Saw arm mechanism for belt transmission dual-blade cutting sawing machine

A belt-driven, double-piece technology is applied in the field of the saw arm mechanism of the saw machine, which can solve the problems of inability to change the transmission ratio, consume the operator's energy, and high cost, achieve reliable mechanical overload self-stop protection function, improve practicability and The effect of safety, difficulty and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

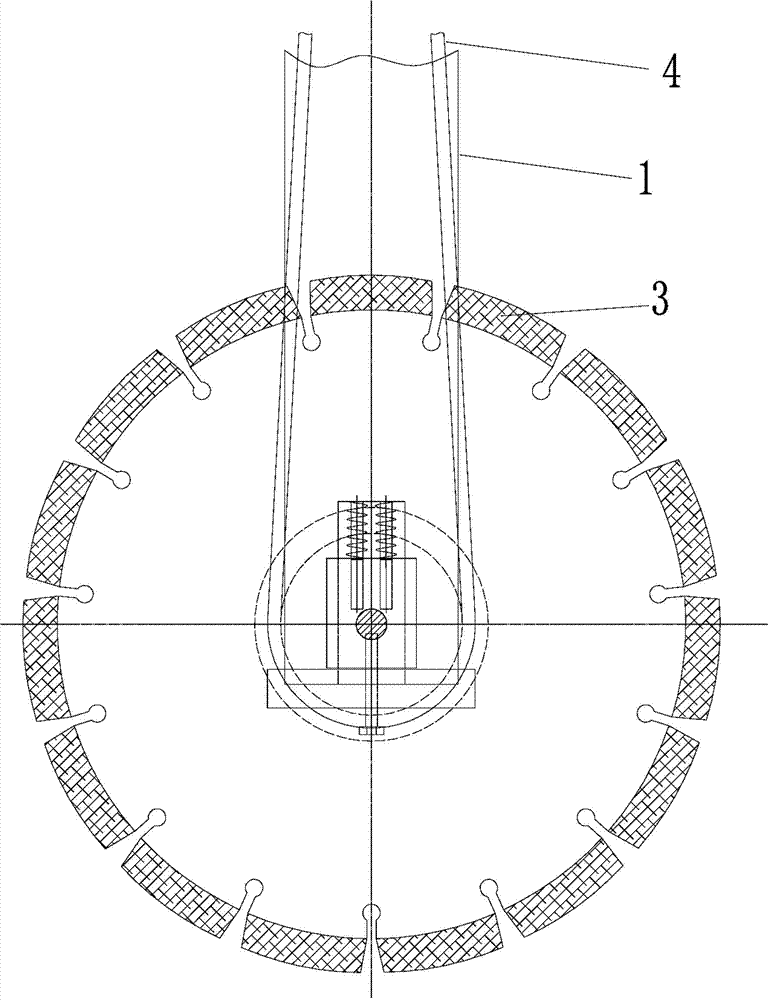

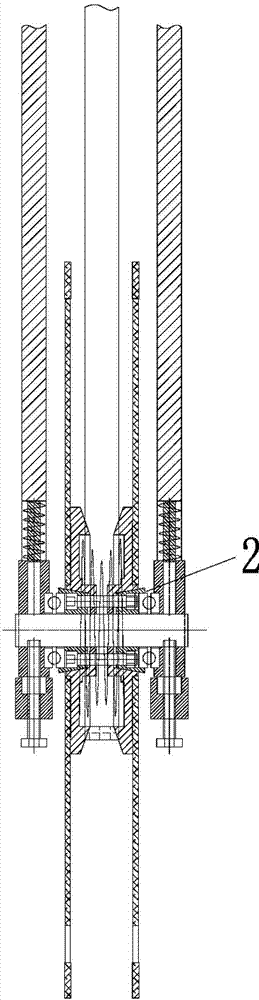

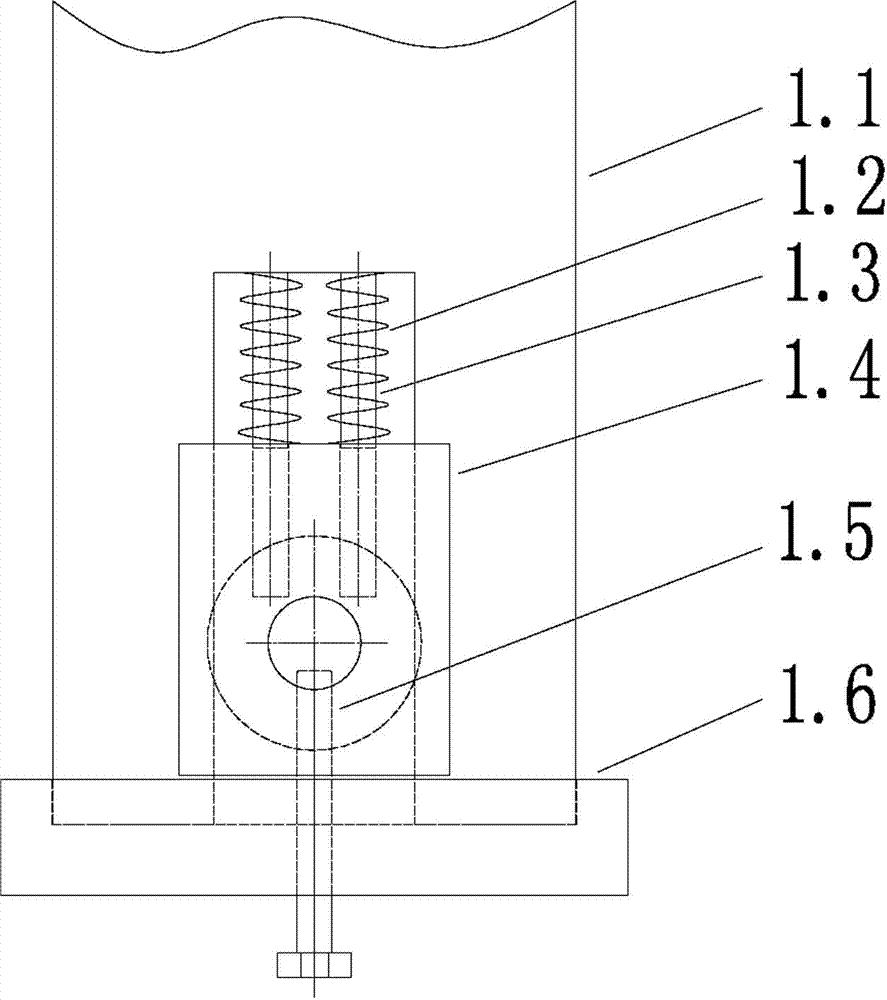

[0017] see Figure 1-5 , the saw arm mechanism of the belt-driven double-blade cutting saw machine of this embodiment mainly includes a transmission belt 4, an arm frame 1, a saw blade installation mechanism 2 and two spaced saw blades 3, and the main shaft 2.4 of the arm frame 1 and the saw blade installation mechanism 2 Connection, the spaced double saw blades 3 are fixedly connected through the compression spring 2.1 and the pressure block 2.2, the inner hole of the pressure block 2.2 is matched with the main shaft 2.4 of the saw blade installation mechanism 2, and the transmission belt is clamped on the formed by the spaced double saw blades 3 In the V-shaped groove, the main shaft of the saw blade installation mechanism 2 can move within a certain range relative to the boom 1, and the spaced double saw blades 3 rotate around the main shaft 2.4 along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com