Forced grass-crushing and feeding anti-blocking device of round baler

A round baler and shredded grass technology, which is applied in the field of forced shredded grass feeding and anti-blocking, can solve the problems of broken grass parts damage, feeding inlet blockage, poor reliability, etc., achieve uniform shredded grass and grass feeding, improve operating efficiency, Use safe and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

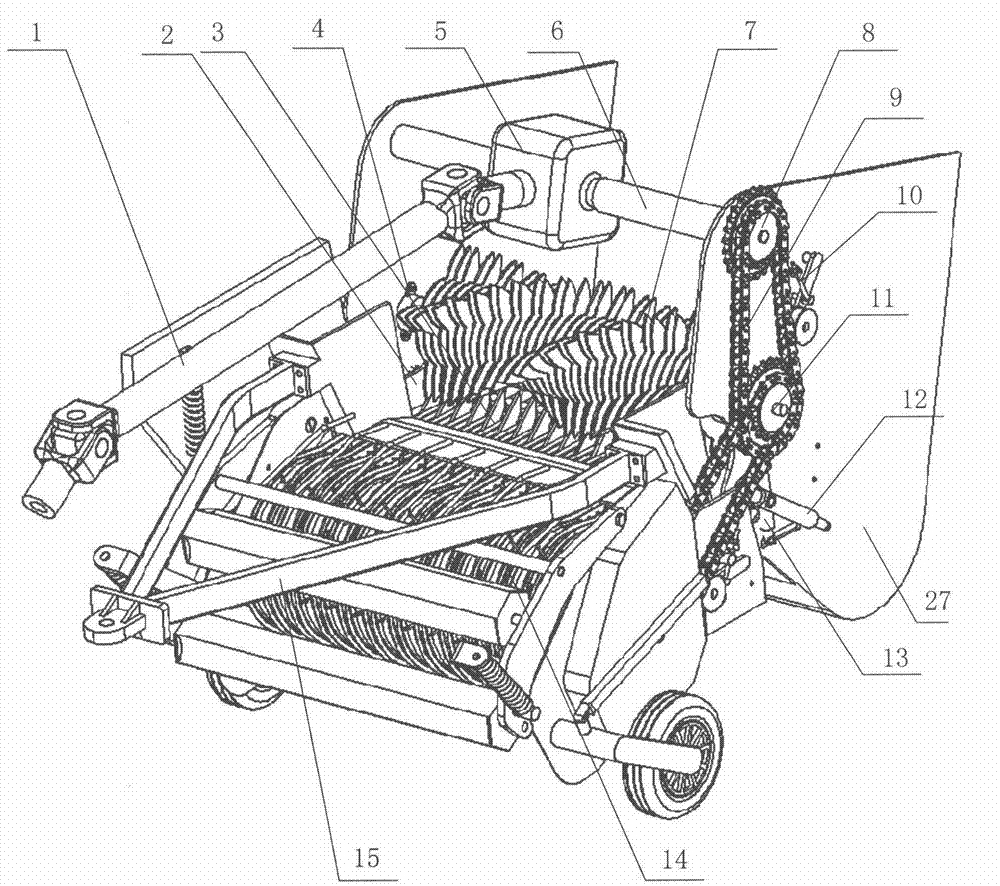

[0020] Such as figure 1 As shown, when the baler is working, it is connected with the tractor through the traction frame 15, and the power output shaft of the tractor is connected with the universal joint transmission 1 of the baler, and then the power is transferred through the transfer case 5 through the transfer case transmission shaft 6. Pass it to the driving sprocket 8, and then drive the driven sprocket 11 through the chain 9, and the chain tensioning device 10 plays the role of tensioning the chain.

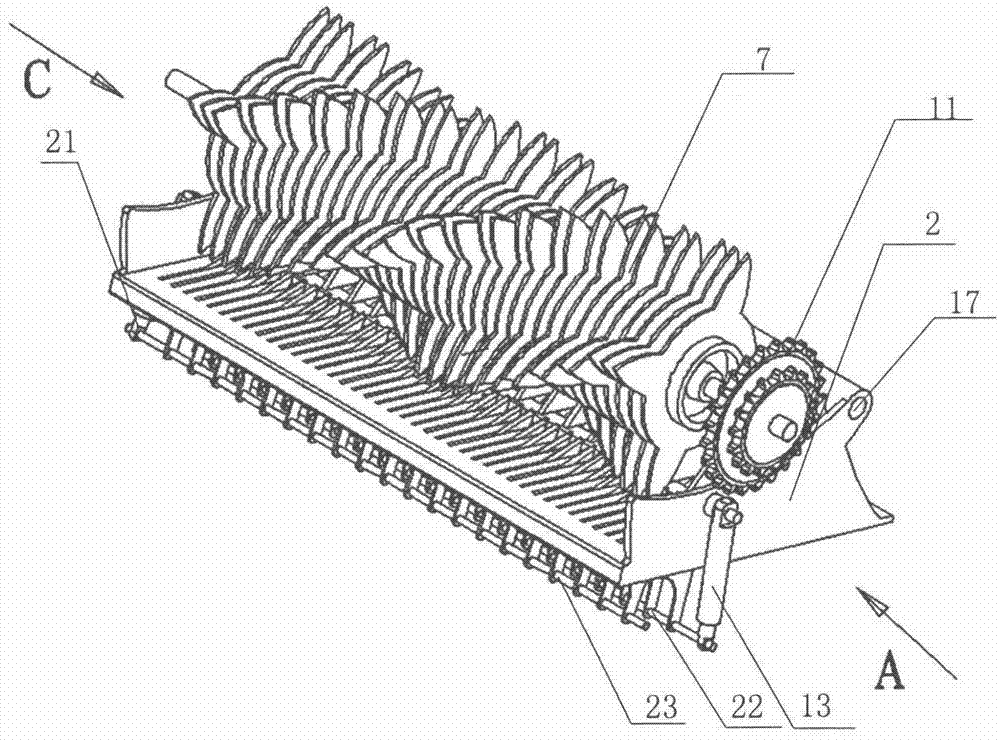

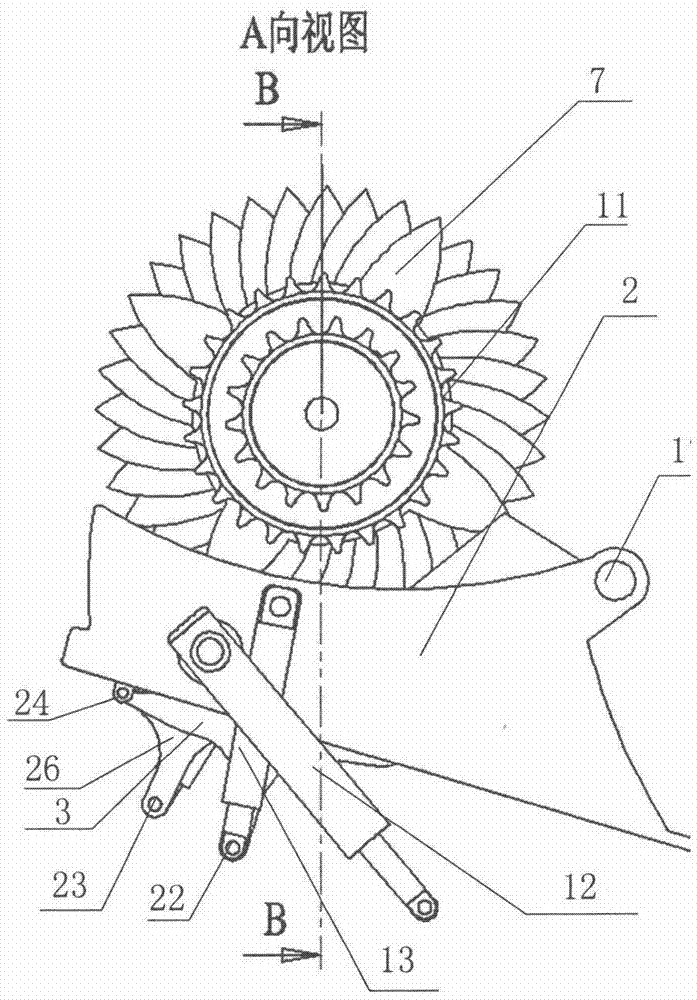

[0021] Such as figure 2 and Figure 5 As shown, the screw cutter roller 7 is rotatably supported on the frame 26 through the screw cutter roller shaft 20, the screw cutter roller shaft 20 is fixed with the flange 18, and the driven sprocket 11 is idly sleeved on the screw cutter roller shaft 20 , the driven sprocket 11 and the flange 18 are affixed through the safety bolt 19 to realize the rotation of the screw cutter roller 7 . The spirally arranged 4-head blade grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com