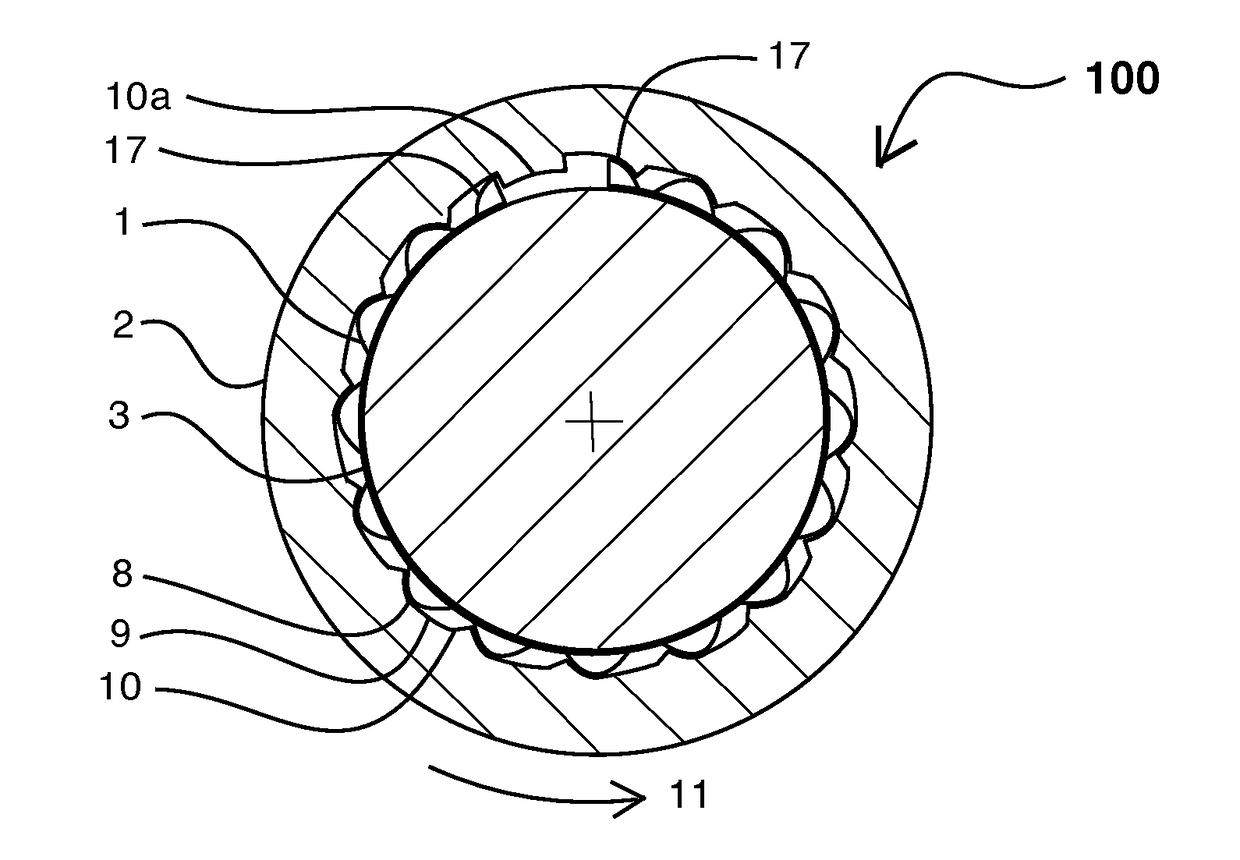

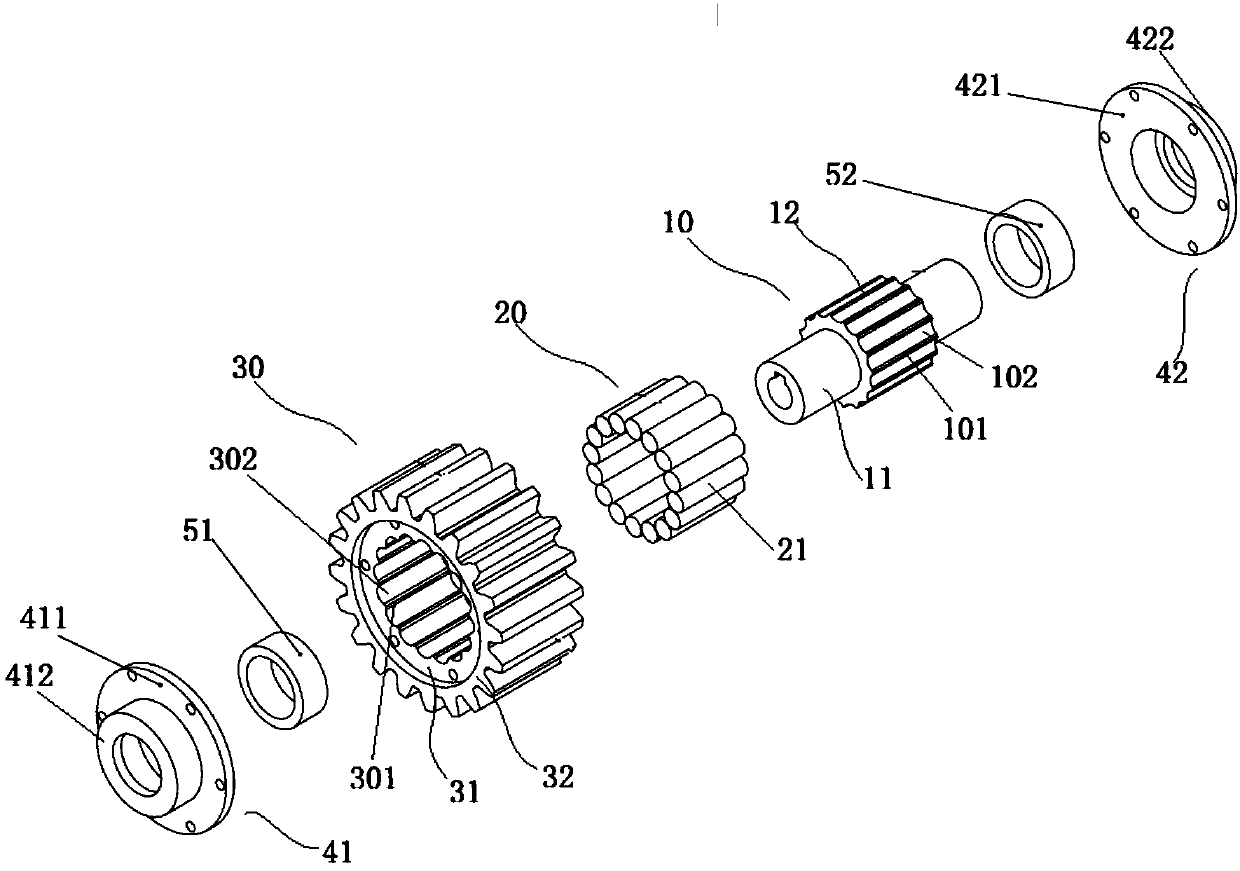

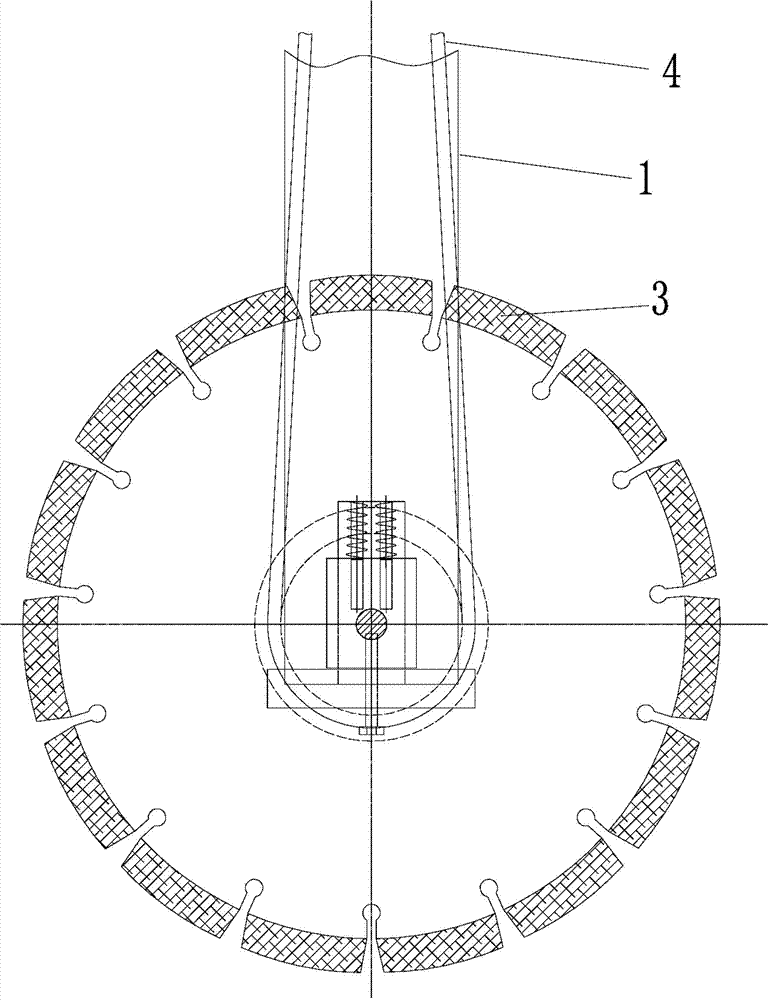

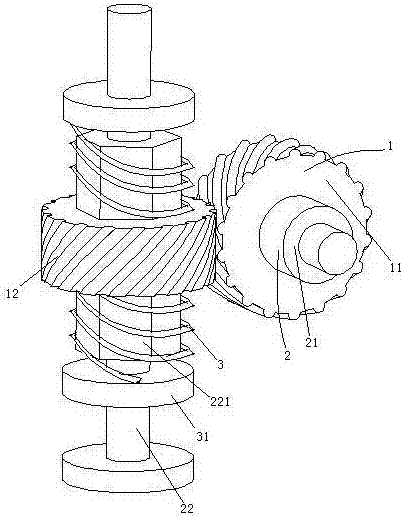

Mechanical overload protection device

The invention relates to a mechanical overload protection device which comprises a driving gear shaft, an overload protection element and a driven gear ring. First transmission gears distributed in acircumferential direction of the driving gear shaft are arranged on the driving gear shaft; a first arc-shaped groove is formed between every two adjacent first transmission gears; arcs of every two adjacent first arc-shaped grooves are tangent; and the overload protection element is arranged on the driving gear shaft in a sleeving manner, and comprises a plurality of elastic cylinders. The drivengear ring is arranged on the overload protection element in a sleeving manner; second transmission gears distributed along a circumferential direction are arranged on an inner wall, close to the overload protection element, of the driven gear ring; a second arc-shaped groove is formed between every two adjacent second transmission gears; and arcs of every two adjacent second arc-shaped grooves are tangent. Each elastic cylinder is arranged between each first arc-shaped groove and the corresponding second arc-shaped groove, and the elastic cylinders are coaxial to center shafts of the first arc-shaped grooves and the second arc-shaped grooves. The mechanical overload protection device provided by the invention is simple in structure, can cut off the transmission of a torque during overload, and solves the problems that a tail end rotating element is damaged and a motor is burnt due to transmission blocking and motor stalling.

Owner:苏州甘鲁机电科技有限公司

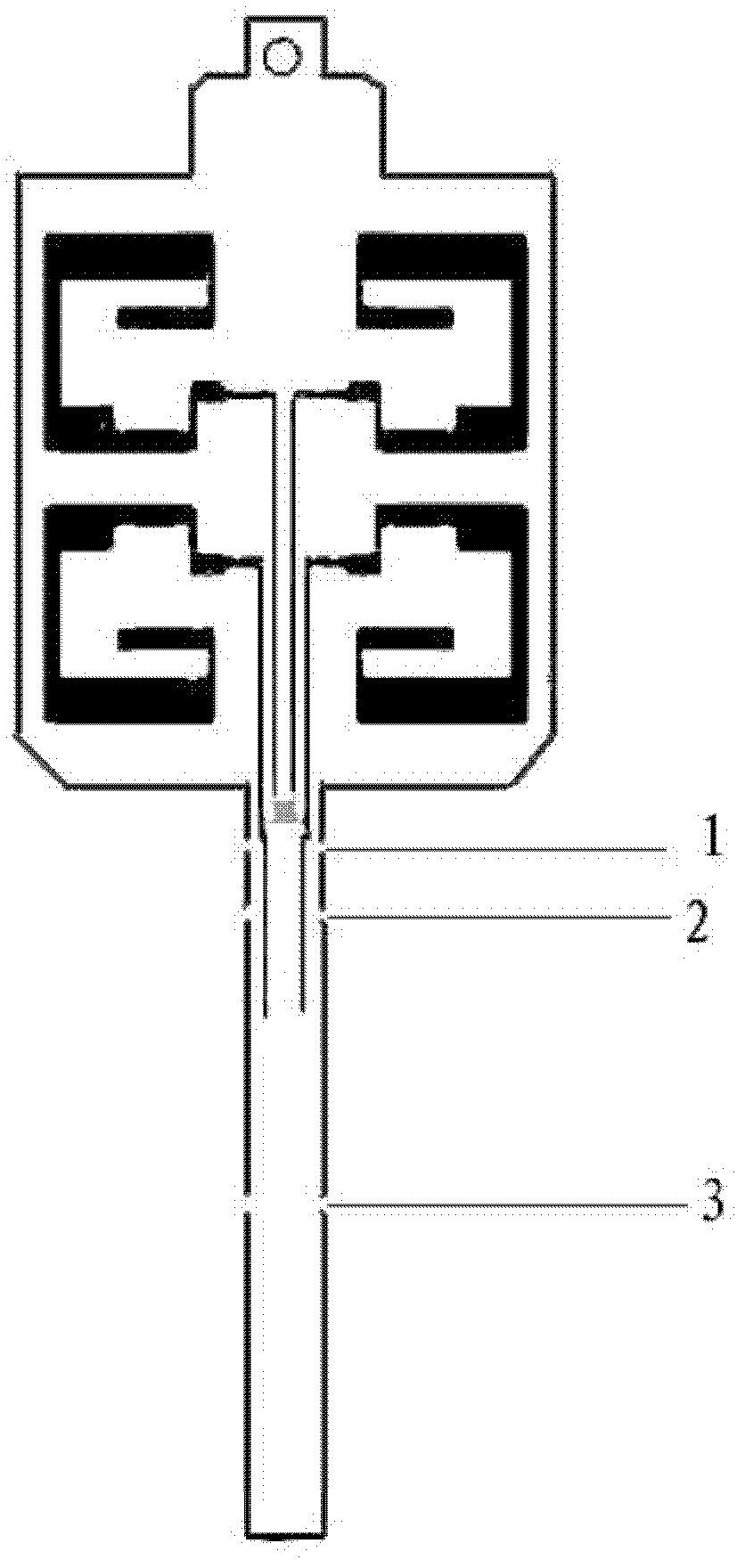

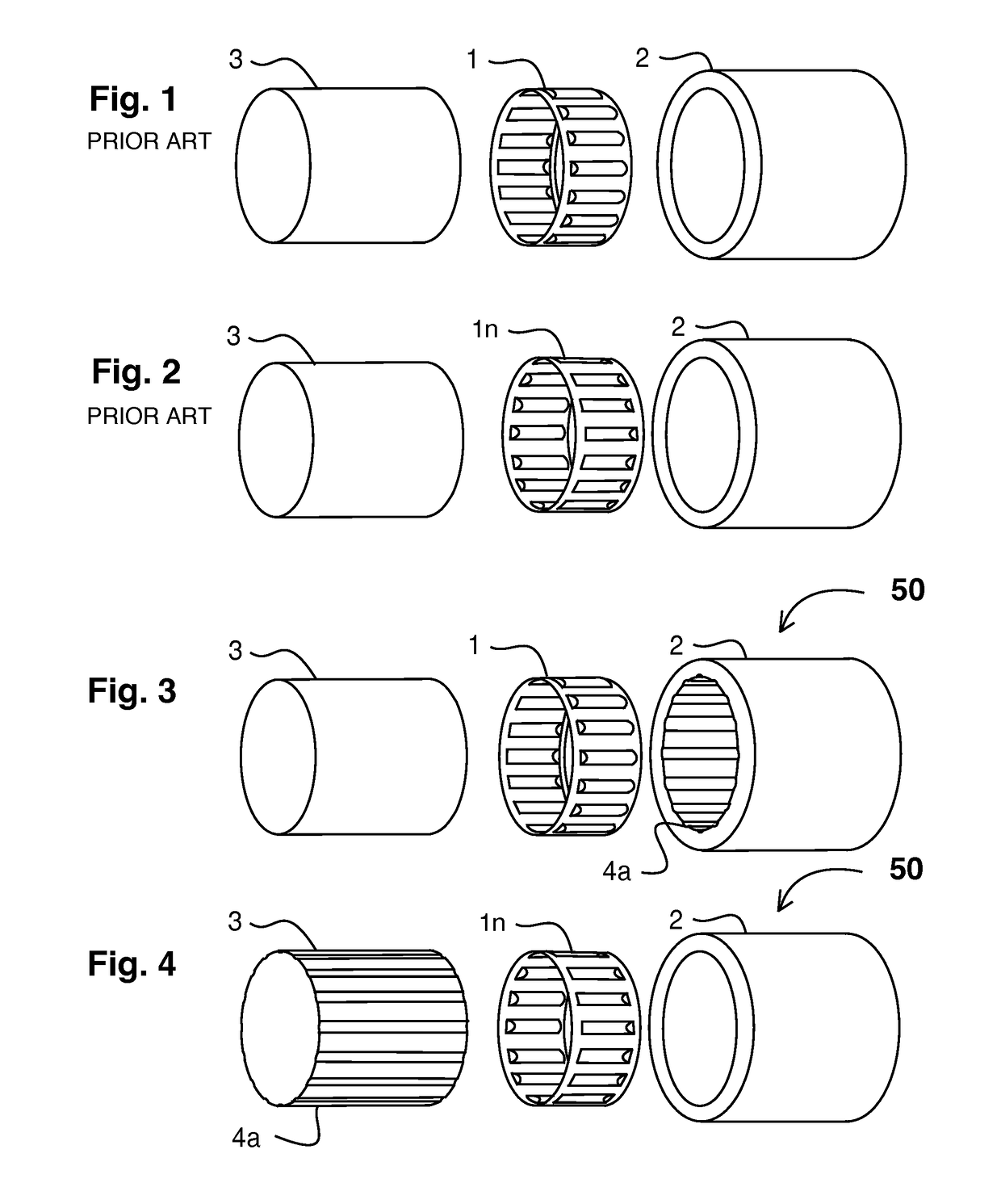

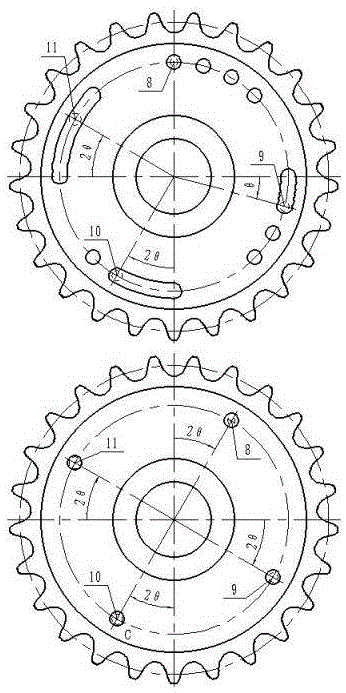

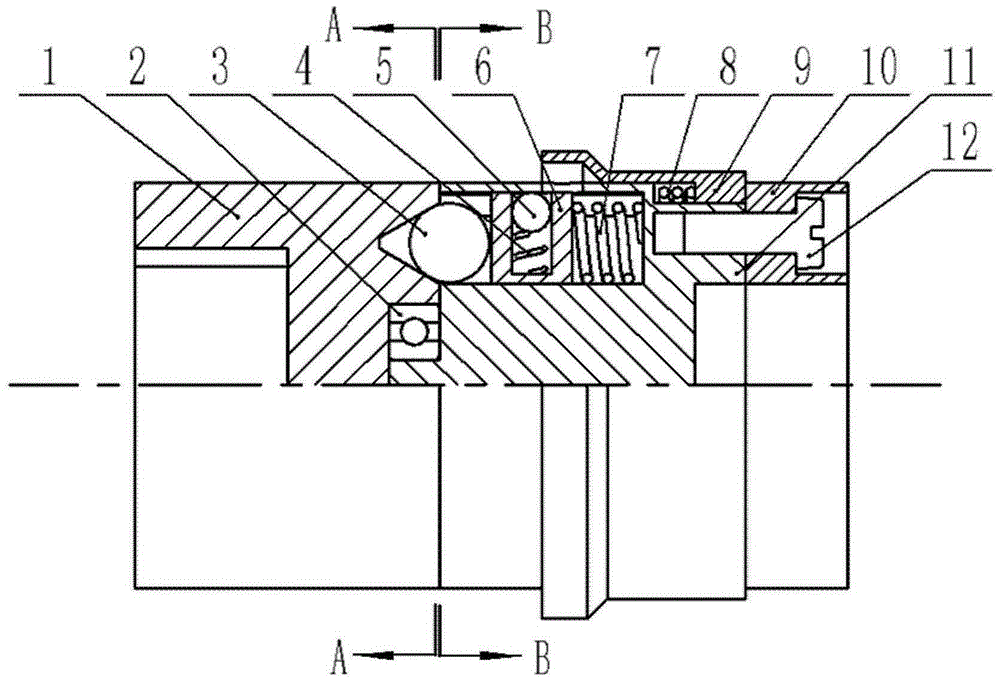

Multi-stage overload protection type shear pin type mechanical overload protection structure

ActiveCN105042003ASimple structureWork reliablyGearingCouplings with disconnecting safety membersDrive wheelThree stage

The invention relates to a structural type, in particular to a multi-stage overload protection type shear pin type mechanical overload protection structure. The multi-stage overload protection type shear pin type mechanical overload protection structure can achieve protection in two stages, three stages, four stages and more than four stages. The multi-stage overload protection type shear pin type mechanical overload protection structure mainly comprises a driving wheel 1, a driven wheel 2, a displacement sensor, a control unit, shear pins in various stages and the like. The multi-stage overload protection type shear pin type mechanical overload protection structure is characterized in that the tooth form of the driving wheel is consistent with that of the driven wheel; the driving wheel is provided with a plurality of shaft pin installation holes; the driven wheel is provided with a plurality of shear pin installation holes and a plurality of shear pin installation sliding holes; when the overload phenomenon exits, the shear pins in various stages will be sheared in sequence, then displacement deviation is produced when the driving wheel continues to rotate and the driven wheel does not rotate, the displacement sensor is triggered, and finally the control unit can achieve the alarm, halt and other protection functions according to settings. The multi-stage overload protection type shear pin type mechanical overload protection structure is simple in structure, reliable to work, convenient to maintain and extremely low in cost, and thoroughly solves the technical problem that the multi-stage overload protection type shear pin type mechanical overload protection structure cannot be applicable to moving loads or unknown loads.

Owner:山东省水电设备厂

Hand-power tool with a reduction gear

ActiveCN103379983ALarge rotational energyAvoid passingSlip couplingToothed gearingsDrive shaftMechanical overload

Owner:ROBERT BOSCH GMBH

Saw arm mechanism for belt transmission dual-blade cutting sawing machine

ActiveCN103658846AReduce volumeReduce weightMetal sawing devicesCircular sawsTransmission beltMechanical overload

The invention relates to a saw arm mechanism for a belt transmission dual-blade cutting sawing machine. The saw arm mechanism comprises a transmission belt, an arm frame, a saw blade installing mechanism and dual spaced saw blades, wherein the arm frame comprises a substrate, a compression spring, a guide post, a main shaft installing block, a pressing bolt and an end cover; the saw blade installing mechanism comprises a compression spring, a pressure block, a locking bolt, a pressure bearing and a main shaft; each of the dual spaced saw blades consists of a saw blade substrate and a belt pulley disk. By adopting the saw arm mechanism, the belt transmission dual-blade cutting is realized, the size and weight of the sawing machine are reduced effectively, the service performance of the sawing machine is improved, the service life of the sawing machine is prolonged, the maintaining difficulty of the sawing machine is lowered, and the difficulty in changing the transmission ratio and the cost of a light-duty sawing machine are lowered effectively; moreover, a reliable mechanical overload self-stopping protection function is provided, so that the practicability and safety of the light-duty sawing machine are improved effectively from a plurality of aspects.

Owner:HEIXUANFENG SAW IND

Cantilever beam acceleration transducer manufactured by micro-machining on single side of single silicon chip and method

ActiveCN101968495BHigh sensitivityImprove stabilityAcceleration measurement using interia forcesDecorative surface effectsEtchingAccelerometer

The invention relates to a cantilever beam acceleration transducer manufactured by micro-machining on a single side of a single silicon chip and a manufacturing method. The acceleration transducer is characterized in that: an accelerometer is manufactured by micro-mechanical single side machining through the single silicon chip, so that stress caused by the bonding process of a plurality of chips and different materials is avoided. In order to realize a single side-machined cantilever beam sensitive structure, the cantilever beam structure is released by transversely etching the bottom of the cantilever beam by an anisotropic corrosion method after deep structural etching. The structure provides air squeeze-film damping and mechanical overload protection in a sensitive direction, solves the problem of the absence of air squeeze-film damping in the vertical sensitive direction of the conventional structure and prevents parasitic signal interference caused by structural resonance in the vertical direction. The acceleration transducer has the characteristics of particular suitability for measuring a high g value, simple structure, small size of the chip and the like. Simultaneously, a single side process can use low-cost single throwing silicon chips, is suitable for low-cost mass manufacturing and has higher performance and wide application prospects.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

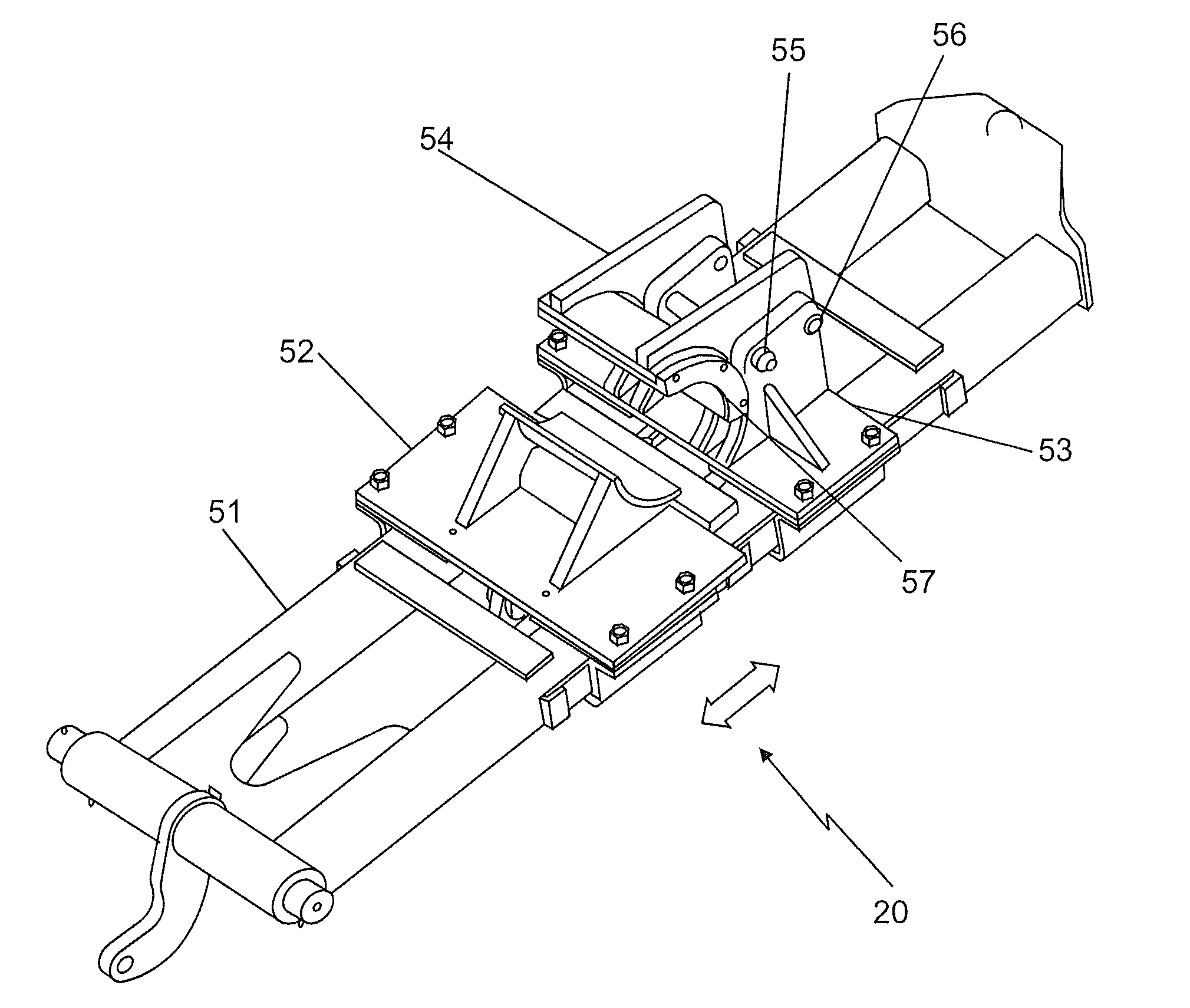

Rotary blasthole drilling rig flexible jaw pipe positioner

Owner:CATERPILLAR GLOBAL MINING LLC

Mechanical transmission mechanism with overload position capable of being preset

PendingCN106979301AImprove overloadToothed gearingsLaser cooling arrangementsDrive shaftMechanical overload

The invention relates to a mechanical transmission mechanism. A mechanical transmission mechanism that can preset an overload position, comprising a pair of meshed gears and an overload position setting spring, the gears are helical gears, and at least one gear in the pair of gears is slidable in the axial direction Sleeved on the transmission shaft and at least one end is supported by the overload position setting spring, when the pair of gears rotate, the gears slidably sleeved on the transmission shaft generate axial movement to drive the overload position setting spring Deformation energy storage, when the load driven by the mechanical transmission mechanism reaches the set upper limit, the position of the gear slidably sleeved on the transmission shaft is the overload position. The invention provides a mechanical transmission mechanism whose overload position can be preset, which solves the problem that the overload position of the existing mechanical transmission mechanism cannot be preset.

Owner:陈王颖

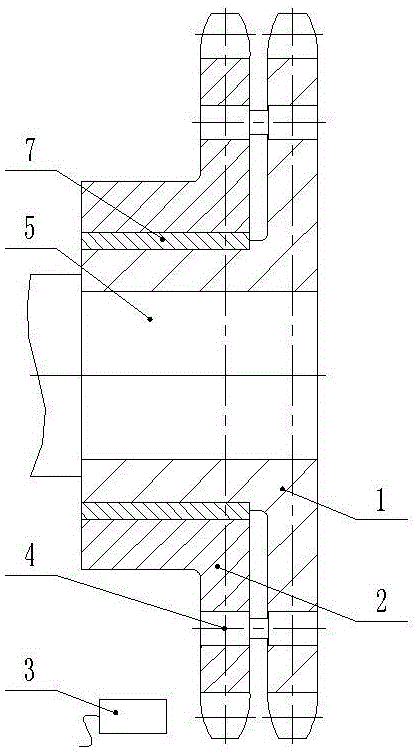

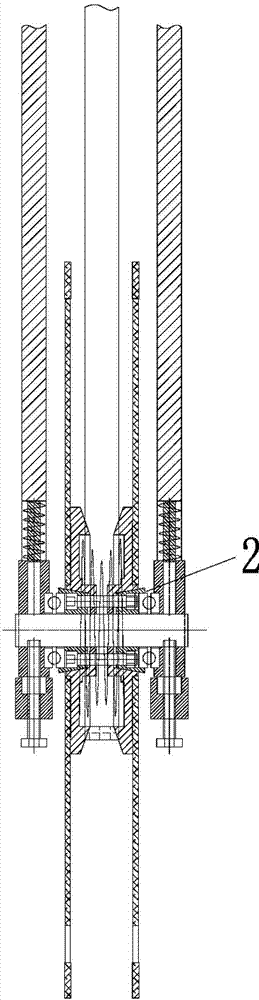

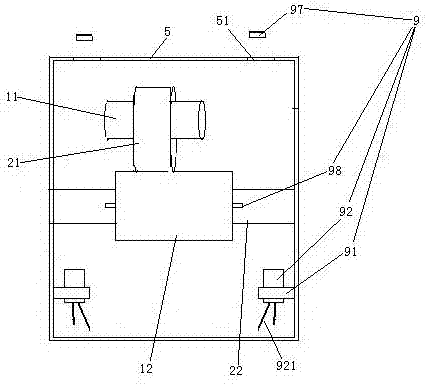

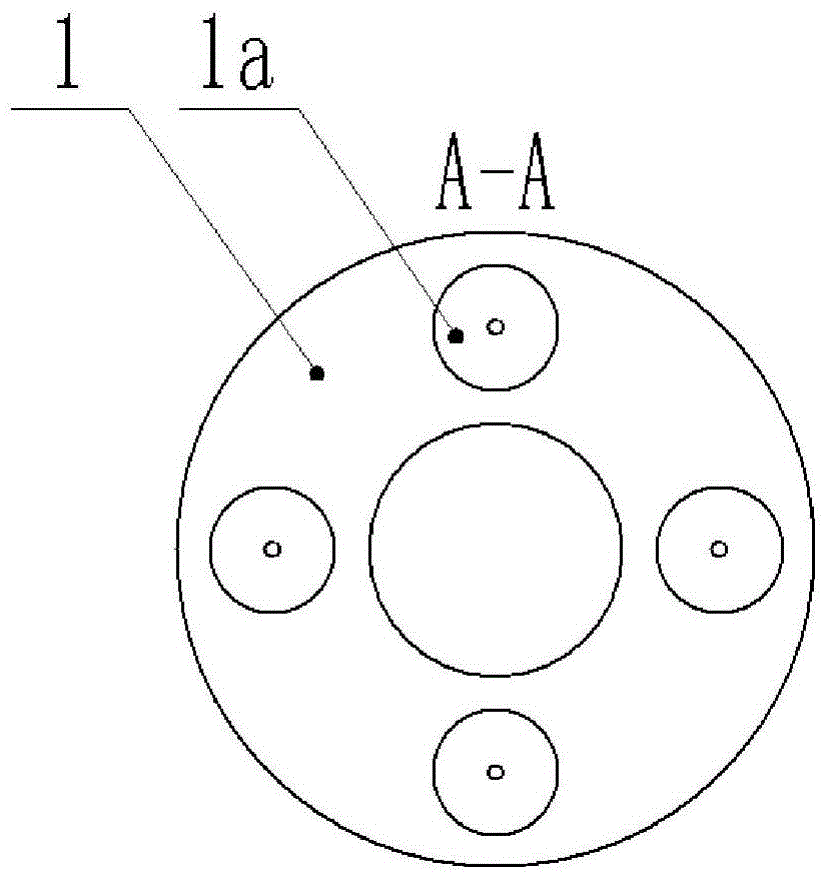

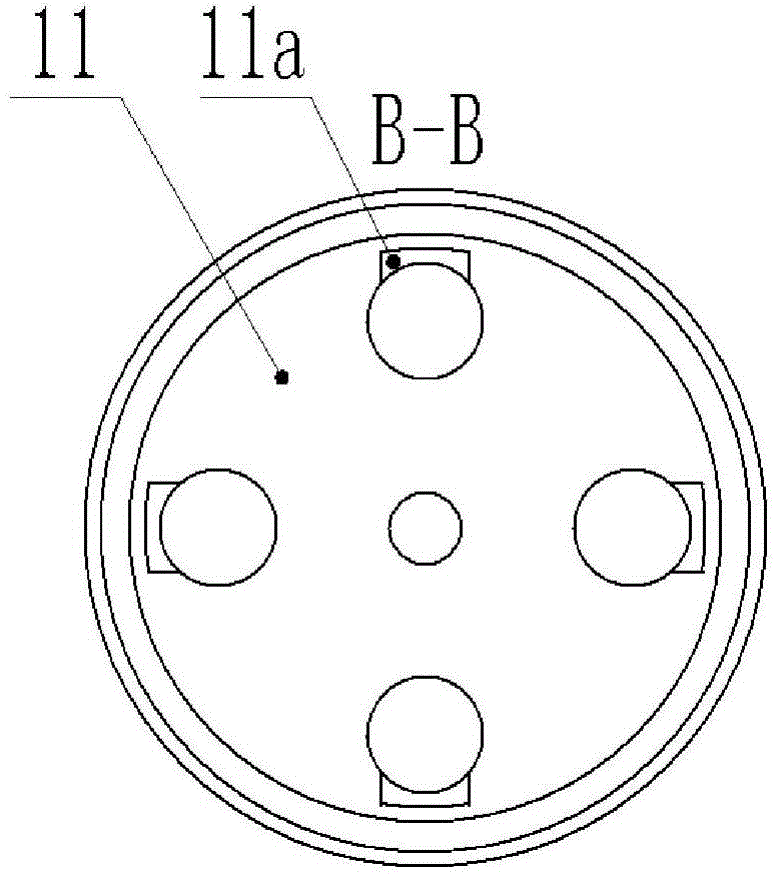

Servo turret head overload protection device

ActiveCN104632934AEffective protectionSimplify the exclusion processAutomatic clutchesProtection mechanismMechanical overload

The invention provides a servo turret head overload protection device. The protection device comprises a drive side shaft sleeve (1), a steel ball (3), a blocking block (6), a bearing (2), a spring (4), a driven side shaft sleeve (11), a bolt (12), a clamping sleeve (10) and a moving shaft sleeve (9), wherein one side of the driven side shaft sleeve (11) is connected with the drive side shaft sleeve (1), and the other side of the driven side shaft sleeve (11) is connected with the clamping sleeve (10); the bearing (2) is located between the drive side shaft sleeve (1) and the driven side shaft sleeve (11); the moving shaft sleeve (9) is located outside the driven side shaft sleeve (11); the end face of the drive side shaft sleeve (1) is provided with grooves (1a), the driven side shaft sleeve (11) is provided with a first steel ball hole, and the steel ball (3) is arranged in the first steel ball hole. According to the servo turret head overload protection device, a mechanical overload protection mechanism is adopted, the fault clearing process is simplified while a knife rest is protected effectively, and the fault clearing and debugging cycle is shortened.

Owner:SOUTHEAST UNIV

Mechanical overload protection device, speed reduction mechanism and electrically-driven flip driver

PendingCN109826875AExtended service lifeEasy to placeSlip couplingToothed gearingsElectricityMechanical overload

The invention discloses a mechanical overload protection device. The mechanical overload protection device comprises a power disc of a round structure and an overload protection disc, wherein the power disc is provided with a structure piece in power connection with the outside, one side surface of the power disc is provided with a round containing cavity, and the inner wall of the containing cavity is in a continuous closed sinusoid shape; the overload protection disc is used for being connected with the power disc and provided with an arc avoiding groove, and an elastic overload deformationpart is formed between the outer arc surface of the arc avoiding groove and the outer periphery of the overload protection disc; flanges are uniformly distributed in the middle of the outer peripheralwall of the elastic overload deformation part and are consistent with wave troughs of the sinusoid of the inner wall of the containing cavity in shape; one side of the overload protection disc is provided with a power output component; and the overload protection disc is put in the containing cavity of the power disc, and the flanges are located in the wave troughs of the inner wall of the containing cavity. The invention further discloses a speed reduction mechanism and an electrically-driven flip driver. The mechanical overload protection device, the speed reduction mechanism and the electrically-driven flip driver have the characteristics of being small in size, low in weight, high in bearing capacity, long in service life, stable in operation, low in noise and safe in performance, andthe product using safety is greatly improved.

Owner:TIANJIN SNEIJDER PRECISION MACHINERY

Method and arrangement for controlling an electro-acoustical transducer

ActiveUS10110995B2Sufficient amplitude and sound quality and efficiencyEasy to operateTransducer protection circuitsTransducer acoustic reaction preventionAudio power amplifierTransducer

An arrangement and method for converting an input signal into a mechanical or acoustical output signal by using a transducer and additional means for generating a desired transfer behavior and for protecting said transducer against overload. Transducers of this kind are for example loudspeaker, headphones and other mechanical or acoustical actuators. The additional means comprise a controller, a power amplifier and a detector. The detector identifies parameters of the transducer model if the stimulus provides sufficient excitation of the transducer. The detector permanently identifies time variant properties of the transducer for any stimulus supplied to the transducer. The controller provided with this information generates a desired linear or nonlinear transfer behavior; in particular electric control linearizes, stabilizes and protects the transducer against electric, thermal and mechanical overload at high amplitudes of the input signal.

Owner:KLIPPEL WOLFGANG

Method for prevention/detection of mechanical overload in a reciprocating gas compressor

ActiveUS7406864B1Positive displacement pump componentsStructural/machines measurementGas compressorMechanical overload

Mechanical overloads in a reciprocating gas compressor can cause irreparable damage to compressor components if the source of the overloads is not repaired. A method of detecting mechanical overloads includes forming a mechanical fuse that is configured to strain under overload conditions, and observing a condition of the mechanical fuse. The condition of the mechanical fuse is indicative of whether the compressor experienced a mechanical overload. By simply observing the mechanical fuse, overload conditions can be checked during routine inspections and maintenance checks.

Owner:NUOVO PGNONE HOLDING SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com